Introduction

Welcome to the world of cast zinc, a versatile and durable material that has revolutionized various industries. Whether you're familiar with die-cast zinc or just starting to explore its potential, this guide will provide you with a comprehensive understanding of its properties, benefits, and applications.

What is Cast Zinc?

Cast zinc, also known as die-cast zinc or die-cast zinc alloy, is a metal alloy formed by injecting molten zinc into a mold cavity under high pressure. This process produces intricate and precise shapes with excellent dimensional accuracy and surface finish.

The Benefits of Cast Zinc

Die-cast zinc's combination of properties makes it a popular choice for manufacturers and designers. Here's why:

- Exceptional Corrosion Resistance: Zinc naturally resists rust and corrosion, ideal for applications exposed to harsh environments.

- High Strength-to-Weight Ratio: Die-cast zinc is strong yet lightweight, offering both durability and design flexibility.

- Excellent Electrical Conductivity: This makes zinc suitable for efficient electrical current transfer applications.

Due to these valuable properties, die-cast zinc is used in various industries, from automotive and electronics to consumer goods and construction.

Applications of Cast Zinc

Due to its versatility and reliability, cast zinc is used in various industries, from automotive components to electronic enclosures. Its ability to be easily plated or finished with different surface treatments further expands its potential uses in various products.

Choosing the right manufacturer is crucial for producing high-quality cast zinc parts. Ningbo Buttler Precision Machinery Co., Ltd., for example, specializes in providing innovative tooling designs engineered for cost-effective manufacturing, maximizing performance and casting quality while minimizing the need for secondary operations!

Understanding Cast Zinc

When understanding cast zinc, it's essential to consider the material properties that make it a popular choice for various applications. Cast zinc is known for its high strength and excellent corrosion resistance, making it ideal for parts that need to withstand harsh environmental conditions. Additionally, die-cast zinc alloy properties include good dimensional stability and the ability to be easily plated or finished.

Properties of Cast Zinc

Cast zinc's material properties make it highly desirable for a wide range of applications. With its excellent strength-to-weight ratio, die-cast zinc provides durable and long-lasting components for industries such as automotive, construction, and electronics. Furthermore, die-cast zinc's material properties include high thermal conductivity and low melting point, allowing for intricate designs and complex shapes.

Different Types of Cast Zinc

Cast zinc offers a versatile material choice for designers and engineers due to the variety of alloys available. Each type boasts unique properties ideal for specific applications:

- Die-Cast Zinc Alloy: Renowned for achieving tight tolerances, thin walls, and high strength, this alloy creates intricate details and complex geometries, making it a popular choice for various parts.

- ZA-8 Alloy: When superior strength and creep resistance are paramount, ZA-8 is the alloy to choose. This alloy is used in applications demanding structural integrity under stress.

- ZAMAK Alloys: This family of alloys offers a balance of desirable properties, including good castability, machinability, and finishing characteristics. Specific ZAMAK variants cater to various needs, such as ZAMAK 3, known for its excellent balance, and ZAMAK 5, favored for its increased hardness.

By understanding the different types of cast zinc and their properties, designers and engineers can select the optimal material to meet the specific needs of their project, ensuring optimal performance and functionality.

How Cast Zinc is Made

Cast zinc is made by melting it at high temperatures before injecting it into precision molds under high pressure. This method, known as die casting, allows for producing complex shapes with excellent surface finishes. The resulting parts exhibit minimal porosity and uniform mechanical properties, making them suitable for various applications.

In addition to its ability to produce complex shapes with excellent surface finishes, die casting also allows for high production rates, making cast zinc an efficient choice for manufacturers. This method enables the creation of intricate designs with tight tolerances, ensuring that the resulting parts meet precise specifications. Furthermore, the uniform mechanical properties of cast zinc parts make them reliable and consistent in performance, offering peace of mind to those using them in various applications.

Advantages of Using Cast Zinc

Cast zinc offers numerous advantages, making it a popular choice for various industries. From its durability and cost-effectiveness to its environmental benefits, die-cast zinc and die-cast zinc alloy are highly sought-after materials for a wide range of applications.

Durability of Cast Zinc

Die-cast zinc is known for its exceptional durability, making it an ideal choice for parts and components that require long-lasting performance. With superior strength and resistance to corrosion, cast zinc's properties ensure that products made from this material can withstand harsh conditions and heavy usage without compromising on quality.

Cost-Effectiveness of Cast Zinc

One key advantage of using die-cast zinc is its cost-effectiveness in manufacturing processes. Die casting allows for high precision and intricate designs, reducing the need for additional machining or finishing operations. This results in lower production costs and shorter lead times, making it a cost-effective solution for large-scale complex parts.

Furthermore, die-cast zinc is highly recyclable, making it an environmentally friendly choice for manufacturers. Recycling zinc without compromising its quality or performance reduces the need for raw material extraction and energy consumption, leading to a reduced carbon footprint. This aligns with the growing emphasis on sustainable manufacturing practices and can contribute to a company's overall environmental objectives.

Environmental Benefits of Cast Zinc

In addition to its durability and cost-effectiveness, cast zinc offers environmental benefits that contribute to sustainable manufacturing practices. Die-cast zinc is fully recyclable, allowing for the reuse of scrap materials in the production process. Furthermore, its low energy consumption during casting makes it an eco-friendly choice for reducing carbon footprint in manufacturing operations.

Now that we've explored the advantages of using cast zinc in detail let's delve into the industries that benefit from this versatile material.

Industries Using Cast Zinc

Automotive Industry and Cast Zinc

In the automotive industry, die-cast zinc and die-cast zinc alloys are widely used for various components such as door handles, brackets, and interior trim. Cast zinc's material properties, such as its high strength, dimensional stability, and corrosion resistance, make it an ideal choice for these applications. Manufacturers in this industry rely on die-cast zinc for its durability and ability to withstand harsh environmental conditions.

In addition to the aforementioned components, die-cast zinc is also used in the automotive industry to produce transmission cases, engine mounts, and other structural parts. The versatility of cast zinc allows for intricate designs and complex shapes to be easily achieved, making it a preferred material for meeting the diverse needs of automotive manufacturers. Furthermore, the ability of die-cast zinc to be coated with a range of finishes, such as chrome plating or powder coating, adds to its appeal in the automotive industry, where aesthetics are just as important as functionality.

Construction Industry and Cast Zinc

Cast zinc is a popular choice for architectural hardware, decorative elements, and structural components in the construction industry. Die-cast zinc's material properties, including its malleability and corrosion resistance, make it suitable for exterior applications such as window hardware and cladding systems. The versatility of die-cast zinc alloy allows architects and designers to create intricate designs while ensuring long-lasting performance in various building projects.

Cast zinc is also famous for interior architectural elements such as door handles, stair railings, and decorative trim. Its ability to be easily molded into intricate shapes and designs makes it a preferred material for adding aesthetic appeal to building interiors. Additionally, the durability of die-cast zinc ensures that these interior elements will withstand daily wear and tear while maintaining their visual appeal over time.

Electronics Industry and Cast Zinc

The electronics industry utilizes die-cast zinc for housing components of electronic devices such as smartphones, tablets, and laptops due to its electromagnetic shielding properties. Die-cast zinc's material properties provide excellent EMI/RFI protection while maintaining a lightweight profile for portable electronics. Manufacturers in this industry also appreciate the precision achievable with die-casting processes when creating intricate parts for electronic devices.

Additionally, die-cast zinc offers high durability and corrosion resistance, making it an ideal choice for electronic device housings that need to withstand daily wear and tear. This ensures the product's longevity and enhances the overall user experience by providing reliable and sturdy housing for sensitive electronic components. Die-cast zinc's ability to be easily molded into complex shapes further adds to its appeal in the electronics industry, allowing for sleek and modern designs that complement the cutting-edge technology housed within.

Choosing the Right Cast Zinc Manufacturer

Ningbo Buttler Precision Machinery Co., Ltd. is a top choice when choosing the proper cast zinc manufacturer. Specializing in die-casting molds, aluminum and zinc castings, processing, surface treatment, assembly, and packaging, Buttler offers comprehensive services to meet all your casting needs.

Ningbo Buttler Precision Machinery Co., Ltd.

Ningbo Buttler Precision Machinery Co., Ltd. stands out as a leading manufacturer of die-cast zinc products. Focusing on quality and precision, they offer intelligent part engineering for better part designs and innovative tooling designs engineered for cost-effective manufacturing to maximize performance and casting quality while minimizing the need for secondary operations.

Quality Standards for Cast Zinc

Buttler maintains high-quality standards for its cast zinc products, ensuring that each piece meets rigorous industry specifications. This commitment to excellence means that you can trust in the durability and reliability of its cast zinc materials for any application.

Customization Options for Cast Zinc

One key advantage of choosing Ningbo Buttler Precision Machinery Co., Ltd. is its ability to provide customization options for cast zinc products. Whether you require specific dimensions, surface finishes, or unique features, they can tailor their offerings to your specifications.

With Ningbo Buttler Precision Machinery Co., Ltd., you can be confident in receiving high-quality cast zinc products tailored to your specific requirements while meeting stringent quality standards.

Designing with Cast Zinc

Smart part engineering for cast zinc involves creating better part designs that maximize performance and casting quality. Die-cast zinc's material properties allow for intricate and complex shapes to be easily achieved, making it an ideal choice for innovative part designs. Whether for automotive, construction, or electronics applications, die-cast zinc alloy properties provide the versatility needed for clever part engineering.

Smart Part Engineering for Cast Zinc

Clever part engineering with die-cast zinc involves leveraging the material properties to create parts that are not only durable but also lightweight and corrosion-resistant. This makes die-cast zinc an excellent choice for applications where strength and longevity are essential. By understanding the unique characteristics of cast zinc material properties, engineers can optimize designs to meet specific performance requirements while minimizing weight and cost.

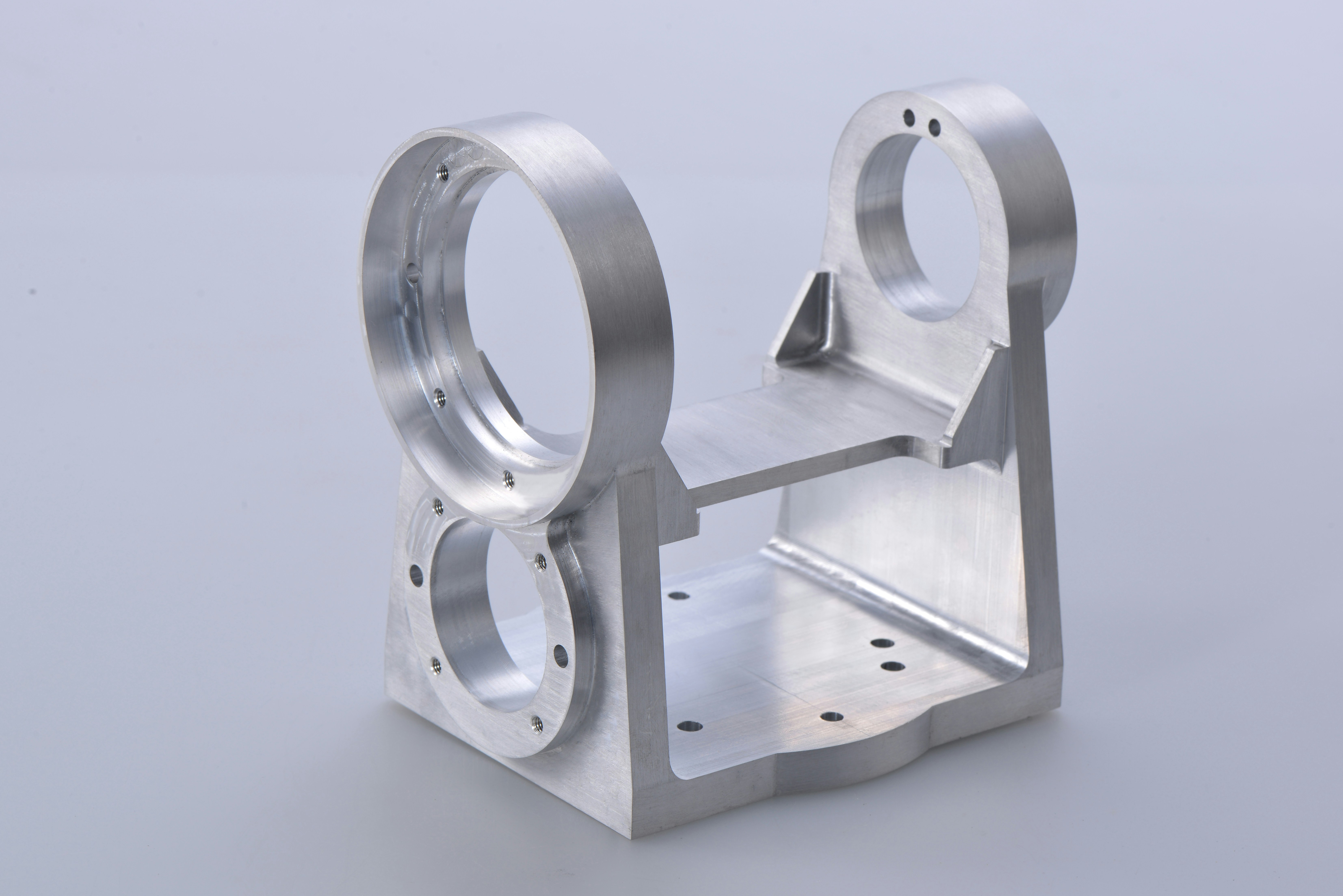

Innovative Tooling Designs for Cast Zinc

Innovative tooling designs are crucial in maximizing the potential of die-cast zinc alloy properties. The precision and complexity of these tooling designs allow for intricate details to be captured in the final castings, ensuring high-quality parts with minimal post-processing required. At Ningbo Buttler Precision Machinery Co., Ltd., our die-casting molds and tooling design expertise enable us to deliver cost-effective solutions that meet the most demanding design requirements.

Maximizing Performance with Cast Zinc

Maximizing performance with cast zinc involves more than just creating a well-designed part – it also requires careful consideration of manufacturing processes and surface treatments. With die-cast zinc corrosion resistance being a key advantage, parts can withstand harsh environmental conditions without compromising performance. By partnering with a reputable manufacturer like Ningbo Buttler Precision Machinery Co., Ltd., you can optimize your designs for maximum performance and longevity.

Design for Success with Cast Zinc

Cast and die-cast zinc alloy offer many benefits when choosing the suitable material for your manufacturing needs. Cast zinc is a versatile and durable option for various industries, from its excellent material properties to its corrosion resistance. Finding the proper cast zinc manufacturer is crucial. Ningbo Buttler Precision Machinery Co., Ltd. stands out with its expertise in die-casting molds and innovative tooling designs that maximize performance and quality while minimizing costs.

Benefits of Choosing Cast Zinc

Zinc casting offers numerous advantages for manufacturers, making it a popular choice across various industries. Here's a breakdown of its key benefits:

- Exceptional Material Properties: Zinc alloys boast impressive strength, dimensional stability, and impact resistance, which makes them ideal for components requiring durability.

- Cost-Effectiveness: Zinc offers a competitive price point compared to other casting materials, making it a budget-friendly option for manufacturers.

- Corrosion Resistance: Zinc naturally resists corrosion, ensuring the longevity of cast parts and minimizing maintenance needs.

- Design Flexibility: Zinc's excellent fluidity allows for intricate designs with thin walls, expanding design possibilities.

- Superior Finish: Zinc castings readily accept various finishes, enhancing aesthetics and adding functional properties like wear resistance.

- Efficient Manufacturing: The zinc casting process is fast and allows for near-net shapes, reducing machining requirements and production time.

- Environmentally Friendly: Zinc is highly recyclable, making it an eco-conscious material choice for sustainable manufacturing practices.

Zinc casting's robust properties, cost-efficiency, and versatility make it a reliable and sustainable solution for various manufacturing applications.

Finding the Right Cast Zinc Manufacturer

Choosing the proper cast zinc manufacturer is essential for ensuring high-quality products. Ningbo Buttler Precision Machinery Co., Ltd. specializes in die-casting molds, aluminum and zinc castings, processing, surface treatment, assembly, and packaging. Their expertise in clever part engineering and innovative tooling designs sets them apart in the industry.

Designing with cast zinc opens up opportunities for creating cost-effective parts that maximize performance while minimizing the need for secondary operations. With Ningbo Buttler Precision Machinery Co., Ltd.'s Engineering Design Review Process, you can optimize your parts at no cost, ensuring success in your manufacturing endeavors.

With the numerous benefits of choosing cast zinc and die-cast zinc alloy, along with the expertise offered by manufacturers like Ningbo Buttler Precision Machinery Co., Ltd., it's clear that this material is a top choice for various industries looking to create durable and cost-effective products. Make sure to consider all the advantages when making your next manufacturing decision!