Introduction

When it comes to upgrading your vehicle, the choice of wheels can make a significant impact on its performance and aesthetics. Forged aluminum wheels have gained popularity in the automotive industry due to their numerous advantages over traditional cast aluminum wheels. From enhanced strength to better customization options, forged aluminum wheels offer a range of benefits that are worth considering for any vehicle owner.

The Advantages of Forged Aluminum Wheels

One of the key advantages of forged aluminum wheels is their superior strength and durability. These wheels are known for being lightweight yet incredibly strong, making them ideal for high-performance vehicles and off-road use. Additionally, forged aluminum wheels are resistant to corrosion, ensuring longevity and reliability even in harsh driving conditions.

The Downsides of Forged Aluminum Wheels

While there are many benefits to using forged aluminum wheels, it's important to consider some potential downsides as well. One drawback is the initial investment required for these premium wheels, which may be higher compared to traditional cast aluminum options. Additionally, the manufacturing process for forged aluminum wheels can be more complex and time-consuming.

Forged vs Cast Aluminum Wheels: A Comparison

When comparing forged vs cast aluminum wheels, it's clear that each type has its own set of pros and cons. While cast aluminum wheels may be more affordable and easier to produce, they often lack the strength and performance capabilities of their forged counterparts. This comparison highlights the importance of carefully evaluating your specific needs and preferences when choosing the right type of wheel for your vehicle.

Durability and Strength

When it comes to durability and strength, forged aluminum wheels are unmatched in the industry. These wheels are incredibly lightweight, making them ideal for high-performance vehicles without sacrificing strength. The forging process creates a more uniform grain structure, resulting in wheels that can withstand heavy loads and intense driving conditions.

Lightweight Yet Strong

Forged aluminum wheels are known for their exceptional strength-to-weight ratio, providing a perfect balance of durability and performance. The forging process compacts the aluminum molecules, creating a denser material that is stronger than cast aluminum. This allows for lighter wheels that can handle the demands of aggressive driving styles while improving overall vehicle dynamics.

Forged aluminum wheels also offer excellent resistance to corrosion, making them a great choice for all-weather driving conditions. The compacted aluminum molecules create a denser and more uniform surface that is less susceptible to rust and deterioration. This means that your wheels will maintain their sleek appearance and structural integrity for longer, even in harsh environments or when exposed to road salt and other corrosive substances.

Resistance to Corrosion

One of the key advantages of forged aluminum wheels is their resistance to corrosion. The forging process creates a more solid and dense structure that is less susceptible to corrosion compared to cast aluminum wheels. This makes them an ideal choice for drivers in regions with harsh weather conditions or those who want long-lasting performance from their wheels.

Additionally, the resistance to corrosion of forged aluminum wheels means that they require less maintenance and upkeep compared to other types of wheels. This can save drivers time and money in the long run, as they won't need to worry about frequent cleaning or repairs due to corrosion. With forged aluminum wheels, drivers can enjoy peace of mind knowing that their wheels will continue to perform well and look great for years to come.

Impact Resistance

Forged aluminum wheels are designed to withstand impacts and shocks better than cast aluminum wheels. The forging process aligns the grain structure of the metal, resulting in increased impact resistance and overall durability. This makes them an excellent choice for off-road or heavy-duty applications where impacts are common.

Forged aluminum wheels are not only more resistant to impacts and shocks, but they also offer better overall performance due to their lighter weight. The forging process allows for a more precise control over the thickness of the wheel, resulting in a lighter and stronger product. This means improved acceleration, braking, and handling, making them an ideal choice for performance-oriented vehicles.

Performance and Efficiency

When it comes to performance, forged aluminum wheels offer a significant advantage over their cast counterparts. The superior strength-to-weight ratio of forged aluminum wheels allows for better acceleration, handling, and overall vehicle performance. With reduced unsprung weight, these wheels provide enhanced agility and responsiveness on the road.

Enhanced Performance

Forged aluminum wheels are known for their ability to improve a vehicle's performance in various ways. The lightweight nature of these wheels reduces rotational mass, resulting in quicker acceleration and improved handling. This translates to a more dynamic driving experience, especially during high-speed maneuvers and cornering.

Additionally, forged aluminum wheels have superior heat dissipation properties compared to traditional steel wheels. This means that they are better equipped to handle the intense heat generated during high-speed driving, reducing the risk of brake fade and ensuring consistent performance. With improved heat dissipation, drivers can push their vehicles to the limit without worrying about overheating components, providing a more reliable and exhilarating driving experience.

Better Heat Dissipation

One of the key benefits of using forged aluminum wheels is their superior heat dissipation properties. As the wheels conduct heat away from the brakes more effectively than cast aluminum wheels, they help prevent brake fade during intense driving conditions. This results in better braking performance and increased safety on the road.

In addition to improving safety, the superior heat dissipation properties of forged aluminum wheels also contribute to better fuel efficiency. By reducing the risk of brake fade, drivers are able to maintain consistent braking performance without having to compensate for decreased effectiveness. This means less energy is wasted during driving, resulting in improved fuel economy and reduced environmental impact. With forged aluminum wheels, drivers can enjoy both enhanced safety and cost savings at the gas pump.

Fuel Efficiency

In addition to enhancing performance, forged aluminum wheels also contribute to improved fuel efficiency. The reduced weight of these wheels means less energy is required to propel the vehicle forward, leading to better gas mileage. This not only saves money at the pump but also reduces environmental impact by lowering carbon emissions.

Furthermore, the reduced weight of forged aluminum wheels also leads to improved handling and maneuverability. With less mass to slow down or change direction, drivers can enjoy a more responsive and agile driving experience. This not only enhances the overall performance of the vehicle but also contributes to a safer and more enjoyable ride for passengers.

By choosing forged aluminum truck wheels from reputable manufacturers like Ningbo Buttler Precision Machinery Co., Ltd., drivers can experience a significant boost in performance and efficiency while enjoying long-lasting durability and stylish aesthetics.

Cost and Maintenance

When it comes to the initial investment, forged aluminum wheels may seem pricier than their cast counterparts. However, the superior strength and durability of forged aluminum wheels make them a smart long-term investment. With their resistance to corrosion and impact, they are less likely to require replacement or repairs, ultimately saving you money in the long run.

Initial Investment

While the upfront cost of purchasing forged aluminum wheels may be higher compared to cast aluminum wheels, it's important to consider the long-term benefits. The initial investment in forged aluminum wheels is justified by their exceptional durability and performance, making them a wise choice for vehicle owners who prioritize quality and longevity.

Long-Term Cost Savings

One of the key advantages of investing in forged aluminum wheels is the potential for long-term cost savings. Due to their superior strength and resistance to corrosion, these wheels are less likely to require frequent replacements or repairs, ultimately reducing maintenance expenses over time. This makes them a cost-effective choice for discerning vehicle owners looking for durable and reliable wheel options.

Maintenance Requirements

Forged aluminum wheels are known for their low maintenance requirements, thanks to their resistance to corrosion and impact. Unlike cast aluminum wheels that may be more prone to damage and wear over time, forged aluminum wheels typically require minimal upkeep, resulting in fewer maintenance costs for vehicle owners. This makes them an attractive option for those seeking hassle-free wheel maintenance.

Remember that when considering your options for new wheels or upgrades to your existing ones, it's essential to weigh both the initial investment and long-term cost savings associated with different types of wheels. With forged aluminum truck wheels from reputable manufacturers like Ningbo Buttler Precision Machinery Co., Ltd., you can enjoy high-quality craftsmanship that prioritizes both performance and durability while minimizing ongoing maintenance needs.

Customization and Aesthetics

When it comes to customization and aesthetics, forged aluminum wheels offer a wide range of options to suit every taste and style. Powder coating options allow for a durable and customizable finish, ensuring that your wheels can match the look of your vehicle perfectly. Whether you prefer a sleek matte black or a vibrant metallic color, the powder coating process provides endless possibilities for personalization.

Powder Coating Options

Powder coating forged aluminum wheels is an excellent way to enhance their appearance while also providing added protection against corrosion and wear. This process involves applying a dry powder to the surface of the wheels, which is then heated to create a smooth and durable finish. With a variety of colors and finishes available, powder coating allows for complete customization to achieve the desired look for your vehicle.

Unique Designs

Forged aluminum wheels also offer unique design options that can set your vehicle apart from the rest. From intricate spoke patterns to bold geometric shapes, there are endless possibilities for creating one-of-a-kind wheel designs that reflect your personal style. Whether you prefer a classic look or something more avant-garde, the flexibility of forged aluminum allows for truly distinctive designs.

Personalization Choices

In addition to powder coating and unique designs, forged aluminum wheels also offer various personalization choices such as custom engraving or branding options. This allows you to add a personalized touch to your wheels, whether it's with your initials, logo, or any other design element that reflects your individuality. With these customization options, you can truly make your wheels stand out on the road.

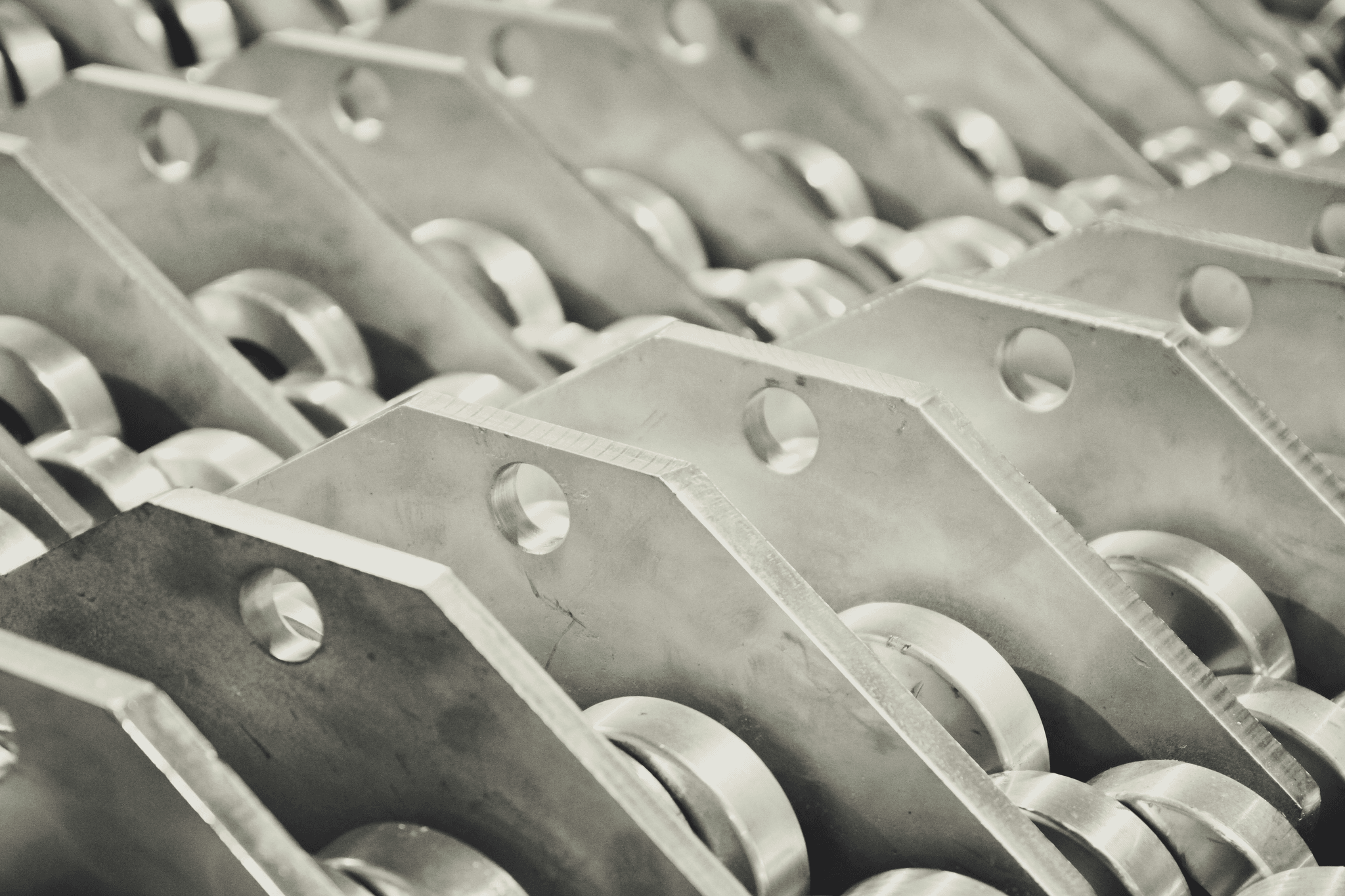

Manufacturing and Quality Control

When it comes to manufacturing high-quality forged aluminum wheels, Ningbo Buttler Precision Machinery Co., Ltd. is a top player in the industry. Specializing in die-casting molds and aluminum castings, they ensure that their products meet the highest standards of durability and performance. With a focus on precision engineering and cost-effective manufacturing, Buttler is dedicated to producing top-notch forged aluminum wheels for various applications.

Ningbo Buttler Precision Machinery Co., Ltd.

Ningbo Buttler Precision Machinery Co., Ltd. has built a strong reputation for producing reliable and durable forged aluminum wheels for a wide range of vehicles, from sports cars to heavy-duty trucks. Their expertise in die-casting molds and aluminum castings allows them to create wheels that are not only lightweight but also incredibly strong, making them an ideal choice for demanding driving conditions.

Smart Part Engineering

Smart Part Engineering is another key player in the production of high-quality forged aluminum wheels. Their innovative tooling designs are engineered for cost-effective manufacturing, maximizing performance and casting quality while minimizing the need for secondary operations. With their focus on efficient part designs, Smart Part Engineering ensures that their forged aluminum wheels meet the highest standards of strength and durability.

Quality Assurance Process

Both Ningbo Buttler Precision Machinery Co., Ltd. and Smart Part Engineering have rigorous quality assurance processes in place to guarantee that every forged aluminum wheel meets strict performance standards. From initial design review to final inspection, these companies are committed to delivering top-notch products that exceed customer expectations in terms of durability, strength, and overall performance.

Conclusion

When it comes to choosing the right wheels for your vehicle, forged aluminum wheels offer a winning combination of durability, performance, and customization options. With their lightweight yet strong construction, resistance to corrosion, and impact resistance, they are an excellent choice for any driver looking for long-term reliability. When considering your driving style, the enhanced performance and fuel efficiency of forged aluminum wheels make them a smart investment. And as the future of automotive technology continues to evolve, forged aluminum wheels are sure to remain a top choice for drivers looking to enhance both the aesthetics and performance of their vehicles.

Making the Right Choice for Your Vehicle

When making decisions about your vehicle's upgrades, it's important to consider all aspects of your driving experience. Forged aluminum wheels offer a wide range of benefits that can improve both the look and performance of your vehicle. With their durability and strength, as well as their customization options, they are an excellent choice for anyone looking to invest in their vehicle's long-term value.

Considerations for Your Driving Style

Your driving style plays a significant role in determining which type of wheels will best suit your needs. Whether you're a daily commuter or an off-road enthusiast, forged aluminum wheels can enhance your driving experience with improved performance and fuel efficiency. By considering how you use your vehicle on a day-to-day basis, you can make an informed decision about whether forged aluminum wheels are the right choice for you.

The Future of Forged Aluminum Wheels

As automotive technology continues to advance, so too will the capabilities of forged aluminum wheels. With ongoing innovations in manufacturing processes and quality control measures such as those offered by Ningbo Buttler Precision Machinery Co., Ltd., drivers can expect even greater advancements in the strength and customization options available with forged aluminum wheels. As these improvements continue to unfold, drivers can look forward to enhanced driving experiences with these high-quality wheel options.