Introduction

Casting is a manufacturing process where a liquid material, usually metal or plastic, is poured into a mold and allowed to harden into the desired shape. This process is widely used in various industries for creating complex parts and components. Types of casting methods include sand casting, investment casting, and die casting, with materials such as aluminum, zinc, steel, and iron commonly used for castings.

What is Casting?

Casting is the process of shaping molten material into a specific form by pouring it into a mold and allowing it to cool and solidify. It is a versatile method used in the production of intricate components for industries such as automotive, aerospace, and consumer goods.

Types of Casting and Casting Materials

There are different types of casting processes including sand casting, investment casting, and die casting. Each method has its own advantages depending on the application requirements. The materials commonly used for castings include metals such as aluminum, zinc, steel, iron as well as non-metallic materials like plastics.

Materials Used for Castings

Aluminum is often used in casting due to its lightweight properties and corrosion resistance making it suitable for various applications including automotive parts and outdoor fixtures. Zinc is another widely used material in die-casting due to its high strength-to-weight ratio and ability to be easily cast into intricate shapes.

Die Casting Mold

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape.

Buttler Precision Machinery Co., Ltd.

Buttler Precision Machinery Co., Ltd. specializes in die-casting molds and offers cost-effective manufacturing solutions for a wide range of industries. With their expertise in innovative tooling designs, they can provide high-quality die-casting molds that maximize performance and minimize the need for secondary operations.

Innovative Tooling Designs

At Buttler Precision Machinery Co., Ltd., they understand the importance of innovative tooling designs in the die-casting process. Their team of experts utilizes state-of-the-art technology to create precision molds that meet the specific requirements of their clients, ensuring efficient and reliable production.

Cost-Effective Manufacturing

By focusing on cost-effective manufacturing processes, Buttler Precision Machinery Co., Ltd. is able to deliver high-quality die-casting molds at competitive prices. Their commitment to efficiency and innovation allows them to provide cost-effective solutions without compromising on quality or performance.

Aluminium & Zinc Casting

Ningbo Buttler Precision Machinery Co., Ltd. specializes in the production of high-quality aluminum and zinc castings. These materials are often used in casting due to their lightweight, durable, and corrosion-resistant properties, making them ideal for a wide range of applications. The company's expertise in die-casting molds ensures precise and accurate casting production, meeting the highest industry standards.

Ningbo Buttler Precision Machinery Co., Ltd.

Ningbo Buttler Precision Machinery Co., Ltd. is renowned for its advanced manufacturing capabilities and state-of-the-art technology in producing aluminum and zinc castings. With a focus on precision engineering and innovative tooling designs, the company delivers cost-effective solutions that maximize performance and casting quality while minimizing the need for secondary operations.

Surface Treatment

The surface treatment process at Ningbo Buttler Precision Machinery Co., Ltd. involves various techniques such as powder coating, anodizing, and polishing to enhance the appearance and performance of the castings. These treatments not only provide a protective layer but also improve corrosion resistance, durability, and aesthetic appeal, ensuring that the castings meet stringent quality requirements.

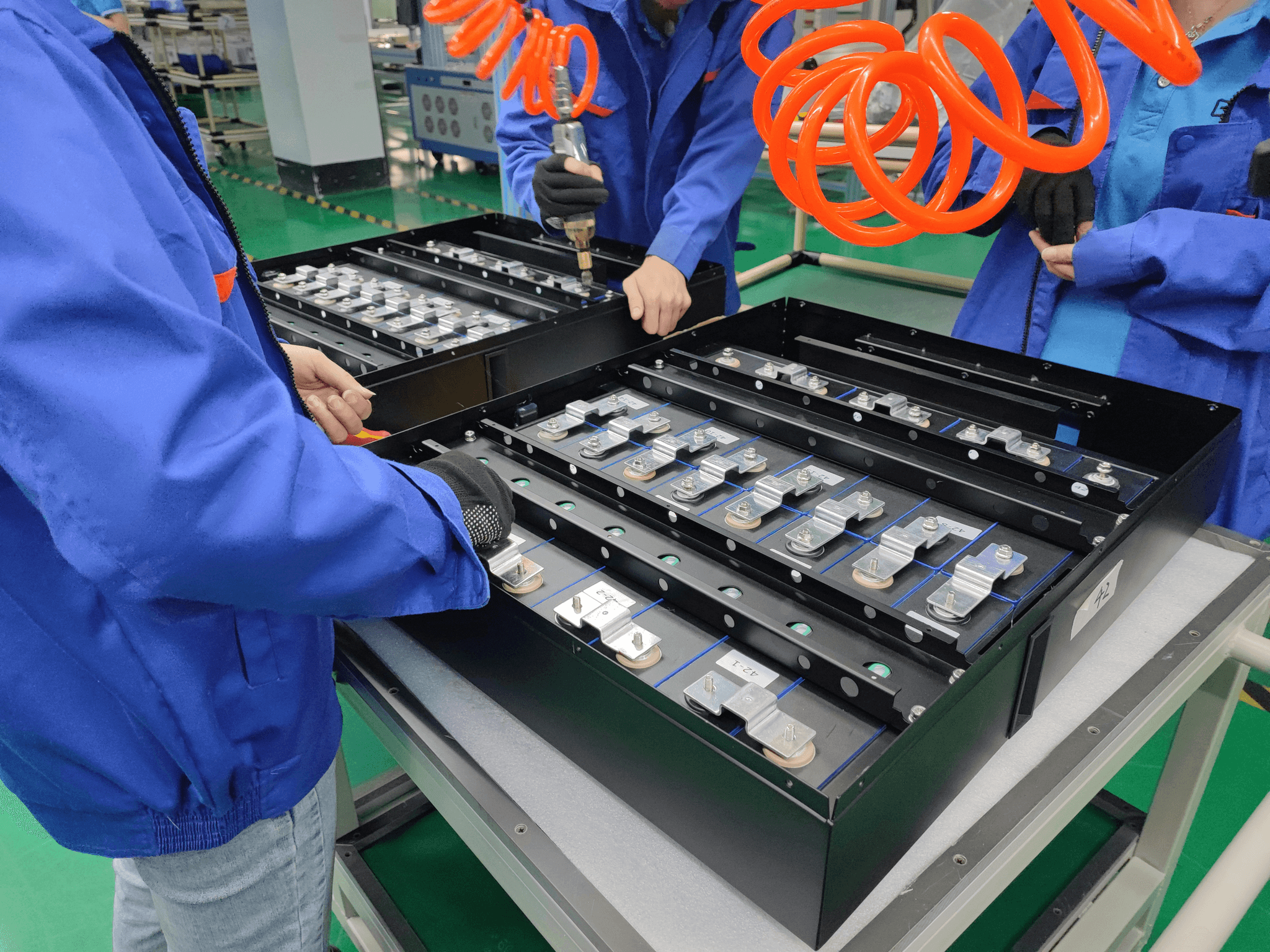

Assembly and Packaging

In addition to casting production, Ningbo Buttler Precision Machinery Co., Ltd. offers comprehensive assembly and packaging services to meet customers' specific requirements. The company's expertise in assembly ensures that all components fit seamlessly together, while its meticulous packaging process ensures safe transportation and delivery of the finished products.

Remember that when it comes to high-quality aluminum & zinc castings with superior surface treatment techniques and efficient assembly & packaging services, Ningbo Buttler Precision Machinery Co., Ltd. is your trusted partner!

Outdoor Lamp Series

When it comes to outdoor lamp series, the key to success lies in smart part engineering. At Buttler Precision Machinery Co., Ltd., we specialize in providing better part designs that are engineered to maximize performance. Our innovative tooling designs are tailored for cost-effective manufacturing, ensuring that you get the best quality castings with minimal need for secondary operations.

Smart Part Engineering

Our smart part engineering process at Buttler Precision Machinery Co., Ltd. involves a meticulous approach to designing and producing outdoor lamp series that are not only visually appealing but also highly functional. By leveraging our expertise in die-casting molds and aluminum and zinc castings, we ensure that every component is engineered for optimal performance and durability.

Better Part Designs

At Buttler Precision Machinery Co., Ltd., we take pride in our ability to deliver better part designs that meet the highest standards of quality and precision. Our team utilizes advanced processing techniques and surface treatments to enhance the aesthetic appeal and longevity of outdoor lamp series, making them ideal for various outdoor environments.

Maximize Performance

When it comes to outdoor lighting, maximizing performance is crucial. With our expertise in assembly and packaging, we ensure that every component of the outdoor lamp series is seamlessly integrated to deliver exceptional performance. Whether it's for residential or commercial applications, our outdoor lamp series are designed to exceed expectations in terms of functionality and reliability.

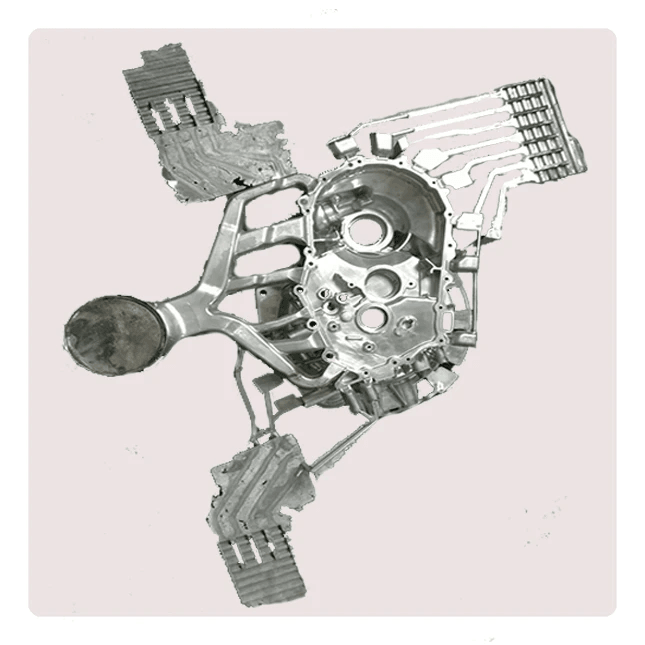

Automotive Parts

When it comes to automotive parts, Buttler Precision Machinery Co., Ltd. is the go-to choice for high-quality castings. Their expertise in die-casting molds and precision engineering ensures that automotive parts are durable and reliable. With a focus on casting quality, they use materials such as aluminum and zinc to deliver top-notch automotive components that meet industry standards.

Buttler Precision Machinery Co., Ltd.

Buttler Precision Machinery Co., Ltd. specializes in producing automotive parts using cutting-edge die-casting molds and state-of-the-art manufacturing processes. Their dedication to quality and precision engineering makes them a trusted partner for automotive manufacturers worldwide.

Casting Quality

At Buttler Precision Machinery Co., Ltd., casting quality is of utmost importance. They utilize advanced techniques and materials to ensure that the automotive parts they produce are strong, durable, and meet strict industry standards.

Minimizing Secondary Operations

By focusing on precision engineering and innovative tooling designs, Buttler Precision Machinery Co., Ltd. minimizes the need for secondary operations in the production of automotive parts. This not only streamlines the manufacturing process but also reduces costs for their clients.

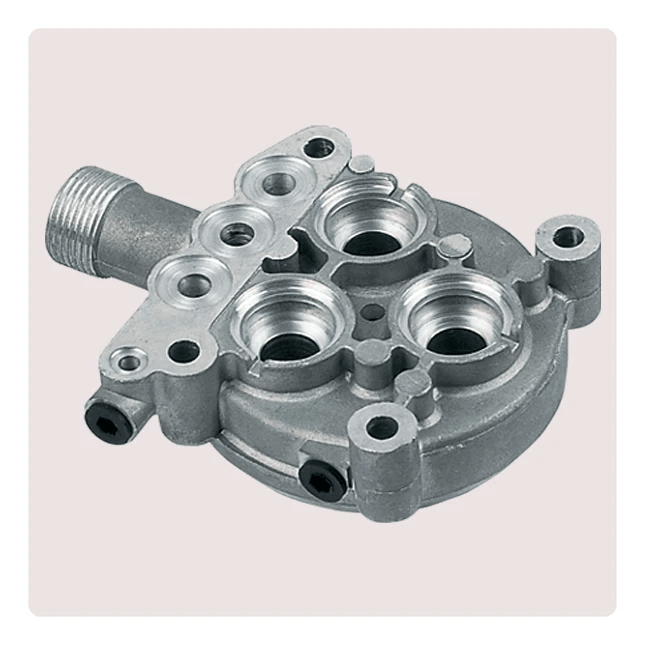

Gas Appliance Parts

When it comes to gas appliance parts, Buttler Precision Machinery Co., Ltd. is a leading expert in producing high-quality castings. With a focus on precision engineering, they ensure that their gas appliance parts meet the highest standards for safety and performance. Whether it's for residential or commercial applications, Buttler's gas appliance parts are designed to withstand the rigors of everyday use.

Buttler Precision Machinery Co., Ltd.

Buttler Precision Machinery Co., Ltd. is renowned for its expertise in die-casting molds and aluminum and zinc castings. Their comprehensive services include processing, surface treatment, assembly, and packaging, making them a one-stop solution for all gas appliance part needs. With a commitment to quality and precision, they have established themselves as a trusted partner in the industry.

Buttler Precision Machinery Co., Ltd. also prides itself on its state-of-the-art manufacturing facilities and cutting-edge technology, ensuring the highest level of precision and efficiency in every aspect of their production process. Their team of skilled engineers and technicians are dedicated to pushing the boundaries of innovation, constantly seeking new ways to enhance the quality and performance of their products. This commitment to excellence has solidified Buttler Precision Machinery Co., Ltd.'s position as a leader in the industry, setting them apart from their competitors.

High-Quality Castings

The materials used for casting play a crucial role in determining the quality of the final product. Buttler Precision Machinery Co., Ltd. utilizes high-quality metals such as aluminum and zinc for their castings, ensuring durability and reliability in gas appliance parts. These materials are known for their excellent thermal conductivity and corrosion resistance, making them ideal for use in demanding environments.

Furthermore, Buttler Precision Machinery Co., Ltd. employs advanced casting techniques to ensure the highest level of precision and accuracy in their products. By utilizing state-of-the-art equipment and stringent quality control measures, they are able to consistently produce castings with tight tolerances and minimal defects. This commitment to precision engineering results in gas appliance parts that meet the most exacting performance standards, providing customers with reliable and long-lasting products.

Precision Engineering

At Buttler Precision Machinery Co., Ltd., precision engineering is at the core of their manufacturing process. From designing intricate mold structures to fine-tuning casting parameters, every step is meticulously executed to achieve the desired outcome. This attention to detail results in gas appliance parts that not only meet industry standards but also exceed customer expectations in terms of performance and longevity.

Furthermore, Buttler Precision Machinery Co., Ltd. invests in state-of-the-art technology and equipment to ensure the highest level of precision in their manufacturing processes. This commitment to innovation allows them to stay ahead of the competition and continuously improve their products. By staying up-to-date with the latest advancements in precision engineering, they are able to offer gas appliance parts that are not only reliable but also at the forefront of technological advancements in the industry.

Conclusion

When it comes to casting, the choice of materials is crucial to the success of the process. The most widely used cast materials include aluminum, zinc, and various alloys. These materials offer a good balance of strength, durability, and cost-effectiveness for a wide range of applications. Whether it's for appliance parts or automotive components, the right casting material can make all the difference in performance and longevity.

Appliance Parts

In the production of appliance parts, casting plays a vital role in creating durable and reliable components. Aluminum and zinc are often used for their excellent casting properties, allowing for intricate designs and precise details that meet the demands of modern appliances. Buttler Precision Machinery Co., Ltd. offers high-quality castings that are engineered to withstand the rigors of daily use in various appliances.

In addition to aluminum and zinc, Buttler Precision Machinery Co., Ltd. also offers castings in other materials such as brass and stainless steel, providing a wide range of options to suit different appliance needs. These materials are chosen for their strength, corrosion resistance, and ability to maintain their appearance over time, ensuring that the appliance parts remain functional and aesthetically pleasing. With a variety of casting materials available, manufacturers can select the most suitable option for their specific appliance design and performance requirements.

Casting Materials Overview

The choice of casting materials is essential to achieving the desired performance and quality in cast components. Aluminum is widely used for its lightweight yet strong properties, making it ideal for a range of applications from automotive parts to outdoor lamp series. Zinc is also popular due to its excellent corrosion resistance and ability to be easily cast into complex shapes.

Buttler Precision Machinery Co., Ltd. Services

Buttler Precision Machinery Co., Ltd.'s expertise in die-casting molds, aluminum and zinc castings, surface treatment, assembly, and packaging makes them a top choice for manufacturers seeking high-quality castings with precision engineering. Their innovative tooling designs are engineered for cost-effective manufacturing while maximizing performance and minimizing secondary operations.

In addition to their expertise in die-casting molds and surface treatment, Buttler Precision Machinery Co., Ltd. also offers comprehensive assembly and packaging services to ensure a seamless production process for their clients. Their meticulous attention to detail and commitment to quality control means that manufacturers can trust Buttler Precision Machinery Co., Ltd. to deliver finished products that meet the highest standards. By offering a one-stop solution for die-casting, assembly, and packaging, they streamline the manufacturing process and help their clients save time and resources.