Introduction

Car mounting brackets are essential components in vehicle manufacturing, providing crucial support for various systems such as the AC compressor and engine. Die casting is a key process in producing these brackets, ensuring high performance and durability. Aluminum brackets play a vital role in supporting the car's AC compressor and engine, contributing to overall vehicle performance.

What Is Die Casting and Its Importance in Car Mounting Brackets

Die casting is a manufacturing process that involves injecting molten metal into a mold cavity under high pressure. This method is crucial in producing car mounting brackets due to its ability to create complex shapes with high precision. The use of die cast mounting brackets ensures superior strength and durability, making them ideal for supporting critical car components.

The Role of Aluminum Brackets in Car AC Compressor and Engine Mounting

Aluminum brackets are widely used in car manufacturing, particularly in supporting the AC compressor and engine. These brackets provide the necessary structural support while being lightweight, contributing to improved fuel efficiency and overall vehicle performance. Their durability and corrosion resistance make them an ideal choice for demanding automotive applications.

How Die Cast Mounting Brackets Improve Performance and Durability

Die cast mounting brackets offer superior performance and durability compared to other manufacturing methods. The precise shaping of die-cast parts ensures a perfect fit, reducing the risk of component failure or malfunction. This results in enhanced vehicle reliability and safety, making die cast mounting brackets an essential component in modern automotive engineering.

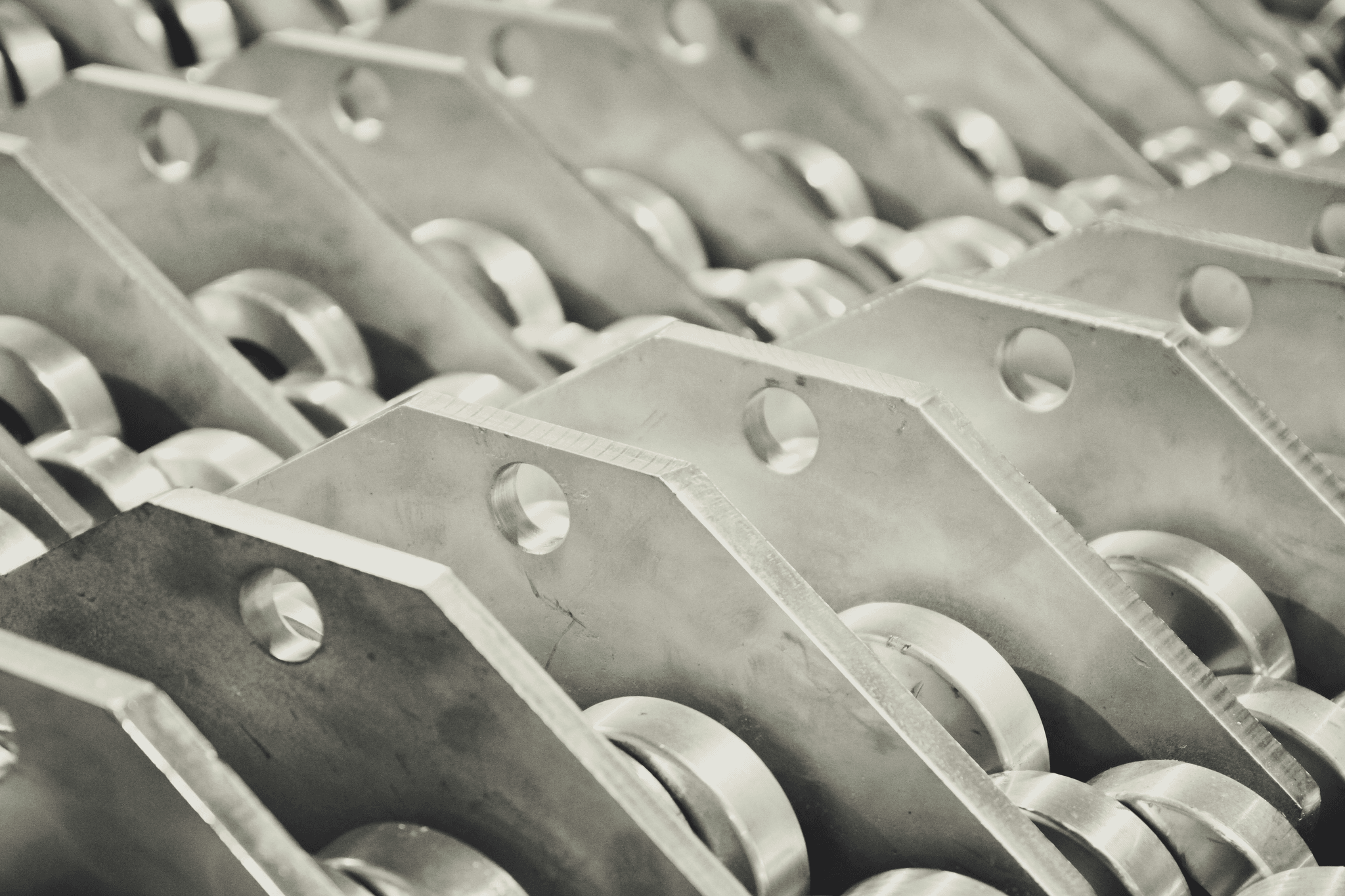

The Process of Die Casting Car Mounting Brackets

Die casting car mounting brackets involves the use of high-pressure injection to create complex and durable parts. This process starts with melting the aluminum or zinc, then injecting it into a mold cavity at high pressure. The result is a precise and high-quality part that requires minimal post-production work.

Understanding the Die Casting Process for Car Mounting Bracket Production

The die casting process for car mounting bracket production begins with melting the chosen metal in a furnace. Once molten, the metal is injected into a steel mold under extremely high pressure, ensuring that every detail of the mold is replicated in the final product. After cooling, the mold opens to reveal a solidified part ready for use.

Advantages of Die Cast Mounting Brackets Over Other Manufacturing Methods

Die cast mounting brackets offer numerous advantages over other manufacturing methods. They are known for their high strength-to-weight ratio, precision, and ability to produce complex shapes with thin walls. Additionally, die casting allows for tight tolerances and smooth surface finishes, reducing the need for secondary operations.

Furthermore, die cast mounting brackets are highly durable and resistant to corrosion, making them ideal for outdoor or harsh environment applications. This durability ensures that the brackets will maintain their structural integrity over time, reducing the need for frequent replacements and maintenance. In addition, die casting allows for the integration of multiple components into a single piece, reducing assembly time and potential points of failure in the finished product.

Quality Control Measures in Die Casting Car Mounting Brackets

Quality control measures are integral to die casting car mounting brackets to ensure consistent and reliable production. These measures include rigorous inspection processes at every stage of production to identify any defects or imperfections. By maintaining strict quality control standards, die casting companies can deliver superior products that meet industry requirements.

In addition to inspection processes, die casting companies also implement advanced technology and equipment to ensure the highest level of precision and accuracy in the production of car mounting brackets. This includes the use of computer-aided design (CAD) software and automated manufacturing systems to minimize human error and maximize efficiency. By leveraging these technological advancements, manufacturers can maintain a competitive edge in the industry while consistently delivering top-quality products.

The Role of Aluminum Brackets in Car AC Compressor and Engine Mounting

Importance of High-Quality Aluminum Brackets in Car AC Compressor

High-quality aluminum brackets play a crucial role in supporting the car AC compressor, ensuring it stays securely in place while the vehicle is in motion. The die cast mounting bracket provides the necessary stability and durability to withstand the constant vibrations and pressure fluctuations that come with operating the air conditioning system. With superior strength and corrosion resistance, aluminum brackets are essential for maintaining the integrity of the car AC compressor.

How Engine Mounting Brackets Contribute to Vehicle Performance

Engine mounting brackets are vital components that contribute to the overall performance and stability of a vehicle's engine. These brackets securely hold the engine in place, preventing excessive movement or vibrations that could lead to mechanical issues or decreased performance. By using high-quality die cast mounting brackets, car manufacturers can ensure that engines remain properly aligned and supported, leading to improved vehicle handling, reduced noise, and enhanced driving experience.

Innovations in Aluminum Bracket Design for Car Engines

Innovative advancements in aluminum bracket design have revolutionized how car engines are mounted and supported. By leveraging cutting-edge technology and engineering expertise, manufacturers can create lightweight yet extremely durable mounting brackets that meet stringent performance requirements. These innovative designs not only improve overall vehicle efficiency but also contribute to reducing fuel consumption and emissions, making them essential components for modern automotive engineering.

The Importance of Choosing the Right Die Casting Company

How to Select the Best Die Casting Company for Car Mounting Brackets

When choosing a die casting company for car mounting brackets, it's crucial to consider their expertise in producing high-quality and durable parts. Look for a company with a proven track record in manufacturing engine mounting brackets, aluminum brackets for car AC compressors, and RC car gearbox and transmission mounts. Additionally, ensure that the company has advanced technology and quality control measures in place to guarantee top-notch products.

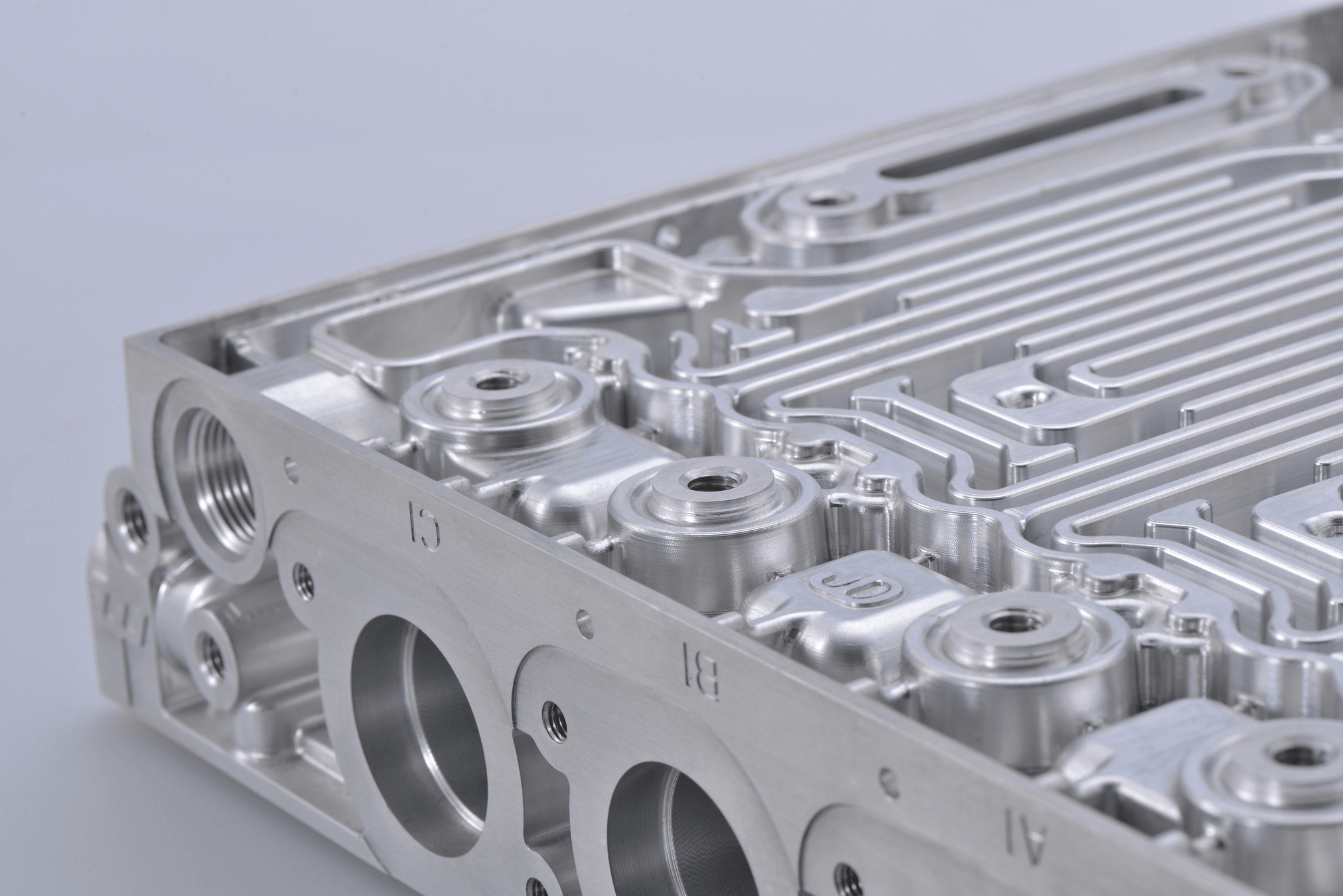

Exploring the Expertise of Ningbo Buttler Precision Machinery Co., Ltd. in Die Casting

Ningbo Buttler Precision Machinery Co., Ltd. stands out as a leader in die-casting molds and aluminum and zinc castings. With their Smart Part Engineering approach, they offer innovative tooling designs that maximize performance and casting quality while minimizing the need for secondary operations. Their expertise extends to processing, surface treatment, assembly, and packaging, making them a comprehensive solution provider for car mounting bracket production.

Key Considerations When Choosing a Die Casting Company for Car Mounting Brackets

When selecting a die casting company for car mounting brackets, it's essential to consider their ability to provide cost-effective manufacturing solutions without compromising on quality. Look for companies that offer an Engineering Design Review Process at no cost to optimize new and existing parts. Additionally, prioritize companies that have experience working with China die casting companies to ensure global best practices are incorporated into the production process.

By carefully considering these key factors when choosing a die casting company for car mounting brackets, you can ensure that you partner with a reliable and capable manufacturer who will meet your specific needs while delivering exceptional results.

Innovative Designs for Car Mounting Brackets

Smart Part Engineering by Ningbo Buttler Precision Machinery Co., Ltd. for Better Designs

Ningbo Buttler Precision Machinery Co., Ltd. is at the forefront of smart part engineering, offering innovative designs for car mounting brackets that are engineered to maximize performance and casting quality while minimizing the need for secondary operations. Their expertise in die-casting molds and aluminum castings ensures cost-effective manufacturing solutions for superior bracket designs.

Maximizing Performance with Innovative Tooling Designs for Car Mounting Brackets

With a focus on maximizing performance, Ningbo Buttler Precision Machinery Co., Ltd. utilizes innovative tooling designs to enhance the functionality and durability of car mounting brackets. By leveraging their expertise in die-casting and surface treatment, they are able to create high-quality brackets that meet the rigorous demands of automotive applications.

The Impact of Design Innovation on the Quality and Performance of Car Mounting Brackets

The impact of design innovation from Ningbo Buttler Precision Machinery Co., Ltd. is evident in the quality and performance of car mounting brackets. Their commitment to engineering excellence ensures that each bracket meets the highest standards for reliability and functionality, making them an ideal choice for car AC compressors, engine mounts, RC car gearboxes, and transmission mounts.

The Future of Die Casting in Car Mounting Bracket Production

Advancements in Die Casting Technology for Car Mounting Brackets

As the automotive industry continues to evolve, die casting technology for car mounting brackets is also advancing. New techniques and materials are being developed to enhance the performance and durability of die cast mounting brackets, ensuring they can withstand the demands of modern vehicles. These advancements aim to improve efficiency in production and create even stronger and lighter mounting brackets for various car components.

As die casting technology continues to advance, manufacturers are also focusing on improving the sustainability of the process. By utilizing more eco-friendly materials and implementing energy-efficient production methods, die cast mounting brackets can be produced with a reduced environmental impact. This not only aligns with the automotive industry's push for sustainability but also allows car manufacturers to meet stricter regulations and reduce their carbon footprint.

Exploring the Role of Die Casting in RC Car Gearbox and Transmission Mount

Die casting plays a crucial role in producing high-quality mounting brackets for RC car gearbox and transmission mount. The precision and strength offered by die cast aluminum brackets ensure that these components can handle the intense demands of remote-controlled vehicles, providing reliability and longevity for RC enthusiasts.

China Die Casting Companies and the Evolution of Car Mounting Bracket Production

China has become a hub for die casting companies, contributing significantly to the evolution of car mounting bracket production. With advanced manufacturing capabilities and expertise in producing high-quality aluminum brackets, Chinese die casting companies are driving innovation in the automotive industry. Their commitment to precision engineering and cost-effective solutions is shaping the future of car mounting bracket production on a global scale.

By focusing on these key areas, such as advancements in die casting technology, exploring its role in specific applications like RC cars, and recognizing China's influence on car mounting bracket production, we can gain valuable insights into the future direction of this critical component within the automotive industry.

Conclusion

When it comes to choosing the right die casting company for your car mounting bracket needs, it's crucial to consider expertise, quality, and innovation. Ningbo Buttler Precision Machinery Co., Ltd. stands out with its specialization in die-casting molds and aluminum and zinc castings. Their Smart Part Engineering approach ensures better part designs and maximized performance, making them a top choice for all your car mounting bracket requirements.

Choosing the Right Die Casting Company for Your Car Mounting Bracket Needs

Selecting the best die casting company for your car mounting bracket needs is essential for ensuring high-quality, durable parts that contribute to vehicle performance. With Ningbo Buttler Precision Machinery Co., Ltd.'s expertise in die-casting molds and innovative tooling designs, you can trust that your car mounting brackets will meet the highest standards of quality and performance.

When it comes to choosing the right die casting company for your car mounting bracket needs, it's important to consider the level of expertise and innovation that the company offers. With Ningbo Buttler Precision Machinery Co., Ltd.'s extensive experience in die-casting molds and cutting-edge tooling designs, you can be confident that your car mounting brackets will not only meet but exceed industry standards for quality and performance. By partnering with a company that prioritizes precision and excellence, you can be sure that your car mounting brackets will contribute to the overall performance and durability of your vehicles.

The Future of Die Casting in Car Mounting Bracket Production

As technology continues to advance, die casting is poised to play an even more significant role in car mounting bracket production. With innovations in material science and manufacturing processes, we can expect to see further improvements in the performance and durability of car mounting brackets. China Die Casting Companies like Ningbo Buttler Precision Machinery Co., Ltd. are at the forefront of these advancements.

Maximizing Performance with Innovative Design Solutions

Innovative design solutions are key to maximizing the performance of car mounting brackets. By leveraging smart part engineering and advanced tooling designs offered by companies like Ningbo Buttler Precision Machinery Co., Ltd., manufacturers can achieve superior part designs that enhance overall vehicle performance and durability.

In addition to enhancing vehicle performance and durability, innovative design solutions for car mounting brackets can also contribute to improved fuel efficiency. By optimizing the weight and aerodynamics of the mounting brackets, manufacturers can help vehicles operate more efficiently, ultimately saving on fuel costs for consumers. This focus on efficiency aligns with the growing demand for environmentally friendly and sustainable automotive solutions.

Remember, when it comes to choosing a die casting company for your car mounting bracket needs, prioritize expertise, innovation, and quality to ensure optimal performance and durability for your vehicles!