Introduction

Are you looking for high-quality aluminum die-casting products? Look no further! Aluminum die casters are the go-to solution for many applications, offering exceptional strength and durability. You need a reliable partner to deliver top-notch products and excellent service when finding the right aluminum die-casting factory. Let's dive into the world of aluminum die casting and explore the benefits of this versatile process and the key factors to consider when choosing a supplier.

Understanding Aluminum Die Casting

Aluminum die casting is a metal casting process that involves injecting molten aluminum into a steel mold under high pressure. This results in precision-engineered parts with excellent dimensional accuracy and smooth surface finishes. The versatility of aluminum die casting makes it suitable for various industries, from automotive to electronics.

Benefits of Aluminum Die Casters

Aluminum die casting offers compelling benefits for manufacturers seeking high-quality, functional parts. Here's why:

- Lightweight Strength: Aluminum die castings are both strong and surprisingly light. This translates to weight savings in the final product, improving factors like fuel efficiency in vehicles or overall handling in machinery.

- Excellent Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it highly resistant to corrosion. This extends the lifespan of parts and reduces maintenance needs.

- High Thermal Conductivity: Aluminum efficiently transfers heat, making it ideal for heat dissipation applications, like engine components or electronic heat sinks.

- Precise Complex Shapes: The die-casting process allows for creating intricate parts with tight tolerances. This eliminates extensive machining and ensures consistent quality in complex designs.

Aluminum die casting offers a versatile and cost-effective solution for manufacturing a wide range of parts, particularly those requiring intricate designs, lightweight strength, and excellent heat management.

Choosing the Right Aluminum Die Casting Factory

When searching for an aluminum die-casting factory, it's crucial to consider factors such as quality assurance, expertise in smart part engineering, and a track record of delivering innovative tooling designs. Finding a supplier specializing in aluminum die-casting products can make all the difference in maximizing performance and efficiency.

The Process of Aluminum Die Casting

Aluminum die casting is a metal casting process that is characterized by forcing molten aluminum under high pressure into a mold cavity. This highly efficient and cost-effective process makes it popular for producing a wide range of aluminum die-casting products.

Understanding the Process

The aluminum die-casting process involves melting the aluminum, injecting it into the mold under high pressure, and then allowing it to cool and solidify. This results in precision parts with smooth surfaces and excellent dimensional accuracy. The versatility of this process allows for the production of complex shapes with thin walls, making it ideal for various applications.

In addition to its ability to produce complex shapes with thin walls, aluminum die casting offers several other advantages. One of the key benefits is the high strength-to-weight ratio of aluminum, making it an ideal material for applications where lightweight yet durable parts are required. Furthermore, aluminum die casting allows for excellent thermal conductivity, making it suitable for components that require efficient heat dissipation. Additionally, the corrosion resistance of aluminum makes it a preferred choice for parts exposed to harsh environmental conditions.

Advantages of Aluminum Die Casting

One key advantage of aluminum die casting is its ability to produce parts with a high strength-to-weight ratio, excellent corrosion resistance, and good thermal conductivity. Additionally, aluminum die casters can achieve tight tolerances and intricate designs while also offering good electrical conductivity.

Furthermore, aluminum die casting is a cost-effective manufacturing process, making it an attractive option for producing large parts. Its high-speed production capabilities allow for quick turnaround times, helping to meet tight project deadlines. Additionally, aluminum die casting's versatility makes it suitable for a wide range of industries, including automotive, aerospace, electronics, and more.

Applications of Aluminum Die Casters

Aluminum die casting is a versatile manufacturing process used across numerous industries due to its many advantages. Here's a breakdown of its applications:

- Automotive: Aluminum die castings are lightweight yet durable, making them ideal for engine enclosures, transmission cases, and other components.

- Aerospace: In the demanding aerospace industry, aluminum die casting is used for parts requiring a balance of strength and weight, such as aircraft components.

- Electronics: Heat sinks and electronic connectors are prime examples due to aluminum's excellent thermal conductivity and ability to be formed into intricate shapes.

- Consumer Goods: From smartphones and tablets to laptops and beyond, aluminum die casting allows for the creation of sleek, lightweight, and corrosion-resistant casings for various consumer electronics.

Aluminum die casting's ability to produce complex shapes with high precision and strength makes it a valuable tool for manufacturers across diverse industries.

Finding the Right Aluminum Die Casting Supplier

When searching for the right aluminum die casting supplier, several factors should be considered. Look for a company with a proven track record of delivering high-quality products, excellent customer service, and competitive pricing. Choosing a supplier with expertise in aluminum die-casting design and engineering is also important to ensure that your specific needs are met.

Factors to Consider

In addition to quality and expertise, proximity is essential when choosing an aluminum die-casting supplier. Finding a supplier near you can reduce shipping costs and lead times, making the process more efficient. It's also crucial to consider the supplier's production capacity and capabilities to ensure they can meet your demands.

Furthermore, it's essential to consider the supplier's track record and reputation within the industry. A supplier with a history of delivering high-quality products on time and within budget will likely be a reliable partner for your aluminum die-casting needs. Additionally, seeking out customer testimonials and reviews can provide valuable insight into the supplier's performance and customer satisfaction levels, helping you make an informed decision.

Quality Assurance in Aluminum Die Casting

Quality assurance is paramount in aluminum die casting, as it directly impacts the performance and durability of the final products. A reliable supplier should have strict quality control measures throughout the manufacturing process, from material selection to final inspection. Look for certifications such as ISO 9001 to ensure the supplier meets international quality standards.

As a reliable partner in aluminum die casting, Ningbo Buttler Precision Machinery Co., Ltd. understands the critical importance of quality assurance in delivering top-notch products to its customers. With a dedicated team of experienced professionals and state-of-the-art equipment, they ensure that every step of the manufacturing process is meticulously monitored and controlled to meet the highest quality standards. From raw material inspection to final product testing, Ningbo Buttler Precision Machinery Co., Ltd. goes above and beyond to guarantee the performance and durability of their aluminum die castings.

Ningbo Buttler Precision Machinery Co., Ltd.: A Reliable Partner

Ningbo Buttler Precision Machinery Co., Ltd. is a leading aluminum die-casting supplier known for its expertise in die-casting molds, processing, surface treatment, assembly, and packaging. Focusing on smart part engineering for better part designs, they offer innovative tooling designs engineered for cost-effective manufacturing while maximizing performance and casting quality.

Ningbo Buttler Precision Machinery Co., Ltd. is committed to staying ahead of the curve in the aluminum die-casting industry by investing in cutting-edge technology and equipment. By continuously updating their machinery and processes, they ensure their clients receive the highest quality products with improved performance and durability. This dedication to innovation sets them apart as a reliable partner for companies seeking top-notch aluminum die-casting solutions.

Maximizing Performance with Aluminum Die Casters

When it comes to maximizing performance with aluminum die casters, smart part engineering is crucial for achieving better designs. By working with a reliable aluminum die-casting factory like Ningbo Buttler Precision Machinery Co., Ltd., you can benefit from innovative tooling designs engineered for cost-effective manufacturing. These designs help to maximize performance and casting quality while minimizing the need for secondary operations, ultimately improving the overall efficiency of your production process.

Smart Part Engineering for Better Designs

Smart part engineering involves optimizing the design of aluminum die-casting products to ensure better functionality and performance. With the expertise of a reputable metal casting company like Buttler, you can use their Engineering Design Review Process to optimize new and existing parts at no cost to you. This process allows you to enhance the design of your aluminum die casters, leading to improved performance and quality.

By leveraging smart part engineering, you can ensure that your aluminum die-casting products are designed to meet the highest standards of functionality and performance. With Buttler's Engineering Design Review Process, you can optimize both new and existing parts without incurring additional costs. This collaborative approach allows you to tap into the expertise of their team to refine the design of your aluminum die casters, ultimately leading to enhanced performance and superior quality.

Design Guide for Aluminum Die Casting

To maximize the performance of aluminum die casters, it's essential to follow a comprehensive design guide tailored specifically for this type of casting process. A reliable supplier like Ningbo Buttler Precision Machinery Co., Ltd. can effectively provide valuable insights and guidance on designing aluminum die-casting products. Their aluminum expertise in die-casting design ensures that your parts are engineered for optimal performance and functionality.

In addition to guiding in designing aluminum die-casting products, Ningbo Buttler Precision Machinery Co., Ltd. specializes in innovative tooling designs that can significantly improve efficiency in the casting process. By leveraging their expertise in tooling design, you can ensure that your aluminum die-casting operations are optimized for maximum productivity and cost-effectiveness. Their innovative approach to tooling design can help streamline production processes and minimize waste, ultimately leading to improved overall performance.

Improving Efficiency with Innovative Tooling Designs

Innovative tooling designs play a critical role in improving the efficiency of aluminum die-casting processes. By partnering with an experienced supplier such as Buttler, you can benefit from cutting-edge tooling designs that enhance manufacturing efficiency and minimize production costs. These innovative designs maximize the overall performance of your aluminum die casters, resulting in high-quality products that meet your specific requirements.

Furthermore, innovative tooling designs can also reduce scrap rates and rework as the precision and efficiency of the manufacturing process are enhanced. This means you can expect a higher yield of high-quality products, ultimately increasing your profitability and customer satisfaction. By investing in state-of-the-art tooling designs, you are positioning your company as a leader in the industry, able to deliver superior products in a timely and cost-effective manner.

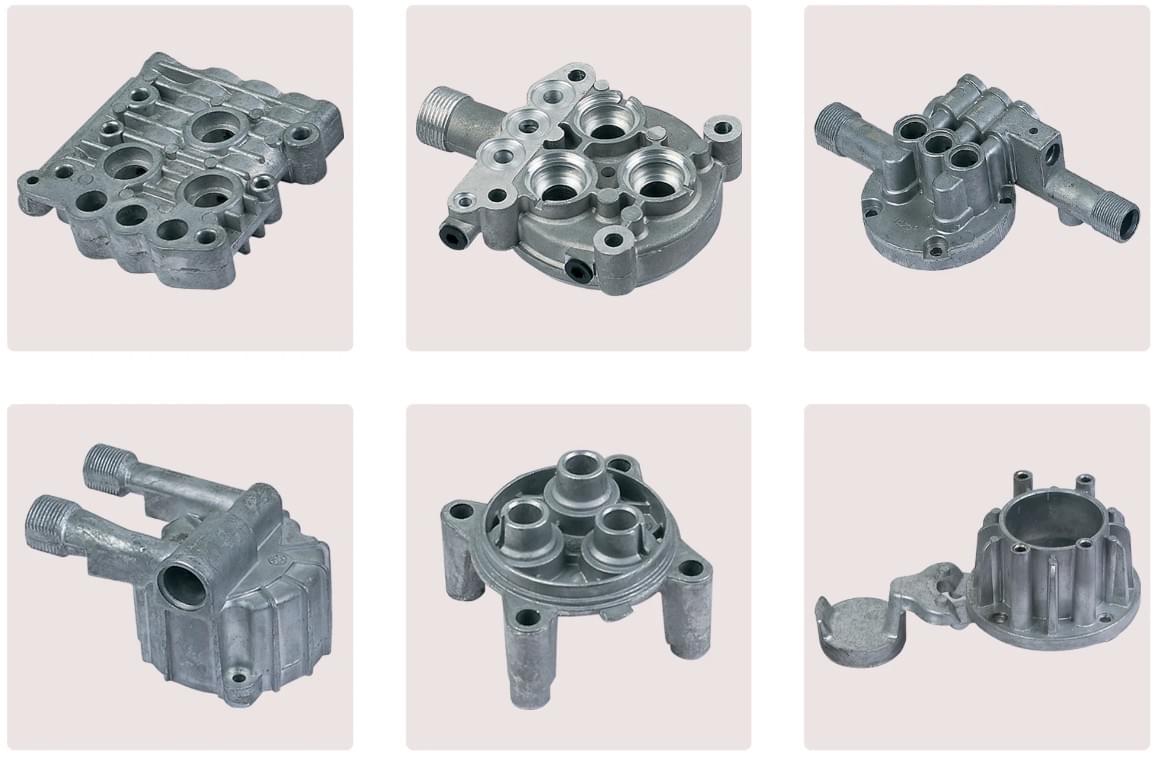

Applications of Aluminum Die Casting Products

Aluminum die-casting products are widely used in various industries due to their durability, strength, and lightweight properties. From outdoor lamp series to automotive parts, gas appliance parts, power tool parts, and appliance parts, aluminum die casters offer versatile solutions for different applications.

Outdoor Lamp Series

Aluminum die-casting products benefit outdoor lamp series due to their corrosion resistance and ability to withstand harsh weather conditions. With intricate designs and robust construction, these products provide reliable lighting solutions for outdoor spaces.

Automotive Parts

Due to its high strength-to-weight ratio and excellent thermal conductivity, aluminum die casting is a popular choice for automotive parts such as engine components, transmission cases, and structural parts. These properties contribute to improved fuel efficiency and vehicle performance.

Gas Appliance Parts

Gas appliance parts manufactured through aluminum die casting offer exceptional heat resistance and dimensional stability. From burner heads to valve bodies, these components ensure the safe and efficient operation of gas appliances in residential and commercial settings.

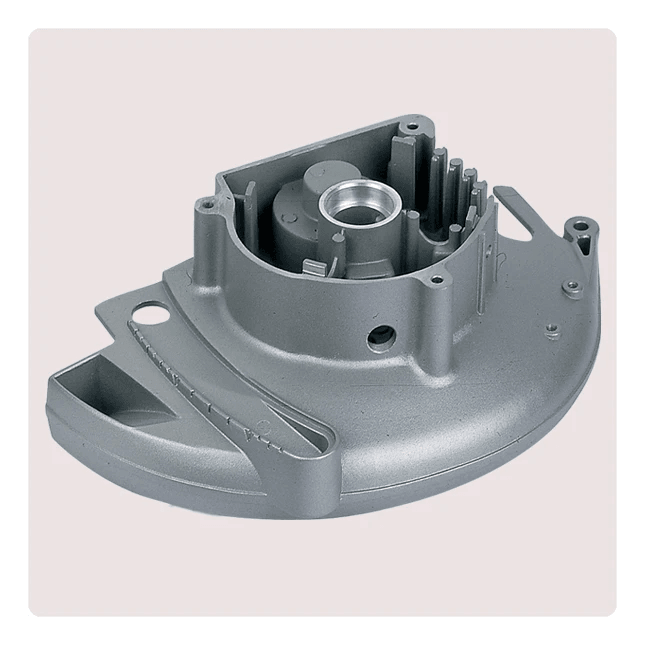

Power Tool Parts

Aluminum die-casting products play a crucial role in manufacturing power tool parts such as housings, handles, and motor components. These products' lightweight yet durable nature enhances the overall performance and user experience of power tools.

Appliance Parts

From dishwasher components to refrigerator parts, aluminum die casters provide reliable solutions for appliance manufacturers. The versatility of aluminum die casting allows for intricate designs while maintaining high durability and precision in appliance parts.

Conclusion

Quality assurance is paramount when it comes to aluminum die casting. Choosing the right supplier is crucial to ensure high-quality aluminum die-casting products. With the benefits of aluminum die casters in mind, it's important to find a reliable partner who can deliver top-notch results. Ningbo Buttler Precision Machinery Co., Ltd. is a leading metal casting company specializing in aluminum die-casting products and providing exceptional quality assurance.

Quality Assurance in Aluminum Die Casting

Quality assurance is a top priority in aluminum die casting. It's essential to work with a reputable supplier who can guarantee the highest standards in manufacturing and production processes. Ningbo Buttler Precision Machinery Co., Ltd. offers aluminum die-casting products of the highest quality and is committed to excellence.

The Benefits of Aluminum Die Casters

Aluminum die casting offers many advantages, making it a compelling choice for many manufacturing applications. Here's why:

- Lightweight and Durable: Aluminum die castings are solid for their weight. This translates to parts that perform well without adding unnecessary bulk.

- Excellent Heat Dissipation: Aluminum efficiently transfers heat away from critical components, keeping your operation running smoothly.

- Cost-Effective: While the initial tooling cost can be higher, aluminum die casting's high production speed and minimal post-processing requirements lead to significant cost savings over time.

- High-Performance Parts: Aluminum die castings deliver exceptional dimensional accuracy and a smooth surface finish, resulting in parts that meet even the most demanding specifications.

Aluminum die casting provides a winning combination of performance, efficiency, and cost-effectiveness for various manufacturing needs.

Choosing the Right Supplier for Your Needs

When searching for an aluminum die casting near me, it's crucial to choose a supplier that meets your production requirements and offers expertise in smart part engineering and innovative tooling designs. Ningbo Buttler Precision Machinery Co., Ltd. stands out as a reliable partner with comprehensive services covering everything from design to assembly, ensuring you receive top-quality aluminum die-casting products tailored to your specific needs.