Introduction

When it comes to manufacturing, understanding aluminum die casting components is crucial. This process involves the use of die-cast aluminum, which is made up of a specific chemical composition. The raw material for aluminum die casting plays a significant role in the quality and durability of the final products. As such, it's essential to explore these components and materials in depth to fully grasp their importance in the manufacturing industry.

Understanding Aluminum Die Casting Components

Aluminum die casting components refer to the various parts and products that are manufactured using the die-casting process with aluminum as the primary material. These components are known for their high strength-to-weight ratio, excellent corrosion resistance, and exceptional thermal conductivity, making them ideal for a wide range of applications across different industries.

Exploring the Chemical Composition of Die-Cast Aluminum

The chemical composition of die-cast aluminum typically consists of a combination of aluminum, silicon, copper, magnesium, iron, and other trace elements. This specific blend is carefully formulated to achieve optimal mechanical properties and performance characteristics in the finished products.

The Raw Material for Aluminum Die Casting

The raw material for aluminum die casting is primarily derived from bauxite ore, which is processed into alumina before being smelted into pure aluminum metal. This high-quality raw material forms the foundation for producing durable and reliable die-cast aluminum components that meet stringent industry standards.

The Process of Die-Casting

What is die-cast aluminum made of? Die-cast aluminum is made of a combination of aluminum, magnesium, and copper. This alloy provides excellent strength and corrosion resistance, making it an ideal choice for a wide range of applications in various industries.

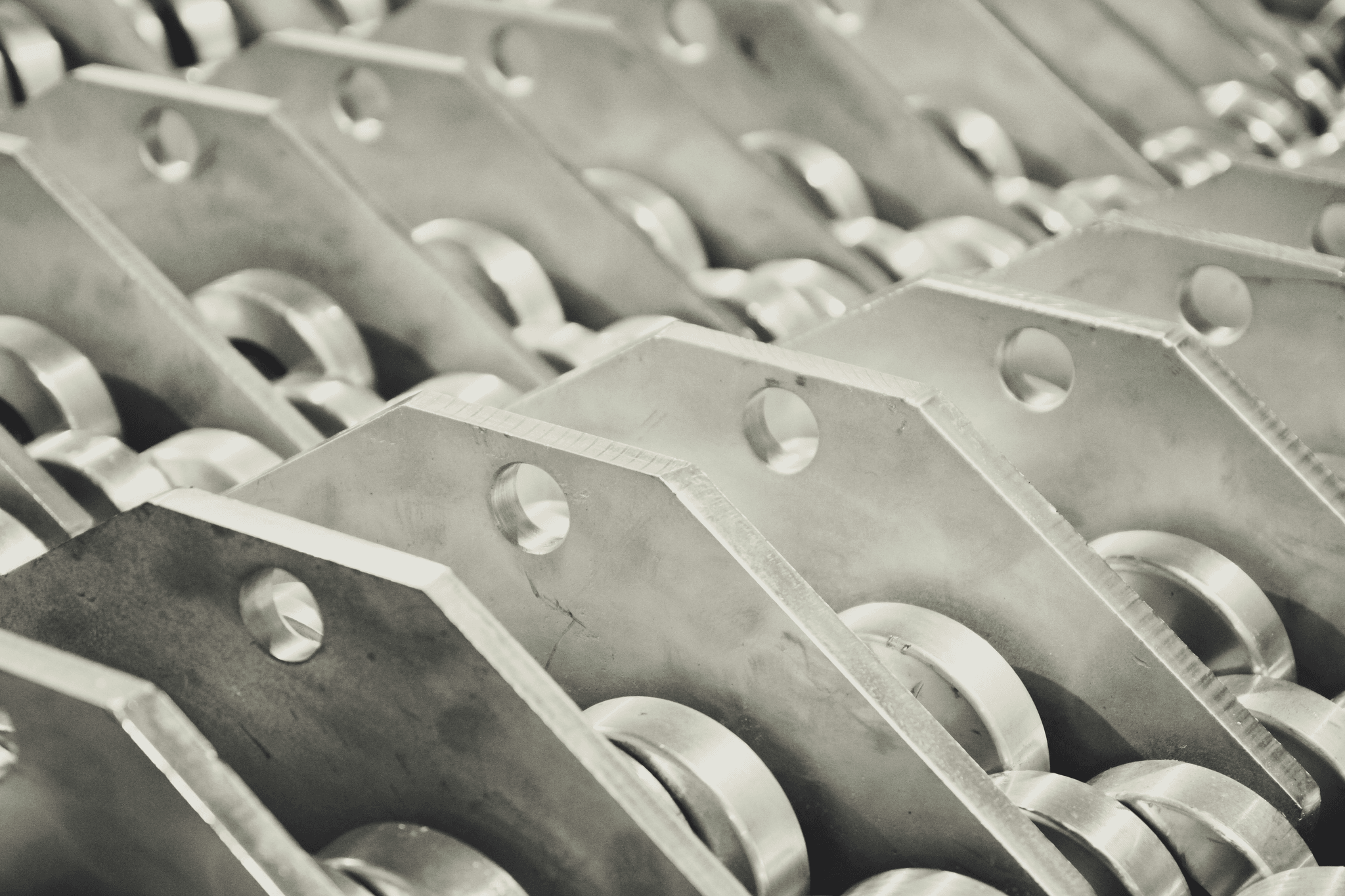

A closer look at the die-casting process reveals that it involves injecting molten metal into a steel mold under high pressure. This allows for the production of complex shapes with high precision and smooth surfaces. The process ensures that the final aluminum die casting components meet strict quality standards.

The benefits of die-casting in manufacturing are numerous. It allows for the production of intricate parts with thin walls and fine details, while also offering high dimensional accuracy and stability. Additionally, die-casting is a cost-effective method for mass production, making it highly efficient for industrial applications.

China Die Casting Companies like Ningbo Buttler Precision Machinery Co., Ltd. specialize in providing Aluminum Alloy Die Casting Services. They offer expertise in producing high-quality aluminum die casting components through advanced processes and quality control measures to meet the specific requirements of their clients.

Remember to take advantage of Smart Part Engineering for Better Part Designs offered by Ningbo Buttler Precision Machinery Co., Ltd. Their innovative tooling designs are engineered to maximize performance and casting quality while minimizing the need for secondary operations, ensuring cost-effective manufacturing solutions.

By understanding the process and benefits of die-casting, businesses can make informed decisions when choosing the right die-casting partner for their manufacturing needs. With China Die Casting Companies like Ningbo Buttler Precision Machinery Co., Ltd., you can expect exceptional quality and service in producing aluminum die casting components for various applications across industries.

Aluminum Die Casting Components

Aluminum die casting components are typically made up of various parts such as engine parts, gearboxes, and heat sinks. These components are known for their high strength-to-weight ratio, excellent corrosion resistance, and dimensional stability.

What are the components of die-cast?

The components of die-cast aluminum include engine blocks, transmission cases, and structural parts for automotive applications. Additionally, they can also be used in the production of electronic housings and power tool components due to their superior mechanical properties.

Furthermore, die-cast aluminum components offer a high degree of dimensional stability and are resistant to corrosion, making them an ideal choice for outdoor and automotive applications. The lightweight nature of aluminum also makes it a popular choice for manufacturers looking to reduce the overall weight of their products without sacrificing strength or durability. This versatility has led to die-cast aluminum components being used in a wide range of industries, from aerospace to consumer electronics.

The versatility of aluminum die casting components

Aluminum die casting components are also known for their excellent strength-to-weight ratio, which makes them a popular choice for applications that require durable yet lightweight parts. This makes them particularly well-suited for use in the automotive industry, where the demand for fuel-efficient vehicles has driven the need for lightweight materials. Additionally, their high thermal conductivity and corrosion resistance make them an ideal choice for components used in aerospace applications, where performance and reliability are of utmost importance.

Applications of aluminum die casting components in various industries

These components find applications in automotive manufacturing for producing engine blocks and transmission cases. They are also used in the production of electronic enclosures for consumer electronics and structural parts for aerospace applications.

In addition to these applications, aluminum die casting components are also widely used in the production of high-performance heat sinks for electronic devices, providing efficient thermal management and ensuring optimal performance. Furthermore, these components play a crucial role in the manufacturing of lighting fixtures, where their lightweight and durable properties make them ideal for creating innovative and aesthetically pleasing designs. Additionally, aluminum die casting components are integral in the production of power tools and machinery, where their strength and precision contribute to the overall performance and longevity of the equipment.

Aluminum Alloy Die Casting Services

Aluminum die casting components are crucial for various industries, and choosing the right die-casting service provider is essential for quality and efficiency. When selecting a partner for your aluminum die casting needs, consider their experience, expertise, and track record in delivering high-quality components. China Die Casting Companies offer a wide range of services, but it's important to find one that specializes in aluminum die casting to ensure the best results for your specific requirements.

Choosing the right die-casting service provider

When evaluating potential partners for aluminum die casting services, look for a company with a proven track record of delivering high-quality components. Consider factors such as their experience in the industry, technical capabilities, and commitment to customer satisfaction. It's also essential to assess their ability to meet your production volume and timeline requirements while maintaining consistent quality standards.

In addition to the company's track record and technical capabilities, it's important to consider their approach to quality control in aluminum die casting services. Look for a provider that has robust quality management systems in place to ensure consistent and reliable results. This could include certifications such as ISO 9001 or IATF 16949, which demonstrate a commitment to meeting international quality standards. By partnering with a die-casting service provider that prioritizes quality control, you can have confidence in the performance and durability of the components they deliver.

Quality control in aluminum die casting services

Quality control is paramount in aluminum die casting services to ensure that components meet precise specifications and performance standards. Look for a service provider that has robust quality control processes in place, including thorough inspections at every stage of production. This includes material testing, dimensional accuracy checks, and surface finish evaluations to guarantee the highest level of quality for your components.

When choosing a service provider for aluminum die casting, it's essential to consider their expertise in quality control. Ningbo Buttler Precision Machinery Co., Ltd. stands out in this regard, with a proven track record of implementing stringent quality control processes throughout their production line. From raw material testing to final surface finish evaluations, their attention to detail ensures that every component meets the highest standards of precision and performance.

The role of Ningbo Buttler Precision Machinery Co., Ltd. in aluminum die casting

Ningbo Buttler Precision Machinery Co., Ltd. plays a pivotal role in the aluminum die casting industry by offering comprehensive services encompassing molds, processing, surface treatment, assembly, and packaging. Their expertise in smart part engineering enables them to provide innovative tooling designs engineered for cost-effective manufacturing while maximizing performance and minimizing the need for secondary operations.

Ningbo Buttler Precision Machinery Co., Ltd. also stands out in the industry for its commitment to sustainability. By utilizing advanced technology and materials, they are able to minimize waste and reduce environmental impact throughout the manufacturing process. This dedication to eco-friendly practices not only benefits the planet but also positions the company as a leader in responsible production methods, appealing to environmentally conscious clients seeking sustainable solutions.

Smart Part Engineering for Better Designs

In the world of aluminum die casting components, innovative tooling designs are crucial for achieving cost-effective manufacturing. By focusing on smart part engineering, companies can maximize performance and casting quality while minimizing the need for secondary operations in die-casting. This approach not only ensures efficient production but also results in high-quality components that meet industry standards.

The importance of innovative tooling designs

Innovative tooling designs play a pivotal role in the production of aluminum die casting components. By leveraging advanced engineering techniques, companies can create molds and tools that optimize the manufacturing process, leading to improved efficiency and cost savings. With the right tooling designs, manufacturers can achieve precise and consistent results, ensuring that each component meets the required specifications.

Maximizing performance and casting quality

Smart part engineering is essential for maximizing performance and casting quality in aluminum die casting components. Through careful design and engineering, manufacturers can enhance the structural integrity of components while minimizing defects and imperfections. This results in parts that not only meet performance requirements but also exhibit superior durability and reliability.

Minimizing the need for secondary operations in die-casting

By embracing smart part engineering, companies can minimize the need for secondary operations in die-casting processes. This means reduced post-processing work such as machining or finishing, leading to significant time and cost savings. With well-engineered designs, manufacturers can produce high-quality components directly from the die-casting process, streamlining production and improving overall efficiency.

Remember to consider Ningbo Buttler Precision Machinery Co., Ltd., a leading expert in innovative tooling designs engineered for cost-effective manufacturing to maximize performance and casting quality while minimizing the need for secondary operations!

Exploring Die-Casting Applications

Die-casting is widely used in various industries for producing high-quality components and parts. One of the popular applications is the production of outdoor lamp series using aluminum die casting components. The lightweight nature of die-cast aluminum makes it an ideal material for creating durable and efficient outdoor lighting fixtures, ensuring longevity and resistance to harsh weather conditions.

Another significant application of die-casting is in the automotive industry, where numerous parts are produced using this method. From engine components to transmission parts, die-cast aluminum plays a crucial role in enhancing the performance and efficiency of vehicles. The ability to create complex shapes with precision makes it an excellent choice for manufacturing automotive parts.

Moreover, die-casting is also extensively utilized in the production of gas appliance and power tool parts. The versatility of aluminum die casting components allows for the creation of intricate designs that meet the specific requirements of gas appliances and power tools. This results in durable and reliable products that perform exceptionally well under demanding conditions.

Conclusion

Aluminum die casting components offer numerous advantages, including high strength-to-weight ratio, excellent corrosion resistance, and tight dimensional tolerances. The future of die-casting in manufacturing looks promising, with continuous advancements in technology and material development. Choosing the right die-casting partner for your business is crucial for success. Look no further than China Die Casting Companies like Ningbo Buttler Precision Machinery Co., Ltd., a reputable provider specializing in aluminum die casting services.

Advantages of aluminum die casting components

Aluminum die casting components are known for their exceptional mechanical properties, making them ideal for a wide range of applications across industries. The lightweight nature of aluminum makes it an attractive choice for producing intricate and complex parts with high precision. With superior thermal conductivity and electrical conductivity, aluminum die castings are highly sought after for various engineering applications.

The future of die-casting in manufacturing

The future of die-casting in manufacturing is bright, with ongoing research and development focused on enhancing the mechanical properties and surface finish of die-cast components. Advancements in simulation software and additive manufacturing techniques are revolutionizing the way die-cast parts are designed and produced, paving the way for more efficient and sustainable manufacturing processes.

Choosing the right die-casting partner for your business

Selecting a reliable partner for aluminum alloy die casting services is essential to ensure the quality and consistency of your components. China Die Casting Companies such as Ningbo Buttler Precision Machinery Co., Ltd. stand out as industry leaders in providing comprehensive solutions from tooling design to surface treatment and assembly. Their commitment to smart part engineering ensures that clients receive top-notch designs engineered for cost-effective manufacturing.

By choosing a trusted partner like Ningbo Buttler Precision Machinery Co., Ltd., businesses can benefit from innovative tooling designs that maximize performance while minimizing secondary operations in the production process.