Introduction

When it comes to cast aluminum alloys, choosing the right one is crucial for achieving high-quality results. Understanding the basics of aluminum alloys and exploring the best options for casting can make a significant difference in the performance and durability of your products. Whether you're looking for die cast aluminum alloy A380 or a high-quality aluminum alloy for high pressure cast parts, making an informed choice is essential for success.

Understanding the Basics of Aluminum Alloys

Aluminum alloys are widely used in casting due to their lightweight, corrosion resistance, and excellent machinability. They are created by mixing pure aluminum with other elements such as copper, zinc, and magnesium to enhance specific properties. Understanding the composition and characteristics of different aluminum alloys is essential for selecting the most suitable option for your casting needs.

The Importance of Choosing the Right Alloy for Casting

The choice of aluminum alloy can significantly impact the performance and quality of cast parts. Factors such as strength, durability, corrosion resistance, and machinability need to be carefully considered when selecting an alloy for casting. Whether it's die cast aluminum alloy A380 or another variety, making the right choice is vital for achieving optimal results in your casting processes.

Exploring the Best Aluminum Alloys for Casting

Exploring different options such as A360, 6061, and 383 aluminum alloys can help identify which ones are best suited for specific casting applications. Each alloy offers unique properties that make them suitable for various industries and products. By delving into the characteristics of these top aluminum alloys, you can make an informed decision on which one is best suited to meet your casting requirements.

The Different Types of Aluminum Alloys

When it comes to cast aluminum alloys, there are several varieties available in the market, each with its own unique set of properties and characteristics. From A380 to 6061, understanding the different types of aluminum alloys is crucial in determining which one is best for your casting needs.

Understanding the Varieties Available in the Market

The market offers a wide range of cast aluminum alloys, including A380, A360, 6061, and 383, each with distinct features that make them suitable for specific casting applications. It's essential to familiarize yourself with these varieties to make an informed decision when choosing the right alloy for your casting project.

Exploring the Properties of Each Aluminum Alloy

Exploring the properties of each aluminum alloy is key to understanding their strengths and weaknesses. For example, A380 aluminum alloy is known for its high pressure die casting capabilities, while A360 stands out for its superior corrosion resistance. Meanwhile, 6061 aluminum alloy is a popular choice for general-purpose casting due to its excellent machinability and weldability.

Identifying the Key Differences in Aluminum Alloys

Identifying the key differences in aluminum alloys involves comparing factors such as strength, durability, corrosion resistance, machinability, and fluidity. This comparison allows you to pinpoint which alloy aligns best with your specific casting requirements and industry standards.

By understanding the varieties available in the market and exploring the unique properties of each aluminum alloy, you can effectively identify the key differences between them and make an informed decision when selecting an alloy for your casting needs.

Key Factors to Consider When Choosing an Aluminum Alloy for Casting

Strength and Durability

When determining which aluminum alloy is best for casting, strength and durability are critical factors to consider. A380 aluminum alloy die cast parts are known for their high strength and excellent durability, making them ideal for applications requiring robust components. The high-quality A380 aluminum alloy die cast company, Ningbo Buttler Precision Machinery Co., Ltd., specializes in producing aluminum alloy high-pressure cast parts that offer exceptional strength and longevity.

Corrosion Resistance

Another important consideration when selecting a cast aluminum alloy is its corrosion resistance. A360 aluminum alloy is renowned for its superior corrosion resistance, making it an excellent choice for components exposed to harsh environmental conditions. Wholesale A380 aluminum alloy die cast suppliers can provide a wide range of corrosion-resistant options to meet the specific needs of various industries.

Machinability and Weldability

Machinability and weldability are essential characteristics to evaluate when choosing an aluminum alloy for casting. 6061 aluminum alloy is a popular choice due to its excellent machinability and weldability, allowing for easy fabrication and assembly of complex parts. Smart Part Engineering specializes in providing innovative tooling designs engineered for cost-effective manufacturing, ensuring seamless machinability and weldability of cast components.

By carefully considering the key factors of strength and durability, corrosion resistance, machinability, and weldability when choosing an aluminum alloy for casting, you can ensure the production of high-quality components that meet the specific requirements of your application.

The Best Aluminum Alloys for Casting

When it comes to choosing the best aluminum alloy for casting, A380 is often the top choice for high pressure die casting applications. Its excellent fluidity and pressure tightness make it ideal for producing complex and intricate parts with high precision. Whether you need automotive components or industrial machinery parts, A380 aluminum alloy die castings offer exceptional performance and reliability.

A380 Aluminum Alloy: Ideal for High Pressure Die Casting

A380 aluminum alloy is widely recognized for its ability to deliver high-quality castings with superior strength and durability. Its low cost and excellent thermal conductivity make it a popular choice for various industries, from automotive to consumer electronics. When you need high-quality A380 aluminum alloy die cast parts, partnering with a reputable company like Ningbo Buttler Precision Machinery Co., Ltd. ensures that you get the best-in-class products tailored to your specific needs.

A360 Aluminum Alloy: Known for its Superior Corrosion Resistance

For applications requiring exceptional corrosion resistance, A360 aluminum alloy is the go-to choice for die casting. Its superior fluidity and pressure tightness make it an excellent option for producing light yet durable components that can withstand harsh environmental conditions. When you need top-notch die cast aluminum alloy A360 parts, working with a high-quality A380 aluminum alloy die cast company guarantees that you receive reliable products that meet your exact specifications.

6061 Aluminum Alloy: A Popular Choice for General-Purpose Casting

6061 aluminum alloy is a versatile option that offers good machinability and weldability, making it suitable for general-purpose casting applications across various industries. Its balanced properties of strength, corrosion resistance, and ease of processing make it an ideal choice for producing a wide range of components, from structural parts to consumer goods.

383 Aluminum Alloy: Offering Excellent Fluidity and Pressure Tightness

When it comes to achieving intricate designs and complex shapes in die-cast parts, 383 aluminum alloy stands out with its exceptional fluidity and pressure tightness properties. This makes it an excellent choice for creating lightweight yet strong components used in automotive, aerospace, and other demanding industries.

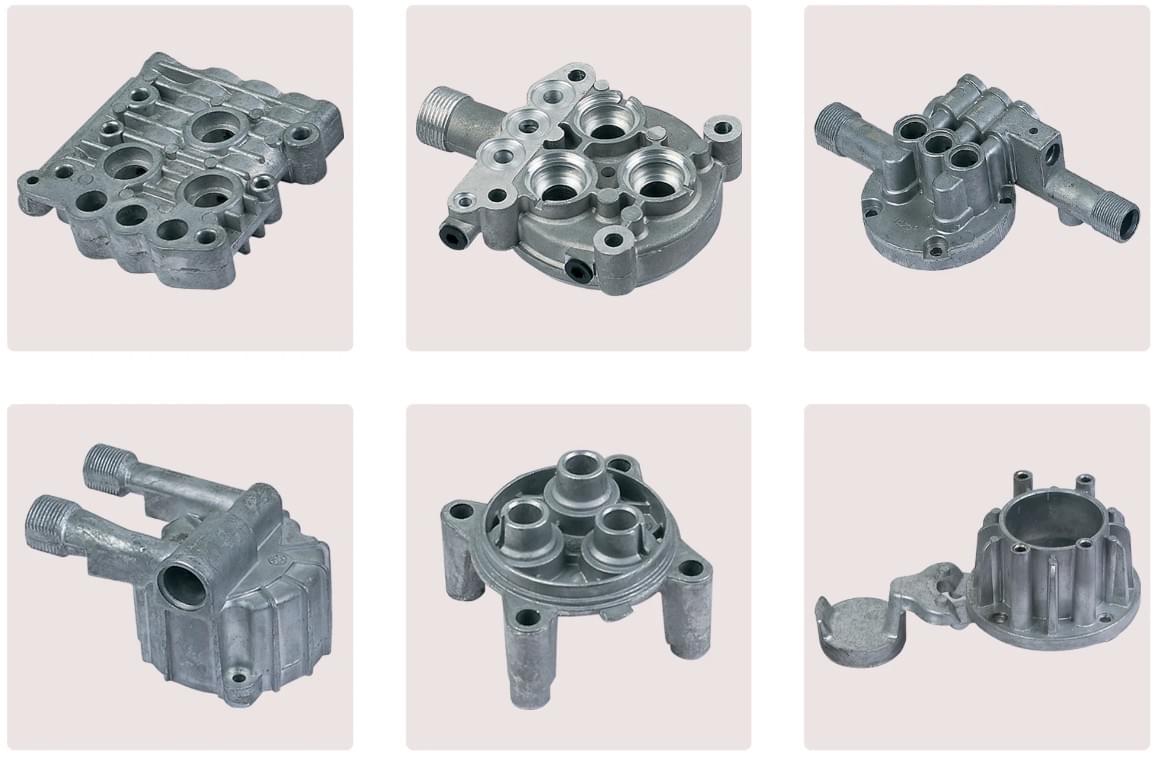

Applications and Industries for Cast Aluminum Alloys

Automotive Parts: Utilizing Aluminum Alloys for Lightweight and Efficient Design

In the automotive industry, the demand for lightweight yet durable components has led to the widespread use of cast aluminum alloys. The high quality a380 aluminum alloy die cast company can provide parts that offer excellent strength-to-weight ratio, making them ideal for applications where fuel efficiency and performance are crucial. Whether it's engine components, transmission parts, or structural elements, die cast aluminum alloy a380 is often the go-to choice for manufacturers looking to achieve superior performance.

Gas Appliance Parts: Taking Advantage of Corrosion-Resistant Aluminum Alloys

Gas appliances require components that can withstand harsh environments and corrosive substances. This is where aluminum alloy die cast light comes into play, offering exceptional corrosion resistance to ensure longevity and safety in gas appliance parts. Wholesale a380 aluminum alloy die cast suppliers can provide high-quality components that meet strict industry standards while maintaining cost-effectiveness.

In addition to corrosion resistance, aluminum alloy die cast components offer excellent thermal conductivity, making them ideal for gas appliance parts that require efficient heat transfer. This ensures that the components can withstand high temperatures and rapid temperature changes without compromising their structural integrity. As a result, gas appliances equipped with aluminum alloy die cast parts can deliver consistent performance and energy efficiency, enhancing the overall user experience.

Outdoor Lamp Series: Harnessing the Durability of Aluminum Alloys for Exterior Lighting

When it comes to outdoor lighting fixtures, durability and weather resistance are paramount considerations. Aluminum alloy high pressure cast part such as 6061 or 383 are well-suited for outdoor lamp series due to their ability to withstand exposure to elements such as rain, wind, and UV radiation without compromising on aesthetics or functionality.

Choosing the Right Partner for Aluminum Alloy Die Casting

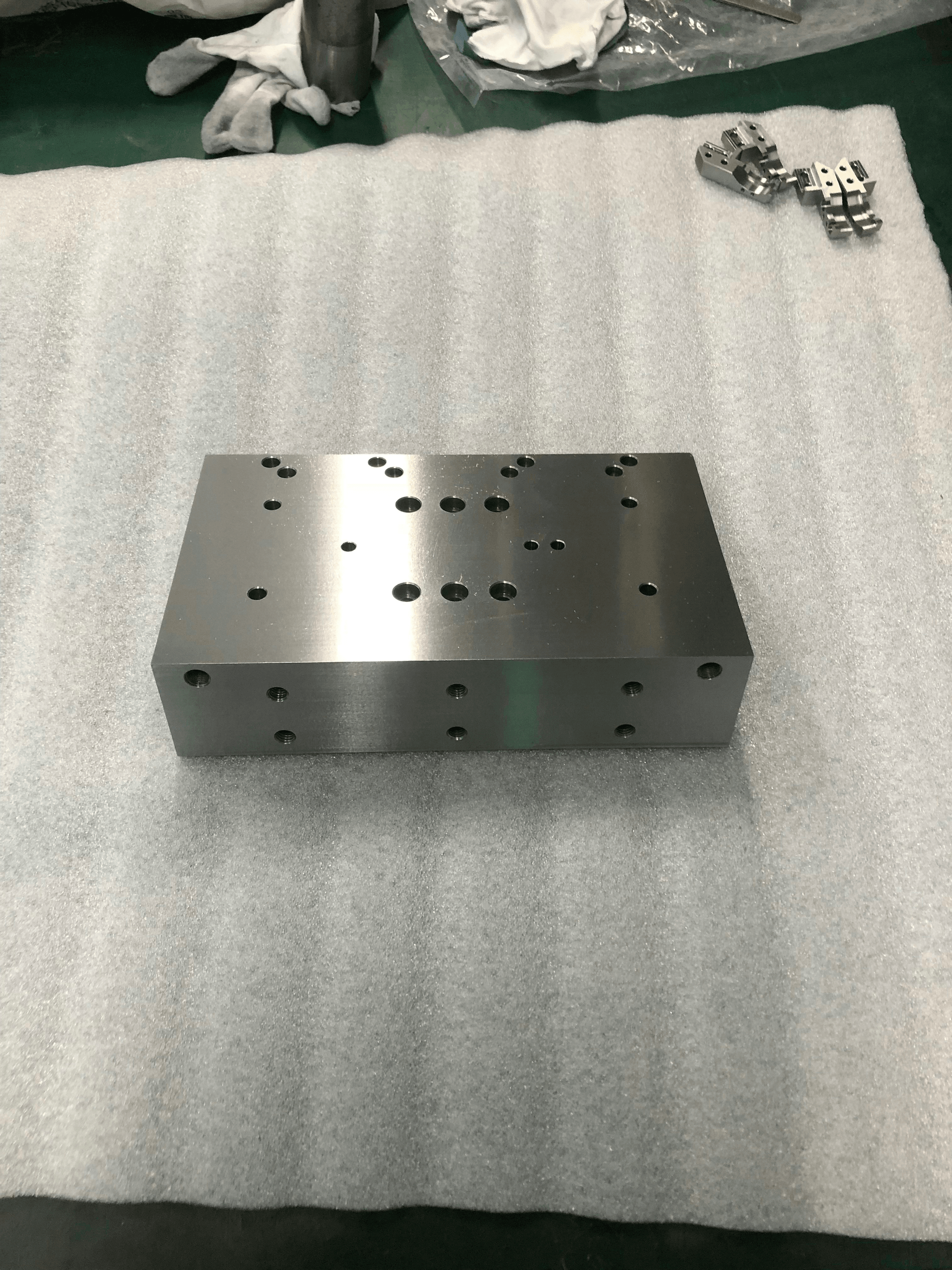

When it comes to finding the best partner for aluminum alloy die casting, Ningbo Buttler Precision Machinery Co., Ltd. stands out as a leader in the industry. Specializing in die-casting molds and aluminum castings, they offer a comprehensive range of services including processing, surface treatment, assembly, and packaging. With their expertise and experience, they can provide high-quality A380 aluminum alloy die cast parts for various applications.

Ningbo Buttler Precision Machinery Co., Ltd.: A Leader in Die-Casting Molds and Aluminum Castings

Ningbo Buttler Precision Machinery Co., Ltd. is known for their exceptional capabilities in producing high-quality A380 aluminum alloy die cast parts. Their expertise in die-casting molds and aluminum castings ensures that they can meet the specific requirements of different industries, offering reliable and durable solutions for various applications such as automotive parts, gas appliance components, and outdoor lighting fixtures.

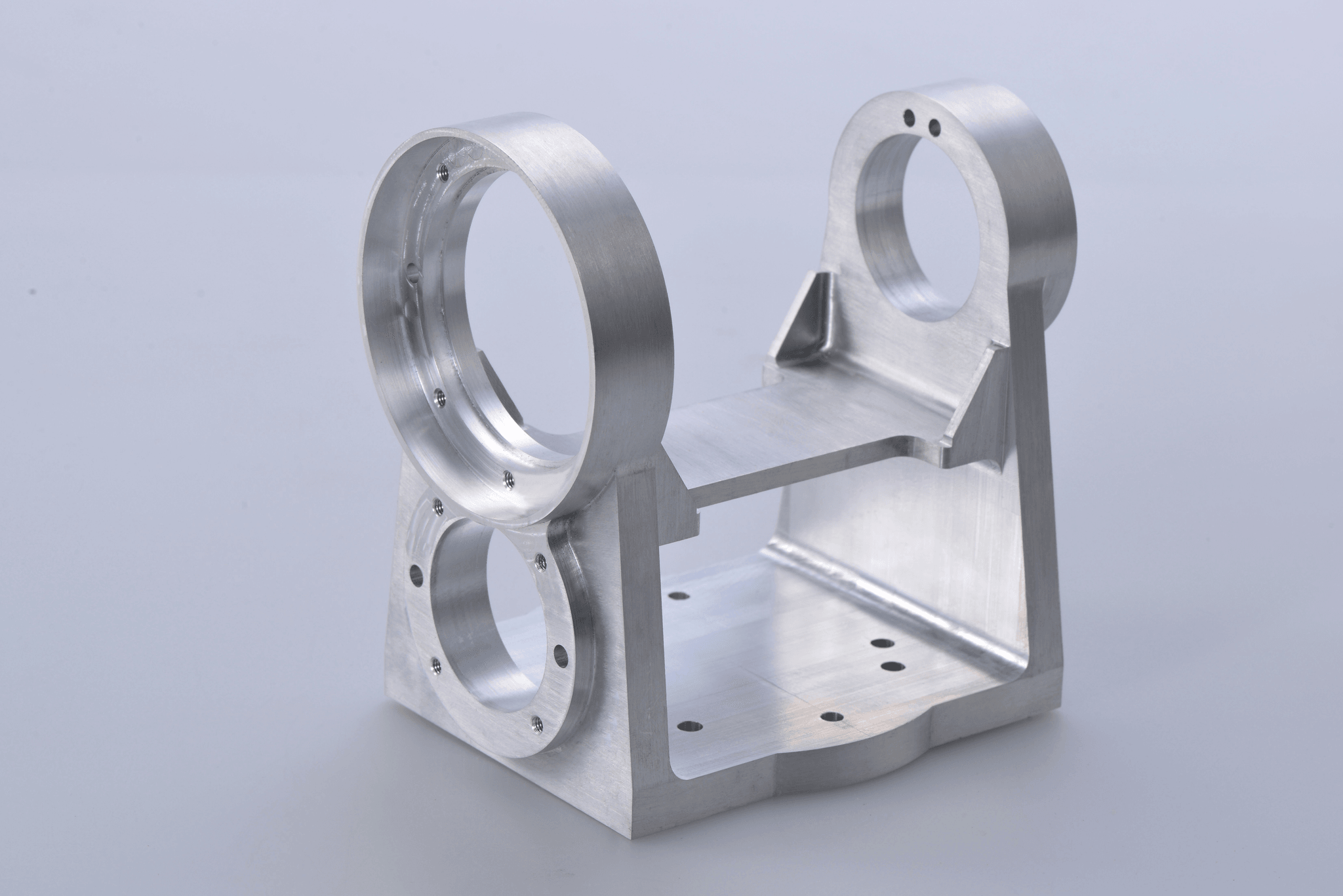

Smart Part Engineering: Providing Innovative Tooling Designs for High-Quality Casting

Smart Part Engineering is dedicated to providing innovative tooling designs engineered for cost-effective manufacturing to maximize performance and casting quality while minimizing the need for secondary operations. With their Engineering Design Review Process, they can optimize new and existing parts at no cost to you, ensuring that your cast aluminum alloy parts are of the highest quality.

Smart Part Engineering's commitment to excellence extends beyond just the initial tooling design. They also provide ongoing support and assistance to ensure that the manufacturing process runs smoothly and efficiently. By partnering with Smart Part Engineering, you can rest assured that your casting needs will be met with precision and expertise, resulting in high-quality products that exceed industry standards.

Wholesale A380 Aluminum Alloy Die Cast: Finding the Right Supplier for Your Casting Needs

For those looking to source high-quality A380 aluminum alloy die cast parts, Wholesale A380 Aluminum Alloy Die Cast offers a reliable solution. As a reputable supplier specializing in aluminum alloy high-pressure cast parts, they can provide the necessary components for your specific casting needs with a focus on quality and durability.

Furthermore, Wholesale A380 Aluminum Alloy Die Cast understands the importance of timely delivery and cost-effectiveness. They work closely with their clients to ensure that deadlines are met without compromising on the quality of the products. With a focus on efficiency and customer satisfaction, they strive to be the go-to supplier for all your A380 aluminum alloy die cast needs.

Conclusion

Making the Right Choice: Selecting the Best Aluminum Alloy for Your Casting Needs

When it comes to choosing the best aluminum alloy for casting, it's important to consider factors such as strength, corrosion resistance, and machinability. By carefully evaluating your specific casting needs and understanding the properties of different aluminum alloys, you can make an informed decision that will result in high-quality castings.

Leveraging the Strengths of Different Aluminum Alloys

Each aluminum alloy has its own unique strengths and properties, making it suitable for specific casting applications. Whether you need a high-pressure cast part or a corrosion-resistant die-cast aluminum alloy A380, leveraging the strengths of different aluminum alloys can help you achieve optimal results in your casting projects.

Ensuring High-Quality Castings with the Right Aluminum Alloys

To ensure high-quality castings, it's crucial to partner with a reputable and experienced company that specializes in aluminum alloy die casting. Companies like Ningbo Buttler Precision Machinery Co., Ltd. and Smart Part Engineering offer expertise in die-casting molds and innovative tooling designs, allowing you to achieve superior casting quality with the right aluminum alloys.

Partnering with a reputable company specializing in aluminum alloy die casting is essential for ensuring high-quality castings. Ningbo Buttler Precision Machinery Co., Ltd. and Smart Part Engineering are known for their expertise in die-casting molds and innovative tooling designs, which are crucial for achieving superior casting quality with the right aluminum alloys. By collaborating with these experienced companies, you can have confidence in the reliability and precision of your castings, ultimately leading to better end products and customer satisfaction.