Introduction

Are you in need of metal casting services for your next project? Whether you're a manufacturer or designer, understanding the metal casting process is crucial for creating high-quality products. Custom metal casting services offer a range of benefits, from design flexibility to cost-effectiveness. But how do you find the right metal casting service provider to meet your needs?

Understanding the Metal Casting Process

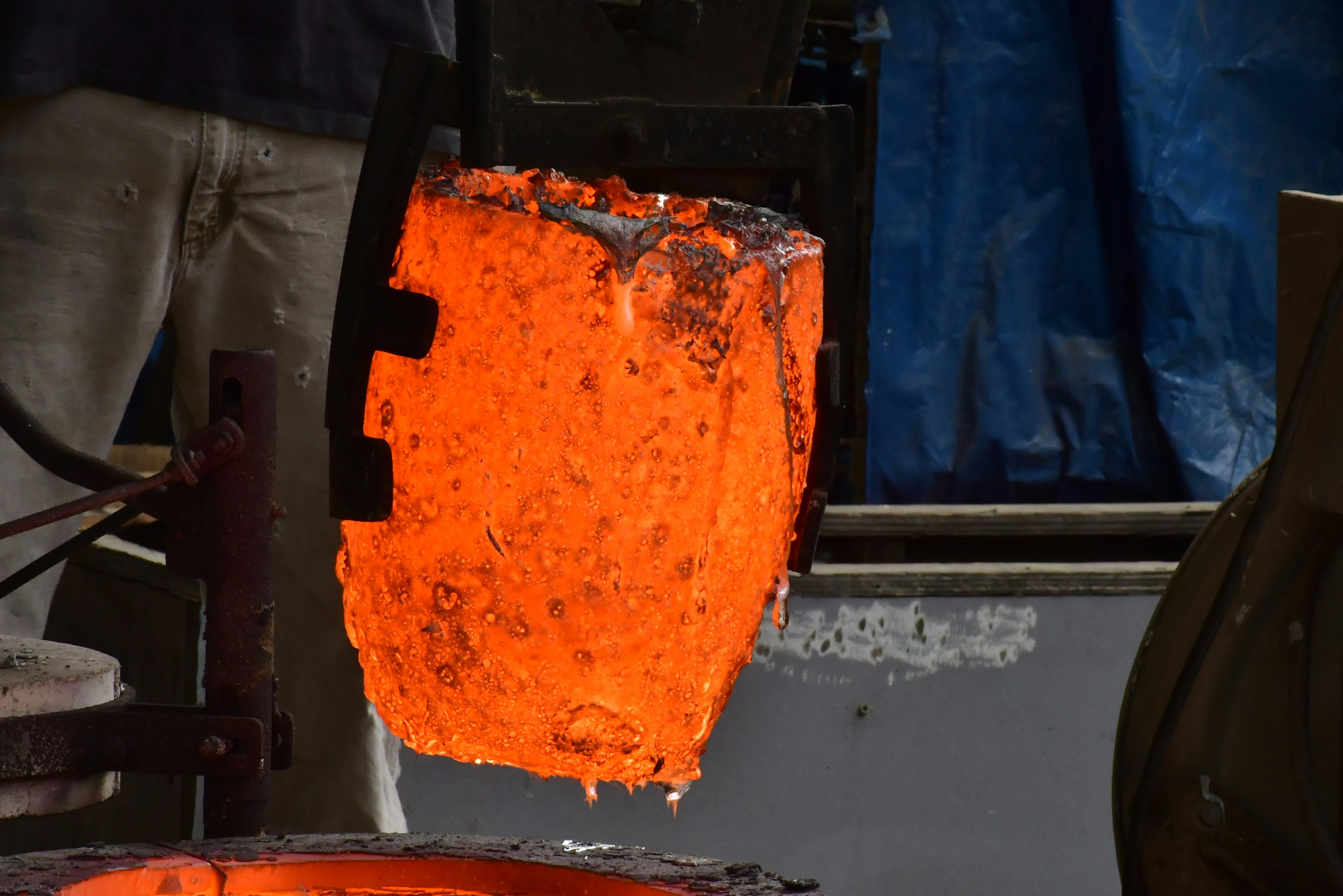

Metal casting is a manufacturing process in which molten metal is poured into a mold and allowed to solidify. This versatile technique allows for the creation of complex shapes and designs with ease, making it an ideal choice for various industries. Additionally, custom metal casting services produce parts with high dimensional accuracy, ensuring that each component meets the required specifications. This precision is essential in industries such as aerospace and automotive, where tight tolerances are crucial for optimal performance.

The Benefits of Custom Metal Casting Services

Custom metal casting services provide a powerful solution for businesses producing complex parts in large quantities. Here's how this versatile process benefits your manufacturing:

- Cost-Effective Production: Metal casting eliminates the need for extensive machining, saving time and money on each part.

- Design Freedom for Intricate Components: Create intricate designs that would be difficult or expensive to produce with other methods.

- Efficient Scaling: Easily ramp up production to meet growing demand without sacrificing quality.

- Unmatched Quality: Cast metal parts are known for their exceptional strength and durability.

By incorporating custom metal casting into your manufacturing strategy, you can achieve high-volume production of complex parts while maintaining efficiency and cost-effectiveness.

Finding the Right Metal Casting Service Provider

When searching for a reliable metal casting service provider, it's essential to consider factors such as experience, capabilities, and customer reviews. Finding a trusted partner who can deliver quality results at an affordable price is crucial in maximizing the value of your investment.

In addition to experience, capabilities, and customer reviews, it is important to look for a metal casting service provider that offers excellent customer service and clear communication. A provider responsive to your needs and keeping you informed throughout the process can help ensure a smooth and successful project. By choosing a partner who values open dialogue and collaboration, you can avoid potential misunderstandings and delays.

Exploring Custom Metal Casting Services

The versatility of custom metal casting cannot be overstated when it comes to metal casting services. With the ability to create complex shapes and designs, custom metal casting offers endless possibilities for manufacturers and designers alike. From intricate jewelry pieces to heavy-duty industrial components, the flexibility of custom metal casting allows for a wide range of applications.

The Versatility of Custom Metal Casting

Custom metal casting services cater to various industries, including aerospace, automotive, and medical equipment manufacturing. Whether it's producing precision parts for aircraft engines or creating specialized tools for surgical procedures, custom metal casting can accommodate the unique needs of each industry. This adaptability makes it a valuable resource for businesses seeking tailored solutions.

Custom metal casting services are also essential in the energy and construction industries, providing components for power generation equipment and infrastructure projects. From turbine blades to structural supports, custom metal casting plays a crucial role in ensuring the reliability and safety of these systems. The ability to produce complex, high-strength parts makes it an indispensable tool for meeting the demanding requirements of these sectors.

Applications of Metal Casting in Various Industries

Metal casting has vast and impactful applications in various industries. From architectural elements like decorative hardware and ornamental fixtures to critical components in renewable energy systems, its reach is extensive. Its ability to withstand high temperatures and harsh environments makes it an ideal choice for industries that demand durability and reliability.

Custom metal casting can enhance product quality by allowing for intricate and complex designs that may not be achievable through other manufacturing processes. This level of customization ensures that products are tailored to meet specific industry requirements, resulting in improved performance and functionality. Additionally, custom metal casting can lead to cost savings as it allows for consolidating multiple components into a single, more efficient part.

How Custom Metal Casting Can Enhance Product Quality

Custom metal casting offers manufacturers a powerful tool to create high-quality products. Here's how:

- Precise Design and Material Selection: Casting allows for intricate details and complex geometries, adhering to your specifications.

- Unmatched Customization: The process isn't limited by traditional methods, enabling the creation of unique and functional parts.

- Enhanced Performance and Longevity: The precise control over design and material selection leads to superior strength, durability, and overall product life.

- Customer Satisfaction: By delivering high-quality, custom-made parts, you can ensure your customers receive a product that meets their needs.

By understanding these benefits, you're ready to explore the factors to consider when choosing a reliable custom metal casting service provider.

Choosing the Right Metal Casting Service Provider

When selecting a metal casting supplier, consider factors such as experience, reputation, and capabilities. Look for a provider with a proven track record of delivering high-quality metal casting services to ensure the success of your project. Additionally, consider their expertise in your specific industry to guarantee they understand and can effectively meet your unique requirements.

Factors to Consider When Selecting a Metal Casting Supplier

The first factor to consider when choosing a metal casting supplier is their experience in the industry. A supplier with years of expertise is more likely to deliver reliable and high-quality metal casting services that meet your expectations. Reputation is also crucial - look for reviews and testimonials from previous clients to gauge the supplier's reliability and customer satisfaction.

Furthermore, it is essential to consider the supplier's production capabilities and capacity. A reliable metal casting supplier should be able to meet your production needs and deadlines. Look for a supplier that can handle both small and large orders and offer flexibility in production processes to accommodate any changes or custom requirements. Understanding their capacity will ensure that they can consistently provide the quantity of parts you require.

Understanding the Metal Casting Supply Chain

Understanding the metal casting supply chain is vital for selecting the right service provider. From raw material sourcing to final product delivery, a robust supply chain ensures efficiency and quality throughout the metal casting process. Look for suppliers with well-established supply chains to ensure seamless production and delivery of your custom metal casted products.

Evaluating the Cost of Metal Casting Services

Evaluating the cost of metal casting services is essential for staying within budget while ensuring quality and precision. Compare quotes from different suppliers while considering material costs, production time, and additional services. Remember that choosing a low-cost option may compromise quality, so prioritize value over price when evaluating costs.

When evaluating the cost of metal casting services, it's essential to consider the supplier's reputation and track record for delivering high-quality products. While price is a significant factor, choosing a supplier with a history of reliability and customer satisfaction can ultimately save time and money in the long run. Additionally, inquire about any certifications or industry standards the supplier adheres to, which can indicate their commitment to quality and precision.

The Process of Custom Metal Casting

Understanding the intricate process is crucial when it comes to metal casting services. The first step involves creating a mold from a pattern, which is then filled with molten metal and left to cool. Once solidified, the metal is removed from the mold, and any excess material is trimmed. This process allows for creating complex shapes and designs, making it a popular choice for various industries.

Steps Involved in the Metal Casting Process

Metal casting is a versatile technique for creating complex metal shapes. Here's a breakdown of the process in steps:

- Patternmaking: A model of the desired part is crafted from wood, plastic, or metal. This pattern will form the cavity in the mold.

- Mold Preparation: The pattern is placed in sand to create a negative impression. This sand mold includes channels for pouring the metal and for venting gases.

- Pouring and Cooling: Molten metal is poured into the mold cavity and left to cool and solidify.

- Casting Removal and Cleaning: The mold is broken away to reveal the cast metal part once cooled. Any excess material or imperfections are trimmed and smoothed to achieve the final dimensions and desired finish.

This process allows for the creation of intricate metal parts for various applications.

The Role of Ningbo Buttler Precision Machinery Co., Ltd. in Metal Casting

Ningbo Buttler Precision Machinery Co., Ltd. is pivotal in providing top-notch custom metal casting services to meet various industry needs. With state-of-the-art facilities and advanced technology, they produce high-quality castings with precision and efficiency. Their expertise in customizing solutions makes them a trusted partner for businesses seeking reliable metal casting services.

Ensuring Quality and Precision in Metal Casting

Quality control is essential in ensuring that every piece produced through metal casting meets industry standards. Ningbo Buttler Precision Machinery Co., Ltd.'s commitment to quality extends from material selection to final inspection, ensuring that each product meets customer specifications accurately and consistently.

In addition to stringent quality control measures, Ningbo Buttler Precision Machinery Co., Ltd. prioritizes metal casting precision. The company utilizes advanced technology and state-of-the-art equipment to ensure that each component is manufactured with the utmost accuracy and attention to detail. This commitment to precision results in high-quality products, minimizes waste, and reduces production costs, ultimately benefiting both the company and its customers.

Industry Insights: Metal Casting Trends and Technologies

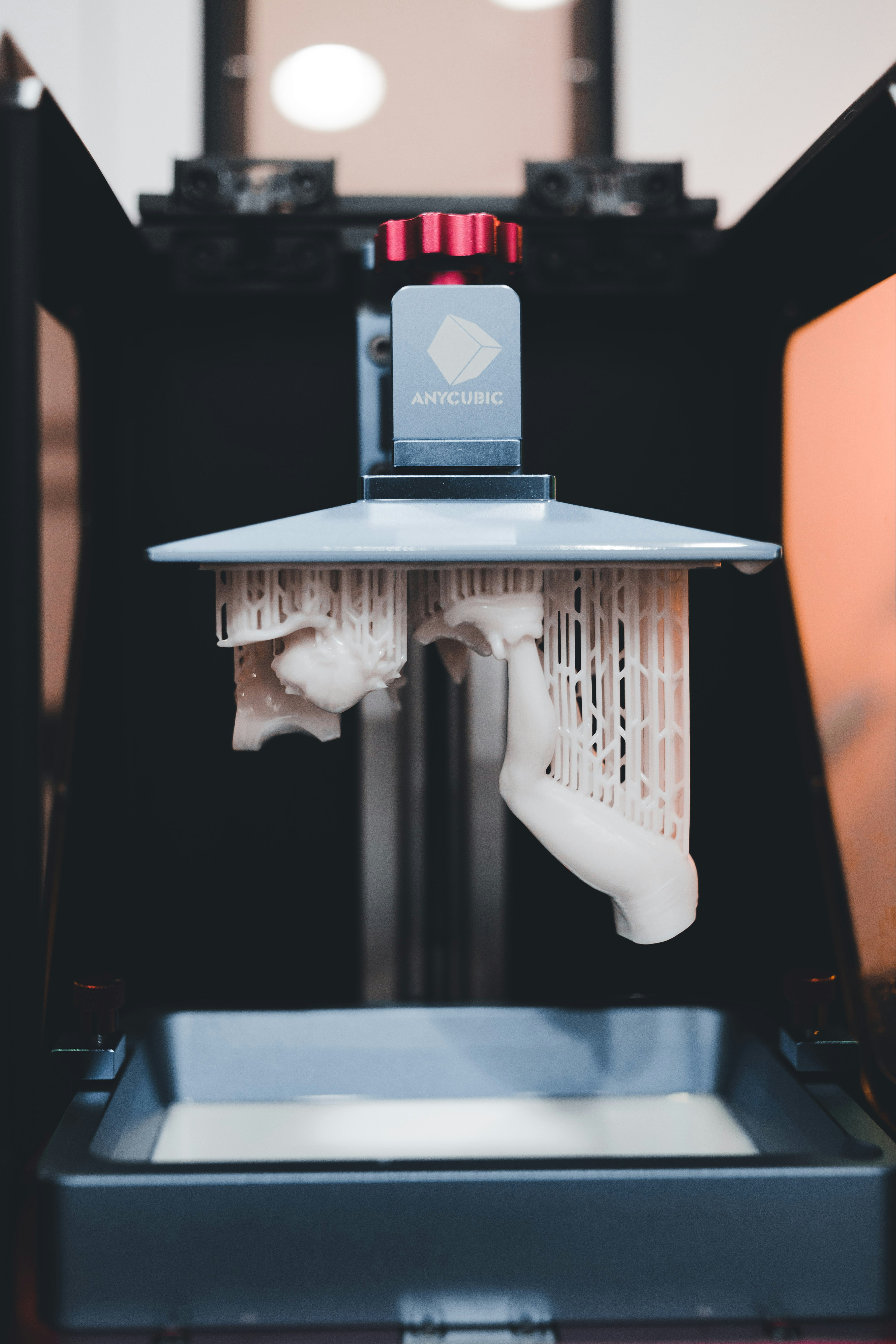

Innovations in Metal Casting Technology

In today's rapidly evolving manufacturing landscape, innovations in metal casting technology have revolutionized the industry. From 3D printing to advanced simulation software, these technological advancements have significantly enhanced the precision and efficiency of metal casting processes. With the integration of digital tools and automation, metal casting services offer unparalleled customization and speed, meeting the demands of diverse industries.

The Growing Influence of Metal Casting in the Manufacturing Industry

The growing influence of metal casting in the manufacturing industry is undeniable. With its ability to produce complex shapes and intricate designs relatively cheaply, metal casting has become a preferred method for creating components across various sectors, such as automotive, aerospace, and medical equipment manufacturing. As a result, metal casting services are increasingly sought after by businesses looking to optimize their production processes.

Sustainable Practices in the Metal Casting Industry

In response to environmental concerns, sustainable practices have become a focal point in the metal casting industry. From using recycled materials to implementing energy-efficient technologies, metal casting services embrace eco-friendly approaches to minimize environmental impact. This commitment to sustainability aligns with global conservation efforts and enhances the appeal of metal casting as a responsible manufacturing solution.

Maximize the Value of Metal Casting Services

When it comes to enhancing product design with custom metal casting, there's no better option than leveraging the expertise of Ningbo Buttler Precision Machinery Co., Ltd. Their extensive experience in the metal casting industry ensures top-notch quality and precision for your products. Maximizing the value of metal casting services can elevate your manufacturing processes and stay ahead of the competition.

Enhancing Product Design with Custom Metal Casting

Custom metal casting services offer unparalleled flexibility in product design. They allow for intricate shapes and complex geometries that traditional manufacturing methods simply cannot achieve. This opens up a world of possibilities for creating innovative, high-quality products that stand out in the market.

Leveraging the Expertise of Ningbo Buttler Precision Machinery Co., Ltd.

Ningbo Buttler Precision Machinery Co., Ltd. is a leading player in the metal casting industry, offering a wide range of capabilities to meet diverse customer needs. With their expertise, you can rest assured that your custom metal casting requirements will be met with utmost precision and attention to detail.

By partnering with a reliable metal casting service provider, you can maximize the value of your investment in custom metal casting. Leveraging metal casting services can significantly enhance your manufacturing operations by reducing lead times and optimizing production costs.