Introduction

Aluminium alloy die casting is a versatile manufacturing process that involves injecting molten aluminum into a steel mold to create aluminum die cast parts. This process allows for the production of complex shapes with high levels of accuracy and repeatability, making it ideal for a wide range of applications. The advantages of aluminium die casting components include their lightweight nature, strength, high dimensional accuracy, corrosion resistance, thermal conductivity, electrical conductivity, recyclability, and cost-effectiveness. These components play a crucial role in various industries such as automotive, aerospace, electronics, and more.

What is Aluminium Alloy Die Casting?

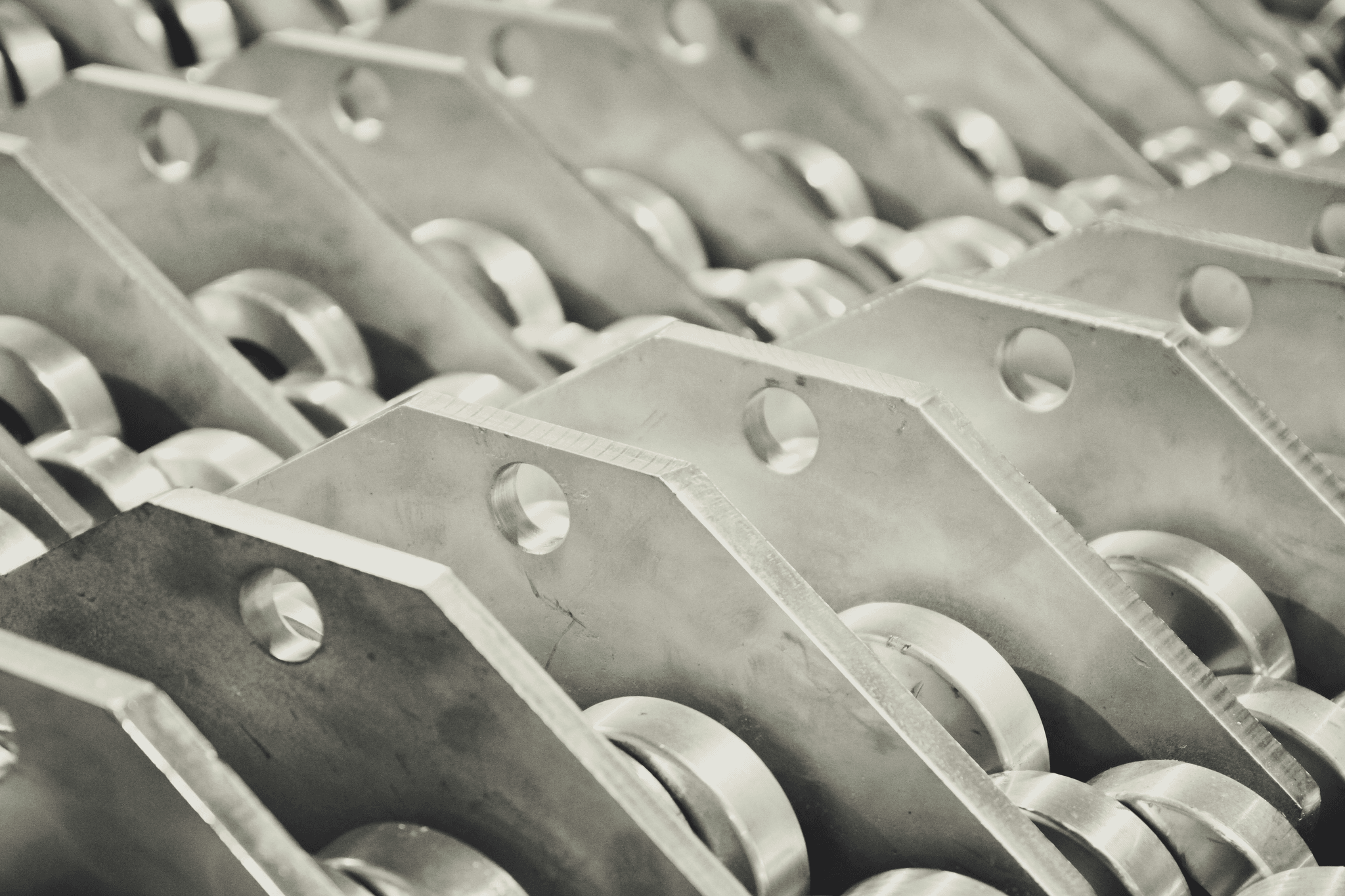

Aluminium alloy die casting is a metal casting process that utilizes aluminum alloys to produce high-quality parts with excellent mechanical properties. The process involves injecting molten aluminum into a steel mold at high pressure to create complex shapes with thin walls and fine details. This makes it an ideal choice for manufacturing components that require intricate designs and tight tolerances.

The Advantages of Aluminium Alloy Die Casting

The advantages of aluminium alloy die casting are numerous and significant. Aluminum casting alloys are known for their lightweight nature, making them ideal for applications where weight reduction is crucial without compromising strength. Additionally, aluminum die casting parts exhibit exceptional strength and durability, making them suitable for demanding environments and applications that require robust components.

The Role of Aluminium Die Casting Components in Manufacturing

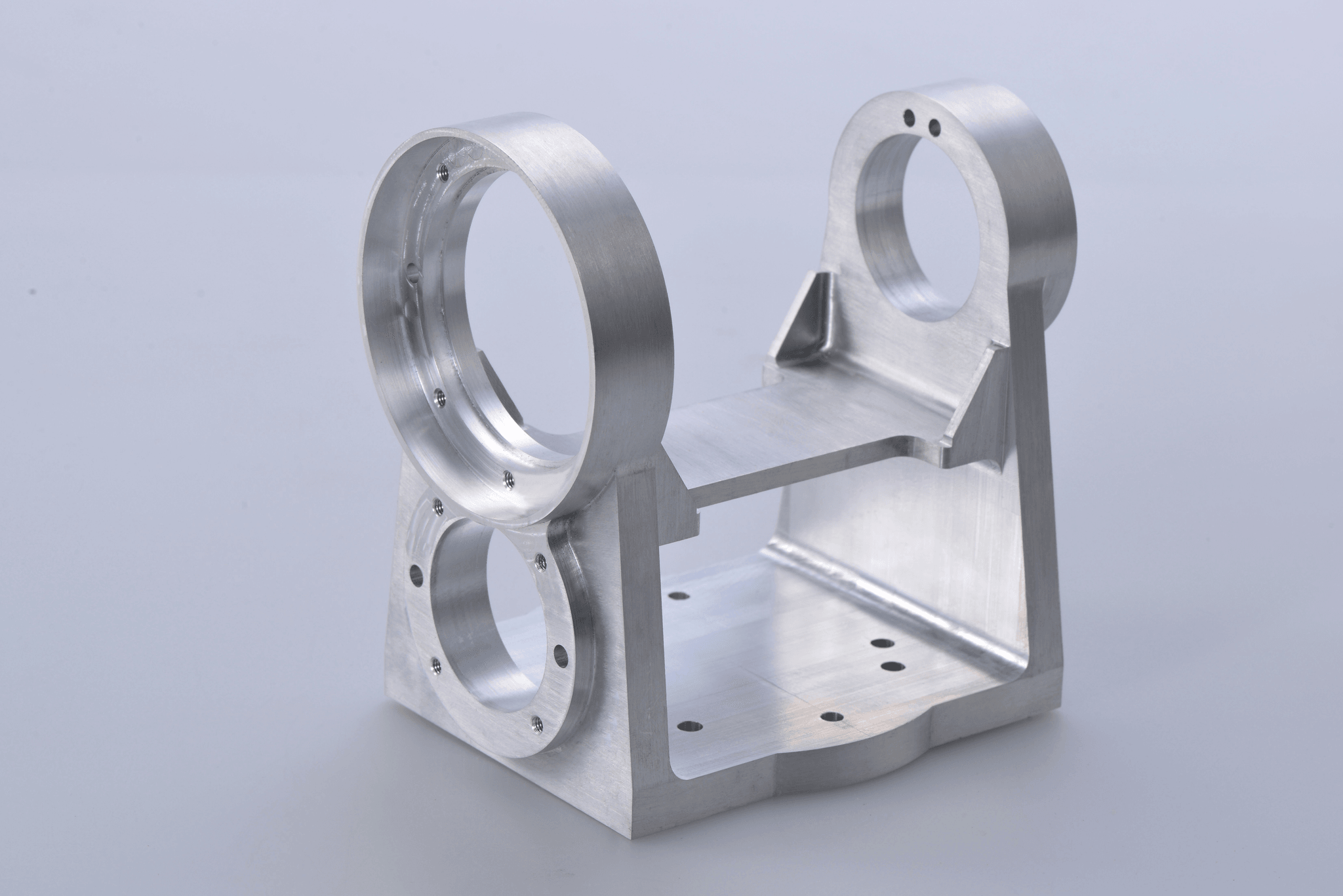

Aluminium die casting components play a vital role in modern manufacturing processes across various industries. These components are widely used in automotive manufacturing for engine parts, transmission housings, and structural components due to their lightweight yet strong properties. In the aerospace industry, die casting aluminum is used for aircraft components such as brackets and fittings due to its high dimensional accuracy and reliability.

Lightweight and Strong

Aluminum Casting Alloys for Lightweight Products

When it comes to creating lightweight products, aluminum casting alloys are the go-to choice for manufacturers. The unique properties of aluminum make it an ideal material for producing components that require strength without adding unnecessary weight. With the use of aluminium die casting components, manufacturers can achieve the perfect balance between durability and lightweight design.

Strength of Aluminium Die Casting Parts

One of the key advantages of die casting aluminum is the exceptional strength it provides to the finished parts. This makes aluminium die cast parts suitable for a wide range of applications where durability and resilience are essential. Whether it's automotive components or electronic enclosures, aluminum die cast parts offer unparalleled strength without compromising on weight.

Advantages of Die Casting Aluminium for Lightweight Applications

The use of die casting aluminium offers numerous advantages for lightweight applications. Not only does it provide superior strength, but it also allows for intricate designs and thin walls without sacrificing structural integrity. This makes aluminium alloy die casting a preferred choice for industries that require lightweight yet robust components.

Smart Part Engineering = Better Part Designs

At Ningbo Buttler Precision Machinery Co., Ltd, we understand the importance of smart part engineering in achieving better part designs. Our innovative tooling designs are engineered to optimize manufacturing processes, ensuring maximum performance and quality while minimizing the need for secondary operations. With our Engineering Design Review Process, we can help you optimize your new and existing parts at no cost to you!

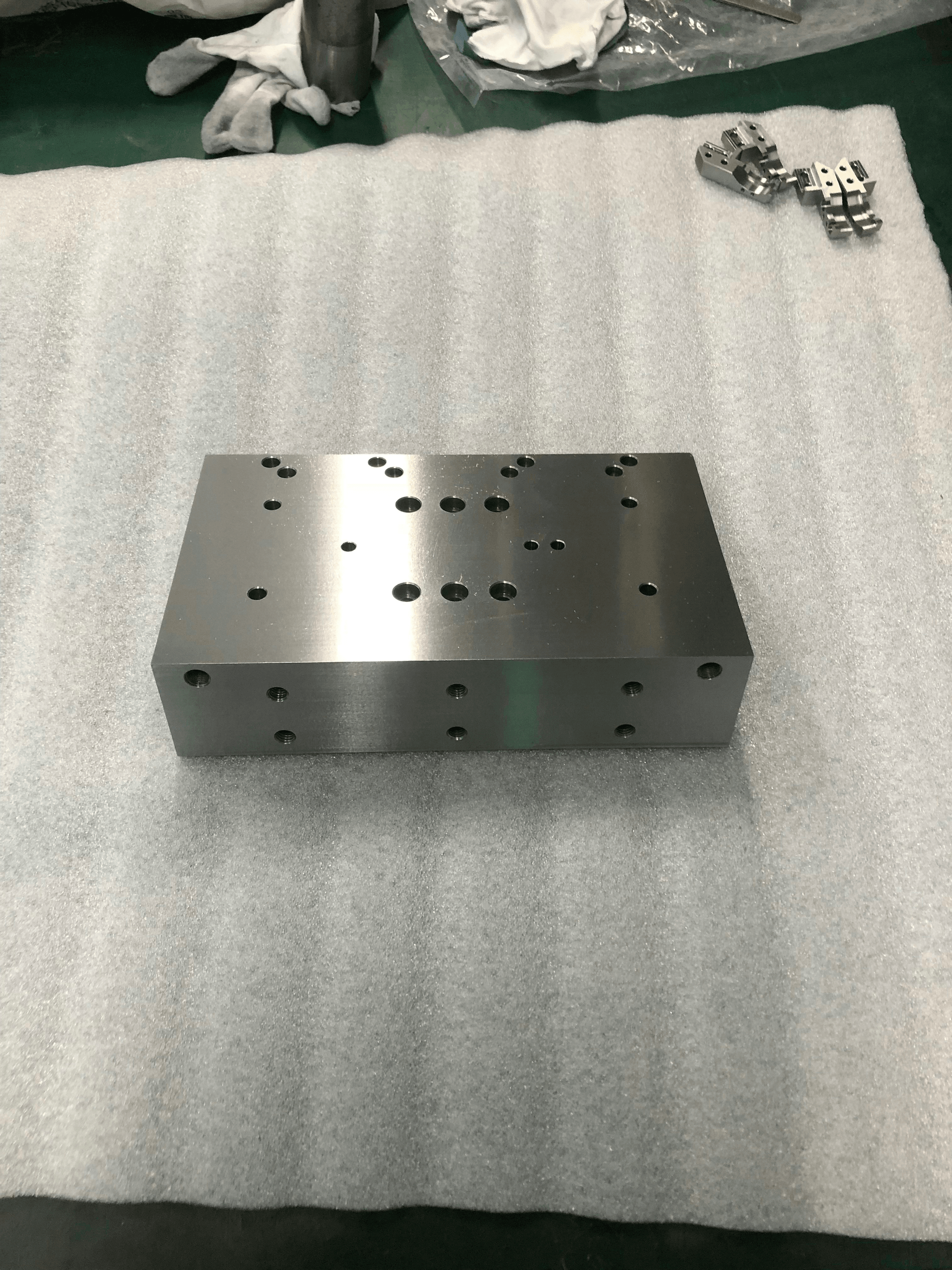

High Dimensional Accuracy

Aluminium alloy die casting is known for its high dimensional accuracy, making it a popular choice for manufacturing components that require precise measurements. Aluminum die cast parts are produced with tight tolerances, ensuring consistency and reliability in the final product. At Ningbo Buttler Precision Machinery Co., Ltd, we specialize in high dimensional accuracy in our aluminum die casting components, providing our clients with top-quality parts that meet their exact specifications.

Ningbo Buttler Precision Machinery Co., Ltd for High Dimensional Accuracy

At Ningbo Buttler Precision Machinery Co., Ltd, we prioritize high dimensional accuracy in our aluminium die casting components. Our state-of-the-art equipment and advanced technology allow us to achieve tight tolerances and intricate designs, ensuring that each part meets the highest standards of precision. With our expertise and attention to detail, we deliver superior quality aluminum die cast parts that exceed our customers' expectations.

Smart Part Engineering = Better Part Designs

Our commitment to smart part engineering translates to better part designs for aluminium die casting. By leveraging innovative tooling designs and engineering processes, we optimize the manufacturing of aluminum casting alloys to maximize performance and minimize the need for secondary operations. Our Engineering Design Review Process ensures that each part is meticulously designed and manufactured to perfection.

Corrosion Resistance

Aluminium die casting parts are highly valued for their corrosion resistance, making them ideal for use in environments prone to rust and deterioration. The surface treatment applied to aluminium castings enhances their ability to withstand corrosion, ensuring longevity and durability in various applications.

Surface Treatment for Corrosion Resistance

The surface treatment process for aluminium die casting involves applying protective coatings or finishes that act as barriers against corrosion. This ensures that the parts remain resistant to rust and degradation, even when exposed to harsh environmental conditions or corrosive substances.

Ningbo Buttler Precision Machinery Co., Ltd for Corrosion-Resistant Aluminum Castings

Ningbo Buttler Precision Machinery Co., Ltd specializes in producing high-quality aluminium and zinc castings with superior corrosion resistance. Their expertise in surface treatment and precision engineering ensures that the resulting castings are well-equipped to withstand corrosion, making them reliable and long-lasting.

With its exceptional corrosion resistance, aluminium die casting parts are ideal for use in environments prone to corrosion, such as marine or industrial settings. The high-quality castings produced by Ningbo Buttler Precision Machinery Co., Ltd are not only resistant to corrosion, but also offer superior strength and durability. This makes them a cost-effective solution for applications where longevity and reliability are essential.

Advantages of Aluminium Die Casting Parts for Corrosion-Prone Environments

The inherent corrosion resistance of aluminium casting alloys makes them a preferred choice for components used in environments susceptible to rust and deterioration. From marine applications to outdoor equipment, die casting aluminum provides a reliable solution for combating the effects of corrosion, ensuring the longevity of the parts.

In addition to its corrosion resistance, die casting aluminum also offers excellent thermal conductivity. This means that components made from aluminium alloys can effectively dissipate heat, making them ideal for use in high-temperature environments. Whether it's in automotive cooling systems or electronic devices, the ability of aluminium die casting parts to efficiently manage heat contributes to their overall durability and performance.

Thermal Conductivity

When it comes to effective thermal conductivity, aluminum die casting parts are the top choice for various applications. The high thermal conductivity of aluminum makes it an ideal material for components that require efficient heat dissipation, such as electronic devices and automotive parts.

Aluminum Die Casting Parts for Effective Thermal Conductivity

Aluminum's excellent thermal conductivity allows for the rapid transfer of heat, making it suitable for applications where temperature control is crucial. Whether it's heat sinks in electronics or engine components in automotive systems, die casting aluminum provides the necessary thermal management performance.

Ningbo Buttler Precision Machinery Co., Ltd for Thermal Conductivity in Die Casting

At Ningbo Buttler Precision Machinery Co., Ltd, we specialize in producing aluminum die castings with superior thermal conductivity properties. Our advanced manufacturing processes and state-of-the-art equipment ensure that our products meet the highest standards for effective thermal management.

Smart Part Engineering = Better Part Designs

By leveraging smart part engineering, we can optimize the design of aluminum die casting parts to enhance their thermal conductivity even further. Our expertise in engineering innovative tooling designs allows us to create cost-effective solutions that maximize performance and minimize the need for additional operations.

Electrical Conductivity

Advantages of Aluminium Alloy Die Casting for Electrical Components

When it comes to electrical components, aluminium alloy die casting offers numerous advantages. The high electrical conductivity of aluminium makes it an ideal material for various electrical applications, ensuring efficient transmission of electricity. Additionally, aluminium die casting components provide excellent thermal conductivity, making them suitable for parts that require both electrical and thermal properties.

Ningbo Buttler Precision Machinery Co., Ltd for High Electrical Conductivity in Aluminum Castings

At Ningbo Buttler Precision Machinery Co., Ltd, we specialize in producing high-quality aluminium die castings with exceptional electrical conductivity. Our state-of-the-art manufacturing processes and advanced equipment allow us to achieve precise dimensions and superior surface finishes, ensuring optimal performance for electrical components. With our expertise in smart part engineering, we can design and produce aluminium castings that meet the specific requirements of your electrical applications.

By choosing aluminium alloy die casting for your electrical components, you can benefit from its high electrical conductivity, lightweight properties, and corrosion resistance. With the expertise of Ningbo Buttler Precision Machinery Co., Ltd in producing top-notch aluminum castings, you can be confident in the reliability and performance of your electrical parts. Trust us to deliver cost-effective solutions that meet your exact specifications while contributing to the future of aluminium die casting.

Recyclability

Aluminium alloy die casting is a sustainable choice for environmentally-conscious manufacturers. The ability to recycle aluminium die casting components makes it an eco-friendly option, reducing the need for new raw materials and minimizing waste. With a focus on sustainability, companies like Ningbo Buttler Precision Machinery Co., Ltd are leading the way in environmentally-friendly die casting solutions.

Sustainability of Aluminium Die Casting

The recyclability of aluminium die cast makes it an ideal choice for sustainable manufacturing practices. By using recycled aluminium alloys, manufacturers can reduce their carbon footprint and contribute to a more circular economy. This not only benefits the environment but also aligns with the growing demand for eco-friendly products in the market.

Ningbo Buttler Precision Machinery Co., Ltd for Environmentally-Friendly Die Casting

Ningbo Buttler Precision Machinery Co., Ltd is committed to environmentally-friendly die casting processes. With a focus on sustainability, they prioritize the use of recycled materials and implement efficient production methods to minimize waste. Their dedication to eco-friendly practices sets them apart as leaders in sustainable aluminium alloy die casting solutions.

Cost-Effective Manufacturing

Aluminium alloy die casting is a cost-effective manufacturing solution for producing high-quality parts with minimal post-processing. The use of aluminium die casting components ensures that the final products are strong, lightweight, and durable, reducing the need for additional reinforcement or finishing. This makes aluminium die cast an ideal choice for industries looking to optimize their production processes and minimize costs.

Maximizing Performance and Casting Quality with Aluminium Die Casting

Aluminum casting alloys are known for their excellent fluidity and dimensional stability, allowing for intricate designs and high precision in the final products. With the right tooling designs and engineering expertise, aluminium die casting parts can achieve superior performance and casting quality without compromising on cost-effectiveness. This makes them a top choice for manufacturers looking to maintain high standards while staying within budget.

Ningbo Buttler Precision Machinery Co., Ltd for Cost-Effective Die Casting Solutions

Ningbo Buttler Precision Machinery Co., Ltd specializes in providing cost-effective die casting solutions that prioritize quality, efficiency, and affordability. By leveraging advanced technology and smart part engineering, they ensure that their clients receive top-notch aluminium die cast components that meet their performance requirements while staying within budget constraints. Their expertise in tooling design and manufacturing processes makes them a reliable partner for cost-effective die casting solutions.

Smart Part Engineering = Better Part Designs

Smart part engineering is the key to achieving better part designs that maximize performance while minimizing costs. By working closely with experienced engineers at Ningbo Buttler Precision Machinery Co., Ltd, manufacturers can optimize their part designs to enhance functionality, durability, and efficiency without inflating production expenses. This approach not only improves the overall quality of the products but also contributes to significant cost savings in the long run.

Conclusion

Aluminium alloy die casting offers a multitude of advantages, making it the ideal choice for manufacturing lightweight, strong, corrosion-resistant, and cost-effective components. With the future of aluminium die casting looking bright, it's clear that smart part engineering leads to better part designs and improved manufacturing processes.

Why Choose Aluminium Alloy Die Casting?

Aluminium die casting components provide exceptional strength, dimensional accuracy, and thermal conductivity while being lightweight and cost-effective. This makes them the top choice for a wide range of applications across various industries.

The Future of Aluminium Die Casting

The future of aluminium die casting is promising, with ongoing advancements in technology and smart part engineering leading to even better designs and manufacturing processes. As demand for high-quality aluminium castings continues to grow, the industry is poised for significant growth.

Smart Part Engineering = Better Part Designs

By leveraging smart part engineering and innovative tooling designs from Ningbo Buttler Precision Machinery Co., Ltd., manufacturers can optimize their parts for cost-effective manufacturing without compromising on quality or performance. This approach ensures that every component meets the highest standards.