Introduction

Are you curious about the zinc die casting process and its role in metal casting? Look no further! In this article, we will explore the advantages of zinc alloy in die casting, as well as the expertise of Ningbo Buttler Precision Machinery Co., Ltd. in this field.

Understanding the Zinc Die Casting Process

Zinc die casting is a metal casting process that utilizes zinc alloy to create intricate and detailed parts with high precision. This process involves injecting molten zinc into die casting dies at high pressure, resulting in durable and lightweight parts suitable for a wide range of applications.

Smart Part Engineering for Better Part Designs

Smart part engineering is crucial for achieving better part designs in zinc die casting. By leveraging innovative tooling designs engineered for cost-effective manufacturing, manufacturers can maximize performance and casting quality while minimizing the need for secondary operations.

The Expertise of Ningbo Buttler Precision Machinery Co., Ltd.

Ningbo Buttler Precision Machinery Co., Ltd. specializes in die-casting molds, aluminum and zinc castings, processing, surface treatment, assembly, and packaging. With their expertise in smart part engineering and innovative tooling designs, they are dedicated to elevating manufacturing standards with zinc alloy metal.

The Advantages of Zinc Die Casting

Zinc die casting process offers numerous advantages in metal casting, making it a popular choice for manufacturing various parts and components. One of the key benefits is the use of lightweight and durable zinc alloy, which ensures that the final products are strong and long-lasting. The zinc metal's properties make it an ideal material for producing parts that require high strength and durability, making it a preferred choice in many industries.

Lightweight and Durable Zinc Alloy

The use of zinc alloy in die casting results in lightweight yet robust parts, making it suitable for a wide range of applications. Its durability ensures that the finished products can withstand harsh conditions and heavy usage, making it an excellent choice for manufacturing high-quality components. With its exceptional strength-to-weight ratio, zinc alloy is an ideal material for producing parts that require both durability and lightness.

Furthermore, the precision and tight tolerances that can be achieved with zinc alloy die casting make it an ideal choice for producing intricate and complex parts. This level of accuracy ensures that the finished products meet the exact specifications required, making them suitable for use in a wide variety of industries. Whether it's automotive components or electronic devices, zinc alloy's ability to maintain tight tolerances makes it a versatile and reliable material for manufacturing high-quality parts.

Precision and Tight Tolerances

Another advantage of zinc die casting is its ability to achieve precision and tight tolerances in the production of parts. This means that intricate designs and complex shapes can be accurately replicated with minimal variation, ensuring consistent quality across all manufactured components. The use of die casting dies allows for precise control over dimensions, resulting in parts that meet strict specifications with minimal deviation.

Furthermore, the precision and tight tolerances achieved through zinc die casting also contribute to cost-effective manufacturing techniques. With minimal variation in replicated parts, there is less need for rework or adjustments, reducing overall production time and costs. This efficiency allows for faster turnaround times and increased productivity, making zinc die casting a highly economical choice for manufacturing complex components.

Cost-Effective Manufacturing Techniques

Zinc die casting also offers cost-effective manufacturing techniques due to its ability to produce high volumes of complex parts at a rapid pace. The process requires minimal post-production finishing, reducing overall production costs while maintaining superior quality. This makes zinc die casting an efficient and economical option for producing a wide variety of components across different industries.

Furthermore, the versatility of zinc die casting allows for the production of intricate and detailed parts that may be difficult or costly to manufacture using other methods. This makes it an ideal choice for industries such as automotive, electronics, and consumer goods where complex components are often required. The ability to produce high-quality parts at a rapid pace also makes zinc die casting a preferred option for meeting tight production deadlines and maintaining a competitive edge in the market.

Applications of Zinc Die Casting

Zinc die casting process is widely used in various industries for its versatility and durability. Automotive parts such as engine brackets, door handles, and transmission components benefit from the lightweight and high-strength properties of zinc alloy metal. Gas appliance parts like burner heads, valve bodies, and regulator housings are also commonly produced using zinc die casting due to its corrosion resistance and intricate design capabilities. Power tool parts such as drill housings, gear cases, and motor frames take advantage of the precision and tight tolerances offered by zinc die casting to ensure optimal performance.

Automotive Parts

The zinc die casting process has revolutionized the manufacturing of automotive parts by providing lightweight yet durable components essential for vehicle performance. With Ningbo Buttler Precision Machinery Co., Ltd.'s expertise in aluminum metal casting and innovative tooling designs, automotive manufacturers can achieve superior part designs that maximize performance while minimizing production costs.

Gas Appliance Parts

Gas appliance manufacturers rely on zinc die casting to produce complex components with precision and efficiency. Ningbo Buttler Precision Machinery Co., Ltd.'s specialization in die-casting molds and surface treatment ensures that gas appliance parts meet strict quality standards while maintaining cost-effectiveness in manufacturing processes. With a focus on innovation, our company continuously invests in advanced technology and equipment to enhance production capabilities and stay ahead of market demands. This commitment to staying at the forefront of industry trends allows us to offer gas appliance manufacturers cutting-edge solutions for their component needs.

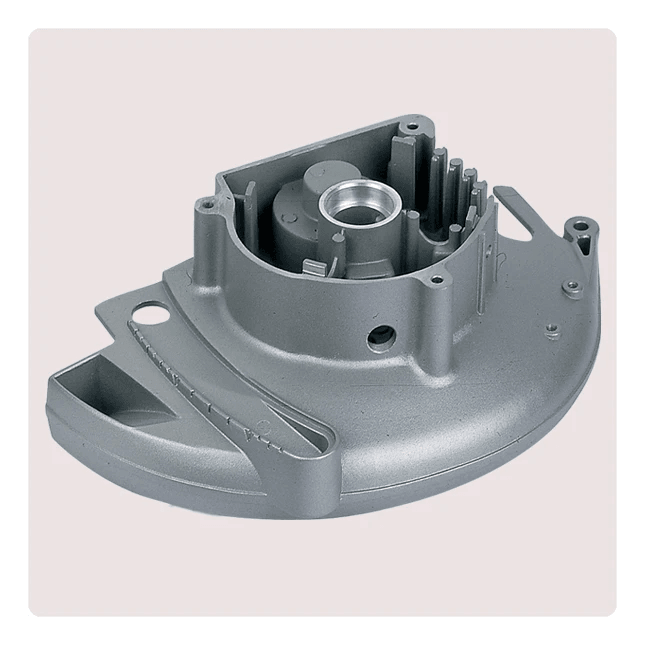

Power Tool Parts

The use of zinc alloy in power tool parts has become increasingly popular due to its ability to withstand heavy-duty applications without compromising on accuracy or strength. Ningbo Buttler Precision Machinery Co., Ltd.'s expertise in processing zinc metal ensures that power tool manufacturers can achieve reliable and high-performing components that meet the demands of modern industry standards.

Ningbo Buttler Precision Machinery Co., Ltd. also prides itself on its commitment to innovation and continuous improvement. By staying ahead of the curve in terms of technology and manufacturing processes, the company ensures that power tool manufacturers have access to cutting-edge solutions that enhance the performance and durability of their products. This dedication to advancement sets Ningbo Buttler Precision Machinery Co., Ltd. apart as a leader in the industry, providing invaluable support to clients seeking to stay competitive in a rapidly evolving market.

The Role of Ningbo Buttler Precision Machinery Co., Ltd.

Specialization in Die-Casting Molds

Ningbo Buttler Precision Machinery Co., Ltd. is renowned for its specialization in creating high-quality die-casting molds for zinc and aluminum metal casting. Our expert team ensures that each mold is designed and manufactured with precision to meet the exact specifications of our clients, guaranteeing superior results in the zinc die casting process.

Our die-casting molds are designed to withstand high temperatures and pressures, ensuring consistent and precise casting results. We utilize advanced technology and innovative techniques to create molds that are durable and long-lasting, reducing the need for frequent replacements. With our commitment to excellence, we have earned a reputation for delivering top-notch die-casting molds that exceed industry standards.

Quality Aluminum and Zinc Castings

At Ningbo Buttler, we take pride in producing top-notch aluminum and zinc castings that are lightweight, durable, and exhibit exceptional dimensional accuracy. Our commitment to quality extends to every stage of the manufacturing process, ensuring that our clients receive only the best zinc alloy metal parts for their applications.

Our expertise in processing and surface treatment sets us apart from the competition. We utilize advanced technology and techniques to ensure that our aluminum and zinc castings meet the highest industry standards. From precision machining to superior finishing, we go above and beyond to deliver flawless metal parts that exceed our clients' expectations.

Expertise in Processing and Surface Treatment

Our expertise in processing and surface treatment sets us apart as leaders in the industry of metal casting. We employ advanced techniques to ensure that each zinc die casting meets the highest standards of quality, strength, and corrosion resistance. By paying meticulous attention to detail during surface treatment, we guarantee a flawless finish for every part.

Our commitment to excellence extends beyond just meeting industry standards. We continuously invest in research and development to explore new processing and surface treatment techniques, allowing us to stay at the forefront of innovation in zinc die casting. This dedication to pushing boundaries enables us to offer our customers cutting-edge solutions that are not only high-quality but also environmentally sustainable, positioning us as pioneers in the industry.

Revolutionizing Manufacturing with Zinc Die Casting

The zinc die casting process revolutionizes manufacturing by maximizing performance and casting quality. With its lightweight and durable zinc alloy, Ningbo Buttler Precision Machinery Co., Ltd. specializes in producing high-quality zinc metal castings that meet tight tolerances and offer exceptional performance in various applications.

Maximizing Performance and Casting Quality

By utilizing the zinc die casting process, manufacturers can achieve superior part designs that maximize performance and casting quality. The expertise of Ningbo Buttler Precision Machinery Co., Ltd. ensures that each zinc alloy metal casting meets the highest standards for durability, precision, and functionality.

By utilizing the zinc die casting process, manufacturers can achieve superior part designs that maximize performance and casting quality. The expertise of Ningbo Buttler Precision Machinery Co., Ltd. ensures that each zinc alloy metal casting meets the highest standards for durability, precision, and functionality. This means that our clients can minimize the need for secondary operations, saving time and resources in the production process. With our high-quality zinc die castings, manufacturers can rely on parts that require minimal finishing or machining, streamlining their operations and reducing costs.

Minimizing the Need for Secondary Operations

One of the key advantages of zinc die casting is its ability to minimize the need for secondary operations. This cost-effective manufacturing technique reduces production time and labor costs, allowing for efficient mass production of high-quality zinc metal parts without compromising on quality or performance.

Zinc die casting also allows for the creation of complex shapes and intricate designs, eliminating the need for additional machining or assembly. This streamlined process not only saves time and money but also ensures a higher level of precision and consistency in the final product. By minimizing the need for secondary operations, manufacturers can deliver zinc metal parts that meet tight tolerances and exact specifications, meeting the demands of various industries such as automotive, electronics, and consumer goods.

Innovative Tooling Designs for Cost-Effective Manufacturing

Ningbo Buttler Precision Machinery Co., Ltd.'s smart part engineering approach includes innovative tooling designs that are engineered to optimize the manufacturing process. These designs not only enhance casting quality but also contribute to cost-effective production, making them an invaluable asset in revolutionizing manufacturing with zinc die casting.

Furthermore, these innovative tooling designs are tailored to meet the specific needs of different industries, ensuring that the manufacturing process is optimized for each unique application. By incorporating advanced technologies and materials, Ningbo Buttler Precision Machinery Co., Ltd. is able to offer tooling designs that not only improve efficiency but also extend the lifespan of the equipment, ultimately reducing maintenance costs and downtime for manufacturers.

Conclusion

The future of metal casting looks bright with the zinc die casting process leading the way. This innovative technique offers lightweight and durable zinc alloy parts, precision and tight tolerances, and cost-effective manufacturing techniques. Elevating manufacturing standards with zinc alloy is the key to superior parts, and Ningbo Buttler Precision Machinery Co., Ltd. is at the forefront of this revolution.

The Future of Metal Casting: Zinc Die Casting Process

The zinc die casting process is set to revolutionize metal casting, offering unmatched advantages in terms of lightweight and durable parts, precision, and cost-effectiveness. As manufacturers continue to explore new ways to improve part designs and manufacturing techniques, zinc die casting is expected to play a pivotal role in shaping the future of metal casting.

Elevating Manufacturing Standards with Zinc Alloy

Zinc alloy has emerged as a game-changer in the manufacturing industry, offering a perfect balance of strength, durability, and cost-effectiveness. By elevating manufacturing standards with zinc alloy, manufacturers can produce high-quality parts that meet the demands of various industries while remaining cost-effective.

The Key to Superior Parts: Ningbo Buttler Precision Machinery Co., Ltd.

Ningbo Buttler Precision Machinery Co., Ltd.'s expertise in die-casting molds, aluminum and zinc castings, processing, surface treatment, assembly, and packaging makes them an invaluable partner in achieving superior parts through zinc die casting. Their smart part engineering approach ensures better part designs for maximum performance and quality while minimizing secondary operations.