Introduction

Welcome to the fascinating world of aluminum die cast! In this comprehensive guide, we will delve into the intricacies of the aluminum die cast process, uncover the remarkable strength of aluminum die cast products, and unveil the wide array of alloys used in this innovative manufacturing technique.

Understanding the Aluminum Die Cast Process

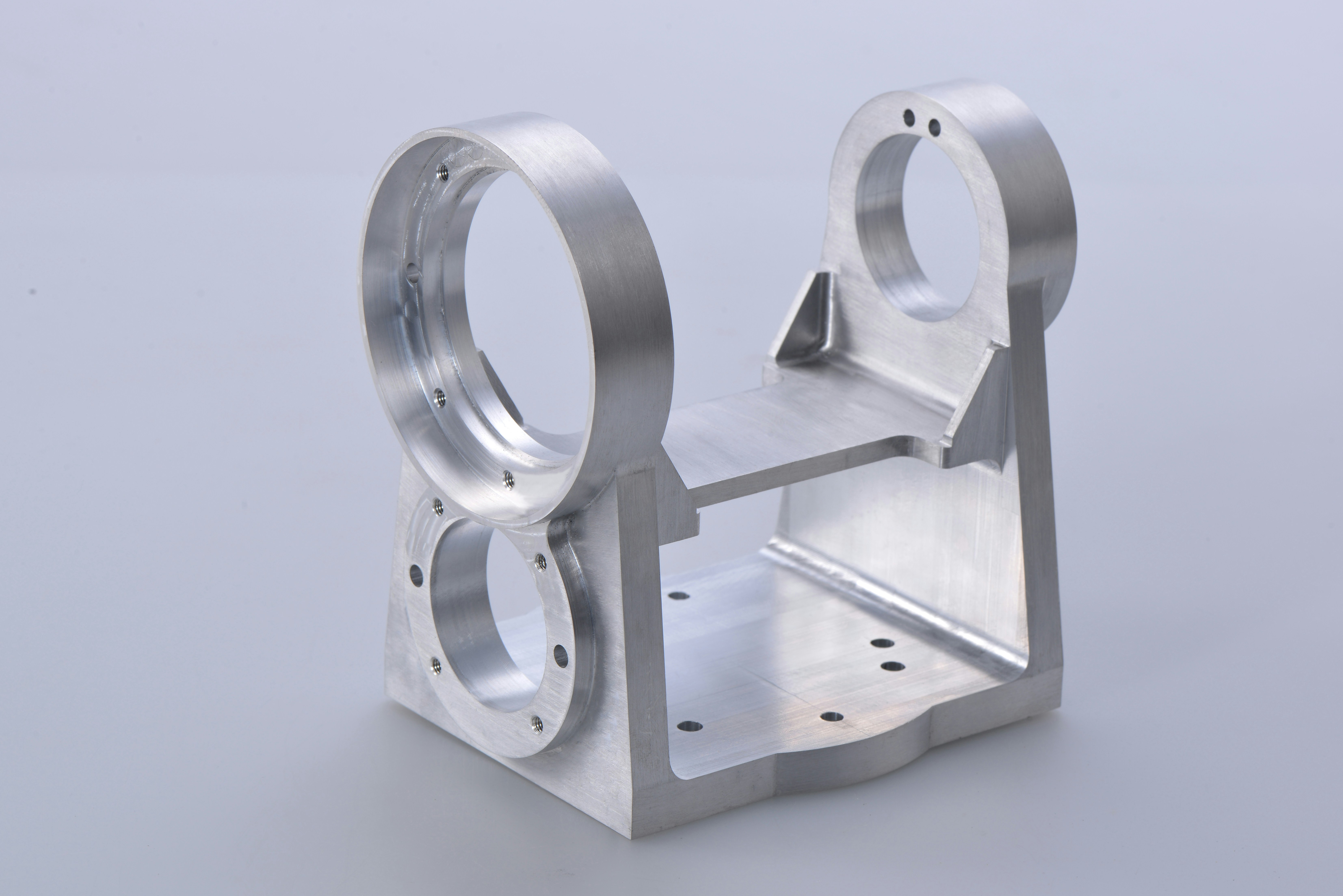

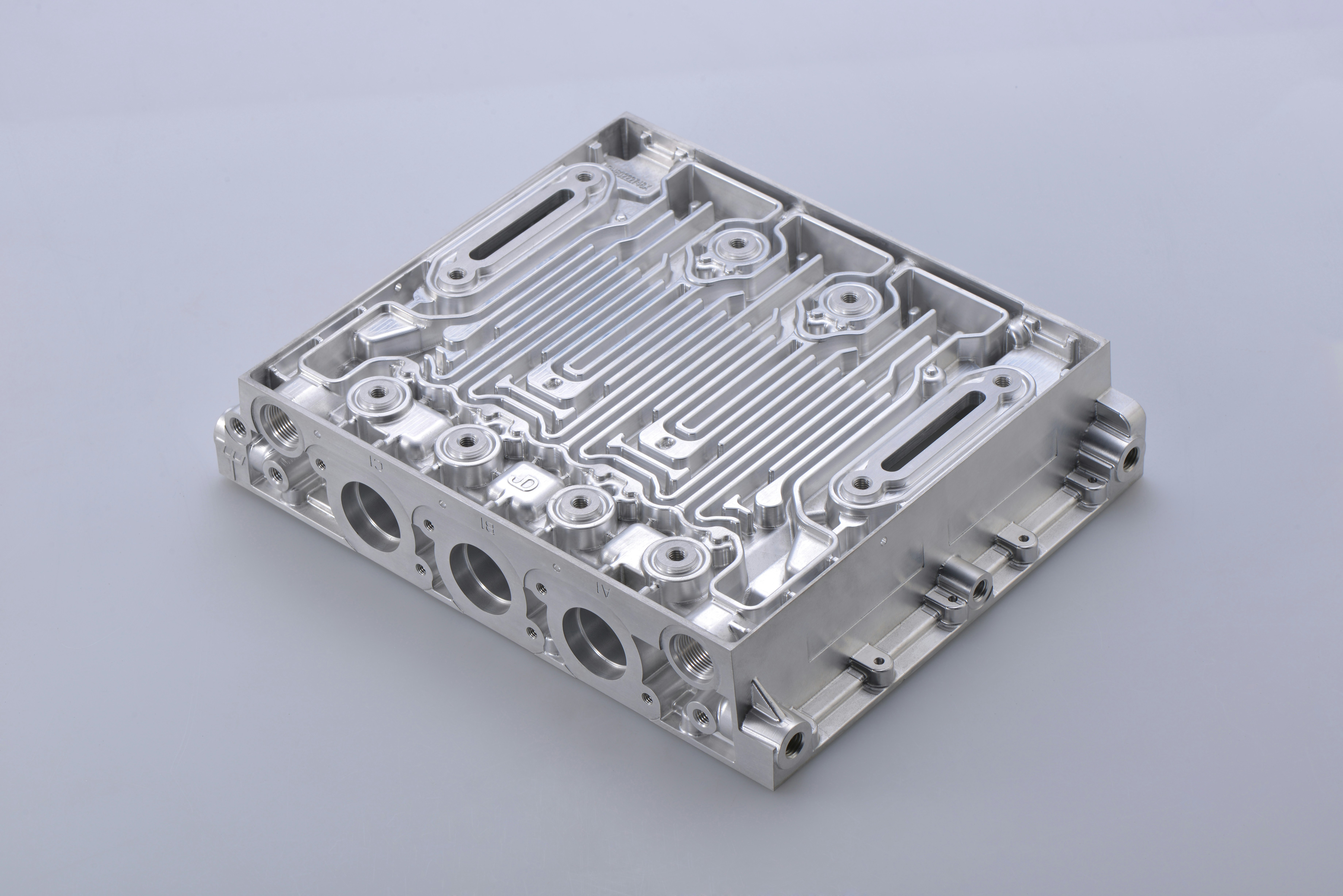

The aluminum die cast process involves injecting molten aluminum into a steel mold at high pressure. This results in intricately detailed and precisely shaped parts that exhibit exceptional strength and durability. From automotive components to household appliances, the versatility of aluminum die cast parts is truly impressive.

Exploring the Strength of Aluminum Die Cast Products

One cannot help but marvel at the sheer strength and resilience of aluminum die cast products. Their lightweight nature belies their incredible sturdiness, making them ideal for various applications across various industries.

Unveiling the Alloys Used in Aluminum Die Cast

Aluminum die cast alloys play a pivotal role in determining the performance and characteristics of the final product. Whether for an aluminum die cast box or intricate parts, these alloys are carefully selected to ensure optimal strength and integrity.

The Basics of Aluminum Die Cast

The advantages of aluminum die cast are plentiful. Not only does it offer high strength and durability, but it also provides excellent thermal conductivity and is lightweight, making it ideal for a wide range of applications. Additionally, aluminum die cast parts can be produced with complex shapes and thin walls, offering design flexibility unmatched by other materials.

The Advantages of Aluminum Die Cast Parts

Aluminum die casting offers many benefits for manufacturers seeking high-quality, cost-effective parts. Here are some key advantages of this process:

- Precise and Efficient Production: Molten aluminum injected into a steel mold creates near-net-shaped parts with minimal post-processing needed. This allows for fast and cost-efficient production.

- Complex Shapes Made Simple: Aluminum die casting produces intricate shapes with tight tolerances. This eliminates the need for complex machining and ensures consistent part quality.

- Excellent Heat Management: Aluminum die cast parts' exceptional thermal conductivity makes them ideal for applications requiring heat dissipation, such as electronic devices and automotive components.

- Lightweight Yet Strong: Aluminum die cast parts offer an impressive strength-to-weight ratio. This combination of lightness and durability makes them a popular choice in weight-critical industries like aerospace and transportation.

Aluminum die casting is a versatile and efficient manufacturing process that produces high-quality parts with a wide range of desirable properties. From intricate electronics to lightweight vehicles, aluminum die casting offers a strong foundation for many industries.

The Manufacturing Process of Aluminum Die Cast

Ningbo Buttler Precision Machinery Co., Ltd. utilizes advanced technology and cutting-edge manufacturing processes to ensure the production of high-quality aluminum die cast parts. Their team of experienced professionals is dedicated to delivering precision-engineered components that meet their clients' specific requirements and standards. By staying abreast of industry developments and investing in the latest equipment, Ningbo Buttler Precision Machinery Co., Ltd. remains at the forefront of aluminum die cast manufacturing.

The Role of Ningbo Buttler Precision Machinery Co., Ltd. in Aluminum Die Cast

By partnering with Ningbo Buttler Precision Machinery Co., Ltd., you can rest assured that your aluminum die cast parts will be manufactured with precision and expertise, meeting the industry's highest standards of quality and performance. With a proven track record of delivering top-notch aluminum die cast products, Ningbo Buttler Precision Machinery Co., Ltd. has established itself as a trusted partner for businesses seeking reliable and durable components. Their commitment to excellence and attention to detail sets them apart in the competitive world of aluminum die casting, ensuring that your specific requirements are met with utmost care and professionalism.

The Strength of Aluminum Die Cast

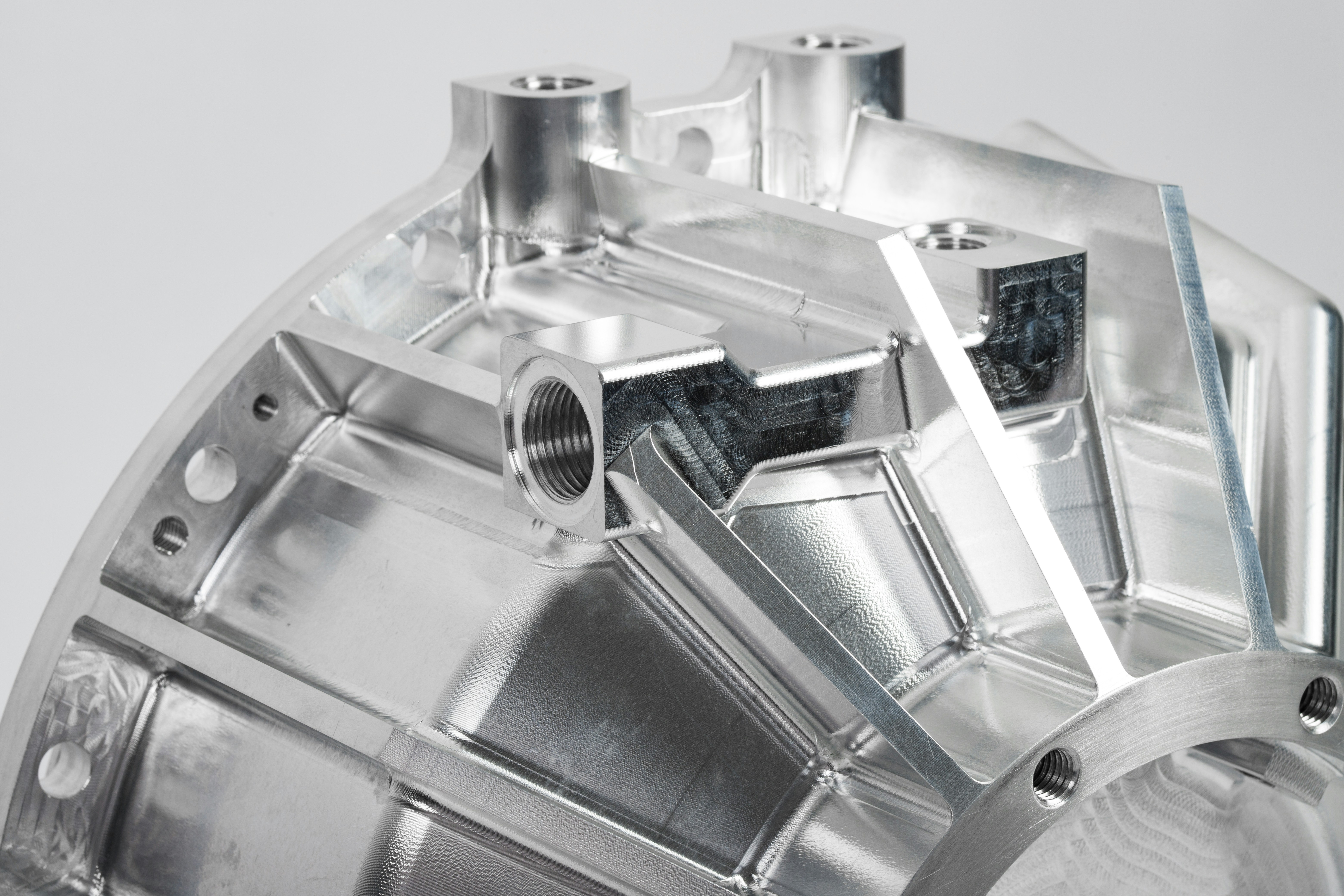

When it comes to durability, aluminum die cast alloys are second to none. These alloys are carefully engineered to withstand heavy loads, extreme temperatures, and harsh environments, making them the top choice for various applications. Whether automotive parts or industrial machinery, aluminum die cast alloys offer unmatched strength and resilience.

The Durability of Aluminum Die Cast Alloys

Aluminum die cast alloys are designed to deliver exceptional durability in demanding conditions. These alloys undergo a meticulous casting process that ensures the microstructure is free from defects, resulting in a material that can withstand heavy stress and pressure without compromising its integrity. This makes aluminum die cast alloys the go-to choice for critical components where strength and reliability are paramount.

Aluminum die cast alloys are also known for their exceptional corrosion resistance, making them ideal for use in harsh environments where exposure to moisture, chemicals, or extreme temperatures is a concern. This corrosion resistance ensures that the material maintains its structural integrity over time, reducing the need for frequent maintenance and replacement. Additionally, the lightweight nature of aluminum die-cast alloys makes them a practical choice for applications where weight reduction is a priority without sacrificing durability.

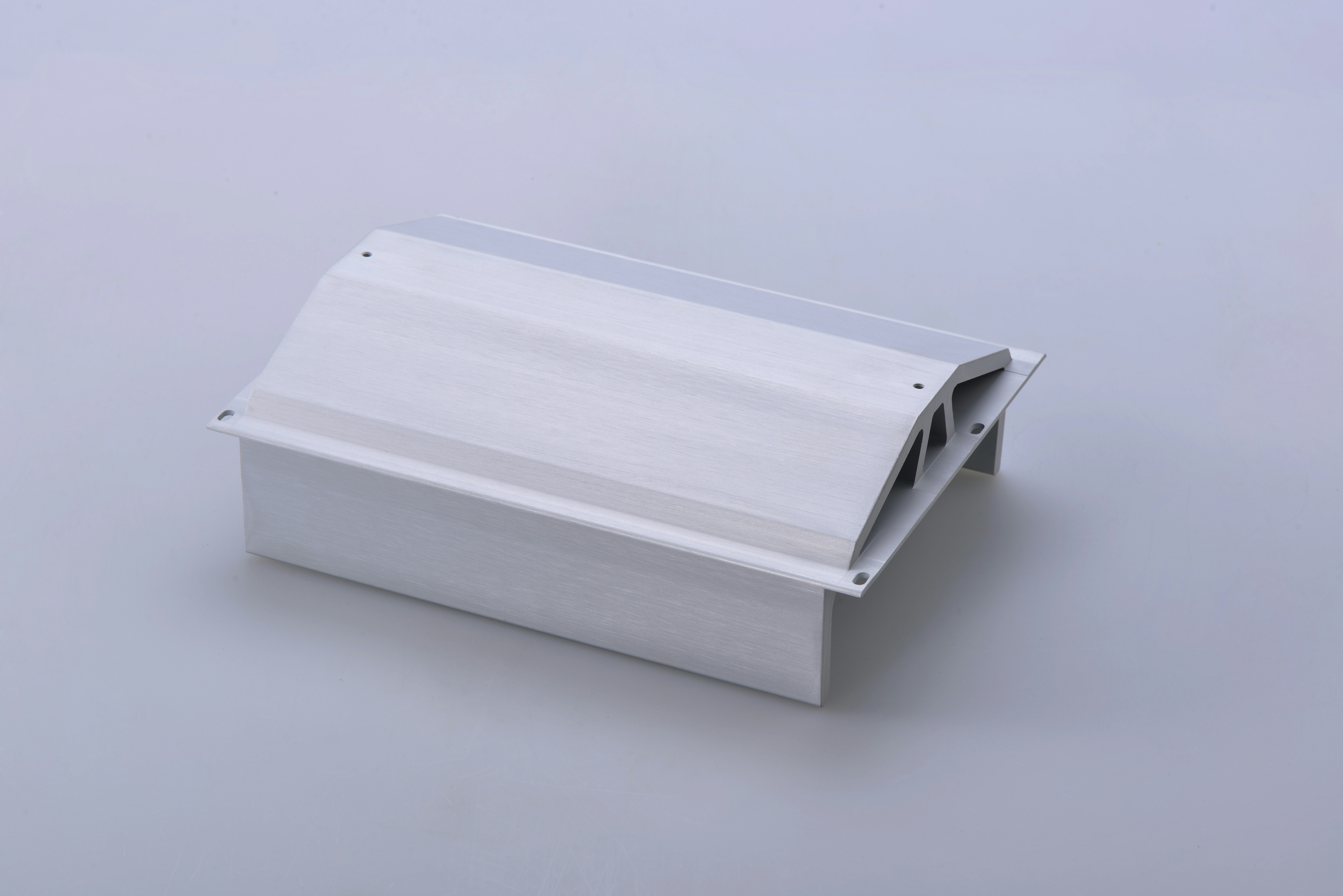

Exploring the Sturdiness of Aluminum Die Cast Box

One prime example of the sturdiness of aluminum die cast products is the aluminum die cast box. These boxes are used in various industries, from electronics to aerospace, where protection and durability are crucial. The seamless construction of aluminum die cast boxes ensures they can withstand impact and rough handling while providing excellent shielding against external elements.

Aluminum die cast boxes are not only known for their sturdiness but also their lightweight construction, making them ideal for applications where weight is a concern. Their ability to resist corrosion and rust further adds to their durability, ensuring they can withstand harsh environmental conditions without deteriorating. Additionally, the seamless design of aluminum die cast boxes eliminates weak points and potential failure areas, enhancing their overall strength and reliability.

The Impact of Laser Welding on Aluminum Die Cast Strength

Laser welding has revolutionized the way we enhance the strength of aluminum die cast parts. By using advanced laser technology, manufacturers can precisely weld aluminum components with minimal heat input, resulting in stronger joints and improved overall integrity. This innovative approach further solidifies the position of aluminum die cast as a top-tier material for high-stress applications.

With its unparalleled durability, sturdiness, and innovative manufacturing techniques like laser welding, it's clear that aluminum die cast technology is setting new standards for strength in modern engineering applications.

Applications of Die Cast Aluminum

The Versatility of Aluminum Die Cast Products

Aluminum die cast products are incredibly versatile, offering various applications across various industries. From automotive parts to electronic components, aluminum die cast products can be found in almost every aspect of modern manufacturing. Their lightweight yet durable nature makes them ideal for many uses, providing strength without adding unnecessary weight to the end product.

Aluminum die cast products are versatile in terms of their applications and offer a high degree of precision and intricate detailing. This makes them an ideal choice for industries such as aerospace, where complex and lightweight components are crucial. The ability to create intricate designs and shapes with aluminum die casting allows for producing high-performance parts that meet the stringent requirements of the aerospace industry.

Industries Benefiting from Aluminum Die Cast Parts

Numerous industries benefit from using aluminum die cast parts, including automotive, aerospace, telecommunications, and consumer electronics. The superior strength-to-weight ratio and corrosion resistance of aluminum die cast parts make them indispensable in these sectors. Whether for engine components or intricate electronic housings, aluminum die cast parts are a staple in these industries.

The automotive industry relies heavily on aluminum die cast parts for their lightweight yet durable properties. From engine blocks to transmission housings, these parts are crucial in enhancing fuel efficiency and overall performance. Additionally, aluminum die cast parts' ability to be easily molded into complex shapes makes them ideal for creating sleek and aerodynamic designs in modern vehicles.

Innovative Uses of Die Cast Aluminum in Modern Products

In recent years, there has been an increase in innovative uses of die cast aluminum in modern products. From high-performance sports equipment to cutting-edge medical devices, manufacturers are constantly finding new ways to utilize the strength and versatility of aluminum die cast. This trend is expected to continue as technology advances and the demand for lightweight yet durable materials grows.

Now that we've explored the versatility and widespread applications of aluminum die-cast products across different industries and innovative uses in modern products, let's delve into quality control measures essential for ensuring precision and accuracy in aluminum die-casting.

Quality Control in Aluminum Die Casting

When it comes to aluminum die casting, precision and accuracy are paramount. Every step of the manufacturing process, from the initial design to the final product, must be meticulously monitored to ensure that the aluminum die cast parts meet the highest quality and performance standards.

Ensuring Precision and Accuracy in Aluminum Die Casting

Advanced technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM) are employed to guarantee precision and accuracy in aluminum die casting. These technologies allow for intricate designs to be translated into precise molds, ensuring that each aluminum die cast part is manufactured with utmost precision.

Furthermore, these advanced technologies also play a crucial role in ensuring the accuracy of the aluminum die casting process. By utilizing CAD and CAM, manufacturers can simulate the entire production process, identifying potential issues or areas for improvement before the actual manufacturing occurs. This proactive approach not only saves time and resources but also contributes to the overall precision of the final aluminum die cast parts.

The Importance of Surface Treatment in Aluminum Die Cast

Aluminum die casting is a versatile and cost-effective manufacturing process used for a wide range of products. However, surface treatment is essential to ensure these products function well and look their best. Here are the key benefits of surface treatment for aluminum die cast components:

- Enhanced Durability and Protection: Surface treatments like powder coating and anodizing create a protective barrier shielding aluminum from scratches, corrosion, and wear. This extends the lifespan of the components and reduces maintenance costs.

- Improved Appearance: Surface treatments offer a wider variety of colors and finishes than raw aluminum. This allows manufacturers to create aesthetically pleasing components that complement the product's overall design.

- Increased Customer Satisfaction: By delivering durable and attractive aluminum die cast parts, manufacturers can enhance customer satisfaction and brand perception.

Surface treatment is critical in the aluminum die casting process. It safeguards the integrity of the components, elevates their visual appeal, and ultimately contributes to a higher-quality product.

Quality Standards for Aluminum Die Cast Manufacturing

To maintain high-quality standards in aluminum die cast manufacturing, strict quality control measures are implemented throughout the entire production process. This includes rigorous testing for dimensional accuracy, material strength, and surface finish to ensure that every aluminum die cast part meets or exceeds industry standards.

In addition to the rigorous testing for dimensional accuracy, material strength, and surface finish, our quality control measures include thorough inspections for any defects or imperfections in the aluminum die cast parts. This ensures that only flawless components are used in the final product assembly, minimizing the risk of malfunctions or failures. By upholding these high standards, we can guarantee the reliability and performance of our aluminum die cast parts in various applications.

The Unmatched Strength and Quality of Aluminum Die Cast Technology

As we look to the future of manufacturing, aluminum die cast technology will continue to play a pivotal role. The demand for lightweight, durable, high-strength products is growing, and aluminum die cast is perfectly positioned to meet these needs.

The Future of Aluminum Die Cast in Manufacturing

With advancements in technology and materials, the future of aluminum die cast looks promising. As industries continue to seek more efficient and cost-effective solutions, the versatility and strength of aluminum die cast will make it an integral part of manufacturing processes for years to come.

Choosing the Right Aluminum Die Cast for Your Project

When selecting the right aluminum die cast for your project, consider factors such as strength, durability, and precision. With a wide range of alloys available and expert manufacturers like Ningbo Buttler Precision Machinery Co., Ltd., finding the perfect solution for your specific needs has never been easier.

The unmatched strength and quality of aluminum die cast products make them an ideal choice for various applications. From automotive components to electronics and beyond, the sturdiness and reliability of aluminum die cast parts ensure they will continue to be at the forefront of modern manufacturing.