Introduction

When it comes to manufacturing, die casting plays a crucial role in producing high-quality metal components. Die casting manufacturers are experts in creating precision-engineered parts using materials like aluminum, zinc, and magnesium. These manufacturers are essential for industries that require custom die casting solutions to meet their specific needs and standards. Choosing the right die casting manufacturer can make a significant difference in the quality and performance of your products.

Introduction to Die Casting Manufacturers

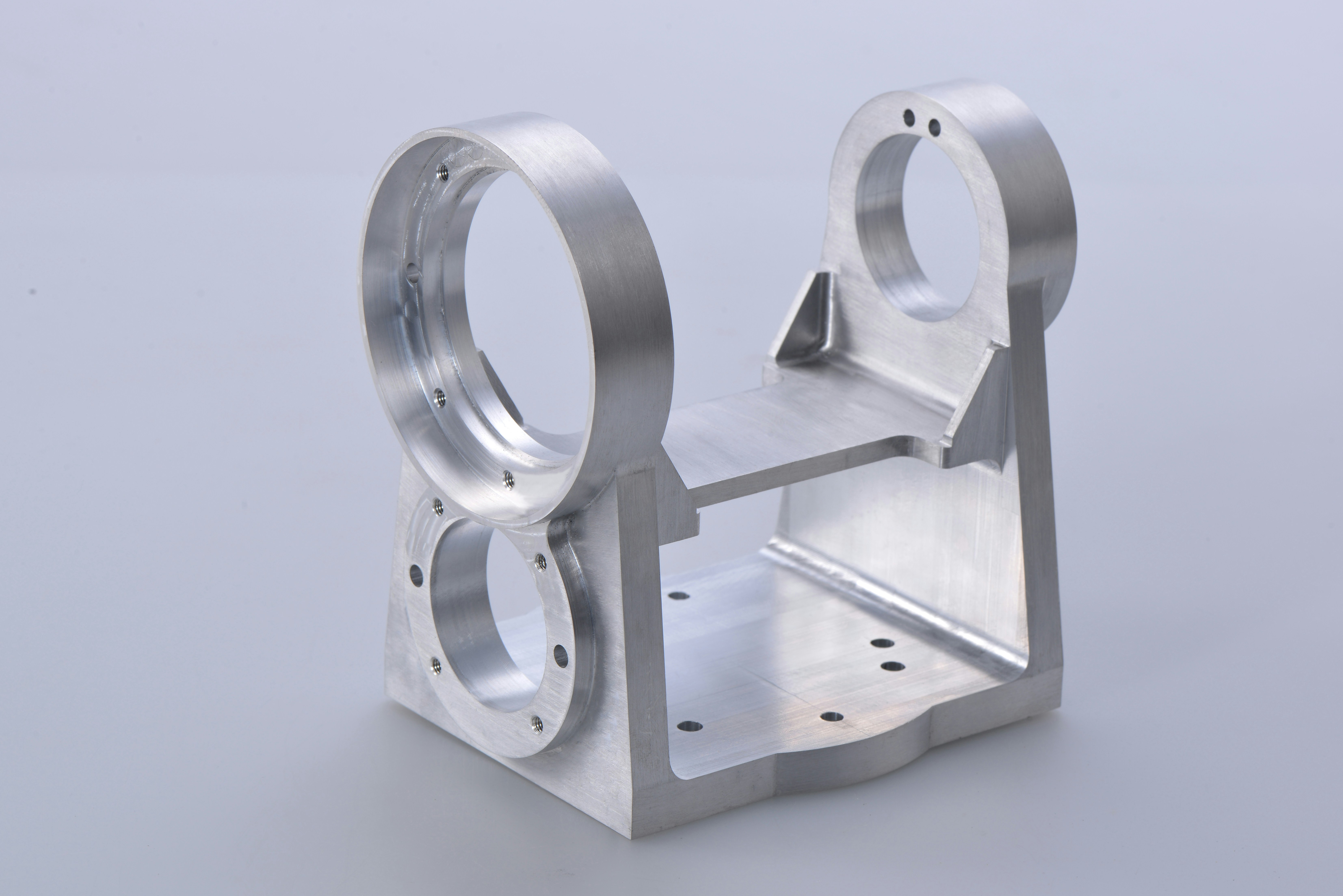

Die casting manufacturers specialize in producing metal components through the process of die casting, which involves injecting molten metal into a mold cavity under high pressure. This results in complex shapes with high levels of accuracy and detail. These manufacturers have the expertise and equipment to work with various materials, including aluminum, zinc, and magnesium, to create parts for different industries.

Understanding the Importance of Die Casting Manufacturers

Die casting manufacturers are important because they can provide cost-effective manufacturing solutions for a wide range of industries. Their expertise in creating custom die casting solutions allows businesses to streamline their production processes and improve overall efficiency. By understanding die casting manufacturers' capabilities, businesses can leverage their expertise to enhance product quality and performance.

Why Quality Die Casting Manufacturers Matter

Quality is paramount when choosing die casting manufacturers. High-quality manufacturers like Ningbo Buttler Precision Machinery Co., Ltd., Dynacast, Ryobi Die Casting Inc., China Die Casting, and Smart Part Engineering offer exceptional precision engineering services that ensure reliable and durable metal components for various applications. The attention to detail these top-notch manufacturers provide sets them apart from others in the industry.

1. Ningbo Buttler Precision Machinery Co., Ltd.

Ningbo Buttler Precision Machinery Co., Ltd. is a renowned leader in the die casting industry, specializing in die-casting molds and aluminum castings. Their innovative tooling designs are engineered to provide cost-effective manufacturing solutions, ensuring maximum performance and casting quality while minimizing the need for secondary operations. Focusing on custom die casting solutions, they are dedicated to delivering exceptional quality and reliability.

Specialized in

Die-Casting Molds and Aluminum Castings

Ningbo Buttler Precision Machinery Co., Ltd. specializes in die-casting molds and aluminum castings, offering comprehensive solutions for various industries. Their expertise in this area allows them to provide high-quality products that meet the specific needs of their clients.

Ningbo Buttler Precision Machinery Co., Ltd. has gained a reputation for its innovative tooling designs, which set them apart from other manufacturers in the industry. Their team of experienced engineers and designers constantly pushes the boundaries of what is possible, resulting in cutting-edge molds and castings exceeding industry standards. This dedication to innovation ensures that their clients receive products that are not only high-quality but also at the forefront of technological advancement.

Known for

Innovative Tooling Designs

One of Ningbo Buttler Precision Machinery Co., Ltd.'s key strengths is its reputation for innovative tooling designs that optimize the manufacturing process. These designs are engineered to enhance efficiency and quality, setting it apart as an industry leader.

Ningbo Buttler Precision Machinery Co., Ltd. excels in innovative tooling designs and offers cost-effective manufacturing solutions. By leveraging their expertise in tooling design, they develop efficient and streamlined manufacturing processes that ultimately save their clients time and money. This commitment to providing cost-effective solutions demonstrates their dedication to meeting the needs of their customers while maintaining high standards of quality.

Offers

Cost-Effective Manufacturing Solutions

In addition to specializing in die-casting molds and aluminum castings, Ningbo Buttler Precision Machinery Co., Ltd. is committed to providing cost-effective manufacturing solutions that deliver value to its clients. By focusing on efficiency and innovation, it ensures that its products meet the highest standards while remaining competitively priced.

Furthermore, Ningbo Buttler Precision Machinery Co., Ltd. leverages advanced technology and state-of-the-art equipment to streamline its manufacturing processes, reducing production time and costs without compromising quality. Their team of skilled engineers and technicians are dedicated to finding creative solutions to complex manufacturing challenges, ensuring that clients receive the best value for their investment. They can offer cost-effective solutions that exceed client expectations by staying ahead of industry trends and embracing cutting-edge techniques.

2. Dynacast

Dynacast is a global leader in precision engineered metal components, specializing in zinc and magnesium die casting. With state-of-the-art facilities and advanced technology, they offer custom die casting solutions to meet their clients' unique needs. Their expertise in custom die casting makes them a top choice for manufacturers looking for high-quality, specialized components.

Global

Manufacturer of Precision Engineered Metal Components

Dynacast has established itself as a trusted global manufacturer of precision engineered metal components, providing innovative solutions for various industries. Their commitment to excellence and cutting-edge technology sets them apart as a leader in die casting manufacturing.

Furthermore, Dynacast's zinc and magnesium die casting expertise allows them to deliver high-quality, cost-effective solutions for various applications. Their state-of-the-art facilities and advanced manufacturing processes ensure that each component meets the strictest quality standards. By specializing in these materials, Dynacast can offer unmatched precision and consistency in their products, making them a top choice for manufacturers worldwide.

Specializes in Zinc and

Magnesium Die Casting

Specializing in zinc and magnesium die casting, Dynacast offers unparalleled expertise in producing complex, high-quality components with exceptional dimensional accuracy. Their focus on these materials allows them to deliver superior products that meet industry standards.

With a dedicated focus on zinc and magnesium die casting, Dynacast has honed their expertise to deliver exceptional dimensional accuracy and high-quality components. By specializing in these materials, they can meet the highest industry standards and provide superior products that exceed customer expectations. Their commitment to custom die casting solutions sets them apart as a reliable partner for businesses seeking complex, specialized components.

Provides

Custom Die Casting Solutions

Dynacast's dedication to customization ensures that they can provide tailored solutions to meet their clients' specific requirements. Whether creating intricate designs or meeting strict performance criteria, Dynacast excels at delivering custom die casting solutions that exceed expectations. With a team of experienced engineers and cutting-edge technology, Dynacast can tackle even the most complex projects with precision and efficiency. Their commitment to innovation and continuous improvement means clients can trust them to deliver high-quality, cost-effective solutions tailored to their unique needs.

3. Ryobi Die Casting Inc.

Ryobi Die Casting Inc. is a leader in high-pressure aluminum die casting, offering top-notch services for custom die casting manufacturers. Focusing on precision and reliability, Ryobi provides value-added services like CNC machining and surface finishing to ensure exceptional quality in every product. As one of the top aluminium die casting manufacturers in the industry, Ryobi is known for delivering superior results that exceed expectations.

Leader in

High-Pressure Aluminum Die Casting

Ryobi Die Casting Inc. stands out as a leader in high-pressure aluminum die casting. It utilizes advanced techniques and state-of-the-art equipment to produce top-quality components for various industries. Its expertise in aluminum die casting manufacturing sets it apart from the competition, making it a trusted partner for custom die casting solutions.

Ryobi Die Casting Inc. excels in high-pressure aluminum die casting and offers value-added services like CNC machining and surface finishing. This comprehensive approach allows them to provide a one-stop solution for their clients, streamlining the production process and ensuring the highest quality standards are met. By integrating these additional services, Ryobi Die Casting Inc. demonstrates its commitment to delivering exceptional results and exceeding customer expectations.

Offers

Value-Added Services like CNC Machining and Surface Finishing

In addition to their expertise in aluminium die casting, Ryobi Die Casting Inc. offers value-added services such as CNC machining and surface finishing to provide comprehensive solutions for their clients. This commitment to excellence ensures that each product meets the highest standards of quality and precision.

Known for

Exceptional Quality and Reliability

Ryobi Die Casting Inc.'s reputation for exceptional quality and reliability precedes them, making them a preferred choice among custom die casting manufacturers. Their dedication to delivering superior results has solidified their position as a trusted partner for clients seeking top-tier aluminium die casting manufacturing solutions.

4. China Die Casting

China Die Casting is a leading die casting manufacturer in China, specializing in aluminum and zinc die casting. With a strong focus on custom die casting solutions, they offer high-quality products tailored to meet the specific needs of their clients. Their expertise in aluminum die casting manufacturers in China makes them a reliable partner for businesses seeking precision and efficiency.

Leading

Die Casting Manufacturer in China

China Die Casting has established itself as a leader in the industry, with a reputation for delivering top-notch products and services. As one of the prominent aluminium die casting manufacturers in China, it can produce complex components with exceptional precision and consistency. Its commitment to excellence sets it apart as a trusted partner for businesses looking for reliable die casting solutions.

Specializes in aluminum and zinc die casting

Specializing in both aluminum and zinc die casting, China Die Casting offers a wide range of options to cater to diverse manufacturing needs. Their expertise as aluminium die casting manufacturers allows them to deliver lightweight yet durable components ideal for various applications. Their proficiency in zinc die casting manufacturers also ensures high-quality products suitable for different industries.

Offers

Custom Die Casting Solutions

China Die Casting takes pride in providing custom die casting solutions tailored to the unique requirements of its clients. Whether creating intricate designs or meeting specific performance criteria, its team is dedicated to delivering customized solutions that exceed expectations. As custom die casting manufacturers, it prioritizes flexibility and innovation to address the evolving demands of modern manufacturing processes.

5. Smart Part Engineering

Ningbo Buttler Precision Machinery Co., Ltd. specializes in die-casting molds, aluminum and zinc castings, processing, surface treatment, assembly, and packaging. Smart Part Engineering = Better Part Designs—We provide innovative tooling designs engineered for cost-effective manufacturing to maximize performance and casting quality while minimizing the need for secondary operations! Take advantage of our Engineering Design Review Process to optimize your new and existing parts…at NO COST to you!

Specializes in

Better Part Designs For Die Casting

Smart Part Engineering specializes in creating superior part designs for die casting, ensuring optimal performance and quality. Our expertise allows us to design parts that minimize the need for additional operations, saving you time and money while delivering exceptional results.

Offers

Innovative Engineering Design Review Process

Our innovative engineering design review process is a game-changer in the industry. We offer this service at no cost, providing valuable insights and optimizations to ensure that your parts are designed for maximum efficiency and effectiveness in the die-casting process.

Focuses on

Maximizing Performance and Casting Quality

At Smart Part Engineering, our primary focus is maximizing performance and casting quality for all our clients. We understand the importance of precision in die-casting manufacturing, so we prioritize excellence in our design and engineering processes.

Conclusion

Benefits of Choosing Quality Die Casting Manufacturers

Die casting is a crucial process for many industries, but the quality of the manufacturer you choose can significantly impact your final product. Here's why partnering with a reputable die casting manufacturer is essential for your business success:

1. Ensuring Quality and Durability

- High-quality die casting manufacturers prioritize top-notch materials and meticulous processes. This translates to robust, long-lasting products that meet or exceed industry standards. Defective parts and frequent replacements become a thing of the past, reducing overall costs and ensuring your products perform flawlessly.

2. Innovation and Expertise

- Leading die casting manufacturers invest in cutting-edge technology and employ skilled professionals. This translates into innovative tooling designs that optimize production efficiency and casting quality. Their expertise can also help identify potential design flaws and suggest improvements, leading to a superior final product.

3. Cost-Effectiveness and Efficiency

- Reputable manufacturers understand the importance of balancing quality with cost-efficiency. They utilize innovative techniques and optimized processes to minimize waste and streamline production. This translates to cost-effective solutions for your business, allowing you to be competitive in the market.

4. Reduced Need for Secondary Operations

- A skilled manufacturer focuses on precision and quality control throughout the die casting process. This minimizes the need for additional machining or finishing work (secondary operations) after the initial casting, reducing production time and costs and allowing you to get your products to market faster.

5. Reliable Partnership

- Choosing a quality manufacturer goes beyond the initial production run. A reliable partner offers ongoing support, ensuring consistent quality and timely deliveries. They are invested in your success and can work collaboratively to address any challenges that may arise.

By partnering with a quality die casting manufacturer, you gain a valuable asset for your business. Their expertise translates into high-quality, durable products, innovative solutions, and cost-effective production. This lets you focus on what matters most – growing your business and delivering exceptional products to your customers. Don't settle for anything less – choose a die casting manufacturer who prioritizes quality and becomes a trusted partner in your success.

How Die Casting Manufacturers Can Improve Your Product

Die casting manufacturers play a crucial role in improving the quality and performance of your products. Companies like Smart Part Engineering specialize in better part designs for die casting, offering innovative engineering design review processes to optimize new and existing parts at no cost to you. By partnering with such manufacturers, you can enhance your products' overall functionality and appeal.

Factors to Consider When Selecting Die Casting Manufacturers

Die casting is a versatile and efficient process for creating complex metal parts. However, the success of your project hinges on selecting the right manufacturer. Here are some crucial factors to consider when making this important decision:

1. Material Expertise

Die casting can handle various materials, but not all manufacturers specialize in everything. Identify the material best suited for your project (aluminum, zinc, magnesium, etc.) and choose a manufacturer with proven experience and expertise in working with that specific material. This ensures they understand the material's properties and can optimize the casting process for the best results.

2. Custom Solutions

Your project might require unique features or tight tolerances. Look for manufacturers who offer custom die casting solutions. They should be able to create tooling and processes tailored to your specific needs, ensuring a perfect fit for your final product.

3. Quality and Reliability

Consistency and precision are paramount. Research the manufacturer's reputation for quality control and adherence to industry standards. Look for companies known for exceptional quality, like China Die Casting, to minimize the risk of defects and ensure your parts function flawlessly.

4. Capabilities and Technology

Modern die casting involves advanced techniques and machinery. Investigate the manufacturer's capabilities and technology. Do they have the latest equipment to handle complex designs and maintain tight tolerances?

5. Communication and Customer Service

Clear communication is essential. Choose a manufacturer who is responsive to inquiries and fosters open communication throughout the project. Look for a partner who understands your needs and can promptly address any questions or concerns.

6. Cost and Value

While cost is a factor, focusing solely on the cheapest option can backfire in the long run. Look for a manufacturer who offers a good balance between competitive pricing and exceptional quality. Remember, a high-quality manufacturer saves you money in the long run by minimizing defects and rework.

7. Lead Time and Delivery

Timely delivery is crucial. Consider the manufacturer's production capacity and lead times. Can they meet your project timeline and ensure parts are delivered on schedule?

Selecting the right die casting manufacturer is an investment in your project's success. By prioritizing these key factors, you can find a reliable partner who delivers top-quality parts, custom solutions, and efficient production. This ensures you receive the best possible value and a competitive edge in the market.