Introduction

Are you looking to optimize your production process with high-quality die cast aluminum molds? Whether you are a seasoned manufacturer or just starting out, understanding the benefits of increasing production capacity is crucial for success in the industry. At Buttler Precision Machinery Co., Ltd., we specialize in providing top-notch die-casting solutions, including aluminum casting molds and prototypes, to help you achieve your production goals.

Understanding Die Cast Aluminum Molds

When it comes to creating die cast aluminum parts, the choice of mold material plays a critical role in the overall quality and efficiency of the casting process. Selecting the right aluminum casting mold material is essential for achieving superior results and maximizing production output. With our expertise at Buttler Precision Machinery Co., Ltd., we can guide you in choosing the best material for your specific needs.

Benefits of Increasing Production Capacity

Increasing production capacity with high-quality aluminum casting molds offers numerous advantages, such as improved efficiency, reduced lead times, and cost savings. By investing in innovative tooling designs and smart part engineering, manufacturers can enhance their overall performance while minimizing the need for secondary operations. This ultimately leads to higher productivity and profitability.

The Role of Buttler Precision Machinery Co., Ltd.

At Buttler Precision Machinery Co., Ltd., we are committed to providing comprehensive die-casting solutions that cater to a wide range of industries. From designing and manufacturing aluminum casting molds for sale to offering die cast aluminum prototypes, we strive to meet our clients' specific needs with precision and expertise. Partnering with us means leveraging our extensive experience and cutting-edge technology for superior results.

Choosing the Right Aluminum Casting Mold Material

When it comes to selecting the right material for your aluminum casting molds, it is crucial to consider factors such as durability, heat resistance, and cost-effectiveness. The material chosen will directly impact the quality and longevity of your die cast aluminum parts, making it essential to make an informed decision.

Importance of Material Selection

The importance of material selection for aluminum casting molds cannot be overstated. The right material will ensure that your molds can withstand the high temperatures and pressures involved in the casting process, resulting in high-quality and precise parts. Additionally, choosing the appropriate material can also contribute to cost savings and improved production efficiency.

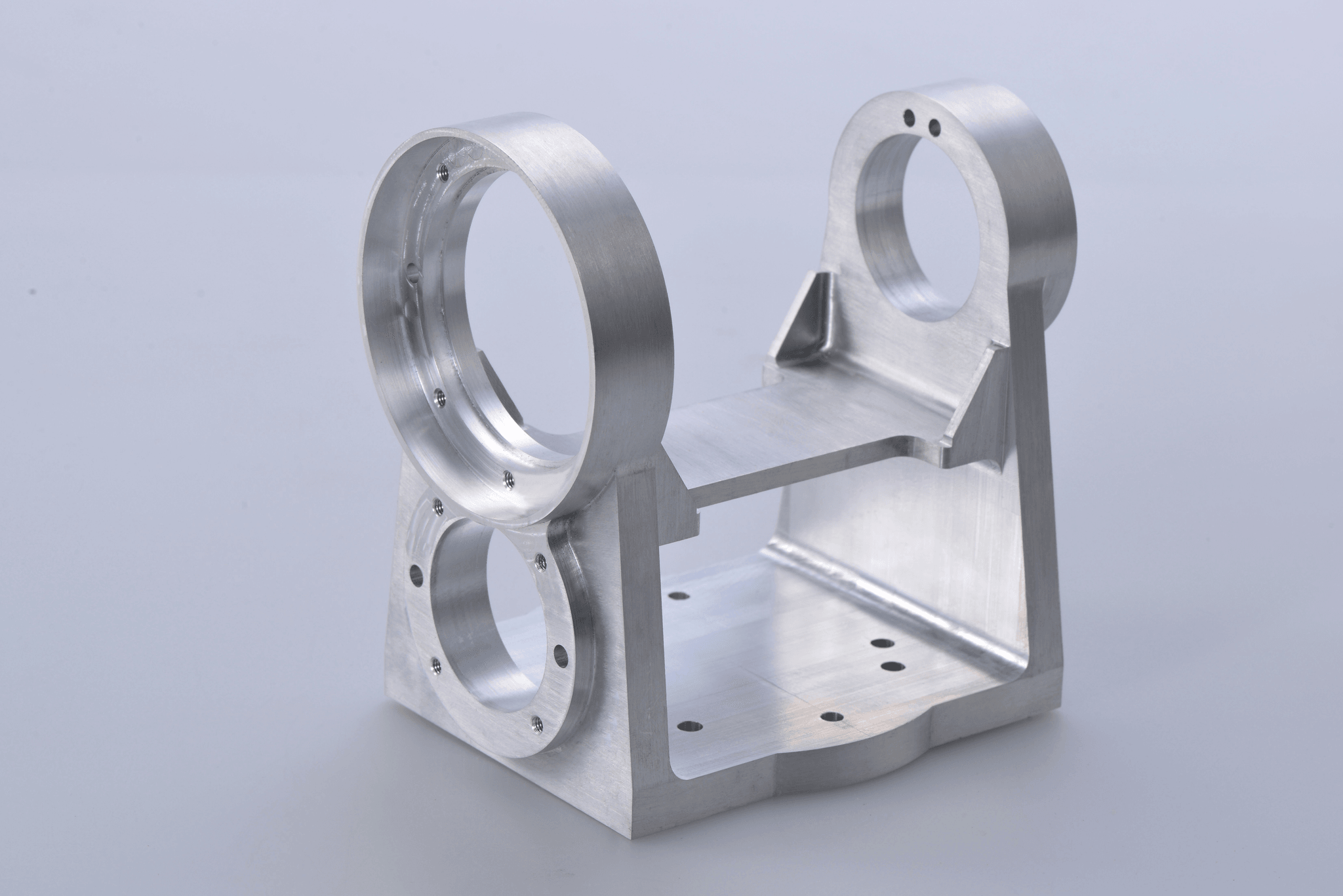

Key Features of Aluminum Casting Molds

Aluminum casting molds offer a range of key features that make them an ideal choice for die casting applications. These features include excellent thermal conductivity, which allows for rapid cooling of molten metal, as well as high dimensional stability and corrosion resistance. Moreover, aluminum molds are lightweight yet durable, making them easy to handle while maintaining structural integrity.

Comparing DIY vs Professional Aluminum Casting Molds

While some may consider DIY aluminum casting molds as a cost-effective option, it is important to recognize the limitations they present in terms of precision and durability. Professional aluminum casting molds are engineered with precision tooling designs that ensure consistent part quality and performance. Partnering with a reputable company like Buttler Precision Machinery Co., Ltd., guarantees access to expertly crafted aluminum casting molds that meet industry standards for reliability and longevity.

Optimizing Production Process with Smart Part Engineering

Smart Part Engineering involves the use of advanced design and manufacturing techniques to create better part designs that enhance performance and efficiency. By leveraging innovative tooling designs, manufacturers can maximize the quality of die cast aluminum parts while minimizing the need for secondary operations. This results in cost-effective production processes that yield superior products.

Smart Part Engineering for Better Part Designs

Smart Part Engineering is essential for creating better part designs that meet the highest quality standards. By utilizing advanced engineering techniques, manufacturers can optimize part geometries, material selection, and manufacturing processes to achieve superior performance and functionality in die cast aluminum parts. This ensures that products meet or exceed customer expectations while maintaining cost-effectiveness in production.

Maximizing Performance with Innovative Tooling Designs

Innovative tooling designs play a crucial role in maximizing the performance of die cast aluminum parts. By incorporating advanced tooling technologies, manufacturers can achieve greater precision, consistency, and efficiency in production processes. This not only enhances the overall quality of products but also reduces lead times and production costs, resulting in a competitive edge in the market.

Minimizing Secondary Operations for Efficient Production

Efficient production is achieved by minimizing secondary operations through smart part engineering. By optimizing part designs and tooling technologies, manufacturers can significantly reduce the need for additional finishing processes such as machining, polishing, or coating. This streamlines production workflows, reduces labor costs, and accelerates time-to-market for die cast aluminum parts.

Expanding Capacity with Die Cast Aluminum Prototype

Advantages of Die Cast Aluminum Prototype

When it comes to die cast aluminum parts, utilizing a die cast aluminum prototype offers numerous advantages. It allows for the testing and validation of designs before full-scale production, reducing the risk of costly errors. Additionally, it provides the opportunity to make necessary adjustments and improvements to the design, resulting in higher quality final products.

Incorporating Aluminum Casting Molds for Sale

Incorporating aluminum casting molds for sale into your production process can significantly enhance efficiency and productivity. These molds are designed to withstand high temperatures and pressures, ensuring consistent and precise casting results. By investing in high-quality aluminum casting molds for sale, you can streamline your production process and achieve superior casting outcomes.

Increasing Flexibility with Versatile Prototyping

Die cast aluminum prototypes offer a level of flexibility that is unparalleled in traditional manufacturing processes. With versatile prototyping, you have the freedom to test multiple design iterations and make adjustments as needed without committing to large-scale production runs. This flexibility allows for greater innovation and creativity in product development while minimizing potential risks.

By leveraging die cast aluminum prototypes and incorporating high-quality aluminum casting molds for sale into your production process, you can achieve exceptional results while maximizing efficiency and flexibility.

Remembering Buttler's expertise in die-casting molds and smart part engineering is crucial when considering these advancements in your production capabilities. Their commitment to cost-effective manufacturing through innovative tooling designs makes them an invaluable partner in achieving superior die casting solutions.

Enhancing Quality and Efficiency in Casting

When it comes to producing high-quality die cast aluminum parts, precision is key. Buttler Precision Machinery Co., Ltd. understands the importance of precise aluminum and zinc castings, and they specialize in delivering top-notch quality with their advanced manufacturing processes.

Importance of Precision in Aluminum and Zinc Castings

The precision of aluminum casting molds directly impacts the quality of the final products. By using high-quality materials and advanced technology, Buttler ensures that every part meets the exact specifications, resulting in superior performance and durability for a wide range of applications.

Surface Treatment Techniques for Improved Quality

To further enhance the quality of die cast aluminum parts, surface treatment techniques are employed to improve corrosion resistance, appearance, and overall functionality. Buttler's expertise in surface treatment ensures that every part meets industry standards for quality and performance.

Streamlining Assembly and Packaging for Efficient Production

Efficiency is crucial in the production process, which is why Buttler focuses on streamlining assembly and packaging to minimize waste and maximize productivity. Their attention to detail ensures that every part is carefully assembled and packaged for safe delivery to customers worldwide.

By partnering with Buttler Precision Machinery Co., Ltd., you can be confident that your die cast aluminum parts will meet the highest standards for quality and efficiency in casting. With their expertise in precision engineering, surface treatment techniques, and efficient production processes, you can achieve superior results for your manufacturing needs.

Addressing Market Demand for Specific Products

Ningbo Buttler Precision Machinery Co., Ltd. is dedicated to meeting market demands for specific products through our expertise in die-casting molds and aluminum casting. Our specialization in the outdoor lamp series ensures high-quality, durable parts that meet the unique requirements of outdoor lighting applications.

Specialization in Outdoor Lamp Series

Our die cast aluminum parts are designed and manufactured to withstand outdoor elements, providing long-lasting performance and aesthetic appeal. With our advanced aluminum casting molds, we can create intricate designs and precise details that enhance the visual impact of outdoor lighting fixtures, ensuring customer satisfaction and product longevity.

Furthermore, our expertise in outdoor lamp series extends to customizing designs to meet specific customer requirements. Whether it's a sleek modern look or a more traditional style, our die cast aluminum parts can be tailored to fit any aesthetic preference. This level of customization ensures that our outdoor lighting fixtures not only perform well but also complement the overall design of any outdoor space.

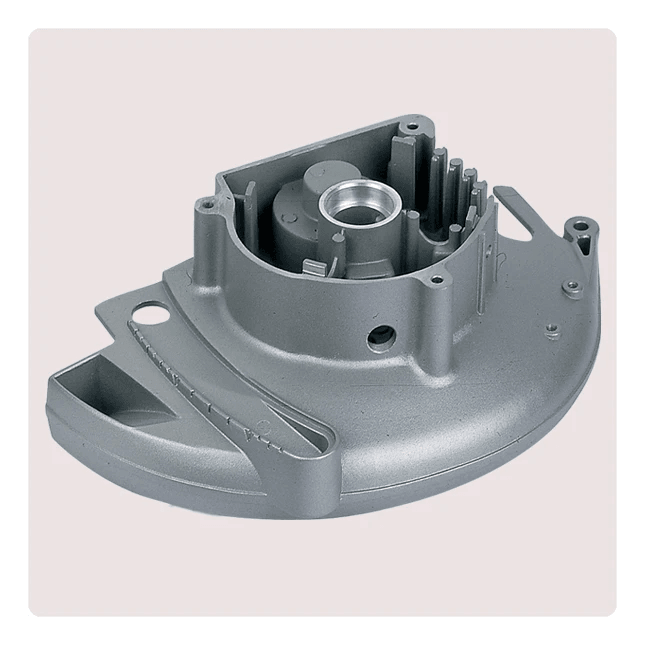

Meeting Requirements for Automotive and Gas Appliance Parts

Buttler Precision Machinery Co., Ltd. also caters to the automotive and gas appliance industries, offering custom aluminum casting molds for sale to meet specific part requirements. Whether it's engine components or gas appliance parts, our expertise in material selection and smart part engineering ensures that the products meet industry standards for performance, durability, and safety.

In addition to our expertise in material selection and smart part engineering, Buttler Precision Machinery Co., Ltd. also offers customization options for power tool and appliance parts. Our team of experienced engineers can work with clients to design and manufacture molds that meet the specific requirements of these industries, ensuring that the end products are of the highest quality. Whether it's a power tool component or an appliance part, we are committed to delivering precision-engineered solutions that exceed industry standards.

Catering to the Demand for Power Tool and Appliance Parts

In addition to outdoor lamps and automotive components, we also cater to the demand for power tool and appliance parts with our high-quality aluminum casting molds. Our precision engineering capabilities enable us to produce complex parts with tight tolerances, ensuring seamless integration into various power tools and appliances while maintaining exceptional quality.

Furthermore, our extensive experience in the industry allows us to understand the specific requirements and challenges of power tool and appliance manufacturers. This insight enables us to provide tailored solutions that address the unique needs of our clients, ensuring that our parts not only meet but exceed their expectations. By staying ahead of industry trends and technological advancements, we are able to offer innovative designs and materials that contribute to the overall performance and durability of power tools and appliances.

Conclusion

Achieving Production Goals with Aluminum Casting Molds

By choosing the right aluminum casting mold material and incorporating die cast aluminum parts, manufacturers can achieve their production goals efficiently. The benefits of increasing production capacity with aluminum casting molds for sale and DIY aluminum casting molds are evident in the enhanced productivity and cost-effectiveness.

Leveraging Smart Part Engineering for Enhanced Efficiency

Smart part engineering plays a crucial role in optimizing the production process by focusing on better part designs, innovative tooling designs, and minimizing secondary operations. This approach ensures maximum performance and casting quality while streamlining the manufacturing process for improved efficiency.

Smart part engineering also focuses on material selection, ensuring that the right materials are used for each specific part to enhance performance and durability. By utilizing advanced materials and alloys, the production process can achieve higher strength-to-weight ratios and improved resistance to corrosion and wear. This not only enhances the overall quality of the casted parts but also extends their lifespan, reducing the need for frequent replacements.

Partnering with Buttler Precision Machinery Co., Ltd. for Superior Die Casting Solutions

To enhance quality and efficiency in casting, partnering with Buttler Precision Machinery Co., Ltd. provides access to expertise in die-casting molds, aluminum and zinc castings, surface treatment, assembly, and packaging. Their innovative tooling designs and precision engineering ensure superior die casting solutions for manufacturers.

In addition, Buttler Precision Machinery Co., Ltd. offers comprehensive support throughout the entire die casting process, from initial design to final product delivery. Their commitment to customer satisfaction means manufacturers can rely on their expertise and guidance at every stage, ensuring a seamless and efficient production process. With Buttler Precision Machinery Co., Ltd. as a partner, manufacturers can expect consistent, high-quality results that meet their exact specifications.