Introduction

Die-cast zinc has become the go-to material for its superior strength, versatility, and sustainability advantages in manufacturing. As a leader in the industry, Buttler Precision Machinery understands the significance of zinc die casting and its impact on various applications.

The Superior Strength of Die Cast Zinc

Die casting refers to the process of forcing molten metal into a mold cavity under high pressure. This results in a product with exceptional strength and durability, making die-cast zinc an ideal choice for demanding applications that require reliable performance.

The versatility of zinc alloys further adds to the appeal of die-cast zinc. Zinc alloys can be easily customized to meet specific requirements, allowing for intricate designs and complex shapes to be easily achieved. This makes die-cast zinc a popular choice for various industries, from automotive and aerospace to electronics and consumer goods. The ability to tailor zinc alloys to suit different applications showcases the adaptability and flexibility of die-cast zinc as a material.

The Versatility of Zinc Alloys

Zinc alloy die casting is a popular manufacturing process due to its numerous advantages. Here are some key benefits of using zinc alloys:

- Diverse Applications: Zinc alloys boast a unique combination of mechanical and physical properties, making them suitable for various applications. From automotive parts and electronic components to consumer goods, zinc alloy die casting provides the flexibility to meet specific design requirements.

- Excellent Corrosion Resistance: Zinc alloys are renowned for their exceptional corrosion resistance. This makes them ideal for outdoor applications such as architectural hardware and marine fittings. Their durability ensures that zinc alloy components maintain their integrity even in harsh environments, minimizing the need for frequent maintenance and replacements.

- Enhanced Finishes: The ability to easily coat zinc alloys with various finishes further strengthens their corrosion resistance. This not only extends their lifespan but also improves overall performance.

Zinc alloy die casting offers versatility, durability, and affordability, making it a valuable choice for various industries.

The Sustainable Advantages of Zinc Die Casting

In today's environmentally conscious world, casting zinc has become an eco-friendly solution for manufacturers. With its recyclability and minimal waste generation during production, zinc die casting offers sustainable advantages that align with green initiatives.

In addition to its eco-friendly nature, zinc die casting offers exceptional strength and durability. This makes it ideal for manufacturing components that require long-term reliability and resilience. With the ability to withstand high operating temperatures and harsh environmental conditions, zinc die-cast parts can outlast other materials, reducing the need for frequent replacements and ultimately contributing to a more sustainable approach to manufacturing.

Strength and Durability

Strength and durability are key factors that make die-cast zinc stand out. The high-quality die-cast zinc material used in the die-casting process ensures that the final product is robust and long-lasting. Zinc alloys further enhance performance, making it an ideal choice for applications requiring resilience and reliability.

High-Quality Die Cast Zinc Material

The meaning of die casting becomes apparent when you consider the superior strength and durability of zinc die casting. The material used in this process undergoes meticulous quality control to ensure that only the best raw materials are utilized. This results in high-quality die-cast zinc material that can withstand rigorous use without compromising performance or integrity.

The superior strength and durability of zinc die casting make it a top choice for manufacturers looking for long-lasting materials. With its ability to withstand rigorous use without compromising on performance or integrity, high-quality die-cast zinc material is a reliable option for a wide range of applications. Whether used in automotive parts, electronic components, or decorative hardware, zinc alloy die casting offers the longevity and resilience that businesses and consumers can depend on.

Long-Lasting Zinc Alloy Die Casting

Zinc alloy die casting enhances its durability by incorporating other metals into the mix to enhance its properties. This results in long-lasting zinc alloy die-casting products that endure harsh conditions and heavy-duty applications. Whether for industrial machinery or consumer electronics, this type of die casting is designed to last.

Zinc alloy die casting not only offers enhanced durability but also provides improved performance. By incorporating other metals into the mix, the properties of the zinc alloy are optimized for maximum strength and resilience. This means that products created through zinc alloy die casting can withstand high-stress environments and perform reliably under demanding conditions. This die-casting ensures top-notch performance for heavy-duty industrial machinery or precision consumer electronics.

Enhanced Performance with Zinc Alloys

Using zinc alloys in the die-casting process enhances performance characteristics, making them a top choice for various industries. From automotive components to architectural hardware, casting zinc alloys offers a combination of strength, durability, and versatility that is hard to match with other materials.

Zinc alloys are known for their excellent dimensional stability, allowing for intricate and precise detailing in the die-casting process. This level of precision is crucial for industries such as electronics and telecommunications, where small, complex components are required to function flawlessly. The ability to achieve tight tolerances and intricate designs with zinc alloys makes them a top choice for manufacturers looking to produce high-quality, reliable products.

Precision and Detail

Regarding precision and detail in die casting, Buttler Precision Machinery stands out as a leader in the industry. With years of expertise in creating high-quality die-casting molds, they ensure every product is crafted with intricate detail and accuracy. Their commitment to excellence is evident in their ability to easily produce flawless aluminum and zinc castings that meet the most demanding specifications.

Buttler Precision Machinery's Expertise in Die-Casting Molds

Buttler Precision Machinery's extensive knowledge and experience in die-casting molds set them apart from the competition. Their skilled professionals use advanced techniques to create molds that result in superior die-cast zinc products. By focusing on precision and attention to detail, they consistently deliver exceptional quality that exceeds expectations.

Intricate Aluminum and Zinc Castings

Zinc alloys offer a powerful combination of benefits for die casting, making them a popular choice across industries.

- Strength and Versatility: Zinc alloys provide exceptional strength and can be cast into intricate shapes, making them ideal for various applications.

- Unmatched Precision: Die casting with zinc alloys delivers precise results, ensuring consistent quality for small and complex parts.

- Excellent Corrosion Resistance: Zinc alloys resist corrosion remarkably well, allowing cast parts to maintain their structural integrity and visual appeal even in harsh environments.

From architectural elements to automotive components and consumer electronics, zinc alloy die casting offers a durable and aesthetically pleasing solution.

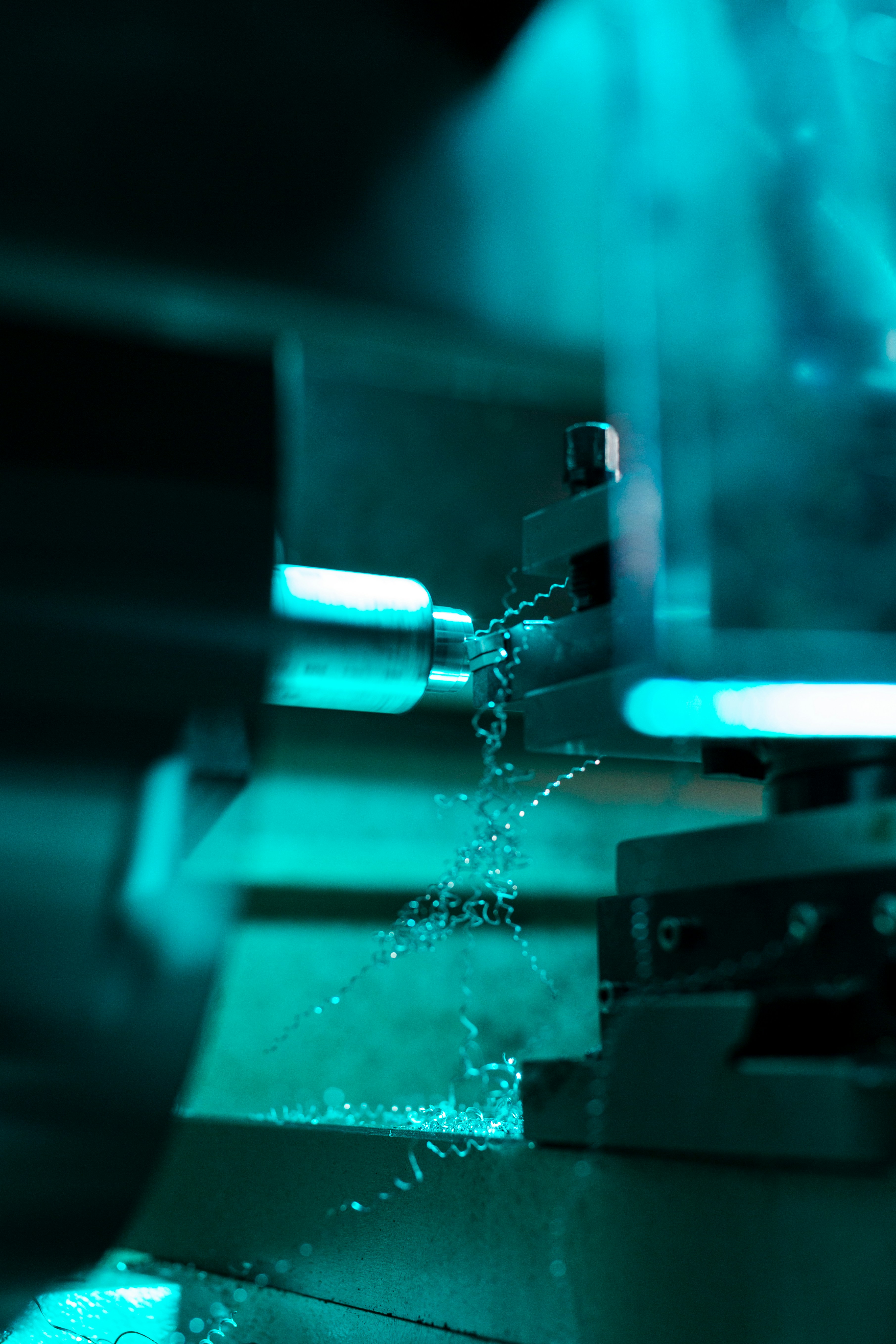

State-of-the-Art CNC Machines for Precision

Buttler Precision Machinery's investment in state-of-the-art CNC machines ensures precision and leads to cost-effective production. Utilizing these advanced machines can minimize material waste and reduce the need for manual labor, resulting in efficient and economical manufacturing processes. This ultimately translates to competitive pricing for their high-quality die-cast zinc products, making them an attractive option for businesses looking to optimize their production costs without compromising quality.

Cost-Effective Production

When it comes to cost-effective production, die-cast zinc offers unparalleled value. The efficient processing of zinc alloy material ensures that production runs smoothly without unnecessary delays. This means manufacturers can save time and money while still achieving high-quality results.

Efficient Processing of Zinc Alloy Material

Efficient processing of zinc alloy material is crucial for maintaining cost-effectiveness in production. Die-cast zinc allows for quick and precise molding, resulting in minimal material waste and maximum productivity. This streamlined process ensures manufacturers can meet demand without sacrificing quality or efficiency.

Streamlined Surface Treatment Techniques

In addition to efficient processing, streamlined surface treatment techniques further contribute to the cost-effectiveness of die-cast zinc production. By minimizing the need for additional finishing processes, manufacturers can reduce the time and expenses associated with post-casting treatments, ultimately leading to a more economical and sustainable manufacturing approach.

Value-Added Assembly and Packaging Services

To top it off, value-added assembly and packaging services add another layer of cost-effectiveness to die-cast zinc production. Manufacturers can streamline their supply chain and reduce overall operational costs by offering comprehensive solutions under one roof. This integrated approach saves money and ensures a seamless transition from production to market.

Furthermore, value-added assembly and packaging services contribute to environmental sustainability by minimizing waste and reducing the carbon footprint of die-cast zinc production. By optimizing packaging materials and streamlining assembly processes, manufacturers can minimize the use of resources and energy, ultimately leading to a more eco-friendly production cycle. This commitment to environmental responsibility benefits the planet and enhances manufacturers' reputation as socially conscious and environmentally aware entities.

Environmental Benefits

Sustainable Zinc Die Casting Process

At Buttler Precision Machinery, we prioritize sustainability in our die-casting process. Our state-of-the-art facilities are designed to minimize energy consumption and reduce emissions, making zinc die casting an environmentally friendly manufacturing option. By utilizing sustainable practices, we ensure that our die-cast zinc products have minimal environmental impact.

Eco-Friendly Zinc Alloy Material

Zinc alloys used in die casting are inherently eco-friendly, as they are fully recyclable without losing properties. This means the same zinc alloy material can be melted down and reused multiple times, reducing the need for new raw materials and minimizing waste. Choosing zinc alloys for your manufacturing needs is a sustainable choice that aligns with environmental responsibility.

Reduced Waste

by Casting Zinc

Die-cast zinc production generates minimal waste due to its precision and efficiency. The ability to produce complex shapes with minimal material usage results in fewer scrap and offcuts than other manufacturing methods. This not only reduces waste but also lowers the environmental impact of the production process as a whole.

Now that you understand the environmental benefits of using die-cast zinc and zinc alloys, let's explore how these materials offer cost-effective solutions for your manufacturing needs!

Versatile Applications

Zinc alloys are incredibly versatile and find applications in various industries. From automotive parts to electronic components, die-cast zinc is the material of choice for its superior strength and durability. Its ability to be molded into complex shapes makes it ideal for intricate designs and detailed parts.

Wide Range of Zinc Alloy Material Uses

Die-cast zinc is used in the production of various products, including door handles, gears, and even musical instruments. Its exceptional dimensional stability and corrosion resistance make it a popular choice for decorative hardware and architectural fittings. The versatility of zinc alloys allows for endless possibilities in design and functionality.

Diverse Industries Benefiting from

Die-Cast Zinc

The automotive industry heavily relies on zinc alloy die casting to manufacture components such as carburetor housings, transmission cases, and brackets. Additionally, the electronics industry benefits from die-cast zinc's excellent electrical conductivity properties in producing connectors, adapters, and other electronic enclosures.

Endless Possibilities with Zinc Alloys

Zinc alloys are a popular choice for various industries due to their unique casting properties. Here are some of the key benefits of using zinc alloys:

- Tight Tolerances: Zinc alloys can be cast with minimal machining, making them ideal for precision components where accuracy is critical. This translates to less waste and lower production costs.

- Versatility: Zinc alloys can be diecast, machined, stamped, and formed, allowing for various applications in different industries. From car parts to medical devices, zinc alloys offer flexibility for many designs.

- Strength and Durability: Although lightweight, zinc alloys offer good strength and dimensional stability. This makes them a suitable choice for parts that must be strong and hold their shape over time.

- Corrosion Resistance: Zinc can be plated or coated for enhanced corrosion resistance in various environments. This makes them ideal for applications where exposure to the elements is a concern.

- Cost-Effectiveness: Zinc is a relatively inexpensive material, making it a cost-effective choice for many applications. This advantage allows manufacturers to keep production costs down.

Zinc alloys offer unique properties that make them valuable for various applications. Their versatility, strength, and affordability make them a go-to material for many industries.

Unlock the Potential of Zinc Alloy Material

Empowering Manufacturing with Zinc Alloys

At Buttler Precision Machinery, we believe in the power of zinc alloys to revolutionize manufacturing. With their superior strength, durability, and precision, zinc die casting is the key to unlocking new possibilities in various industries.

Buttler Precision Machinery's Leading Role in Zinc Die Casting

As a leading expert in zinc die casting, Buttler Precision Machinery is dedicated to delivering high-quality products and exceptional service. Our state-of-the-art facilities and expertise in die-casting molds ensure that we remain at the forefront of the industry.

Zinc alloys offer endless potential for innovation and creativity. From sustainable production methods to versatile applications, casting zinc can transform ideas into reality, making it an invaluable resource for manufacturers worldwide.