Introduction

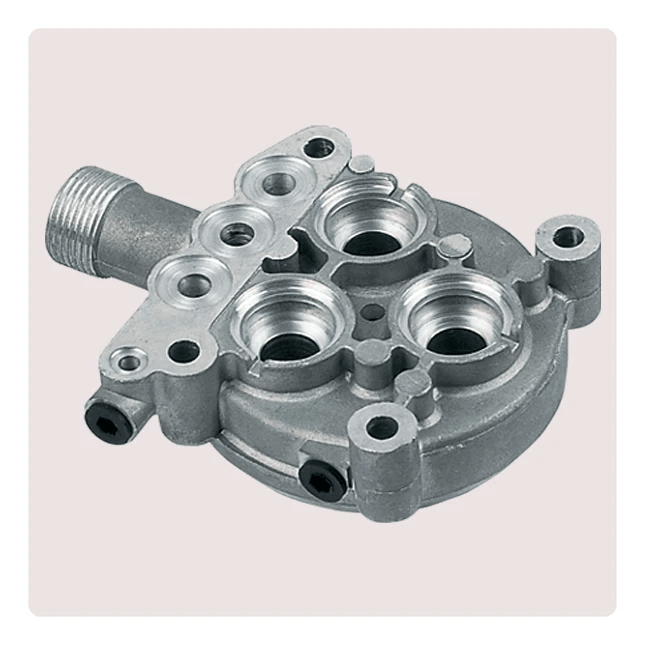

Die-cast aluminum parts are known for their versatility and numerous manufacturing advantages. From their lightweight material to their high strength-to-weight ratio, die-cast aluminum parts play a crucial role in various industries. They are essential for creating durable, cost-effective, and precision-engineered components that meet the demands of modern manufacturing processes.

The Versatility of Die Cast Aluminum Parts

Due to their lightweight nature and exceptional strength, die-cast aluminum parts offer many applications. Whether it's automotive parts, outdoor lamp series, or appliance components, die-cast aluminum is the go-to material for manufacturers seeking versatility and performance.

Advantages of Die Cast Aluminum Parts in Manufacturing

Die-cast aluminum parts offer a compelling combination of properties that make them highly desirable for various applications. These parts excel due to the following:

- Superior strength-to-weight ratio: Providing durability without compromising weight.

- Precision engineering capabilities: Enabling complex designs and tight tolerances.

- Excellent corrosion resistance: Ensuring longevity in harsh environments.

- Exceptional thermal conductivity: Facilitating efficient heat management.

These attributes make die-cast aluminum parts a versatile and reliable choice for manufacturers across numerous industries.

Why

Die-Cast Aluminum Parts Are Essential

Die-cast aluminum parts are essential in modern manufacturing because they provide cost-effective production, versatile design options, and reliable performance across various applications. Their essential role in creating high-quality components cannot be overstated.

Lightweight Material

Die-cast aluminum is a lightweight material perfect for automotive parts. It offers high strength and durability without adding unnecessary weight to the vehicle. Its lightweight nature allows for improved fuel efficiency and overall performance, making it an ideal choice for automotive manufacturers looking to enhance their products.

Perfect for Automotive Parts

When it comes to automotive parts, die-cast aluminum offers the perfect combination of strength and lightweight construction. This makes it an ideal choice for components such as engine blocks, transmission cases, and structural parts that require high durability without adding excessive weight to the vehicle. Die-cast aluminum in automotive manufacturing also improves fuel efficiency and reduces emissions, making it a smart choice for environmentally conscious consumers.

Ideal for Outdoor Lamp Series

Die-cast aluminum is ideal for outdoor lighting applications due to its lightweight yet durable properties. Outdoor lamp series benefits from die-cast aluminum's corrosion resistance, ensuring longevity in harsh outdoor environments while maintaining an aesthetically pleasing appearance. The lightweight nature of die-cast aluminum also makes installing and maintaining outdoor lighting fixtures easier and more efficient.

Convenient for Appliance Parts

Die-cast aluminum is a convenient choice for appliance parts due to its lightweight yet sturdy construction. From kitchen appliances to HVAC systems, die-cast aluminum components offer superior performance while being easy to handle during assembly and installation. Its excellent thermal conductivity makes it well-suited for appliances requiring efficient heat dissipation.

High Strength-to-Weight Ratio

Die-cast aluminum parts offer superior performance in gas appliance parts. They provide the strength needed for reliable operation while remaining lightweight for easy handling and installation. Die-cast aluminum's high strength-to-weight ratio makes it the perfect choice for components in gas appliances, ensuring durability and safety.

Durable power tool parts benefit from die-cast aluminum's high strength-to-weight ratio, allowing for robust construction without adding unnecessary weight to the tools. This ensures that power tools remain comfortable while withstanding the rigors of heavy-duty applications, making them a top choice for professionals and DIY enthusiasts alike.

Sturdy die-cast heat sink projects use die-cast aluminum's high strength-to-weight ratio to provide efficient heat dissipation in various applications. With the ability to handle thermal loads while maintaining structural integrity, aluminum die-cast heat sinks are a reliable solution for managing heat in electronic devices and industrial equipment.

Precision and Dimensional Stability

Die-cast aluminum parts are known for their precision and dimensional stability, making them ideal for various applications. With smart part engineering, manufacturers can create better part designs that meet specific requirements and standards. By utilizing advanced design software and expertise, die-casting companies can ensure that each part is perfectly engineered, providing superior performance and reliability.

Smart Part Engineering for Better Part Designs

Smart part engineering is essential for creating high-quality die-cast aluminum parts that meet the exact specifications of the intended application. Through careful analysis and design optimization, die-casting manufacturers can develop parts with intricate geometries and complex features, ensuring optimal functionality and performance. Manufacturers can achieve precise dimensional accuracy and exceptional part quality by leveraging advanced engineering techniques like simulation and modeling.

Innovative Tooling Designs for Cost-Effective Manufacturing

Innovative tooling designs are crucial in the cost-effective manufacturing of die-cast aluminum parts. By employing cutting-edge technologies and tooling solutions, die-casting companies can streamline production while maintaining high precision and efficiency. Innovative tooling designs enable manufacturers to reduce material waste, minimize production time, and optimize overall manufacturing costs, resulting in superior quality parts at competitive prices.

Maximizing Performance and Casting Quality

Achieving optimal performance and casting quality is paramount for aluminum die-casting manufacturers. To ensure that each part meets stringent standards, manufacturers can employ several key strategies:

- Rigorous Quality Control: Implementing comprehensive inspection procedures to identify and address defects.

- Advanced Production Techniques: Utilizing state-of-the-art manufacturing processes to enhance dimensional stability and part integrity.

- Continuous Improvement: Staying updated on industry best practices and technological advancements to optimize production efficiency.

By combining these elements, die-casting companies can consistently deliver high-quality aluminum parts that exceed customer expectations.

Corrosion Resistance

Anodizing them black is a smart choice when it comes to ensuring the longevity of die-cast aluminum parts. This process creates a protective oxide layer on the surface of the aluminum, making it more resistant to corrosion and wear. By anodizing aluminum black, you can significantly extend the lifespan of your parts, especially in outdoor or harsh environments.

How to Anodize Aluminum Black for Longevity

To anodize aluminum black, the parts are cleaned and placed in a chemical bath where an electrical current is applied. This causes a controlled oxidation process on the aluminum's surface, creating a durable and corrosion-resistant finish. The black color is achieved through dyeing or special electrolytic solutions during the anodizing process.

Surface Treatment for Maximum Durability

In addition to anodizing, other surface treatments can further enhance the durability of die-cast aluminum parts. These include powder coating, painting, and chromate conversion coating, all providing additional protection against corrosion and environmental damage. Choosing the right surface treatment for your specific application ensures that your aluminum parts withstand even the harshest conditions.

Reliable Aluminum Casting Manufacturers

Choosing a reliable aluminum casting manufacturer is crucial when it comes to ensuring high-quality die-cast aluminum parts with superior corrosion resistance. Look for a company with extensive experience in die casting and surface treatment processes and a proven track record of delivering durable and long-lasting products. With the right partner, you can confidently address your corrosion resistance requirements while maximizing the performance of your aluminum components.

Excellent Thermal Conductivity

Die-cast aluminum parts are known for their excellent thermal conductivity, making them perfect for applications that require efficient heat dissipation. Ningbo Buttler Precision Machinery Co., Ltd. is a leading die-casting manufacturer specializing in producing high-quality die-cast heat sink projects, ensuring optimal thermal management in various industries. Their expertise in creating smart designs for heat sinks ensures that the parts effectively dissipate heat, contributing to the overall performance and longevity of the products.

Ningbo Buttler Precision Machinery Co., Ltd. Die Casting Molds

Ningbo Buttler Precision Machinery Co., Ltd. offers top-notch die-casting molds for producing high-quality aluminum and zinc castings with excellent thermal conductivity. Their precision engineering and attention to detail result in molds that enable the production of parts with superior heat dissipation capabilities, making them ideal for a wide range of applications across different industries.

Efficient Heat Dissipation in Automotive Parts

One key advantage of die-cast aluminum parts is their ability to dissipate heat efficiently. This is crucial in automotive applications where temperature management is vital for optimal performance and safety. With the expertise of companies like Ningbo Buttler Precision Machinery Co., Ltd., automotive manufacturers can rely on producing durable and efficient heat-dissipating components that contribute to vehicles' overall reliability and longevity.

Smart Design of Die Cast Heat Sink Projects

Die-cast heat sink projects require smart design solutions for effective thermal management. Companies like Ningbo Buttler Precision Machinery Co., Ltd. excel in creating innovative designs that maximize surface area and airflow for enhanced heat dissipation, resulting in reliable and long-lasting components for various electronic and mechanical systems.

Cost-Effective Production

In the manufacturing industry, maximizing performance while minimizing secondary operations is crucial for efficiency and cost-effectiveness. Die-cast aluminum parts offer the advantage of achieving high precision and dimensional stability, reducing the need for additional machining or finishing processes. This saves time and lowers production costs, making die-cast aluminum parts a cost-effective choice for manufacturers.

Maximizing Performance while Minimizing Secondary Operations

By utilizing die-cast aluminum parts, manufacturers can achieve superior performance while minimizing the need for secondary operations such as welding or assembly. The high dimensional accuracy and tight tolerances of die-cast aluminum parts ensure that they are ready for use straight out of the mold, reducing the time and resources required for additional processing. This results in higher productivity and cost savings for manufacturers across various industries.

Efficient Processing and Assembly

Die-cast aluminum parts are known for their excellent dimensional stability and precision, allowing for efficient processing and assembly. With minimal variation in dimensions, these parts fit together seamlessly during assembly, reducing the likelihood of errors or rework. This efficiency speeds up production and ensures consistent quality in the finished products, ultimately leading to cost savings and customer satisfaction.

High-Quality Die Cast Aluminum Parts

Die-cast aluminum is renowned for its exceptional strength, durability, and reliability, making it an ideal choice for high-quality components.

- Superior Strength and Durability: Die-cast aluminum parts exhibit exceptional strength and durability, ensuring long-lasting performance in demanding applications.

- Consistent Quality: Reputable die-casting companies implement rigorous quality control measures, guaranteeing that each part meets stringent standards.

- Versatility: Die-cast aluminum components excel in various industries due to their versatility and adaptability.

Ningbo Buttler Precision Machinery Co., Ltd. specializes in die-casting molds and surface treatment processes, enabling them to deliver top-tier die-cast aluminum parts tailored to specific customer needs. From achieving enhanced corrosion resistance through anodizing aluminum black to optimizing thermal conductivity in heat sink projects, Buttler's comprehensive services ensure customer satisfaction.

By partnering with Ningbo Buttler, manufacturers can confidently rely on producing high-quality die-cast aluminum components that meet their exact specifications.

Versatility in Design

When it comes to die-cast aluminum parts, customization options are key. A reputable die-casting manufacturer like Ningbo Buttler Precision Machinery Co., Ltd. offers a wide range of customization options to meet the specific needs of various industries. Whether it's an automotive, appliance, or outdoor lamp series, the flexibility in design allows for tailored solutions that maximize performance and efficiency.

Die Casting Manufacturer's Customization Options

Ningbo Buttler Precision Machinery Co., Ltd. stands out for its ability to provide tailored solutions through smart part engineering and innovative tooling designs. Focusing on cost-effective manufacturing, its customization options allow for the precise and efficient production of die-cast aluminum parts that meet the highest industry standards.

Wide Range of Die Cast Aluminum Parts

Due to its lightweight and high-strength properties, die-cast aluminum offers a wide range of applications, from automotive parts to heat sink projects. Ningbo Buttler Precision Machinery Co., Ltd. specializes in producing a diverse range of die-cast aluminum parts that cater to different industries, ensuring that there is a suitable solution for every need.

Tailored Solutions for Various Industries

The versatility of die-cast aluminum extends beyond its physical properties and into industry-specific solutions. With the expertise of a reputable die-casting company like Ningbo Buttler Precision Machinery Co., Ltd., tailored solutions are available for industries such as automotive, gas appliances, power tools, and more. This ensures that each industry can benefit from the unique advantages of die-cast aluminum in their specific applications.

The Future of Die Cast Aluminum Parts

Die-cast aluminum parts are the future of manufacturing, offering various benefits for various industries. With advancements in die-casting technology, the possibilities for customization and cost-effective production are endless. Embracing the benefits of die-cast aluminum parts is essential for staying ahead in the competitive manufacturing landscape.

As technology continues to evolve, die-cast aluminum parts will play a crucial role in shaping the future of manufacturing. Their versatility, lightweight nature, and high strength-to-weight ratio make them ideal for various applications across different industries.

Advancements in Die Casting Technology

With ongoing advancements in die-casting technology, manufacturers can expect even greater precision, efficiency, and cost-effectiveness in producing die-cast aluminum parts. From smart part engineering to innovative tooling designs, the potential for enhancing performance and quality is limitless.

Embracing the Benefits of

Die-Cast Aluminum Parts

Companies should recognize and embrace the numerous advantages of die-cast aluminum parts. These parts provide durable and reliable solutions for various manufacturing needs, from corrosion resistance to excellent thermal conductivity.

Ningbo Buttler Precision Machinery Co., Ltd., a leading die-casting manufacturer, specializes in providing top-quality die-casting molds and aluminum casting services with efficient processing and assembly capabilities. By partnering with Buttler Precision Machinery Co., Ltd., companies can benefit from tailored solutions for their specific industry needs while maximizing performance and minimizing secondary operations.

By leveraging the unique properties of die-cast aluminum parts and staying updated on technological advancements within the industry, manufacturers can set themselves up for success in meeting evolving market demands while maintaining a competitive edge.