Introduction

When it comes to manufacturing, finding reliable casting suppliers is crucial for ensuring the quality and performance of your products. Whether you're in need of aluminum casting suppliers, die casting suppliers, or aluminium casting suppliers, choosing the right partner can make all the difference in your production process. Working with a reputable casting parts manufacturer can provide numerous benefits, from cost savings to improved product quality and timely delivery.

Finding Reliable Casting Suppliers

Finding trustworthy casting suppliers can be a daunting task, but it's essential for the success of your manufacturing operations. With so many options available in the market, it's important to thoroughly research and vet potential partners to ensure they have the expertise and capabilities to meet your specific needs.

Understanding Aluminum Casting

Aluminum casting is a widely used manufacturing process that involves pouring molten aluminum into a mold cavity to create intricate parts and components. It offers numerous advantages, including lightweight properties, high strength-to-weight ratio, and excellent corrosion resistance, making it a popular choice across various industries.

Benefits of Quality Casting Suppliers

In today's competitive manufacturing landscape, success hinges on strong partnerships. When it comes to casting, choosing quality suppliers goes beyond just procuring parts. Here's a breakdown of the key benefits a reliable casting supplier can bring to your business:

Enhanced Capabilities and Innovation

- Advanced Technologies: Top casting suppliers invest in cutting-edge technologies like 3D printing for mold creation, simulation software for process optimization, and advanced casting techniques. Partnering with such a supplier gives you access to these advancements, allowing you to produce complex parts with greater precision and efficiency.

- Material Expertise: Quality suppliers possess deep knowledge of various casting materials, their properties, and best practices for working with them. This expertise translates into valuable advice on material selection for optimal performance and cost-effectiveness in your application.

Improved Design and Manufacturing

- Design Optimization: Leading casting suppliers offer design for manufacturability (DFM) services. They can analyze your design and suggest improvements to enhance castability, reduce weight, and potentially lower production costs.

- Streamlined Manufacturing: A reliable supplier can work collaboratively with your team to optimize the casting process for your specific needs. This can involve minimizing waste, reducing lead times, and implementing efficient production methods.

Quality, Consistency, and Reliability

- Strict Quality Control: Quality casting suppliers prioritize stringent quality control measures throughout the process. This ensures parts meet your specifications and industry standards, minimizing the risk of defects and rework.

- Consistent Performance: Reliable suppliers prioritize consistent production of high-quality castings. This translates to fewer production delays and ensures you receive parts that meet your performance expectations every time.

- On-Time Delivery: Timely delivery is crucial. Partnering with a dependable supplier ensures you receive your castings on schedule, preventing disruptions in your production flow.

Additional Advantages:

- Cost Savings: While upfront costs might seem the only factor, a quality supplier can help you achieve cost savings in the long run. Through optimized design, efficient production methods, and reduced rework due to quality control, you can minimize overall manufacturing expenses.

- Reduced Risk: Partnering with an experienced supplier mitigates risks associated with casting processes. Their expertise helps identify potential issues early on and implement solutions to ensure project success.

- Industry Knowledge: Leading casting suppliers stay updated on industry trends and advancements. This knowledge can be invaluable in keeping your manufacturing processes at the forefront and your products competitive.

Choosing quality casting suppliers is an investment in the efficiency, quality, and overall success of your production operations. By partnering with a reliable supplier, you gain access to advanced technologies, material expertise, design optimization, and a commitment to quality and on-time delivery. This strong partnership empowers you to achieve your manufacturing goals and gain a competitive edge in the market.

Overview of Aluminum Casting

Aluminum casting involves pouring molten aluminum into a mold to create various parts and components. This versatile method allows for producing complex shapes and designs, making it a popular choice in many industries.

Process of Aluminum Casting

The aluminum casting process begins with melting aluminum in a furnace. Once molten, the aluminum is poured into a mold cavity, where it solidifies and takes on the shape of the mold. After cooling, the newly formed aluminum part is removed from the mold, and any excess material is trimmed away.

Importance of High-Quality Aluminum Casting

High-quality aluminum casting is crucial for ensuring the structural integrity and performance of the final product. Inferior casting can lead to defects, such as porosity or shrinkage, compromising the part's functionality and durability.

Advantages of Aluminum Casting Suppliers

Working with reputable aluminum casting suppliers ensures you receive high-quality castings that meet your specifications. These suppliers have the expertise and resources to deliver precision-crafted parts that adhere to industry standards and best practices.

Ningbo Buttler Precision Machinery Co., Ltd.

Ningbo Buttler Precision Machinery Co., Ltd. is a leading die-casting molds and casting parts manufacturer specializing in high-quality aluminum and zinc castings. Focusing on innovative tooling designs, it offers cost-effective manufacturing solutions that maximize performance and casting quality while minimizing the need for secondary operations.

Specialization in Die-Casting Molds

Ningbo Buttler Precision Machinery Co., Ltd. stands out as a reliable die casting supplier. They specialize in producing high-quality die-casting molds for various industries. Their expertise in designing and manufacturing these molds ensures the precise and efficient production of aluminum and zinc castings that meet the highest quality and durability standards.

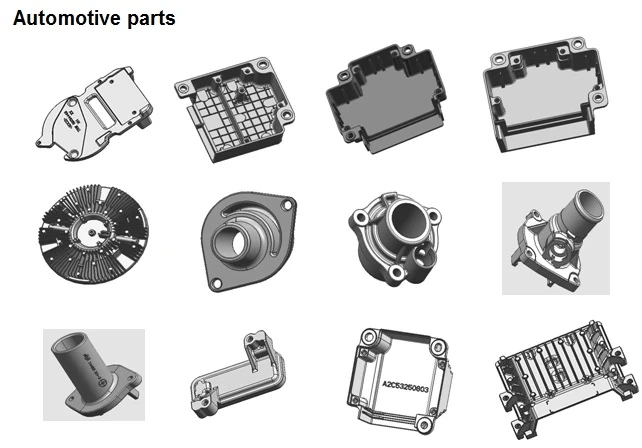

Expertise in Aluminum and Zinc Castings

As an experienced aluminum casting supplier, Ningbo Buttler Precision Machinery Co., Ltd. offers a wide range of aluminum and zinc castings tailored to meet specific industry requirements. Their expertise in understanding the unique properties of these materials allows them to produce durable, high-performance castings that are essential for various applications.

In addition to their expertise in aluminum and zinc castings, Ningbo Buttler Precision Machinery Co., Ltd. excels in innovative tooling designs for cost-effective manufacturing. By leveraging advanced design software and state-of-the-art manufacturing techniques, they create tooling solutions that optimize production processes and minimize material waste. This commitment to efficiency reduces manufacturing costs and ensures the highest quality standards for their castings, making them a reliable partner for businesses seeking cost-effective solutions.

Innovative Tooling Designs for Cost-Effective Manufacturing

Ningbo Buttler Precision Machinery Co., Ltd.'s commitment to innovation is evident in its approach to tooling designs, which are engineered for cost-effective manufacturing processes. By leveraging advanced techniques and technologies, it is able to optimize production efficiency while maintaining exceptional quality standards, making it a trusted partner for businesses seeking reliable casting suppliers.

Additionally, Ningbo Buttler Precision Machinery Co., Ltd. stays ahead of the curve by continuously investing in research and development to enhance its tooling designs. This proactive approach allows it to anticipate industry trends and adapt its processes accordingly, ensuring that its clients benefit from the latest advancements in manufacturing technology. As a result, businesses can rely on Ningbo Buttler for innovative solutions that meet current needs and future-proof their operations.

Smart Part Engineering for Better Part Designs

Ningbo Buttler Precision Machinery Co., Ltd. is a leading die casting supplier specializing in aluminum and zinc castings. Our smart part engineering approach maximizes performance and casting quality, ensuring that our products meet the highest industry standards. By leveraging innovative tooling designs, we minimize the need for secondary operations, resulting in cost-effective manufacturing processes.

Maximizing Performance and Casting Quality

At Ningbo Buttler, we understand the importance of delivering high-quality aluminum and zinc castings to our clients. Our smart part engineering techniques enhance the performance of our products while maintaining exceptional casting quality. This commitment to excellence has established us as a trusted partner for companies seeking reliable casting suppliers.

Our advanced manufacturing processes and cutting-edge technology allow us to minimize the need for secondary operations, saving our clients time and money. By optimizing our casting techniques, we can produce parts with minimal porosity and surface defects, reducing the need for additional finishing processes. This streamlined approach improves efficiency and ensures that our clients receive high-quality castings that meet their exact specifications.

Minimizing the Need for Secondary Operations

By prioritizing smart part engineering in our manufacturing processes, we aim to minimize the need for secondary operations such as machining or finishing. This streamlines production and reduces costs for our clients, making us a preferred choice among aluminum casting suppliers. Our focus on precision casting techniques and advanced tooling technology allows us to achieve the desired surface finish and dimensional accuracy right from the initial casting, eliminating the need for additional processing. Additionally, our in-house expertise in design optimization ensures that parts are engineered for manufacturability, reducing reliance on secondary operations and delivering cost savings to our clients.

Free Engineering Design Review Process

We offer a unique advantage with our free engineering design review process, allowing clients to optimize their new and existing parts at no additional cost. This service underscores our dedication to providing value-added solutions and sets us apart from other die casting suppliers in the industry.

Our free engineering design review process is a testament to our commitment to delivering exceptional value to our clients. By optimizing new and existing parts at no additional cost, we empower our clients to stay ahead of the competition and achieve their performance goals while minimizing costs. This unique advantage sets us apart from other die casting suppliers in the industry, showcasing our dedication to providing innovative solutions that drive success.

Stay ahead of your competition with Ningbo Buttler Precision Machinery Co., Ltd.'s cutting-edge smart part engineering techniques! Maximize performance while minimizing costs with our innovative tooling designs and free engineering design review process.

Choosing Quality Casting Suppliers

When selecting casting suppliers, it's crucial to consider factors such as experience, expertise, and reputation in the industry. Look for suppliers with a proven track record of delivering high-quality casting parts and meeting customer requirements. Additionally, consider their ability to provide timely delivery and excellent customer support to ensure a smooth and efficient partnership.

Factors to Consider in Selecting Suppliers

Reliability is key when choosing aluminum casting or die casting suppliers. Look for suppliers that focus strongly on quality control, efficient production processes, and adherence to industry standards. It's also important to assess their capacity for handling large orders and their flexibility in accommodating specific project requirements.

After considering the reliability of potential aluminum casting or die casting suppliers, evaluating their communication and customer service is essential. A supplier that is responsive, transparent, and easy to work with can make a significant difference in a project's success. Clear and open lines of communication can help prevent misunderstandings and ensure that any issues are addressed promptly, leading to a smoother and more efficient production process.

Qualities of Reliable Casting Parts Manufacturer

A reliable casting parts manufacturer should demonstrate expertise in producing precision components with superior mechanical properties and surface finishes. They should also be capable of working with various materials such as aluminum, zinc, and other alloys, offering a wide range of options for different applications. Additionally, look for manufacturers prioritizing continuous improvement and investing in advanced technology for optimal results.

How to Ensure Consistent Quality in Castings

To ensure consistent quality in castings, it's essential to partner with suppliers with stringent quality control measures throughout the production process. This includes thorough inspection procedures, testing protocols, and compliance with international quality standards. Effective communication between the supplier and the client is crucial for addressing any concerns or modifications needed during production.

When working with trusted suppliers, clients can benefit from a consistent supply of high-quality castings, reducing the risk of defects or inconsistencies in the final products. This can ultimately lead to cost savings through decreased rework and scrap and improved overall product performance and customer satisfaction. Additionally, reliable suppliers can offer valuable expertise and guidance in material selection, design optimization, and production techniques to enhance the quality of castings further.

Benefits of Working with Trusted Suppliers

1. Timely Delivery of High-Quality Castings

When partnering with reliable casting suppliers like Ningbo Buttler Precision Machinery Co., Ltd., you can expect timely delivery of high-quality castings. With their expertise in die-casting molds and aluminum casting, you can rest assured that your orders will be fulfilled efficiently and without compromising quality.

In addition to the timely delivery of high-quality castings, partnering with Ningbo Buttler Precision Machinery Co., Ltd. can also lead to long-term cost savings for your business. You can avoid production delays and keep your operations running smoothly by consistently receiving top-notch castings on time. This reliability ultimately translates into cost savings by minimizing downtime and maximizing efficiency in your manufacturing processes.

2. Long-Term Cost Savings

Choosing the right casting parts manufacturer can lead to long-term cost savings for your business. By working with aluminum casting suppliers who prioritize quality and precision, you can minimize the need for rework or replacements, ultimately saving both time and money in the long run.

You can also benefit from seamless communication and excellent customer support by choosing a reliable aluminum casting supplier. A manufacturer that values open and transparent communication will ensure that your needs and specifications are clearly understood and met throughout production. Additionally, responsive customer support can promptly address any concerns or issues, allowing for a smoother and more efficient collaboration.

3. Seamless Communication and Customer Support

One key benefit of working with trusted casting suppliers is the seamless communication and customer support they provide. Ningbo Buttler Precision Machinery Co., Ltd. offers a dedicated team that ensures clear communication throughout the production process, promptly addressing any concerns or inquiries to provide a smooth and satisfying experience for their clients.

In addition to clear communication, Ningbo Buttler Precision Machinery Co., Ltd. also provides exceptional customer support by offering personalized solutions to meet the specific needs of their clients. Whether providing technical assistance, addressing quality concerns, or offering guidance on material selection, their dedicated team goes above and beyond to ensure that clients feel supported at every step. This level of attentive customer service sets them apart as a reliable and trustworthy casting supplier.

Partner with Ningbo Buttler Precision Machinery Co., Ltd.

Ningbo Buttler Precision Machinery Co., Ltd. is your go-to partner for all your die-casting mold and aluminum casting needs. With their specialization in aluminum and zinc castings, innovative tooling designs, and free engineering design review process, you can trust them to deliver high-quality products that meet your specifications.

When it comes to finding reliable casting suppliers, Ningbo Buttler Precision Machinery Co., Ltd. stands out as a leader in the industry. Their expertise in die-casting molds and aluminum casting makes them perfect for all your casting needs. Partnering with them ensures top-notch quality and exceptional customer service.

Key Considerations in Choosing Casting Suppliers

Selecting the right casting supplier is crucial for the success of your project. Here are some key factors to consider when making this important decision, going beyond just the types of casting they offer (like die-casting molds, aluminum casting, or zinc casting) **

1. Capabilities and Expertise

- Technology and Equipment: Investigate the supplier's technology and equipment. Do they have the latest casting equipment and capabilities to handle your project's complexity and meet your desired tolerances?

- Material Expertise: Look for a supplier with in-depth knowledge of various casting materials and their properties. This expertise ensures they can recommend the most suitable material for your application, optimizing performance and cost-effectiveness.

2. Quality and Reliability

- Quality Control Procedures: Prioritize a supplier with robust quality control measures in place. This includes stringent inspections throughout production, from raw materials to finished castings. Look for certifications demonstrating their commitment to quality, such as ISO 9001.

- Track Record: Research the supplier's reputation for quality and reliability. Look for a company with a proven track record of delivering high-quality castings consistently and on time.

3. Communication and Customer Service

- Open Communication: Clear and transparent communication is essential. Choose a supplier that is responsive to inquiries and fosters a collaborative partnership. Look for a team that actively listens to your needs, addresses your concerns promptly, and keeps you informed throughout the project.

- Project Management: Effective project management ensures timely delivery and adherence to budget constraints. Look for a supplier with a proven track record of managing projects efficiently and keeping you updated on progress.

4. Cost and Value

- Competitive Pricing: While cost is a factor, focusing solely on the cheapest option can backfire. Look for a supplier that offers competitive pricing while maintaining high-quality standards.

- Value-Added Services: Some suppliers offer additional services like design optimization for casting, surface finishing options, or post-processing services. These value-added services can enhance the functionality and aesthetics of your parts.

5. Additional Considerations

- Lead Time and Production Capacity: Consider your project timeline and volume requirements. Does the supplier have the capacity to handle your specific needs and deliver parts on schedule?

- Location: Geographic location might influence your decision, depending on your project and needs. Consider factors like potential import/export duties and ease of communication if working with an overseas supplier.

Choosing a casting supplier is an investment in your project's success. By prioritizing these key factors and going beyond just the types of casting they offer, you can find a reliable partner with the technology, expertise, commitment to quality, and value-added services to deliver the castings you need on time and within budget. This strong partnership empowers you to achieve your manufacturing goals and gain a competitive edge in the market.

Ensuring Quality with Smart Part Engineering and Reliable Suppliers

Smart Part Engineering is crucial for better part designs, and Ningbo Buttler Precision Machinery Co., Ltd. excels in providing innovative tooling designs for cost-effective manufacturing. By partnering with reliable suppliers like them, you can ensure consistent quality in your castings while minimizing the need for secondary operations.