Introduction

When it comes to manufacturing high-quality metal parts, aluminum die cast alloys are a popular choice due to their excellent properties. But what is the best aluminum alloy for die casting? And what exactly is die cast aluminum alloy? Can 6061 aluminum be die cast? In this article, we will explore the world of die cast aluminum alloys and provide insights into choosing the right one for your project.

Understanding Aluminum Die Cast Alloys

Aluminum die cast alloys are metal alloys made from aluminum with other elements added to enhance their properties. These alloys are known for their lightweight, high strength, and corrosion resistance, making them ideal for a wide range of applications in various industries.

The Best Aluminum Alloy for Die Casting

The best aluminum alloy for die casting depends on the specific requirements of your project. Factors such as strength, hardness, and thermal conductivity need to be considered when selecting the right alloy for your application.

Exploring Die Cast Aluminum Alloys

Die cast aluminum alloys can be used in a multitude of applications, including automotive parts, electronics housings, and consumer goods. Understanding the properties and advantages of these alloys is crucial in making informed decisions for your manufacturing needs.

What is Die Cast Aluminum Alloy?

Aluminum die cast alloys are metal alloys that are manufactured through the die casting process, which involves injecting molten aluminum into a steel mold under high pressure. This results in the creation of complex shapes with high precision and smooth surface finishes. The best aluminum alloy for die casting is one that offers high strength, good corrosion resistance, and excellent machinability.

Properties of Die Cast Aluminum Alloys

Die cast aluminum alloys exhibit exceptional mechanical properties, including high strength-to-weight ratio, excellent thermal conductivity, and good electrical conductivity. They also possess superior dimensional stability and are resistant to corrosion, making them ideal for a wide range of applications.

In addition, die cast aluminum alloys are highly versatile and can be easily customized to meet specific design requirements. This allows for the production of complex shapes and intricate details, making them suitable for a wide range of applications in industries such as automotive, aerospace, and consumer electronics. Furthermore, their ability to withstand high operating temperatures makes them an excellent choice for components exposed to extreme heat or thermal cycling.

Advantages of Die Cast Aluminum Alloys

The advantages of die cast aluminum alloys include their lightweight nature, which makes them suitable for applications where weight reduction is crucial. Additionally, these alloys offer high dimensional accuracy and intricate detailing capabilities, ensuring that complex parts can be produced with minimal post-processing.

Furthermore, die cast aluminum alloys are highly corrosion resistant, making them ideal for use in outdoor or harsh environmental conditions. This durability ensures that parts made from these alloys have a longer lifespan and require less maintenance over time. In addition, the thermal conductivity of aluminum alloys allows for efficient heat dissipation, making them suitable for applications where temperature control is essential.

Applications of Die Cast Aluminum Alloys

Die cast aluminum alloys find extensive use in industries such as automotive, aerospace, electronics, and consumer goods manufacturing. They are commonly used to produce components such as engine enclosures, heat sinks, housings for electronic devices, and structural parts for various machinery.

Die cast aluminum alloys are also widely used in the production of automotive components such as transmission cases, steering knuckles, and suspension parts. Their high strength-to-weight ratio and excellent corrosion resistance make them ideal for use in vehicles, where durability and reliability are essential. Additionally, their ability to be cast into complex shapes allows for the creation of intricate designs that can improve both the functionality and aesthetics of automotive products.

Choosing the Right Aluminum Alloys for Die Casting

Factors to Consider in Aluminum Alloy Selection

When choosing the right aluminum alloy for die casting, it's important to consider factors such as strength, corrosion resistance, machinability, and thermal conductivity. The alloy should also be easily castable and have good dimensional stability. Additionally, consider the specific requirements of your project and the intended application of the die-cast part to ensure that you select the most suitable aluminum alloy.

Commonly Used Aluminum Alloys for Die Casting

Some of the commonly used aluminum alloys for die casting include 380, 383, and 413. These alloys are known for their excellent fluidity, pressure tightness, and resistance to hot cracking. They also offer good mechanical properties and are easily machinable. By choosing one of these commonly used aluminum alloys, you can ensure high-quality die-cast parts that meet your project's requirements.

While 380, 383, and 413 are commonly used aluminum alloys for die casting, it's important to note that 6061 aluminum can also be die cast. However, compared to the aforementioned alloys, 6061 aluminum is not as commonly used for die casting due to its lower fluidity and pressure tightness. Despite this, 6061 aluminum offers excellent corrosion resistance and weldability, making it a popular choice for structural applications in industries such as aerospace and automotive.

Can 6061 Aluminum be Die Cast?

While 6061 aluminum may not be the ideal choice for die casting, Buttler Precision Machinery Co., Ltd. specializes in finding innovative solutions for challenging projects that require specific material properties. Our team of experts can work with clients to develop custom tooling designs that can improve the castability of 6061 aluminum, making it a viable option for die casting applications. By leveraging our expertise and creativity, we can help clients achieve their goals even with materials that may present initial challenges.

Mastering the Process of Die Casting Aluminum Alloys

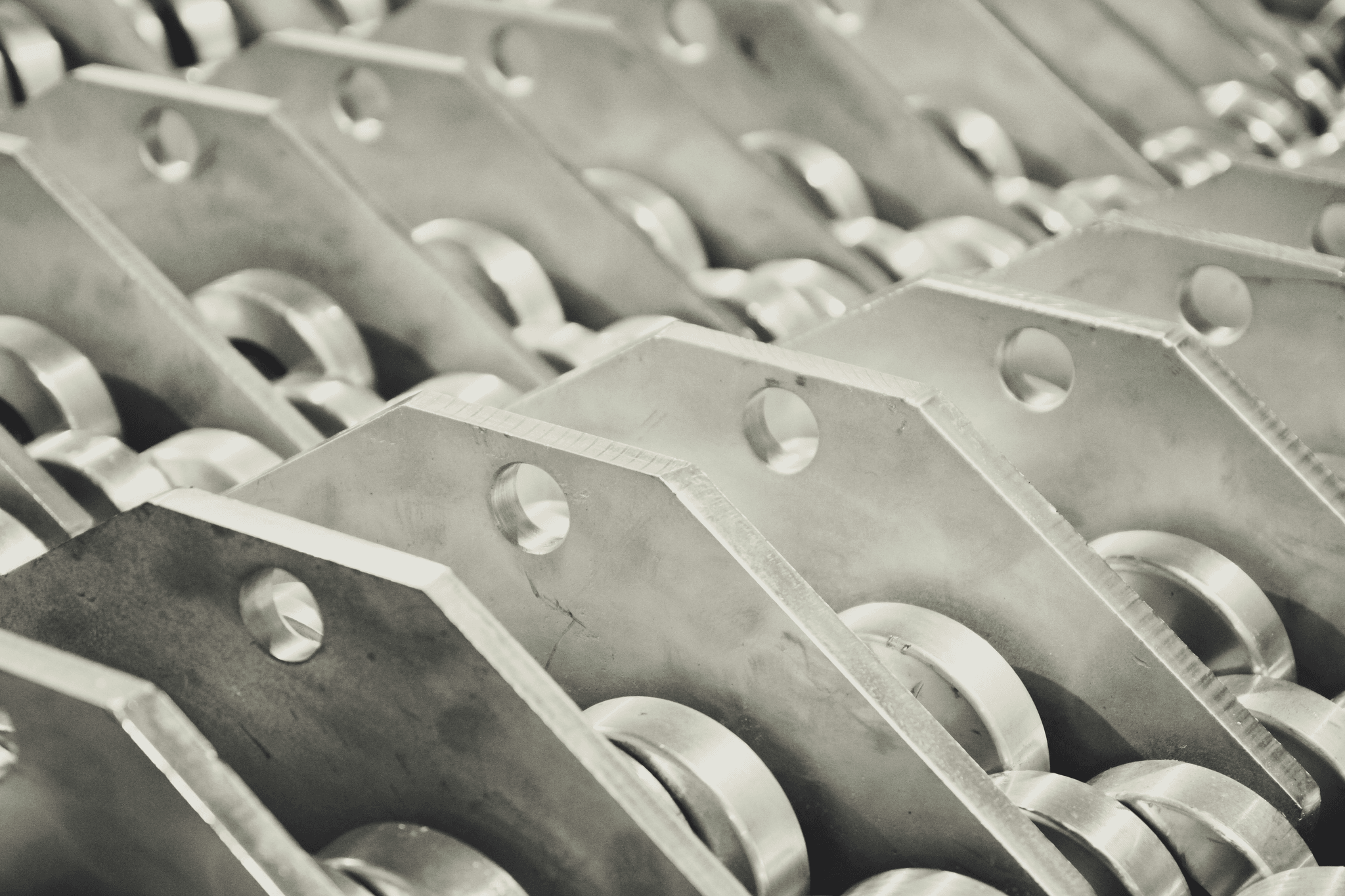

Die Casting Mold Manufacturing

When it comes to die casting aluminum alloys, the first step is to create high-quality molds that can withstand the high pressure and temperature of the casting process. Buttler Precision Machinery Co., Ltd. specializes in innovative tooling designs that are engineered for cost-effective manufacturing and optimized for better part designs.

When it comes to die casting aluminum alloys, the first step is to create high-quality molds that can withstand the high pressure and temperature of the casting process. Buttler Precision Machinery Co., Ltd. specializes in innovative tooling designs that are engineered for cost-effective manufacturing and optimized for better part designs. With a focus on precision and durability, our molds are crafted using advanced materials and cutting-edge technology to ensure consistent and reliable performance in the most demanding production environments.

Aluminum and Zinc Casting Techniques

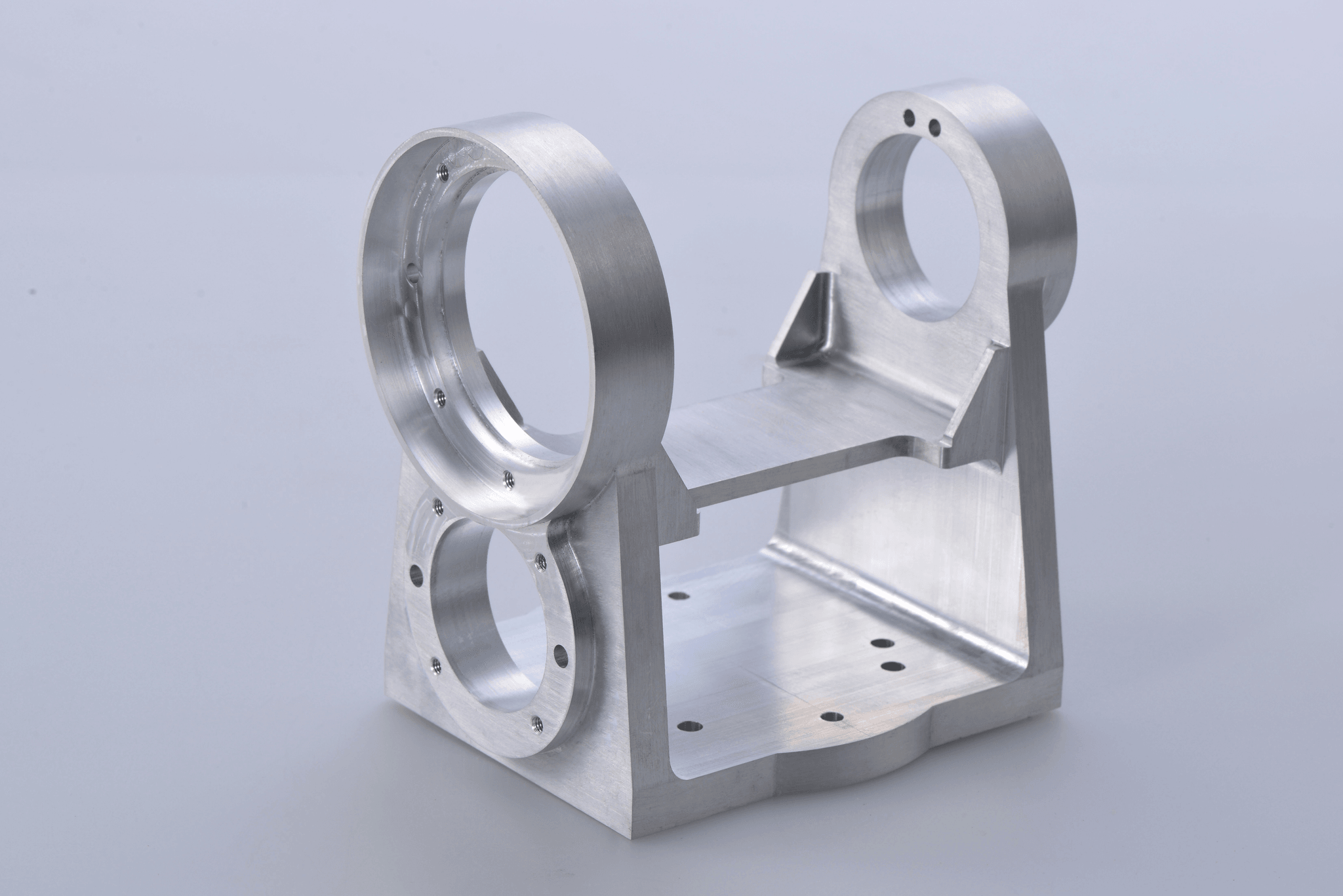

Buttler Precision Machinery Co., Ltd. is known for its expertise in aluminum and zinc casting techniques, ensuring that the final products meet the highest quality standards. With their advanced technology and skilled workforce, they are able to produce complex shapes with thin walls and fine details using die cast aluminum alloys.

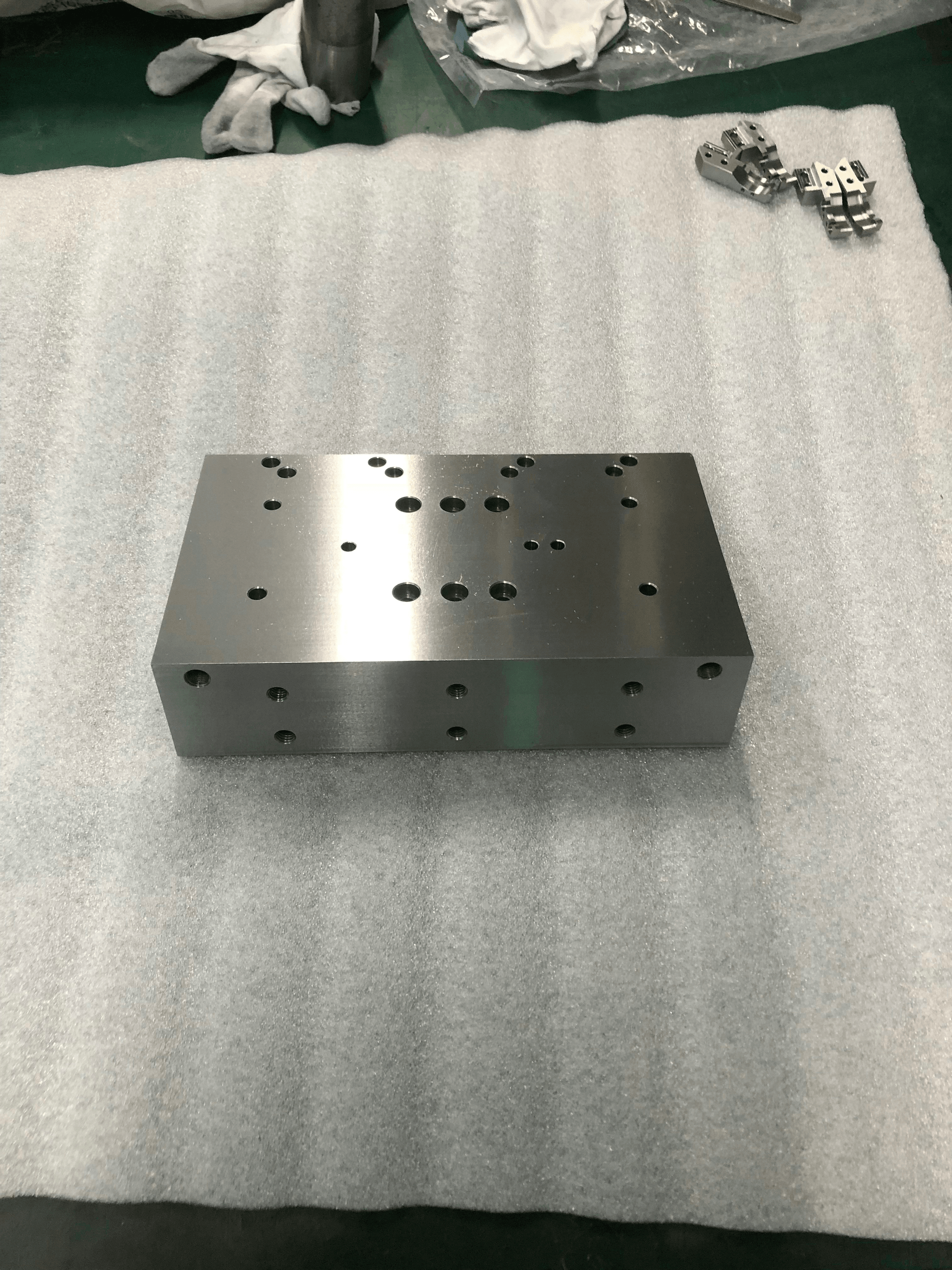

Surface Treatment and Quality Assurance

After the casting process, surface treatment is crucial to enhance the appearance, corrosion resistance, and wear resistance of the die cast aluminum alloys. Buttler's specialization in surface treatment ensures that every part meets strict quality assurance standards before being assembled and packaged for delivery.

Now you have a comprehensive understanding of mastering the process of die casting aluminum alloys with Buttler Precision Machinery Co., Ltd.'s expertise in mold manufacturing, casting techniques, surface treatment, and quality assurance.

Buttler Precision Machinery Co., Ltd.: Expert in Die Casting

Innovative Tooling Designs by Buttler

Ningbo Buttler Precision Machinery Co., Ltd. is renowned for its innovative tooling designs that are engineered to optimize cost-effective manufacturing and maximize performance in aluminum die cast alloys. With a focus on smart part engineering, Buttler's tooling designs ensure better part designs and casting quality, reducing the need for secondary operations.

Maximizing Performance with Buttler's Engineering

Buttler's engineering expertise is dedicated to maximizing performance in die casting, providing solutions that enhance the efficiency and effectiveness of aluminum die cast alloys. By leveraging their Engineering Design Review Process, they offer optimization for new and existing parts at no cost to the client, ensuring superior performance and quality.

Furthermore, Buttler's engineering team is well-versed in the latest technological advancements and industry best practices, allowing them to stay ahead of the curve when it comes to die casting solutions. Their commitment to continuous improvement means that clients can trust that they are receiving the most innovative and cutting-edge services available. This dedication to staying at the forefront of industry trends ensures that Buttler's Engineering is always able to deliver top-notch performance for their clients.

Buttler's Specialization in Die Casting Molds

Specializing in die-casting molds, aluminum and zinc castings, processing, surface treatment, assembly, and packaging, Buttler Precision Machinery Co., Ltd. is a leader in the industry. Their specialization in die casting molds ensures precision and excellence in every aspect of the process.

Buttler Precision Machinery Co., Ltd. also prides itself on its commitment to innovation and continuous improvement. They are constantly investing in the latest technology and equipment to ensure that they stay at the forefront of the industry. This dedication to staying ahead of the curve allows them to offer their clients the most advanced and efficient die-casting mold solutions available.

Conclusion

Smart Part Engineering for Better Design

When it comes to die casting, smart part engineering is crucial for achieving better design and functionality. By utilizing innovative tooling designs engineered for cost-effective manufacturing, you can maximize performance and casting quality while minimizing the need for secondary operations. Buttler Precision Machinery Co., Ltd. specializes in providing such smart part engineering solutions to meet your specific needs.

Maximizing Performance with Die Cast Alloys

Die cast aluminum alloys offer a wide range of properties and advantages that make them ideal for various applications. With the right aluminum alloy selection and mastering the die casting process, you can maximize the performance of your parts and products. Buttler's expertise in die-casting molds, aluminum and zinc castings, as well as surface treatment, ensures that you can achieve the highest level of performance with your die cast alloys.

Choosing the Right Aluminum Alloy for Your Project

Selecting the best aluminum alloy for die casting is essential to ensure the success of your project. Consider factors such as mechanical properties, corrosion resistance, and machinability when choosing from commonly used aluminum alloys like 6061. With Buttler's specialization in die casting molds and their Engineering Design Review Process, you can confidently choose the right aluminum alloy for your specific project needs.

By partnering with experts like Buttler Precision Machinery Co., Ltd., you can leverage their knowledge and experience to achieve optimal results in your die casting projects. Smart part engineering combined with maximizing performance through die cast alloys will ensure that you choose the right aluminum alloy for your project's success.