Introduction

Aluminium die casting is a crucial process in manufacturing, providing lightweight and durable materials for a variety of applications. Choosing the right casting factory for your diecasting needs is essential to achieve superior quality and precision in part designs. At Ningbo Buttler Precision Machinery Co., Ltd., we specialize in die-casting molds and aluminium casting, offering innovative tooling designs and cost-effective manufacturing processes to meet your specific requirements.

The Importance of High-Quality Aluminium Die Casting

High-quality aluminium die casting not only ensures the production of lightweight and durable parts but also provides excellent thermal conductivity, corrosion resistance, and high electrical conductivity. These properties make aluminium die casting ideal for applications in the automotive industry, where parts need to withstand harsh conditions and heavy use. Additionally, the versatility of aluminium die casting allows for the production of components with tight tolerances and smooth surface finishes, meeting the stringent requirements of the lighting and appliance industries.

Why Choose Ningbo Buttler Precision Machinery Co., Ltd.?

Ningbo Buttler Precision Machinery Co., Ltd. stands out as a leading expert in diecasting with extensive experience in processing aluminium castings and zinc castings. Our specialization in innovative tooling designs ensures better part quality while offering cost-effective solutions for your manufacturing needs.

In addition to our expertise in diecasting and innovative tooling designs, Ningbo Buttler Precision Machinery Co., Ltd. also prides itself on our commitment to sustainability. We prioritize the use of environmentally friendly materials and processes in our manufacturing, ensuring that our operations have minimal impact on the planet. By choosing us as your diecasting partner, you can align your brand with eco-conscious practices and contribute to a greener future.

Advantages of Die Casting and Foundry Processes

The advantages of die casting and foundry processes lie in their ability to produce complex shapes with high accuracy, smooth surfaces, and thin walls using alum cast material. This results in cost-effective manufacturing processes that reduce the need for secondary operations while maintaining superior part quality.

Furthermore, the use of alum cast material in die casting and foundry processes allows for excellent thermal conductivity and high electrical conductivity, making it an ideal choice for manufacturing components that require these properties. This makes the processes suitable for a wide range of applications, including automotive, aerospace, and electronics industries. The versatility of alum cast material adds to the appeal of die casting and foundry processes as cost-effective solutions for producing high-quality parts.

The Benefits of Aluminium Die Casting

Aluminium die casting offers a wide range of benefits that make it the ideal choice for various applications. The lightweight and durable materials used in aluminium casting provide strength and resilience, making it perfect for industries where weight and durability are crucial factors. This makes it an excellent choice for automotive parts, outdoor lamp series, gas appliance parts, power tool parts, and appliance parts.

Lightweight and Durable Materials

The use of high-quality aluminium casting material ensures that the final products are lightweight yet incredibly strong and durable. This makes them suitable for a variety of applications where weight is a concern but strength cannot be compromised. Whether it's automotive parts or outdoor lamp series, the lightweight nature of aluminium castings makes them highly desirable.

The versatility of aluminium casting material also allows for intricate and complex designs to be achieved with precision. This means that products can be tailored to specific requirements, whether it's intricate automotive components or detailed outdoor lighting fixtures. The ability to maintain strength and durability while still achieving complex designs sets aluminium castings apart from other materials, making them a top choice for a wide range of applications.

Precision and Complexity in Designs

Aluminium die casting allows for intricate designs with high precision and complexity that may be difficult to achieve with other manufacturing processes. This means that even the most detailed designs can be accurately replicated in the final product, providing exceptional quality and aesthetics. Ningbo Buttler Precision Machinery Co., Ltd.'s specialization in die-casting molds ensures that even the most complex designs can be brought to life with utmost precision.

Additionally, aluminium die casting offers cost-effective manufacturing processes, making it an ideal choice for businesses looking to optimize production costs without compromising on quality. By utilizing die-casting molds, companies can streamline their manufacturing operations and achieve economies of scale, resulting in significant cost savings in the long run. This cost-effectiveness further enhances the appeal of aluminium die casting as a preferred method for producing intricate and complex designs.

Cost-Effective Manufacturing Processes

One of the key advantages of aluminium die casting is its cost-effectiveness in manufacturing processes. The ability to produce large quantities of complex parts at a rapid pace reduces production costs significantly, making it an economical choice for various industries. With extensive experience in aluminium and zinc castings, Ningbo Buttler Precision Machinery Co., Ltd. has perfected cost-effective manufacturing processes to deliver superior quality products at competitive prices.

Additionally, aluminium die casting offers the advantage of high dimensional accuracy and stability, ensuring consistent quality across large production runs. This reliability reduces the need for rework or corrections, further driving down manufacturing costs. Ningbo Buttler Precision Machinery Co., Ltd.'s commitment to precision and attention to detail in their manufacturing processes guarantees that customers receive parts that meet their exact specifications every time.

Exploring Ningbo Buttler Precision Machinery Co., Ltd.

Ningbo Buttler Precision Machinery Co., Ltd. is a leading casting factory specializing in die-casting molds for high-quality aluminium and zinc castings. With extensive experience in the industry, they offer innovative tooling designs that ensure better part quality and cost-effective manufacturing processes.

Specialization in Die-Casting Molds

Ningbo Buttler Precision Machinery Co., Ltd. excels in producing top-notch die-casting molds for various applications, including automotive, appliance, and power tool parts. Their expertise in creating precise and durable molds sets them apart as a trusted partner for all die casting needs.

Ningbo Buttler Precision Machinery Co., Ltd. also prides itself on its extensive experience in producing high-quality aluminium and zinc castings. With a deep understanding of the unique properties of these materials, they are able to create molds that consistently deliver superior results. Their commitment to staying at the forefront of industry trends and technological advancements ensures that their clients receive the most innovative and efficient die-casting solutions available.

Extensive Experience in Aluminium and Zinc Castings

With a proven track record of delivering superior aluminium and zinc castings, Ningbo Buttler Precision Machinery Co., Ltd. has solidified its reputation as a reliable supplier in the industry. Their commitment to excellence ensures that every casting material meets the highest standards of quality and performance.

With a focus on continuous improvement, Ningbo Buttler Precision Machinery Co., Ltd. invests in innovative tooling designs to enhance part quality. By staying ahead of industry trends and technological advancements, they are able to offer cutting-edge solutions that meet the evolving needs of their customers. This commitment to innovation sets them apart as a leader in the production of aluminium and zinc castings.

Innovative Tooling Designs for Better Part Quality

One of the key strengths of Ningbo Buttler Precision Machinery Co., Ltd. lies in their ability to provide innovative tooling designs that enhance part quality while streamlining manufacturing processes. Their smart engineering solutions result in cost-effective production without compromising on performance or durability.

Furthermore, Ningbo Buttler Precision Machinery Co., Ltd. is committed to staying ahead of the curve when it comes to technological advancements in tooling designs. By investing in research and development, they are able to offer cutting-edge solutions that meet the evolving needs of their clients. This proactive approach ensures that their tooling designs are always at the forefront of innovation, setting them apart from their competitors.

Applications of High-Quality Aluminium Die Casting

Ningbo Buttler Precision Machinery Co., Ltd. is a leading casting factory that specializes in high-quality aluminium casting for a wide range of applications. With their expertise in die casting and foundry processes, they are able to produce top-notch alum cast parts for various industries.

Outdoor Lamp Series

The outdoor lamp series benefits greatly from the lightweight and durable materials provided by aluminium die casting. Buttler's expertise in die for casting ensures precision and complexity in the designs, resulting in high-quality, cost-effective outdoor lighting solutions that can withstand harsh weather conditions.

Automotive Parts

Automotive parts require strength, durability, and precision, all of which are delivered through high-quality aluminium die casting. Ningbo Buttler Precision Machinery Co., Ltd.'s innovative tooling designs ensure that automotive parts meet strict industry standards while remaining cost-effective for manufacturers.

Gas Appliance Parts

Gas appliance parts demand reliability and safety, making aluminium die casting the ideal choice due to its lightweight yet sturdy nature. By utilizing Buttler's expertise in diecast die production, gas appliance manufacturers can achieve superior quality while maintaining cost-efficiency.

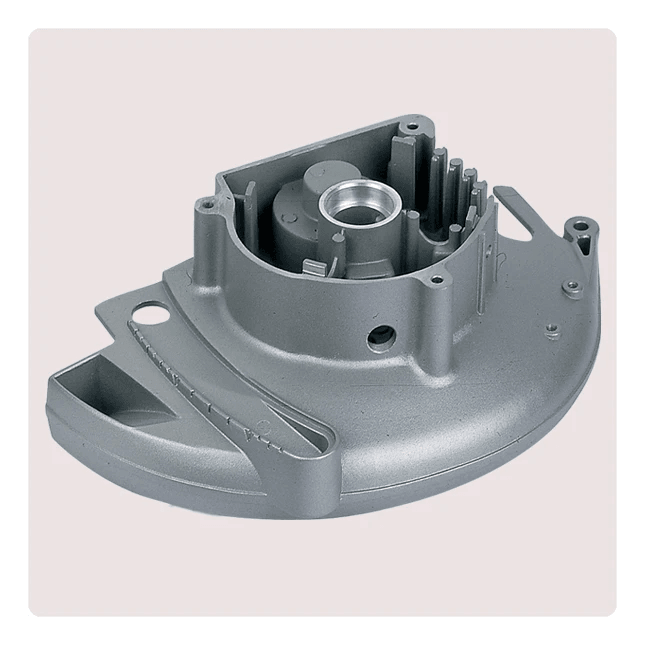

Power Tool Parts

Power tool parts benefit from the lightweight yet robust nature of aluminium castings, providing users with durable tools that are easy to handle. Ningbo Buttler Precision Machinery Co., Ltd.'s specialization in die-casting molds ensures that power tool manufacturers receive top-notch components for their products.

Appliance Parts

Aluminium die casting is widely used for various appliance parts due to its ability to produce complex shapes with high precision at a competitive cost. With Buttler's extensive experience in aluminium and zinc castings, manufacturers can rely on them to deliver superior quality components for their appliances.

Conclusion

Ningbo Buttler Precision Machinery Co., Ltd. is your go-to casting factory for superior quality aluminium casting and die casting. With their specialization in die-casting molds and extensive experience in processing, surface treatment, and assembly, you can trust them to deliver top-notch alum cast parts for your projects.

Achieving Superior Quality with Ningbo Buttler Precision Machinery Co., Ltd.

When it comes to achieving superior quality in die casting, Ningbo Buttler Precision Machinery Co., Ltd. stands out as a reliable partner. Their commitment to innovative tooling designs and cost-effective manufacturing processes ensures that you get the best casting material for your needs. Trust them to deliver high-quality diecast dies that meet your exact specifications.

Ningbo Buttler Precision Machinery Co., Ltd. also prides itself on staying ahead of the curve when it comes to the future of aluminum die casting. With a focus on sustainability and efficiency, they are constantly exploring new techniques and technologies to improve the die casting process. By partnering with them, you can be confident that you are investing in cutting-edge solutions that will set your products apart in the market.

The Future of Aluminium Die Casting

As the demand for lightweight and durable materials continues to grow, the future of aluminium die casting looks promising. With advancements in precision and complexity in designs, aluminium casting is set to play a crucial role in various industries, from automotive to appliances. Ningbo Buttler Precision Machinery Co., Ltd. is well-positioned to lead the way with their expertise in this field. Furthermore, with the increasing emphasis on sustainability and environmental consciousness, aluminium die casting offers a recyclable and energy-efficient solution for manufacturers looking to reduce their carbon footprint. This makes it an attractive option for companies aiming to meet green standards and regulations while maintaining high-quality products.

Choosing Excellence in Die Casting and Foundry Processes

When it comes to choosing excellence in die casting and foundry processes, look no further than Ningbo Buttler Precision Machinery Co., Ltd. Their proven track record of delivering high-quality parts for outdoor lamps, automotive components, gas appliances, power tools, and more makes them the ideal partner for all your casting needs.

Look no further than Ningbo Buttler Precision Machinery Co., Ltd. for cutting-edge technology and innovative solutions in die casting and foundry processes. With a team of experienced engineers and technicians, they are capable of delivering complex parts with precision and efficiency. Whether it's a custom design or a high-volume production run, Ningbo Buttler Precision Machinery Co., Ltd. has the expertise to meet your specific requirements.