Introduction

When it comes to understanding aluminum alloy pricing, there are several key factors that come into play. From market rates to the impact of scrap prices, having a clear grasp of how much aluminum alloy costs per pound is crucial for businesses in the manufacturing industry. Accurate pricing is essential for making informed decisions and maximizing value in the production process.

Understanding Aluminum Alloy Pricing

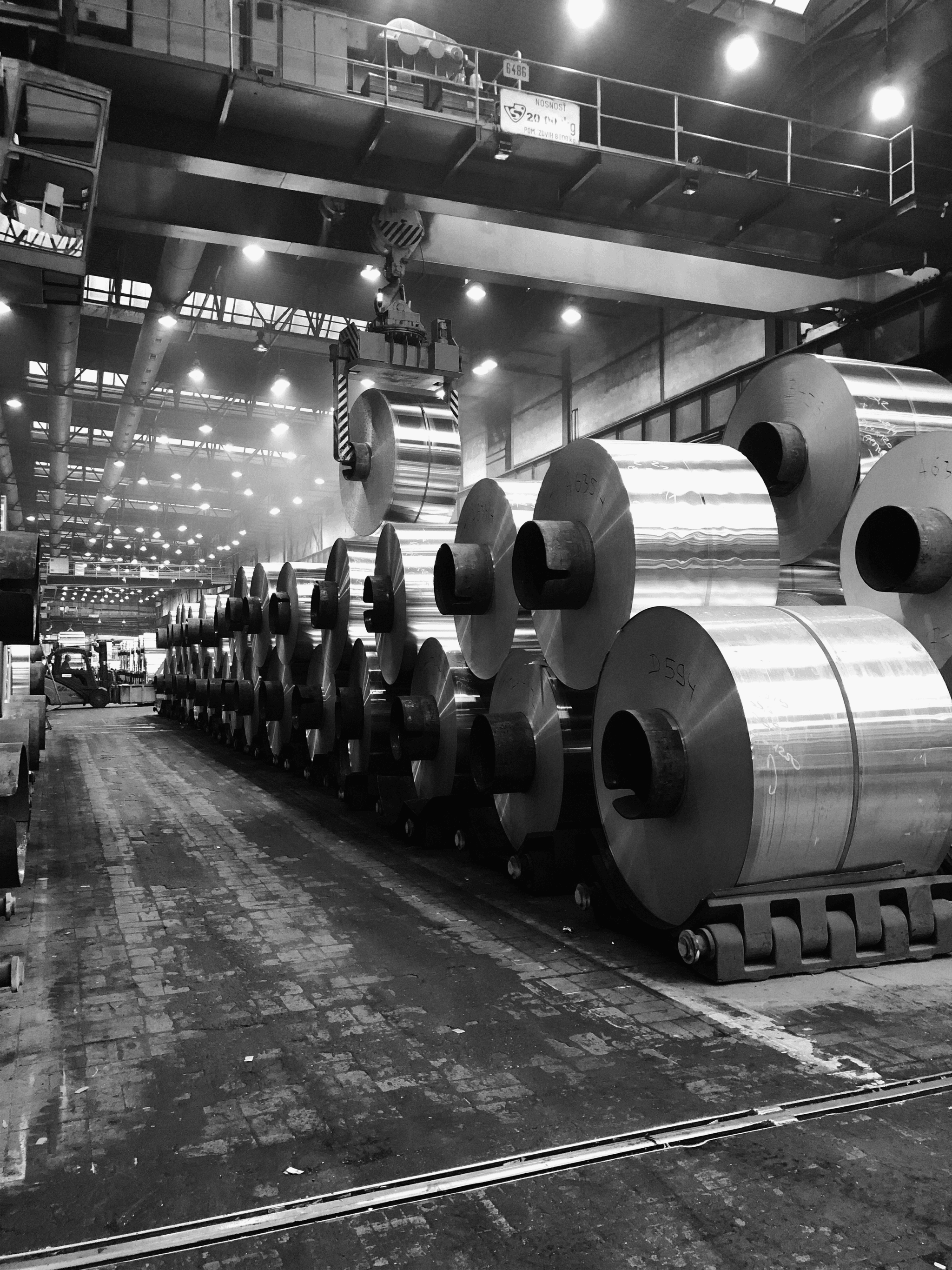

The pricing of aluminum alloy is influenced by a variety of factors, including market demand, supply chain dynamics, and global economic trends. Manufacturers need to stay updated on the current rates for aluminum alloy to effectively plan their production processes and budget accordingly.

Market demand for aluminum alloy can fluctuate based on various industries' needs, such as automotive, aerospace, and construction. Understanding these demand shifts can help manufacturers anticipate changes in pricing and adjust their production schedules accordingly. By staying informed about market demand trends, manufacturers can make strategic decisions to optimize their operations and maintain a competitive edge in the industry.

Factors Affecting Aluminum Alloy Price

The cost of aluminum alloy per pound can be affected by various elements such as raw material prices, energy costs, transportation expenses, and tariffs. Understanding these factors is essential for gauging the overall financial impact on manufacturing operations.

The Importance of Accurate Pricing

Accurate pricing plays a critical role in determining the profitability and competitiveness of businesses in the manufacturing sector. Having reliable information on aluminum price per lb enables companies to make strategic decisions regarding material sourcing, production planning, and cost management.

Accurate pricing also impacts a company's ability to effectively manage its cash flow and budget for future expenses. By knowing the exact aluminum price per pound, businesses can more accurately forecast their costs and allocate resources accordingly. This level of precision in financial planning can ultimately lead to improved financial stability and long-term success for manufacturing companies.

How Much Is Aluminum Alloy Per Pound?

Current Market Rates for Aluminum Alloy

When considering how much aluminum alloy is per pound, it's essential to stay updated on the current market rates. The price of aluminum alloy can fluctuate due to various factors such as supply and demand, economic conditions, and geopolitical events. Therefore, keeping track of the latest market rates is crucial for accurate pricing and cost estimation in manufacturing processes.

In addition to supply and demand, economic conditions, and geopolitical events, another factor that can impact the price of aluminum alloy is the cost of production. Fluctuations in energy prices, labor costs, and raw material expenses can all contribute to changes in market rates for aluminum alloy. Manufacturers must consider these additional factors when estimating costs and pricing their products to ensure competitiveness in the market.

Comparing Aluminum Scrap Price per Pound

In addition to understanding the current market rates for aluminum alloy, it's also important to compare the scrap price per pound. This comparison allows manufacturers and suppliers to assess the value of recycling aluminum scrap versus purchasing new material. By analyzing the scrap rate for aluminum, businesses can make informed decisions on cost-effective sourcing and sustainability initiatives.

Furthermore, by comparing the scrap price per pound, businesses can also evaluate the environmental impact of their sourcing decisions. Recycling aluminum scrap reduces the need for new mining and extraction, which can have a significant ecological footprint. This analysis allows companies to align their procurement strategies with their sustainability goals, demonstrating a commitment to responsible resource management and reducing their carbon footprint.

Finding Reliable Sources for Aluminum Price per lb

To obtain accurate information on aluminum price per pound, it's crucial to find reliable sources that provide up-to-date data and insights. This may include industry publications, commodity exchanges, or reputable online platforms specializing in metal pricing. By relying on trustworthy sources, businesses can make confident decisions based on accurate and reliable information.

In addition to industry publications and commodity exchanges, businesses can also turn to government agencies and trade associations for reliable aluminum price per pound information. These organizations often have access to comprehensive data and can provide valuable insights into market trends and pricing dynamics. By leveraging a variety of sources, businesses can gain a more holistic understanding of the factors influencing aluminum prices, allowing them to make informed decisions.

Tips for Getting Accurate Aluminum Price per Pound

Utilizing Online Price Calculators

When determining how much aluminum alloy is per pound, online price calculators can be a valuable tool. These calculators take into account current market rates and provide a reliable estimate of aluminum price per lb based on the type and quantity of alloy you have. By inputting specific details, such as the alloy type and weight, you can quickly obtain an accurate price per pound, helping you make informed decisions about your aluminum scrap.

Consulting with Industry Experts

For a more personalized approach to understanding aluminum price per pound, consulting with industry experts can provide valuable insights. These professionals have in-depth knowledge of market trends, demand-supply dynamics, and other factors affecting aluminum rates. By seeking their expertise, you can gain a better understanding of the current scrap rate for aluminum and make strategic decisions to maximize value from your scrap metal.

Buttler's Expertise in Aluminum Alloy Pricing

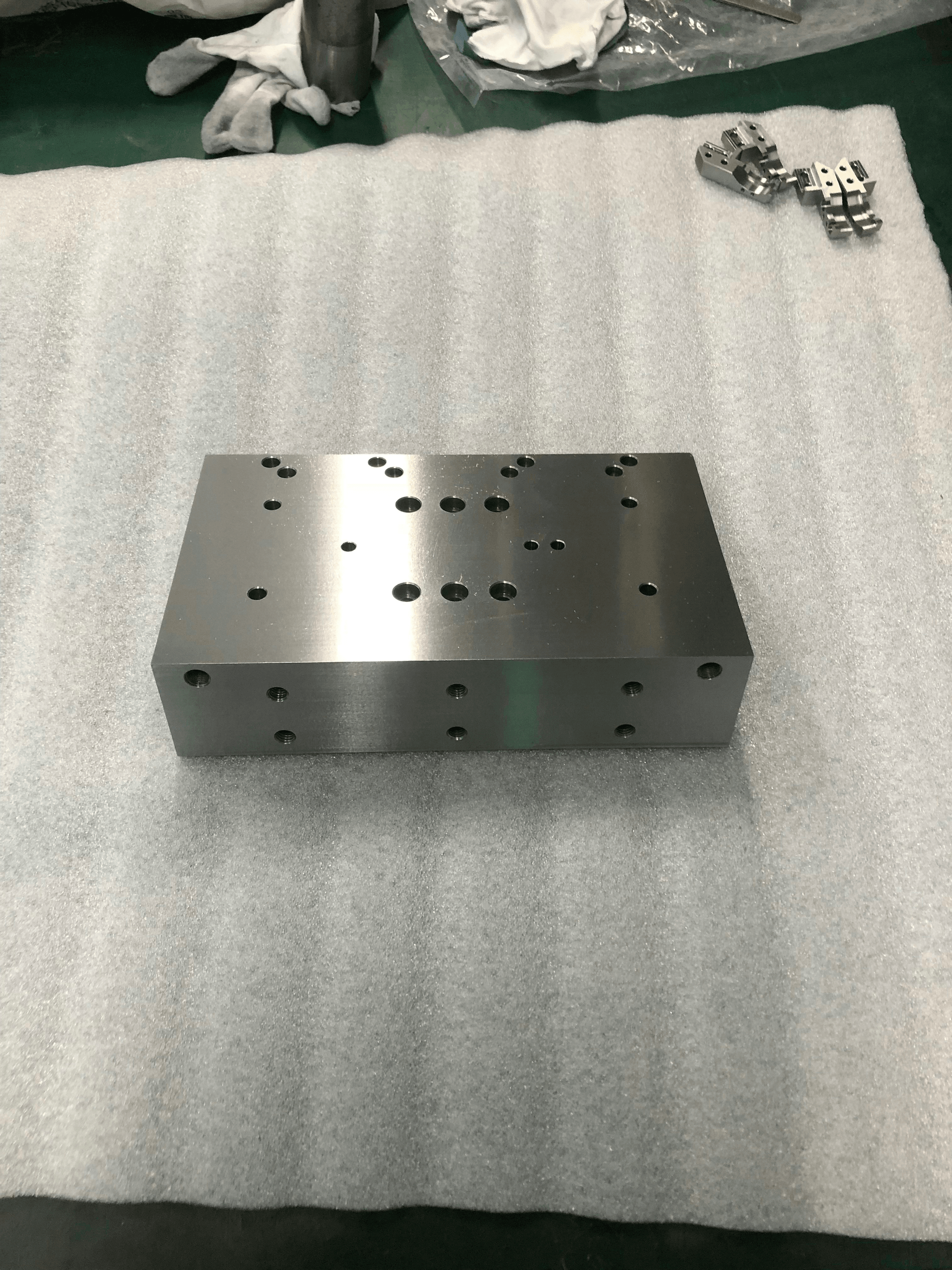

Ningbo Buttler Precision Machinery Co., Ltd., offers expertise in aluminum alloy pricing through its specialization in die-casting molds and aluminum/zinc castings. With a focus on cost-effective manufacturing, Buttler provides innovative tooling designs that optimize part performance and casting quality while minimizing the need for secondary operations. Leveraging their expertise can help ensure accurate pricing for your aluminum scrap, maximizing its value.

Maximizing Value with Accurate Aluminum Pricing

When it comes to manufacturing costs, the impact of price accuracy cannot be overstated. Knowing how much aluminum alloy per pound can significantly affect the overall expenses of production. By accurately gauging the aluminum rate per pound, manufacturers can make informed decisions that optimize their budget and resources.

Impact of Price Accuracy on Manufacturing Costs

Accurate aluminum pricing directly impacts manufacturing costs by providing a clear understanding of material expenses. With reliable information on aluminum price per lb, companies can streamline their budgeting process and make strategic decisions to minimize unnecessary spending. This ensures that resources are allocated efficiently, leading to cost-effective production processes.

Smart Part Engineering for Cost-Effective Manufacturing

Smart part engineering plays a crucial role in achieving cost-effective manufacturing. By leveraging innovative tooling designs tailored for efficient production, companies can optimize performance and casting quality while reducing the need for additional operations. This approach maximizes value by aligning part designs with the most favorable aluminum scrap price per pound.

Matching Aluminum Rate per Pound with Quality Standards

Matching the aluminum rate per pound with quality standards is essential for ensuring that cost-effectiveness does not compromise product excellence. By obtaining accurate pricing information, manufacturers can balance cost considerations with quality requirements, enabling them to produce high-caliber products without overspending on materials.

Ningbo Buttler Precision Machinery Co., Ltd., a leader in die-casting molds and castings processing, offers expertise in smart part engineering and cost-effective manufacturing solutions tailored to match industry standards while maximizing value through accurate pricing information.

The Role of Ningbo Buttler Precision Machinery Co., Ltd.

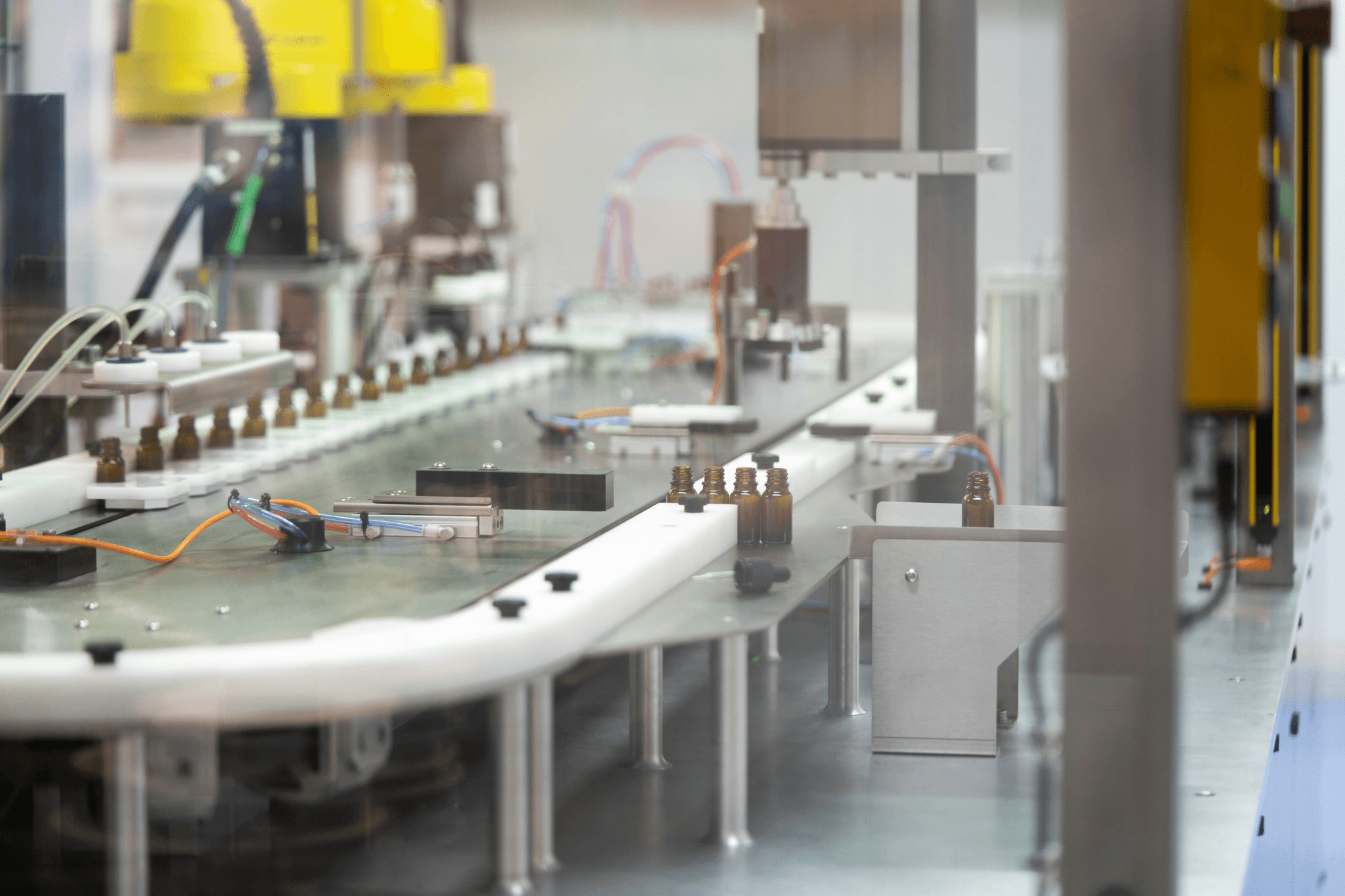

Ningbo Buttler Precision Machinery Co., Ltd. is a leading expert in die-casting molds and specializes in producing high-quality aluminum and zinc castings. With a focus on processing, surface treatment, assembly, and packaging, Buttler offers comprehensive solutions for cost-effective manufacturing. Their innovative tooling designs are engineered to maximize performance and casting quality while reducing the need for secondary operations.

Specialization in Die-Casting Molds and Aluminum/Zinc Castings

Buttler's expertise lies in the production of top-notch die-casting molds and high-quality aluminum/zinc castings. Their specialization ensures that clients receive precision-engineered products that meet their specific requirements, providing them with a competitive edge in their respective industries.

Innovations in Tooling Designs for Cost-Effective Manufacturing

The company's commitment to innovation is evident in its tooling designs, which are tailored to optimize manufacturing processes for maximum efficiency and cost-effectiveness. By leveraging smart part engineering, Buttler delivers better part designs that enhance overall performance while minimizing the need for additional operations.

Reliable Source for Accurate Aluminum Scrap Price per Pound

In addition to their manufacturing expertise, Ningbo Buttler Precision Machinery Co., Ltd. also serves as a reliable source for accurate aluminum scrap price per pound information. With their deep understanding of the industry, they provide valuable insights into current market rates and trends, empowering clients to make informed decisions regarding their aluminum alloy pricing strategies.

The Future of Aluminum Pricing

As the demand for lightweight, durable materials continues to rise, trends affecting aluminum alloy pricing are expected to be influenced by global economic conditions, geopolitical factors, and advancements in manufacturing technology. These trends will impact how much is aluminum alloy per pound and the overall cost of production for various industries.

Trends Affecting Aluminum Alloy Pricing

The increasing focus on sustainability and environmental regulations is driving the demand for aluminum alloys, which could lead to higher prices per pound. Additionally, the shift towards electric vehicles and renewable energy technologies is expected to further drive up the demand for aluminum, impacting its pricing in the future.

The increasing demand for aluminum alloys due to sustainability and environmental regulations is also being fueled by the growing popularity of aluminum in the construction and aerospace industries. As these sectors continue to expand, the need for lightweight, durable materials like aluminum will only increase, putting further pressure on pricing. In addition, the ongoing trade tensions and tariffs between major aluminum-producing countries could also impact pricing as supply chains are disrupted and production costs rise.

Outlook for Scrap Rate for Aluminum

The outlook for scrap rate for aluminum is likely to be influenced by recycling initiatives and advancements in recycling technologies. As the importance of sustainability grows, there will be a greater emphasis on recycling aluminum scrap, potentially impacting its availability and pricing in the market.

As sustainability becomes a top priority for businesses and consumers, the demand for recycled aluminum scrap is expected to rise. This increased emphasis on sustainability will likely lead to more stringent regulations and standards for recycling practices, further impacting the availability and pricing of aluminum scrap in the market. As a result, companies that can accurately price their aluminum scrap based on these evolving factors will have a competitive advantage in meeting the growing demand while maintaining profitability.

Leveraging Accurate Pricing for Competitive Advantage

In a competitive market landscape, accurate pricing of aluminum per pound can provide companies with a strategic advantage. By leveraging reliable sources for aluminum price per lb and staying informed about market trends, businesses can make informed decisions that optimize their manufacturing costs and enhance their competitiveness.

By understanding the current aluminum price per pound and anticipating future trends, businesses can adjust their pricing strategies to remain competitive in the market. This proactive approach allows companies to stay ahead of their competitors and attract customers with attractive pricing. Additionally, accurate pricing information enables businesses to forecast their costs more effectively, leading to better financial planning and budgeting for long-term success.

With these future trends in mind, it's crucial for businesses to stay ahead of the curve by understanding how much is aluminum alloy per pound and leveraging accurate pricing information to maintain a competitive edge in their respective industries.

Conclusion

In conclusion, having reliable and accurate information on how much aluminum alloy costs per pound is crucial for making informed decisions in manufacturing and production. With fluctuating market rates, it's essential to have access to trustworthy sources for aluminum price per lb to ensure cost-effective operations. Ningbo Buttler Precision Machinery Co., Ltd. is committed to providing accurate aluminum alloy pricing, leveraging their expertise in die-casting molds and innovative tooling designs for maximizing value in manufacturing.

Making Informed Decisions with Reliable Aluminum Price Information

Having access to accurate aluminum price per pound information allows businesses to make well-informed decisions when it comes to material procurement and production planning. Reliable sources for aluminum scrap price per pound enable manufacturers to stay competitive in the market while optimizing their operational costs.

In addition to aiding in material procurement and production planning, reliable aluminum price information also helps businesses in forecasting and budgeting. By having access to accurate aluminum scrap price per pound, manufacturers can anticipate market fluctuations and adjust their financial plans accordingly. This proactive approach allows companies to mitigate risks and make strategic decisions that positively impact their bottom line.

Buttler's Commitment to Accurate Aluminum Alloy Pricing

Ningbo Buttler Precision Machinery Co., Ltd.'s commitment to accurate aluminum alloy pricing stems from their specialization in die-casting molds and aluminum/zinc castings, as well as their innovative tooling designs engineered for cost-effective manufacturing. Their expertise ensures that clients have access to reliable and precise information on how much aluminum alloy costs per pound.

Ningbo Buttler Precision Machinery Co., Ltd. recognizes the value of accurate scrap rate for aluminum in the manufacturing process. By providing clients with precise information on aluminum alloy pricing, they enable businesses to make informed decisions regarding material sourcing and production costs. This commitment to accuracy ultimately helps companies optimize their operations and maximize their profitability.

The Value of Accurate Scrap Rate for Aluminum

Accurate scrap rate for aluminum is invaluable in ensuring efficient material utilization and cost management in manufacturing processes. By leveraging reliable sources for aluminum scrap price per pound, businesses can maximize the value of their raw materials while maintaining high-quality standards.

Furthermore, accurate scrap rate for aluminum allows manufacturers to identify areas for process improvement and waste reduction. By closely monitoring the scrap rate, businesses can pinpoint inefficiencies in their production processes and take corrective actions to minimize material wastage. This proactive approach not only saves costs but also contributes to sustainable manufacturing practices, enhancing the overall environmental impact of the business.