Introduction

Die casting is a manufacturing process that involves forcing molten metal into a mold cavity under high pressure. This results in a precise, accurate, and smooth surface finish, making it ideal for producing complex and detailed parts. Understanding how die casting works is essential for maximizing its benefits and addressing any potential drawbacks.

Understanding Die Casting

The die casting process starts with the creation of a steel mold, also known as a die, which is designed to shape the molten metal into the desired part. The mold consists of two halves that are securely clamped together during the casting process to ensure accuracy and consistency in the final product. Understanding how die casting works step by step is crucial for achieving optimal results and minimizing defects in the castings.

Importance of Die Casting

Die casting offers numerous advantages, including high dimensional accuracy, excellent surface finish, and the ability to produce intricate shapes with tight tolerances. However, it's important to acknowledge why die casting can be bad in certain situations, such as limited material options and high initial tooling costs. By understanding these factors, manufacturers can make informed decisions about when to utilize die casting for their production needs.

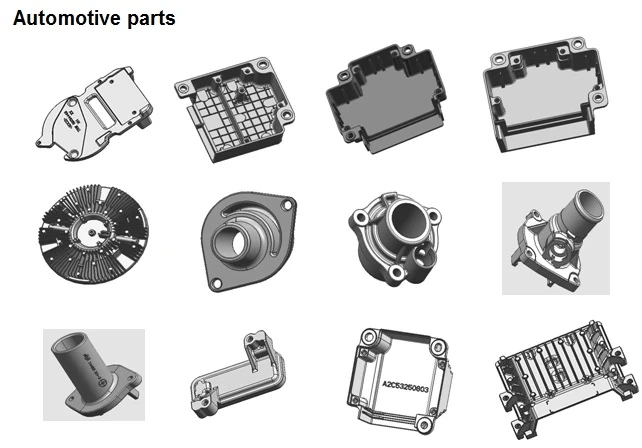

Applications of Die Casting

Die casting is widely used across various industries for producing components such as automotive parts, consumer electronics, household appliances, and more. The versatility of die casting makes it suitable for both large-scale production runs and smaller custom projects. Exploring the diverse applications of die casting showcases its potential for creating complex parts with exceptional strength and durability.

Materials Used in Die Casting

Aluminum and zinc alloys are the primary materials used in die casting due to their excellent flow properties, high strength, and lightweight characteristics. These alloys are easily cast into intricate shapes with thin walls, making them ideal for a wide range of applications.

Aluminum and Zinc Alloys

Aluminum and zinc alloys are widely preferred in die casting due to their exceptional mechanical properties, corrosion resistance, and thermal conductivity. These materials offer high dimensional stability for complex shapes and thin walls, making them suitable for a variety of industries such as automotive, aerospace, and electronics.

Surface Treatment of Castings

Surface treatment is essential in die casting to improve the appearance, corrosion resistance, and wear resistance of the castings. Processes such as shot blasting, powder coating, anodizing, and painting are commonly used to enhance the surface finish and protect the castings from environmental factors.

Smart Part Engineering for Better Designs

Smart part engineering plays a crucial role in optimizing part designs for die casting. By leveraging innovative tooling designs engineered for cost-effective manufacturing, companies like Ningbo Buttler Precision Machinery Co., Ltd. can maximize performance and quality while minimizing the need for secondary operations.

Die Casting Process

Die Casting Mold

The die casting mold, also known as a die, is a custom-designed tool used in the die casting process to produce metal parts with high precision and accuracy. The mold is typically made from hardened steel and consists of two halves, the cover die and the ejector die, which are securely mounted in the die casting machine.

Step by Step Die Casting Process

The die casting process begins with the preparation of the mold, followed by the injection of molten metal into the cavity at high pressure. Once the metal solidifies, the mold opens and the part is ejected. This method allows for rapid production of complex shapes with tight tolerances and excellent surface finishes.

Maximizing Performance and Quality

To maximize performance and quality in die casting, it's crucial to carefully control factors such as temperature, pressure, and cooling rate during the process. This ensures that parts are free from defects such as porosity or shrinkage. Additionally, proper maintenance of molds and regular inspections help maintain consistency in part production.

Advantages and Disadvantages of Die Casting

Why Die Casting is Beneficial

Die casting is beneficial because of its high-speed production, precise dimensional accuracy, and the ability to produce complex shapes with thin walls. The process allows for the production of parts with a smooth surface finish, reducing the need for additional finishing processes. Furthermore, die casting is cost-effective for large production runs due to its high efficiency and low scrap rates.

Drawbacks of Die Casting

One drawback of die casting is that it can be expensive to set up the initial tooling and mold equipment. Additionally, die casting may not be suitable for small production runs or prototype parts due to these setup costs. Another potential drawback is that die casting can result in porosity or air pockets within the castings if not properly controlled, which can affect the structural integrity of the part.

Addressing Die Casting Concerns

To address concerns about cost, companies like Ningbo Buttler Precision Machinery Co., Ltd. specialize in providing cost-effective tooling designs and engineering solutions to maximize performance and minimize secondary operations. Additionally, quality control measures are implemented to ensure that porosity issues are minimized through proper process optimization and control.

By addressing concerns about cost and quality control measures through innovative engineering designs and process optimization, companies like Ningbo Buttler Precision Machinery Co., Ltd. are able to provide efficient and high-quality die casting solutions for various industries.

Making of Die Casting Dies

Ningbo Buttler Precision Machinery Co., Ltd. is a leading expert in the manufacturing of die-casting molds, specializing in the production of high-quality aluminum and zinc castings. With a focus on smart part engineering, they offer innovative tooling designs that result in better part designs and cost-effective manufacturing processes.

Specialization of Ningbo Buttler Precision Machinery Co., Ltd.

Ningbo Buttler Precision Machinery Co., Ltd. is renowned for its expertise in die-casting molds and aluminum and zinc castings. Their specialization lies in providing innovative tooling designs engineered for cost-effective manufacturing to maximize performance and casting quality while minimizing the need for secondary operations.

Importance of Quality Die Casting Molds

The importance of quality die casting molds cannot be overstated, as they directly impact the final product's precision, surface finish, and overall quality. Ningbo Buttler Precision Machinery Co., Ltd. prioritizes the production of high-quality die casting molds to ensure optimal performance and durability in the die casting process.

Innovative Tooling Designs

Innovative tooling designs play a crucial role in enhancing part designs and streamlining manufacturing processes. Ningbo Buttler Precision Machinery Co., Ltd.'s focus on smart part engineering results in innovative tooling designs that optimize performance, minimize costs, and eliminate the need for secondary operations.

Finishing Process in Die Casting

When it comes to achieving the desired die casting finish, a combination of factors comes into play. The process involves carefully inspecting the surface of the casting to ensure that it meets the required specifications. This includes checking for any imperfections or defects that may have occurred during the casting process.

Achieving Desired Die Casting Finish

The desired finish in die casting is achieved through a series of steps that involve polishing, buffing, and shot blasting to remove any surface imperfections and create a smooth, uniform surface. This ensures that the final product meets the highest quality standards and is visually appealing.

After achieving the desired finish through polishing, buffing, and shot blasting, the next step in die casting is surface treatment and coating. Surface treatment involves applying a protective layer to the die-cast part to enhance its durability and resistance to corrosion. This can be done through methods such as anodizing, plating, or painting, depending on the specific requirements of the final product. Coating, on the other hand, adds a decorative or functional finish to the surface, further enhancing its visual appeal and performance.

Surface Treatment and Coating

Surface treatment and coating not only protect die-cast parts from corrosion and wear but also provide an opportunity to customize the appearance of the parts. Powder coating, for example, allows for a wide range of color options and finishes, giving manufacturers the flexibility to match their products with specific branding or design requirements. Anodizing, on the other hand, can enhance the surface hardness and durability of die-cast parts, making them suitable for applications that require high wear resistance.

Ensuring High-Quality Die Casting Finish

To ensure a high-quality die casting finish, it is essential to adhere to strict quality control measures throughout the finishing process. This includes conducting thorough inspections at each stage to identify any defects or irregularities that may affect the final finish.

In addition to inspections, it is crucial to use high-quality materials and tools for the finishing process. Using subpar materials or tools can lead to a lower-quality finish, so investing in the best resources is essential. This can also help prevent defects and irregularities from occurring in the first place, leading to a smoother finishing process overall.

Conclusion

Die casting is a highly efficient manufacturing process that offers numerous benefits for producing intricate metal parts. Understanding how die casting works and the step-by-step process involved is crucial for achieving optimal results. By using high-quality materials and ensuring a meticulous die casting finish process, manufacturers can overcome any drawbacks associated with die casting.

Key Considerations in Die Casting

It's essential to comprehend how die casting works, as it involves injecting molten metal into a steel mold under high pressure to create complex shapes with exceptional accuracy and surface finish. This process allows for the production of intricate parts with thin walls and fine details, making it ideal for a wide range of applications. When considering die casting, the quality of materials used is crucial to ensure the durability and performance of the final product. High-quality metals and alloys are essential for achieving the desired strength and characteristics in the casted parts. Additionally, attention to detail in the die casting process is paramount, as any flaws or imperfections can significantly impact the overall quality and functionality of the finished components.

Importance of Quality Materials and Process

While die casting offers numerous advantages, it's important to address concerns about its potential drawbacks. Poor-quality materials or an inadequate die casting process can lead to issues such as porosity, shrinkage, or premature failure of the castings. Therefore, using high-quality aluminum and zinc alloys and implementing smart part engineering are crucial for achieving superior results.

Furthermore, the die casting process must be carefully monitored to ensure that the materials are being used effectively and efficiently. This involves maintaining the correct temperature and pressure throughout the casting process, as well as ensuring that any molds or tools are in optimal condition. By paying close attention to these details, manufacturers can minimize the risk of defects and produce high-quality castings consistently.

Achieving Optimal Die Casting Finish

The finishing process in die casting plays a vital role in enhancing the aesthetic appeal and functionality of the parts. Surface treatment and coating techniques are employed to achieve the desired finish, ensuring that the castings meet stringent quality standards while also providing corrosion resistance and improved durability.

By partnering with specialized companies like Ningbo Buttler Precision Machinery Co., Ltd., manufacturers can access expertise in die-casting molds and innovative tooling designs engineered for cost-effective manufacturing. With their focus on smart part engineering and quality materials processing, they can help address concerns related to die casting while optimizing performance and achieving an optimal finish.

Overall, by understanding how die casting works step by step, addressing any potential drawbacks through quality materials and processes, and ensuring an optimal die casting finish through innovative tooling designs, manufacturers can harness the full potential of this advanced manufacturing technique.