Introduction

Tesla Giga Casting has revolutionized the automotive industry with its innovative manufacturing process. Giga casting is a game-changer in car production, and Tesla has embraced this technology to enhance performance and durability. Buttler's expertise in die-casting molds and specialization in aluminum and zinc casting make them an invaluable partner in this exciting venture.

Understanding Tesla Giga Casting

Giga casting at Tesla involves the use of massive machines called giga presses to create large, single-piece parts for their vehicles. This groundbreaking approach allows for stronger, more durable components that contribute to the overall performance and safety of the cars. Moreover, giga casting reduces the need for welding and joining multiple smaller parts, which can weaken the structure and increase production time. By streamlining the manufacturing process, Tesla is able to produce vehicles with improved structural integrity and efficiency.

Importance of Giga Casting in Automotive Industry

The significance of giga casting in the automotive industry cannot be overstated. It enables car manufacturers like Tesla to streamline production, reduce costs, and enhance the quality of their vehicles. This cutting-edge technology is shaping the future of car manufacturing.

Giga casting is revolutionizing the automotive industry by allowing for the production of larger, more complex parts in a single piece, reducing the need for welding and assembly. This not only saves time but also improves the structural integrity of the vehicle, making it safer for drivers and passengers. Additionally, giga casting technology allows for greater design flexibility, enabling car manufacturers to create sleeker, more aerodynamic vehicles that are also more fuel-efficient.

Buttler's Expertise in Die-Casting Molds

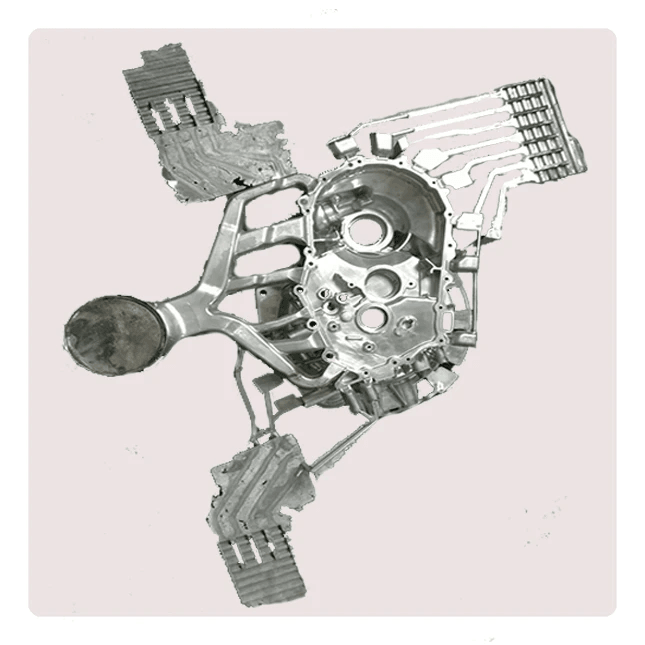

Ningbo Buttler Precision Machinery Co., Ltd.'s specialization in die-casting molds, aluminum, and zinc castings makes them a key player in the giga casting landscape. Their smart part engineering approach ensures that parts are designed for optimal performance and cost-effective manufacturing.

Ningbo Buttler Precision Machinery Co., Ltd.'s expertise in die-casting molds extends to their innovative approach to material selection, ensuring that the final products meet the highest quality standards. By utilizing advanced technologies and precision engineering, they are able to produce complex and intricate molds that are essential for the giga casting industry. Their commitment to continuous improvement and staying ahead of industry trends positions them as a reliable partner for companies seeking high-quality die-casting solutions.

What is Tesla Giga Casting?

Tesla Giga Casting is a groundbreaking manufacturing process that has revolutionized car production. With the use of giant die-casting machines known as Giga Presses, Tesla has been able to create large, single-piece components for their vehicles, eliminating the need for multiple smaller parts and welding. This innovative method allows for faster production and improved structural integrity in automotive manufacturing.

The Revolution of Giga Casting in Car Production

The introduction of Giga Casting by Tesla has marked a significant shift in the automotive industry, as it enables the creation of large, complex parts with unprecedented speed and efficiency. Traditional manufacturing methods often involve welding together multiple smaller components, leading to potential weaknesses and increased production time. However, Giga Casting streamlines the process by producing single-piece parts that are both lighter and stronger.

Giga Casting also reduces the need for extensive machining and assembly, further streamlining the production process and reducing overall costs. This innovative method allows for the creation of intricate designs that were previously impossible to manufacture in a single piece, opening up new possibilities for car designers and engineers. Additionally, the use of Giga Casting significantly reduces material waste, making it a more sustainable option for car production.

Giga Casting Process Explained

The Giga Casting process involves using massive die-casting machines to mold molten metal into intricate shapes with extreme precision. These machines can exert immense pressure to ensure that the castings are free from defects and have consistent mechanical properties throughout the entire part. By employing this advanced technique, Tesla has been able to produce critical components such as chassis structures and battery enclosures for their electric vehicles.

The Giga Casting process has revolutionized the production of complex metal components for electric vehicles. With the ability to mold molten metal into intricate shapes with extreme precision, these massive die-casting machines have allowed Tesla to achieve unparalleled quality and consistency in their critical components. The immense pressure exerted by these machines ensures that the castings are free from defects, providing a level of reliability that is crucial for the safety and performance of electric vehicles.

Smart Part Engineering for Giga Casting Quality

In order to achieve high-quality results with Giga Casting, smart part engineering plays a crucial role in optimizing designs for cost-effective manufacturing while maintaining superior performance and durability. This involves leveraging innovative tooling designs engineered by experts like Ningbo Buttler Precision Machinery Co., Ltd., who specialize in die-casting molds and aluminum/zinc castings. Their expertise ensures that each component is produced with maximum efficiency and casting quality, reducing the need for secondary operations.

By utilizing smart part engineering for Giga Casting, manufacturers can also benefit from reduced material waste and improved sustainability. The precise design optimization and efficient production processes result in minimal scrap and energy consumption, contributing to a more environmentally friendly manufacturing approach. This aligns with the growing demand for sustainable practices in the automotive industry, further enhancing the appeal of Giga Casting for companies like Tesla.

Benefits of Tesla Giga Casting

Tesla Giga Casting offers a range of benefits that revolutionize car production. Enhanced performance and durability are key advantages of Giga Casting, as it allows for stronger and more resilient automotive parts. The innovative process also enables cost-effective manufacturing, making it a game-changer in the automotive industry. Buttler's specialization in aluminum and zinc casting further enhances the quality and efficiency of Giga Casting, ensuring top-notch results.

Enhanced Performance and Durability

Giga Casting by Tesla ensures that automotive parts are built to last, with enhanced performance and durability. This revolutionary process allows for the creation of stronger, more resilient components that can withstand the rigors of daily use on the road. With Tesla's focus on innovation and quality, Giga Casting sets a new standard for automotive part production.

Giga Casting by Tesla not only enhances the performance and durability of automotive parts but also offers a cost-effective manufacturing solution. By streamlining the production process and reducing the need for multiple smaller components, Giga Casting helps to lower overall production costs. This means that customers can benefit from high-quality, long-lasting parts without breaking the bank.

Cost-Effective Manufacturing with Giga Casting

One of the most significant benefits of Tesla Giga Casting is its cost-effectiveness in manufacturing. By streamlining the production process and eliminating the need for secondary operations, Giga Casting reduces overall manufacturing costs while maintaining high-quality standards. This makes it an attractive option for automakers looking to optimize their production processes.

Furthermore, Giga Casting technology allows for the production of larger and more complex parts in a single piece, reducing the need for assembly and welding. This not only saves time but also minimizes the risk of defects and inconsistencies that can arise from joining multiple smaller components. As a result, automakers can enjoy greater efficiency and reliability in their manufacturing processes, ultimately leading to cost savings and improved product quality.

Buttler's Specialization in Aluminium & Zinc Casting

Ningbo Buttler Precision Machinery Co., Ltd.'s expertise in die-casting molds, aluminum, and zinc castings plays a crucial role in enhancing the benefits of Tesla Giga Casting. Their specialization ensures that the casting process is optimized for maximum efficiency and quality, aligning perfectly with Tesla's commitment to excellence in automotive part production.

Tesla's Innovation with Giga Casting

Tesla has been at the forefront of innovation in automotive part design, particularly with their revolutionary use of Giga Casting. By leveraging this cutting-edge technology, Tesla has been able to create intricate and durable parts that were previously unattainable through traditional manufacturing methods. The ability to produce larger and more complex components has allowed for advancements in vehicle performance and safety.

Advancements in Automotive Part Design

With Giga Casting, Tesla has been able to push the boundaries of automotive part design, creating components that are not only lighter and stronger but also more efficient in terms of production. This innovative approach has opened up new possibilities for vehicle design, allowing for greater flexibility and creativity in engineering solutions. In addition to the benefits of Giga Casting, Tesla's use of Giga Presses has further maximized efficiency in part production. These massive machines have the capability to rapidly produce large components with minimal waste, reducing both cost and environmental impact.

Maximizing Efficiency with Giga Presses

Tesla currently operates several Giga Presses across its manufacturing facilities, enabling the company to maximize efficiency in producing large-scale castings for their vehicles. These state-of-the-art machines allow for rapid production cycles and precise control over the casting process, resulting in high-quality components that meet Tesla's exacting standards.

Furthermore, the use of Giga Presses allows Tesla to reduce the number of parts needed for their vehicles, simplifying the manufacturing process and minimizing potential points of failure. This streamlined approach not only enhances efficiency but also contributes to overall cost savings and sustainability efforts. By investing in cutting-edge technology like Giga Presses, Tesla continues to set the standard for innovation in the automotive industry.

Ningbo Buttler Precision Machinery Co., Ltd.'s Role in Giga Casting

Ningbo Buttler Precision Machinery Co., Ltd. plays a crucial role in supporting Tesla's Giga Casting initiatives by providing expertise in die-casting molds, aluminum and zinc castings, processing, surface treatment, assembly, and packaging. Their smart part engineering approach aligns perfectly with Tesla's commitment to quality and innovation, making them an invaluable partner in the advancement of Giga Casting technology.

Ningbo Buttler Precision Machinery Co., Ltd. has also demonstrated a strong commitment to sustainability, aligning with Tesla's mission to create a more sustainable future. By utilizing advanced manufacturing processes and materials, Buttler Precision Machinery Co., Ltd. is able to minimize waste and energy consumption, ultimately reducing the environmental impact of Giga Casting production. This shared dedication to sustainability further solidifies their partnership and contributes to the overall success of Tesla's Giga Casting initiatives.

Conclusion

As Tesla continues to revolutionize the automotive industry with its innovative giga casting technology, the future of car production is set to be transformed. With multiple giga presses in operation, Tesla is leading the way in efficient and cost-effective manufacturing processes. The advancements made by Tesla in giga casting are truly groundbreaking and are sure to set new standards for the industry.

The Future of Giga Casting in Car Production

The future of giga casting in car production looks promising, with Tesla's pioneering efforts paving the way for enhanced performance and durability in automotive parts. As more companies adopt this revolutionary technology, we can expect to see a significant shift towards more efficient and cost-effective manufacturing processes, ultimately benefitting both manufacturers and consumers.

Tesla's innovations in giga casting have not only improved the performance and durability of automotive parts but have also set a new standard for sustainability in car production. By utilizing advanced materials and manufacturing techniques, Tesla has been able to reduce waste and energy consumption, leading the way for a more environmentally friendly approach to vehicle manufacturing. As other companies follow suit, we can anticipate a significant reduction in the carbon footprint of the automotive industry as a whole, aligning with global efforts to combat climate change.

Innovations by Tesla in Giga Casting

Tesla's innovations in giga casting have redefined the way automotive parts are designed and manufactured. By maximizing efficiency with their state-of-the-art giga presses, Tesla has set new benchmarks for quality and performance in car production. Their commitment to pushing boundaries and embracing cutting-edge technologies is truly commendable.

Tesla's commitment to innovation is evident in their partnership with Buttler for giga casting excellence. By collaborating with industry leaders, Tesla is reinforcing their dedication to staying at the forefront of automotive manufacturing. This strategic alliance not only enhances Tesla's capabilities but also sets a new standard for the entire automotive industry, inspiring other companies to prioritize technological advancements and efficiency in their production processes.

Partnering with Buttler for Giga Casting Excellence

In order to achieve excellence in giga casting, partnering with a specialized company like Ningbo Buttler Precision Machinery Co., Ltd. can make all the difference. With their expertise in die-casting molds, aluminum and zinc castings, as well as smart part engineering for cost-effective manufacturing, Buttler is well-positioned to support companies looking to leverage the benefits of giga casting technology.