Introduction

The automotive industry relies on high-quality automotive castings to ensure the performance and durability of vehicles. Die-casting components are crucial in efficient manufacturing, providing cost-effective solutions for producing intricate automobile casting parts. With the growing market for aluminum structural components in electric vehicles, the demand for high-quality automotive castings is rising. At Ningbo Buttler Precision Machinery Co., Ltd., we specialize in die-casting molds and aluminum and zinc castings, offering comprehensive processing, surface treatment, assembly, and packaging services to meet the industry's needs. Smart Part Engineering provides better part designs for efficient manufacturing, optimizing performance and casting quality while minimizing secondary operations.

The Importance of High-Quality Automotive Castings

High-quality automotive castings are paramount for ensuring optimal vehicle performance and longevity. These components play a critical role in various automobile parts' structural integrity and functionality, significantly impacting safety and reliability.

To achieve the highest standards, automotive castings must:

- Exhibit exceptional strength and durability to withstand rigorous driving conditions.

- Possess precise dimensions and tolerances for optimal fit and performance.

- Demonstrate resistance to corrosion and wear for extended service life.

- Be manufactured using advanced materials and processes to enhance efficiency and sustainability.

Investing in superior automotive castings is crucial for building vehicles that deliver exceptional performance, safety, and driver satisfaction.

The Role of Die Casting Components in Efficient Manufacturing

Die-casting components are crucial in efficient manufacturing processes within the automotive industry. By utilizing die casting techniques, manufacturers can quickly produce complex shapes with high precision, resulting in cost-effective solutions for casting parts in automobiles.

The Growing Market for Aluminum Structural Components in Electric Vehicles

The increasing demand for electric vehicles has led to a growing market for aluminum structural components. Lightweight yet durable, aluminum is ideal for enhancing energy efficiency and range in electric vehicles, further driving the need for high-quality automotive castings.

Ningbo Buttler Precision Machinery Co., Ltd.: Your Expert in Automotive Castings

Ningbo Buttler Precision Machinery Co., Ltd. specializes in die-casting molds, aluminum and zinc castings, processing, surface treatment, assembly, and packaging services tailored to meet the specific requirements of the automotive industry.

Smart Part Engineering: Better Part Designs for Efficient Manufacturing

Smart Part Engineering offers innovative tooling designs engineered to maximize performance and casting quality while minimizing the need for secondary operations – all aimed at achieving cost-effective manufacturing solutions.

Understanding Die Casting in the Automotive Industry

The Advantages of Die Casting Components

Die-casting components offer numerous advantages in the automotive industry, including high dimensional accuracy, smooth surfaces, and the ability to produce complex shapes with thin walls. This makes them ideal for automotive parts such as engine blocks, transmission cases, and structural components.

In addition to their dimensional accuracy and smooth surfaces, die-casting components also offer excellent strength and durability, making them suitable for withstanding the rigors of automotive applications. This means that automotive parts produced through die casting can maintain their integrity and performance over time, ensuring the safety and reliability of vehicles. Furthermore, die casting allows for high production volumes at a fast pace, meeting the automotive industry's demands for efficient manufacturing processes.

The Impact of Die Casting in Automotive Industry

Die casting has significantly impacted the automotive industry by providing cost-effective solutions for manufacturing high-quality parts with tight tolerances. This has improved overall vehicle performance and durability while reducing production costs and lead times.

Die casting has revolutionized the automotive industry by enabling the production of complex, lightweight parts that contribute to fuel efficiency and overall vehicle performance. This technology has also allowed for creating intricate designs and shapes that were previously unattainable through traditional manufacturing methods. As a result, die casting has played a crucial role in enhancing the aesthetic appeal of vehicles, attracting consumers with its sleek and modern designs.

The Market for Automotive Parts Die Casting

The automotive parts die-casting market is growing rapidly due to the increasing demand for lightweight and durable components in modern vehicles. With advancements in die-casting technology, manufacturers can now produce intricate parts that meet stringent industry standards.

The Role of Aluminum Structural Components in Electric Vehicles

Aluminum structural components play a crucial role in the development of electric vehicles, as they reduce overall vehicle weight and increase energy efficiency. Die-casting techniques are instrumental in producing these lightweight yet robust components, which are essential for electric vehicle performance.

Aluminum structural components not only reduce overall vehicle weight and increase energy efficiency but also offer excellent corrosion resistance, ensuring the longevity of electric vehicles. Manufacturers can produce complex shapes and thin-walled sections with die-casting techniques, providing design flexibility and integrating multiple components into a single piece. This innovation in smart part engineering allows for creating more streamlined and aerodynamic electric vehicles, ultimately enhancing their performance and range.

The Innovation of Smart Part Engineering

Smart Part Engineering specializes in better part designs that optimize manufacturing processes while ensuring superior performance and quality. Their innovative tooling designs are engineered to minimize secondary operations and maximize efficiency, making them an invaluable partner in automotive castings.

Smart Part Engineering's commitment to innovation and excellence extends beyond just the design phase. They also prioritize material selection and process optimization to ensure that their automotive castings meet the highest quality and performance standards. By leveraging advanced technologies and industry best practices, Smart Part Engineering sets a new benchmark for precision and reliability in automotive part manufacturing.

Benefits of High-Quality Automotive Castings

Superior Performance and Durability

High-quality die-casting components ensure superior performance and durability in automotive castings. The use of aluminum structural components in electric vehicles further emphasizes the need for durable castings that can withstand the demands of modern automotive technology.

Cost-Effective Manufacturing

Investing in high-quality automotive castings ultimately leads to cost-effective manufacturing processes. By utilizing die casting in the automotive industry, manufacturers can efficiently produce complex parts with minimal material waste, reducing production costs.

Minimizing the Need for Secondary Operations

One key benefit of high-quality automotive castings is their ability to minimize the need for secondary operations. This streamlines the manufacturing process and reduces additional costs and labor associated with finishing and refining casting parts in automobiles.

High-quality automotive castings also contribute to automobile parts' overall durability and longevity. By minimizing the need for secondary operations, the integrity of the casting is preserved, resulting in stronger and more reliable components. This ultimately leads to reduced maintenance and repair costs for vehicle owners, as they can trust that their automotive parts will withstand the test of time without frequent replacements or repairs.

Ensuring Casting Quality

High-quality automotive castings are essential for ensuring casting quality throughout the production process. From initial design to final assembly, maintaining quality in die-casting components is crucial for meeting industry standards and customer expectations.

Innovative Tooling Designs by Smart Part Engineering

Smart Part Engineering offers innovative tooling designs to enhance manufacturing efficiency while maximizing performance and casting quality. Their expertise in providing better part designs aligns perfectly with the demand for high-quality automotive castings in today's competitive market.

Smart Part Engineering's tooling designs are tailored to meet the specific needs of automotive manufacturers, ensuring that their production processes run smoothly and efficiently. By leveraging cutting-edge technology and innovative design concepts, Smart Part Engineering is able to deliver tooling solutions that not only improve manufacturing efficiency but also contribute to long-term cost savings. With a focus on maximizing performance and casting quality, their designs are a testament to their commitment to excellence in the automotive industry.

The Expertise of Ningbo Buttler Precision Machinery Co., Ltd.

Specialization in Die-Casting Molds

Ningbo Buttler Precision Machinery Co., Ltd. is a leading expert in designing and manufacturing high-quality die-casting molds for automotive castings. Their molds are built with precision and durability in mind, tailored to meet the exacting demands of the automotive industry.

- Precision engineering for optimal performance.

- Durable construction for extended lifespan.

- Customization to meet specific automotive requirements.

By combining these elements, Ningbo Buttler delivers die-casting molds that enhance efficiency and productivity on the assembly line.

Ningbo Buttler is committed to providing exceptional die-casting mold solutions to the automotive industry.

High-Quality Aluminum and Zinc Castings

Buttler's commitment to excellence is evident in its production of high-quality aluminum and zinc castings for automotive applications. Its advanced manufacturing processes and strict quality control measures result in durable and reliable casting parts that meet the industry's stringent standards.

Comprehensive Processing, Surface Treatment, Assembly, and Packaging

From processing to surface treatment, assembly, and packaging, Ningbo Buttler Precision Machinery Co., Ltd. offers a comprehensive range of services to ensure that automotive castings meet the highest quality and functionality standards. Their attention to detail at every production stage sets them apart as a trusted partner in the automotive casting industry.

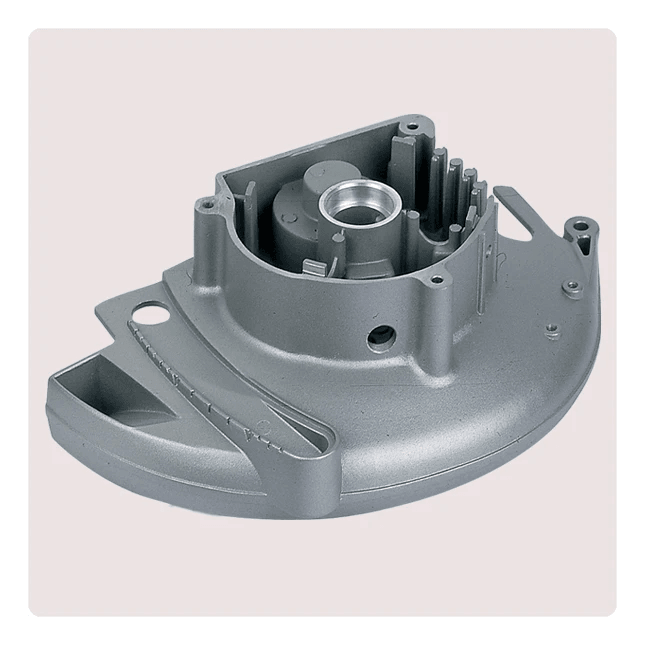

Diverse Product Range

, Including Outdoor Lamp Series, Gas Appliance Parts, Power Tool Parts, and Appliance Parts

With a diverse product range that includes outdoor lamp series, gas appliance parts, power tool parts, and appliance parts, Buttler demonstrates versatility in meeting the casting needs of various automotive applications. Their extensive experience allows them to cater to multiple casting requirements with precision and expertise.

Commitment to Quality and Innovation

Ningbo Buttler Precision Machinery Co., Ltd.'s unwavering commitment to quality and innovation is reflected in its continuous pursuit of excellence in die-casting technology for automotive applications. Its dedication to pushing boundaries ensures that it remains at the forefront of delivering cutting-edge solutions for automotive castings.

Industry Trends in Automotive Castings

Growing Demand for Lightweight Automotive Parts

The automotive industry is experiencing a surge in demand for lightweight parts to improve fuel efficiency and reduce emissions. This trend has led to an increased focus on aluminum and zinc castings, which offer high strength-to-weight ratios and excellent formability, making them ideal for producing lightweight components.

Increasing Utilization of Aluminum and Zinc Castings

As automakers strive to meet stringent fuel economy standards, the utilization of aluminum and zinc castings in automotive manufacturing has significantly increased. These materials provide exceptional mechanical properties, corrosion resistance, and thermal conductivity, making them essential for producing durable and efficient automotive components.

Role of Die Casting in Advancing Automotive Technology

Die casting plays a crucial role in advancing automotive technology by enabling the production of complex, high-precision parts with tight tolerances. This manufacturing process allows for creating intricate designs that enhance vehicle performance, safety, and overall driving experience.

The Shift Towards Sustainable and Eco-Friendly Materials

With an increasing emphasis on sustainability, there is a noticeable shift towards using eco-friendly materials in automotive manufacturing. Aluminum and zinc castings are lightweight and recyclable, making them environmentally responsible for producing automotive parts.

Smart Part Engineering's Contribution to Industry Trends

Smart Part Engineering is contributing to industry trends by providing innovative tooling designs engineered for cost-effective manufacturing. Smart Part Engineering is shaping the future of automotive castings with its forward-thinking approach by optimizing part designs to maximize performance while minimizing the need for secondary operations.

Meeting the Needs of the Automotive Industry

Customized Solutions for Automotive Casting Requirements

Ningbo Buttler Precision Machinery Co., Ltd. offers customized solutions for all your automotive casting requirements, ensuring each part is tailored to meet specific industry standards and performance needs.

Adapting to Changing Industry Standards

In the fast-paced automotive industry, staying ahead of changing industry standards is crucial. Ningbo Buttler Precision Machinery Co., Ltd. is committed to adapting and innovating to meet the evolving demands of the automotive sector.

Enhancing Manufacturing Efficiency

With a focus on enhancing manufacturing efficiency, Ningbo Buttler Precision Machinery Co., Ltd. leverages advanced technology and expertise to streamline production processes and deliver high-quality automotive castings cost-effectively.

Addressing the Demand for High-Quality Automotive CastingsAs the demand for high-quality automotive castings continues to rise, Ningbo Buttler Precision Machinery Co., Ltd. remains committed to delivering exceptional products and unparalleled customer service. Our focus lies in providing solutions that meet the evolving needs of the automotive industry.

To achieve this, we prioritize:

- Precision engineering: Utilizing state-of-the-art technology to produce castings with exacting tolerances.

- Material expertise: Selecting the optimal materials for each application to ensure optimal performance and durability.

- Customer collaboration: Working closely with clients to understand their requirements and deliver tailored solutions.

By adhering to these principles, Ningbo Buttler is positioned as a trusted partner in the automotive industry.

Ningbo Buttler Precision Machinery Co., Ltd.: Your Partner in Automotive Manufacturing

For all your automotive casting needs, trust Ningbo Buttler Precision Machinery Co., Ltd. as your reliable partner in delivering top-notch products and solutions for the ever-evolving automobile industry.

Ensure Quality in Automotive Castings

Quality is paramount for performance and durability in automotive castings. High-quality die-casting components play a crucial role in ensuring the reliability and safety of automobile parts. With the growing market for aluminum structural components in electric vehicles, the demand for superior automotive castings continues to rise.

Smart Part Engineering's Role in Efficient Manufacturing

Smart Part Engineering has revolutionized part designs for efficient manufacturing, offering innovative tooling designs that maximize performance and casting quality while minimizing the need for secondary operations. Their expertise in engineering design review processes ensures that automotive castings meet high standards without additional costs.

Partnering with Ningbo Buttler Precision Machinery Co., Ltd.

Ningbo Buttler Precision Machinery Co., Ltd. stands out as a leading expert in automotive castings. It specializes in die-casting molds, aluminum and zinc castings, processing, surface treatment, assembly, and packaging. Its commitment to quality and innovation makes it an ideal partner for automotive manufacturers seeking high-quality casting parts.

By understanding the importance of high-quality automotive castings and the role of innovative companies like Smart Part Engineering and Ningbo Buttler Precision Machinery Co., Ltd., manufacturers can ensure that their products meet industry standards while staying ahead of market trends. Partnering with experts in automotive castings is essential for meeting the growing demand for reliable and sustainable automobile components.