Introduction

In the world of manufacturing, die cast aluminum parts play a crucial role in creating durable and high-quality products. Whether it's for automotive, appliances, or industrial equipment, die casting parts offer exceptional strength and precision. When choosing an OEM die cast aluminum parts manufacturer, it's important to consider key factors such as expertise, quality assurance, and sustainable manufacturing solutions. Working with a reliable die cast aluminum parts manufacturer can bring numerous benefits to your production process and end products.

Importance of Die Cast Aluminum Parts in Manufacturing

Die casting parts are essential in the manufacturing industry due to their ability to produce complex shapes with high accuracy and repeatability. The lightweight nature of aluminum A380 and the strength of aluminum alloy A413 make them ideal materials for a wide range of applications.

Furthermore, die cast aluminum parts offer excellent thermal conductivity, making them suitable for applications where heat dissipation is crucial. This property allows for the efficient transfer of heat away from critical components, enhancing the overall performance and longevity of the end product. Additionally, the corrosion resistance of aluminum alloys ensures that the parts can withstand harsh environmental conditions, making them suitable for outdoor and automotive applications.

Key Factors to Consider When Choosing an OEM Die Cast Aluminum Parts Manufacturer

Selecting the right die casting manufacturer is critical for ensuring the quality and consistency of your products. Factors such as experience, technological capabilities, and adherence to industry standards should be carefully evaluated when making this decision. Additionally, it's important to consider the manufacturer's ability to provide customized solutions and flexibility in production processes. A manufacturer that can offer tailored die casting solutions to meet your specific requirements can significantly enhance the efficiency and effectiveness of your production operations. Moreover, a reliable manufacturer should also demonstrate a commitment to continuous improvement and innovation in their processes, ensuring that they stay ahead of industry trends and deliver cutting-edge solutions.

Benefits of Working with a Reliable Die Cast Aluminum Parts Manufacturer

Collaborating with a reputable die cast aluminum parts manufacturer can lead to improved product performance, cost-effectiveness, and timely delivery. Additionally, sustainable manufacturing solutions offered by the manufacturer can contribute to environmental responsibility within your supply chain.

In addition to these benefits, working with a reliable die cast aluminum parts manufacturer can also provide you with access to advanced technology and expertise in the field. This can result in the development of innovative and high-quality products that can give you a competitive edge in the market. By leveraging the manufacturer's knowledge and resources, you can stay ahead of industry trends and meet the evolving needs of your customers.

Understanding Die Casting Parts

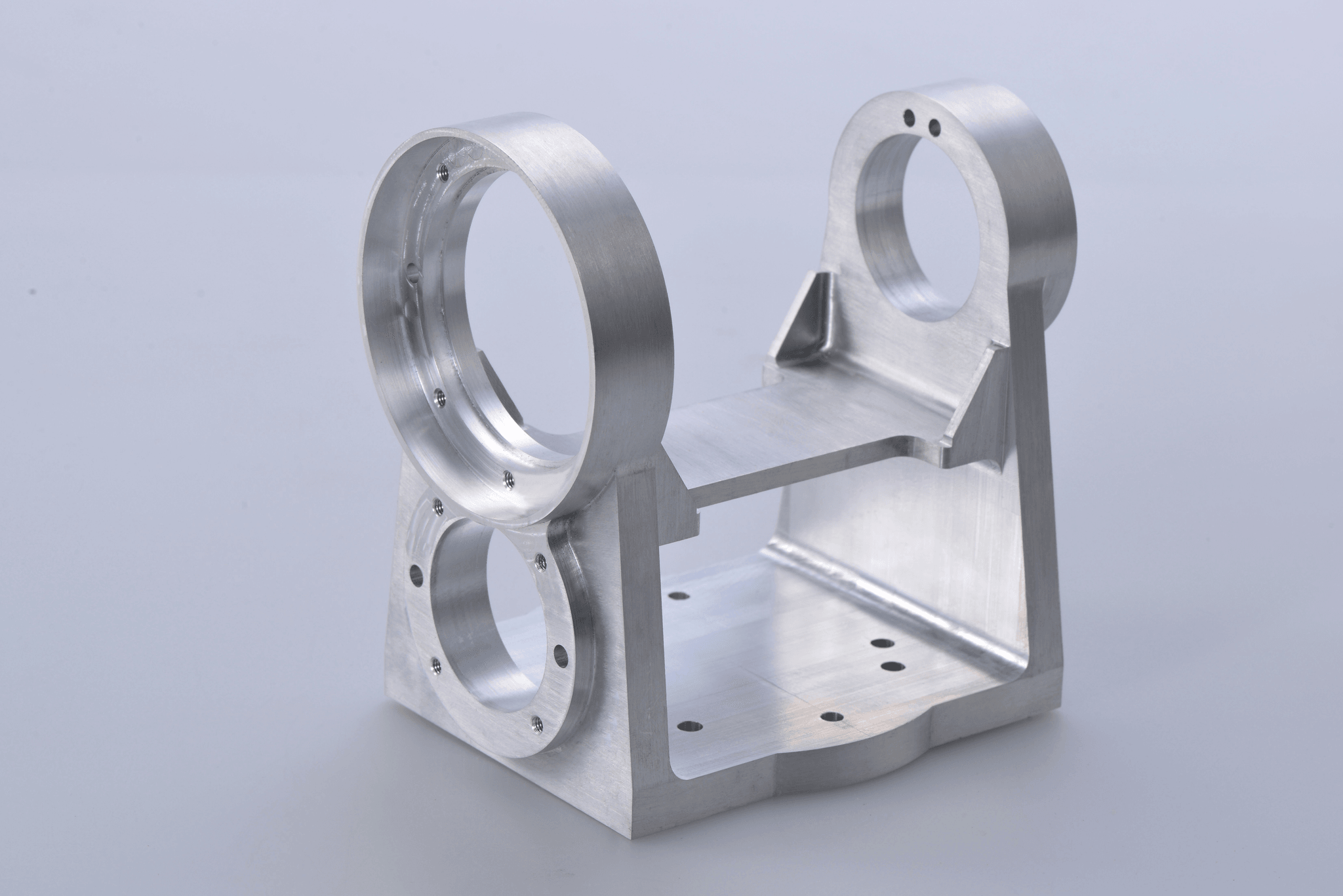

Die casting parts are manufactured using a process that involves injecting molten metal into a steel mold under high pressure. This method allows for the production of complex shapes with high accuracy and smooth surface finishes, making die casting parts stand out from other manufacturing methods.

What Sets Die Casting Parts Apart from Other Manufacturing Methods

What sets die casting parts apart from other manufacturing methods is the ability to produce parts with thin walls and intricate details, while maintaining high dimensional stability. This makes die casting ideal for applications that require lightweight yet durable components, such as automotive and electronic parts.

Additionally, die casting offers high-speed production capabilities, making it a cost-effective manufacturing method for large quantities of parts. This efficiency is crucial for industries with high demand and tight deadlines, such as consumer electronics and industrial machinery. Die casting also allows for the integration of multiple components into a single part, reducing assembly time and costs for manufacturers.

The Advantages of Die Casting Manufacturer

The advantages of working with a die casting manufacturer include cost-effectiveness, fast production cycles, and the ability to produce large quantities of parts with consistent quality. Die casting also offers design flexibility, allowing for the incorporation of features such as ribs, bosses, and inserts without additional machining.

Exploring Aluminum A380 and Aluminum Alloy A413

Aluminum A380 and Aluminum Alloy A413 are two popular materials used in die casting due to their excellent mechanical properties and corrosion resistance. Aluminum A380 is known for its superior fluidity and high strength, while Aluminum Alloy A413 offers good castability and pressure tightness.

Choosing the Right OEM Die Cast Aluminum Parts Manufacturer

Factors to Consider When Selecting a Die Cast Aluminum Factory

When selecting a die cast aluminum factory, it's crucial to consider their expertise in die casting parts, their experience with aluminum A380 and aluminum alloy A413, and their ability to provide high-quality OEM die cast aluminum parts. Additionally, look for a manufacturer that offers comprehensive services such as mold design, casting process, surface treatment, and assembly options.

The Role of Ningbo Buttler Precision Machinery Co., Ltd. in Die Casting

Ningbo Buttler Precision Machinery Co., Ltd. also prides itself on its commitment to sustainability and environmental responsibility. By utilizing advanced technologies and processes, they minimize waste and energy consumption, ensuring that their manufacturing operations are as eco-friendly as possible. This dedication to sustainability not only benefits the environment but also reflects positively on their clients' corporate social responsibility efforts.

Smart Part Engineering = Better Part Designs

Ningbo Buttler Precision Machinery Co., Ltd.'s smart part engineering approach is a game-changer in the industry, as it not only enhances performance and casting quality but also reduces the need for costly secondary operations. By leveraging advanced technology and expertise, the company is able to deliver better part designs without passing on any additional costs to their clients. This commitment to excellence sets Ningbo Buttler apart as a leader in providing high-quality die cast aluminum parts that exceed expectations. With their focus on innovation and efficiency, clients can trust that they are getting the best value for their investment.

Aluminum Die Casting Factory Services

Die Casting Mold Design and Manufacturing

At Ningbo Buttler Precision Machinery Co., Ltd., we excel in die casting mold design and manufacturing, ensuring precision and quality in every part produced. Our team of experienced engineers and designers work tirelessly to create innovative tooling designs that maximize performance and casting quality while minimizing the need for secondary operations.

Our state-of-the-art manufacturing facility is equipped with the latest technology to ensure that our die casting molds are produced with the highest level of precision and accuracy. Our team leverages advanced software and machinery to create intricate designs that meet the exact specifications of our clients. This commitment to cutting-edge technology allows us to consistently deliver superior quality molds that exceed industry standards.

Aluminum and Zinc Casting Process and Surface Treatment

Our aluminum die casting factory specializes in both aluminum A380 and aluminum alloy A413 casting processes, providing a wide range of options for diverse applications. With a focus on surface treatment, we ensure that each part meets the highest standards of durability, corrosion resistance, and aesthetic appeal.

Our expertise in aluminum die casting extends to our comprehensive assembly and packaging options for die cast aluminum parts. We offer a variety of assembly services to meet the specific needs of our customers, including mechanical and electrical assembly, as well as custom packaging solutions. Our goal is to provide a one-stop solution for our clients, ensuring that their die cast aluminum parts are delivered fully assembled and ready for use, with packaging that meets their exact specifications.

Assembly and Packaging Options for Die Cast Aluminum Parts

In addition to our expertise in die casting, we offer comprehensive assembly and packaging options for die cast aluminum parts. From simple sub-assembly to complex final product assembly, our team is dedicated to delivering finished products that are ready for immediate use or distribution. Our assembly services include precision fitting, fastening, and testing to ensure that each part meets the highest standards of quality and functionality. Furthermore, our packaging options range from custom labeling and barcoding to specialized packaging designs that protect the integrity of the finished products during shipping and storage.

Diverse Applications of Die Cast Aluminum Parts

Outdoor Lamp Series

Die cast aluminum parts are widely used in the outdoor lamp series, providing durability and resistance to harsh weather conditions. The lightweight nature of aluminum A380 and A413 makes it ideal for creating intricate designs while maintaining structural integrity. OEM die cast aluminum parts from a reliable manufacturer ensure long-lasting outdoor lighting solutions.

In addition to their durability and resistance to harsh weather conditions, die cast aluminum parts in the outdoor lamp series offer a sleek and modern aesthetic that complements any outdoor space. The lightweight nature of aluminum A380 and A413 allows for easy installation and maintenance, making it a practical choice for outdoor lighting solutions. With the ability to withstand the elements while maintaining its structural integrity, die cast aluminum parts ensure that outdoor lamps will continue to shine bright for years to come.

Automotive Parts

Die casting manufacturer services offer high-quality aluminum die casting factory products for automotive parts, such as engine components, transmission housings, and structural parts. The use of aluminum alloy die casting services guarantees precision and strength in manufacturing automotive components, contributing to the overall performance and safety of vehicles on the road.

Gas Appliance and Power Tool Parts

Gas appliance and power tool parts benefit from the versatility of die cast aluminum parts, as they provide exceptional heat dissipation properties and corrosion resistance. Aluminum die casting factory processes ensure that these components meet strict industry standards for safety, reliability, and performance in gas appliances and power tools.

Conclusion

Quality Assurance in Aluminum Alloy Die Casting Services

When it comes to die cast aluminum parts, quality assurance is paramount. Choosing the right aluminum die casting factory ensures that you receive high-quality, durable parts that meet your specifications. With advanced technologies and stringent quality control measures, reputable manufacturers like Ningbo Buttler Precision Machinery Co., Ltd. guarantee top-notch aluminum alloy die casting services.

Sustainable Manufacturing Solutions for Appliance Parts

The demand for sustainable manufacturing solutions for appliance parts is on the rise, and die cast aluminum parts offer a viable solution. By working with an OEM die cast aluminum parts manufacturer that prioritizes sustainability and eco-friendly practices, you can ensure that your appliance parts are not only high-performing but also environmentally responsible.

The Future of Die Cast Aluminum Parts Manufacturing

As technology continues to advance, the future of die cast aluminum parts manufacturing looks promising. With ongoing innovations in materials, processes, and design techniques, the possibilities for creating complex and intricate die casting parts are endless. As the industry evolves, manufacturers like Ningbo Buttler Precision Machinery Co., Ltd. will play a pivotal role in shaping the future of die cast aluminum parts manufacturing.