Introduction

When it comes to finding the best aluminum die-casting companies near me, it's crucial to understand why trustworthy die-casting manufacturers matter. Choosing reliable die-casting partners offers numerous benefits, including quality assurance and timely delivery of die-cast parts.

Finding the Best Aluminum Die Casting Companies Near Me

In today's competitive market, locating reputable aluminum die-casting companies near me can be daunting. However, with the proper research and due diligence, reliable manufacturers that offer top-notch die-casting parts and exceptional customer service can be identified.

Why Trustworthy Die Casting Manufacturers Matter

Trustworthy die-casting manufacturers play a pivotal role in ensuring the production of high-quality aluminum die-casting parts. Their expertise and commitment to excellence can significantly impact the overall performance and durability of the finished products.

The Benefits of Choosing Reliable Die Casting Partners

Opting for reliable die-casting partners guarantees superior quality and peace of mind, knowing that your manufacturing needs are in capable hands. A trusted aluminum die-casting manufacturer can deliver exceptional results from precise engineering to cost-effective solutions.

Understanding the Die Casting Process

Exploring the Steps of Aluminum Die Casting

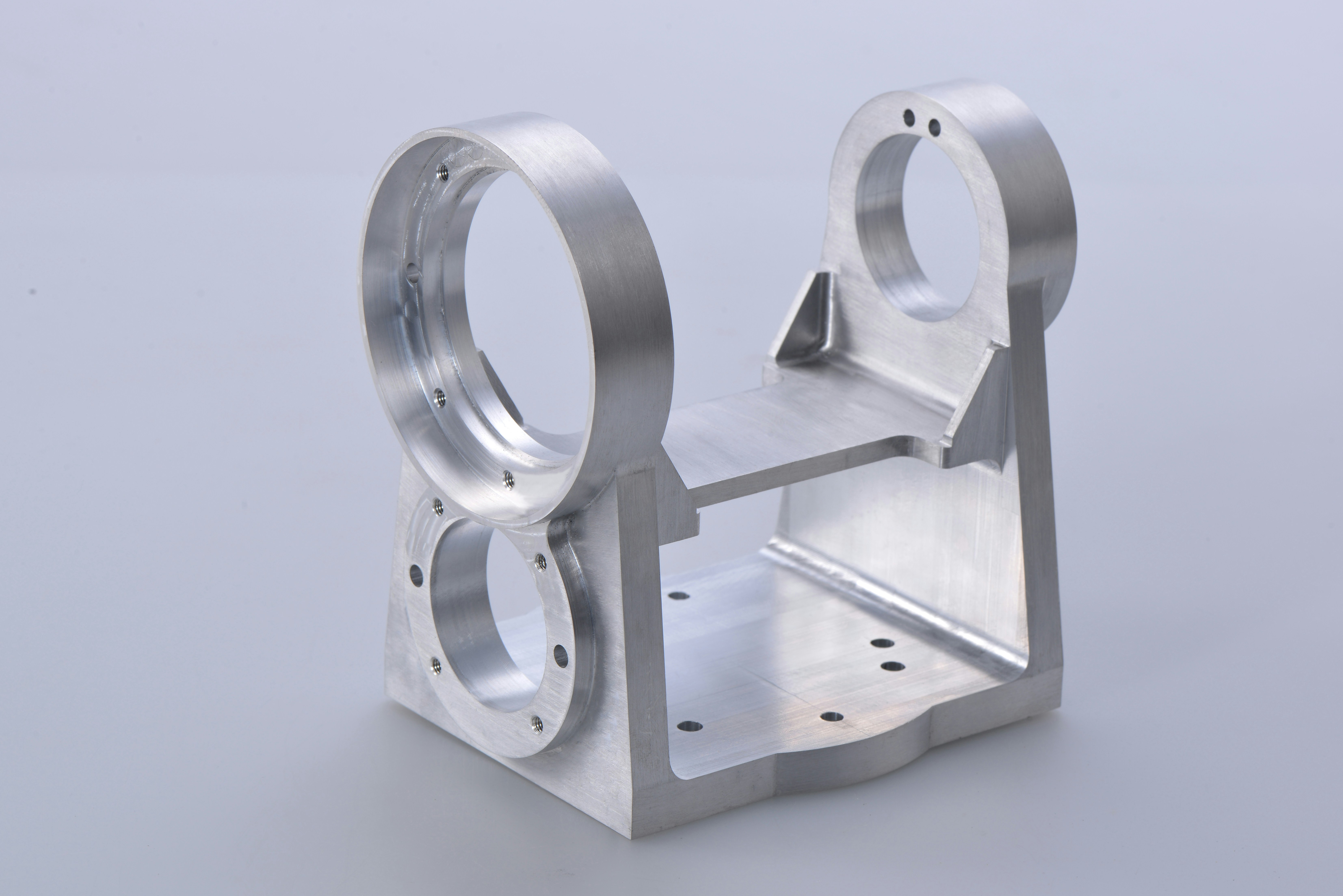

Aluminum die casting is a process that involves melting aluminum and injecting it into a steel mold under high pressure. The aluminum solidifies quickly, taking the shape of the mold cavity. This method allows for complex shapes with high dimensional accuracy, making it ideal for producing parts with intricate designs.

Aluminum die casting is a highly efficient process that produces high-quality parts with excellent dimensional accuracy. The quick solidification of the aluminum allows for intricate designs and complex shapes to be produced easily. This method is ideal for creating parts requiring precision and attention to detail, making it a popular choice in the automotive, aerospace, and electronics industries.

The Importance of Quality Die Casting Parts

Quality die-casting parts are crucial for the performance and durability of various products. Whether it's automotive components, electronic enclosures, or hardware fittings, the integrity of die-cast parts directly impacts the overall functionality and reliability of the end product. Choosing a reputable die-casting manufacturer ensures you receive parts that meet strict quality standards.

Choosing the Right Die Casting Manufacturer

Choosing a suitable aluminum die-casting manufacturer is crucial for your project's success. Here are key factors to consider:

- Expertise: Look for a company with extensive experience in aluminum die casting. Their knowledge ensures they understand the process's intricacies and can produce high-quality parts.

- Facilities: Evaluate the manufacturer's facilities and equipment. Modern machinery and well-maintained processes contribute to consistent quality and efficient production.

- Track Record: Research the manufacturer's reputation for quality control and on-time delivery. Look for positive customer reviews and a history of successful projects.

Ningbo Buttler Precision Machinery Co., Ltd. stands out as a leader in the field, offering expertise, advanced facilities, and a commitment to quality. With their intelligent part engineering approach, they can create cost-effective tooling designs that optimize performance and minimize the need for rework.

Evaluating Trusted Aluminum Die Casting Companies

When looking for aluminum die-casting companies near me, there are key factors to consider in selecting a die casting partner. It's crucial to assess their capabilities in producing high-quality die-cast parts, their experience in the industry, and their track record of delivering reliable results. Choosing a suitable aluminum die-casting manufacturer can significantly affect your parts' quality and performance.

Comparing different aluminum die-casting companies allows you to weigh their strengths and weaknesses. Look for a die-casting company that offers a comprehensive range of services, from tooling design to surface treatment and assembly. Assess their technological capabilities and production capacity to ensure they can meet your specific requirements for aluminum die-casting parts.

The importance of experience in die-casting manufacturing cannot be overstated. An experienced aluminum die-casting manufacturer will have honed its processes over time, leading to more efficient production and higher-quality parts. Their expertise in handling various alloys and complex part geometries can substantially impact your project's success.

Ningbo Buttler Precision Machinery Co., Ltd. specializes in die-casting molds and aluminum castings, focusing on intelligent part engineering for better design. Their expertise lies in providing innovative tooling designs engineered for cost-effective manufacturing, maximizing performance while minimizing secondary operations. With their Engineering Design Review Process, they offer optimization for new and existing parts at no cost to you.

By carefully evaluating trusted aluminum die-casting companies based on these key factors, you can make an informed decision when selecting a reliable partner for your die-casting needs.

The Role of Ningbo Buttler Precision Machinery Co., Ltd.

Ningbo Buttler Precision Machinery Co., Ltd. is a leading expert in die-casting molds and aluminum castings, offering top-notch processing, surface treatment, assembly, and packaging services. Focusing on intelligent part engineering, they ensure better part designs for maximum performance and casting quality while minimizing the need for secondary operations.

Specialization in Die-Casting Molds and Aluminum Castings

Ningbo Buttler Precision Machinery Co., Ltd. specializes in producing high-quality die-casting molds and aluminum castings with precision and expertise. Their advanced manufacturing processes ensure superior quality parts that meet the highest industry standards.

Partnering with Ningbo Buttler Precision Machinery Co., Ltd. means gaining access to their highly skilled engineers and technicians, who are dedicated to delivering top-notch die-casting molds and aluminum castings. Focusing on precision and expertise, the company ensures that every product meets the highest industry standards, giving you peace of mind about the quality of your components. Their advanced manufacturing processes also guarantee superior quality parts, providing a competitive edge in your market.

Advantages of Partnering with Ningbo Buttler Precision Machinery Co., Ltd.

Partnering with Ningbo Buttler Precision Machinery Co., Ltd. guarantees access to state-of-the-art technology and industry-leading expertise in aluminum die casting. Their commitment to excellence and customer satisfaction sets them apart as a reliable partner for all die-casting needs. Moreover, their innovative part engineering capabilities enable better part designs, optimizing performance and efficiency for our client's products. This innovative approach ensures that our clients receive top-notch solutions tailored to their specific requirements, giving them a competitive edge in the market.

Smart Part Engineering for Better Part Designs

Ningbo Buttler Precision Machinery Co., Ltd.'s intelligent part engineering approach ensures innovative tooling designs engineered for cost-effective manufacturing, maximizing performance and casting quality while minimizing the need for secondary operations.

Maximizing Quality with Engineering Design Review

The engineering design review process is crucial in maximizing the quality of die-casting parts. By thoroughly analyzing the parts' design and functionality, potential issues can be identified and resolved before production begins. This ensures that the final parts meet the highest quality and performance standards.

How Engineering Design Review Process Improves Parts Quality

The engineering design review process comprehensively evaluates the part's design, material selection, and manufacturing feasibility. This allows for any potential flaws or inefficiencies to be addressed early, improving part quality and performance. By leveraging this process, aluminum die-casting manufacturers can ensure that every part meets or exceeds industry standards.

The engineering design review process also allows for the identification of potential cost-saving opportunities. By thoroughly evaluating the part's design and manufacturing feasibility, manufacturers can find ways to streamline production processes and reduce material waste. This improves the overall quality of the parts and contributes to a more efficient and cost-effective manufacturing operation.

Benefits of Optimizing New and Existing Parts

During the die-casting process, a thorough engineering design review can significantly improve the outcome of your parts. Here's how:

- Enhanced Functionality and Durability: The review process can identify areas for improvement in design features, leading to parts that perform better and last longer.

- Reduced Production Costs: The review can help streamline production, minimize waste, and ultimately lower costs by optimizing designs for manufacturability.

- Innovation and Efficiency: The review team may uncover opportunities to simplify designs or incorporate new features, fostering innovation and production efficiencies.

- Overall Performance: These improvements, made through engineering design review, lead to better-performing die-cast parts that meet your functional and economic goals.

Investing in an engineering design review for your die-cast parts can enhance functionality, improve durability, reduce costs, and ultimately lead to a superior product.

Cost-Effective Manufacturing and Minimizing Secondary Operations

Optimizing parts through engineering design review can help manufacturers achieve cost-effective manufacturing processes. This includes minimizing secondary operations such as machining or finishing, which can add time and cost to production. With an optimized design, aluminum die-casting companies can streamline their manufacturing processes while maintaining high-quality standards.

Partnering with a Reliable Die Casting Manufacturer

When looking for die-casting companies near me, it’s crucial to partner with a reliable die-casting manufacturer to ensure consistent quality and timely delivery. By choosing a trusted aluminum die-casting company, you can benefit from long-term advantages such as cost-effective manufacturing, minimized secondary operations, and optimized new and existing die-cast parts.

Ensuring Consistent Quality and Timely Delivery

By partnering with an experienced aluminum die-casting manufacturer like Ningbo Buttler Precision Machinery Co., Ltd., you can rest assured that your die-casting parts will meet the highest quality standards and be delivered on time. Their specialization in die-casting molds and aluminum castings ensures that every part is produced precisely and efficiently. Additionally, a trusted die-casting company can offer design assistance, material selection guidance, and cost-effective solutions to help optimize the production process and improve the overall quality of your parts. This collaborative approach can result in long-term benefits for your business, including reduced lead times, lower production costs, and a competitive edge in the market.

Long-Term Benefits of Building a Partnership with a Trusted Die Casting Company

Partnering with a reliable die-casting company offers significant advantages throughout your manufacturing process. Here's how:

- Cost Savings and Improved Designs: Trusted partners like Buttler utilize intelligent part engineering to optimize performance while minimizing secondary operations. This translates to high-quality die-cast parts produced at competitive prices.

- Enhanced Manufacturing Processes: Their expertise can help identify areas for improvement in your manufacturing process, leading to greater efficiency and streamlined production.

- Reliable Support and Exceptional Service: A trusted partner goes beyond just production. Look for a company like Buttler that prioritizes understanding your needs and offers personalized solutions. Responsive communication and a commitment to exceeding expectations ensure a smooth and successful experience.

By partnering with the right die-casting company, you gain access to their expertise, which can lead to cost savings, improved part designs, enhanced processes, and a successful manufacturing operation.

The Value of Reliable Support and Customer Service

In addition to consistent quality and timely delivery, partnering with a reliable die-casting manufacturer offers the value of dependable support and exceptional customer service. Ningbo Buttler Precision Machinery Co., Ltd. goes above and beyond to provide personalized assistance throughout the manufacturing process, ensuring your needs are met at every step.

By choosing the suitable aluminum die-casting manufacturer for your needs, you can maximize the quality of your parts while enjoying the benefits of a long-term partnership built on trust, reliability, and exceptional support.

Ensure Quality and Reliability in Die Cast Parts

Making the Right Choice for Aluminum Die Casting

When looking for the best aluminum die-casting companies near me, it's crucial to consider the expertise and reliability of the die-casting manufacturer. Choosing a reputable company ensures you receive high-quality die-cast parts that meet your specifications and standards.

Reliable aluminum die-casting companies prioritize quality and consistency in their die-cast parts. By partnering with a trusted manufacturer, you can ensure that your parts are produced with precision and attention to detail, meeting industry standards and exceeding expectations.

Finding Your Trusted Partner in Die Casting Manufacturing

In search of a reliable die-casting partner, Ningbo Buttler Precision Machinery Co., Ltd. stands out as a specialized manufacturer of aluminum die castings. Their expertise in clever part engineering and cost-effective manufacturing makes them a trusted choice for high-quality die-cast parts.

Ningbo Buttler Precision Machinery Co., Ltd.'s specialization in die-casting molds and aluminum castings makes it an ideal partner for businesses seeking quality die-cast parts. Its commitment to smart part engineering ensures better part designs, maximizing performance while minimizing secondary operations.

With this conclusion, it's clear that finding a reliable partner in aluminum die-casting is essential for ensuring quality and reliability in your die-cast parts. By choosing a reputable company like Ningbo Buttler Precision Machinery Co., Ltd., you can be confident in consistently delivering high-quality products and exceptional customer service.