Introduction

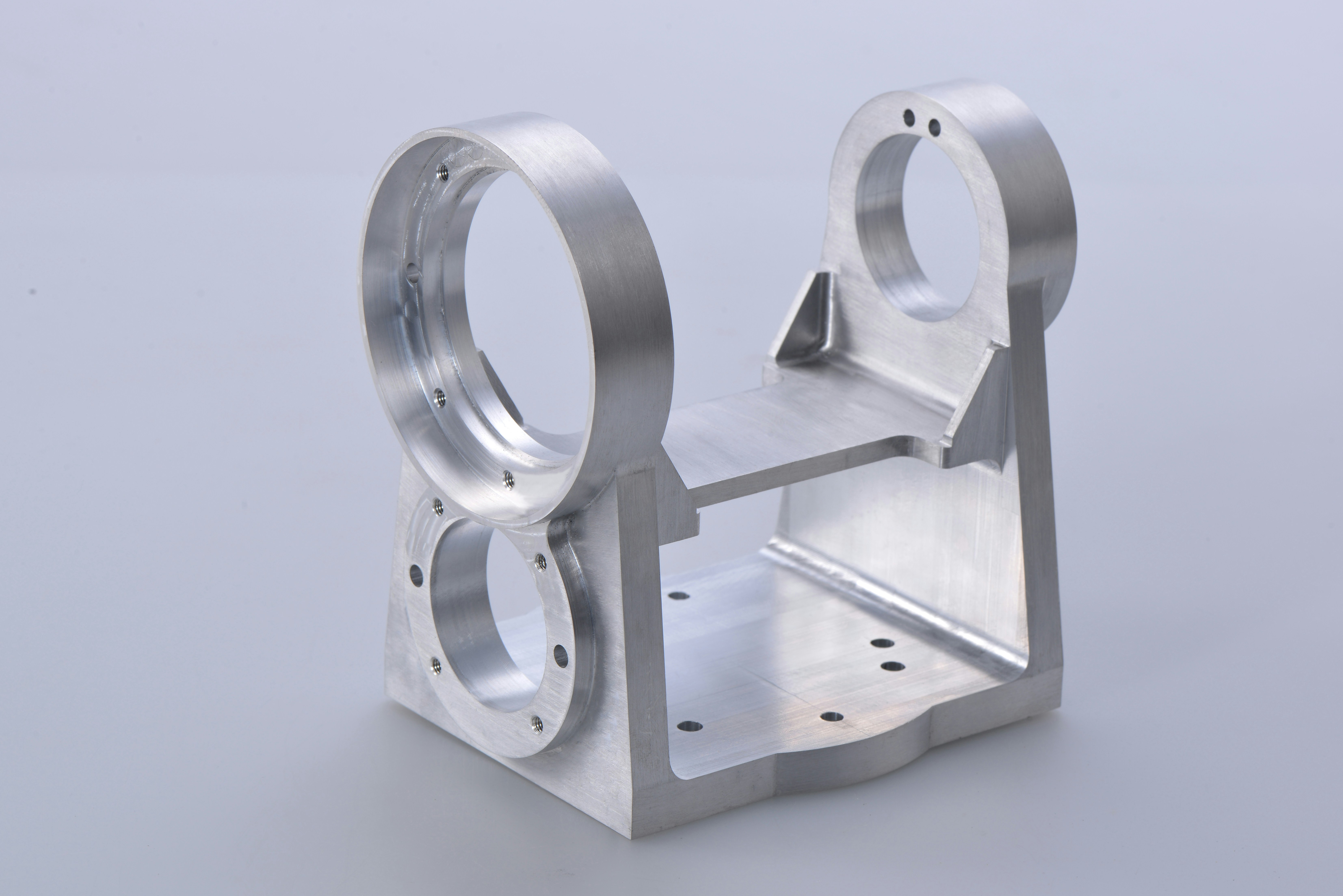

For your next project, are you looking for durable, lightweight, and precision-engineered components? Look no further than aluminium die casting components. With their exceptional strength-to-weight ratio and corrosion resistance, cast aluminum parts are the perfect choice for various applications. When it comes to high-quality die casting components, Buttler Precision Machinery is your trusted partner for delivering top-notch solutions.

The Benefits of Aluminium Die Casting Components

Aluminum die casting is a popular manufacturing technique that offers numerous advantages for various industries. Here's a breakdown of some key benefits:

- Superior Conductivity: Aluminum die castings boast excellent thermal and high electrical conductivity, making them ideal for applications requiring efficient heat dissipation or electrical current transfer.

- Outstanding Mechanical Properties: The process delivers durable parts with good dimensional stability. This makes them suitable for applications demanding structural integrity and precise tolerances.

- Lightweight Champion: Aluminum die casting produces complex shapes with thin walls while maintaining high strength. This translates to lightweight parts, perfect for industries like automotive and aerospace where weight reduction is critical for performance and fuel efficiency. The lighter weight also simplifies handling and transportation, reducing costs throughout the supply chain.

Aluminum die casting offers a compelling combination of strength, versatility, and lightweight design, making it a valuable asset for various industries.

Why Aluminium Die Casting is Ideal for Lightweight Applications

In today's fast-paced world, lightweight materials are in high demand due to their fuel efficiency and reduced environmental impact. Aluminium die casting provides the perfect solution as it offers superior strength at a fraction of the weight compared to other materials.

Aluminium die casting is also highly versatile, allowing for intricate and complex designs to be easily achieved. This makes it ideal for a wide range of lightweight applications, from automotive components to consumer electronics. Additionally, aluminium is highly corrosion-resistant, making it suitable for outdoor and marine environments where durability is essential. With its excellent thermal conductivity, aluminium die casting also ensures efficient heat dissipation, further enhancing its appeal for lightweight applications.

Buttler Precision Machinery: Your Partner for High-Quality Die Casting Components

Buttler Precision Machinery has established itself as a leader in producing top-quality aluminium die casting parts that meet stringent industry standards. With our state-of-the-art facilities and expertise in aluminium casting, we ensure that our clients receive exceptional products tailored to their specific needs.

Buttler Precision Machinery understands the importance of precision and reliability in manufacturing. That's why we take great pride in our ability to deliver high-quality aluminium consistently die casting components that exceed our clients' expectations. Our team of skilled professionals is dedicated to upholding the highest standards of craftsmanship and attention to detail, ensuring that every product we produce is of the utmost quality.

Understanding Aluminium Die Casting

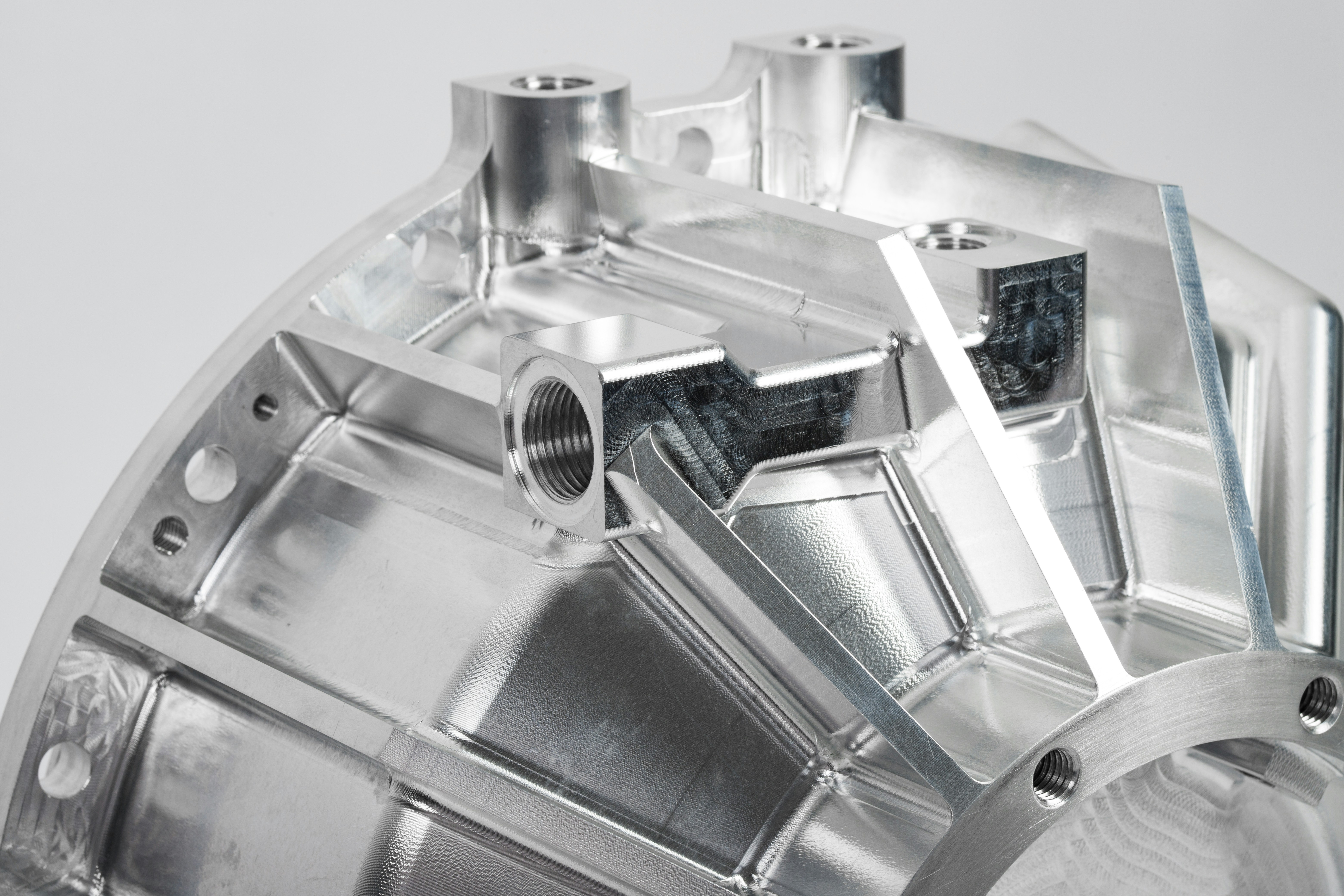

Aluminium die casting components are highly sought after for their lightweight yet durable properties, making them ideal for various applications. Cast aluminum's versatility allows for complex shapes and thin walls, resulting in high-strength parts with excellent dimensional accuracy. This makes aluminum die casting parts perfect for industries such as automotive, aerospace, and consumer electronics.

Advantages of Aluminium Die Casting Components

Aluminium die casting is a popular manufacturing process for a reason. Here are some of the key advantages that make aluminium die cast components so versatile and desirable:

- Excellent Performance Across Various Conditions: Aluminium die castings offer high thermal conductivity, exceptional corrosion resistance, and excellent electrical conductivity. This combination of properties makes them suitable for various environments and applications.

- Tight Tolerances and Smooth Surfaces: Aluminium die cast parts are known for their tight tolerances and smooth surfaces. This reduces the need for secondary machining operations, saving both time and money during production.

The combination of performance, precision, and efficiency makes aluminium die casting a valuable tool for manufacturers across many industries.

Key Considerations for Lightweight Applications

Here are some key considerations when designing lightweight applications:

- Strength-to-weight ratio: This metric is paramount for lightweight applications. The material needs to be strong enough to withstand intended use while remaining light for optimal performance.

- Material selection: Aluminum die casting excels in this area, perfectly balancing strength and weight. This makes it ideal for industries where weight reduction is crucial without sacrificing functionality.

- Application focus: Lightweight design benefits a wide range of products, from automotive components that enhance fuel efficiency to handheld devices that improve user comfort.

By carefully considering these factors, engineers can create lightweight applications that are both functional and efficient.

Buttler’s Expertise in Aluminium Die Casting

At Buttler Precision Machinery, we specialize in producing high-quality aluminium die casting components that meet the stringent requirements of various industries. With our state-of-the-art facilities and experienced team, we can deliver precision-crafted aluminium die cast parts that exceed expectations in quality, performance, and reliability.

Remember to include the image named aluminium-die-casting-component when adding it to your content!

Quality Assurance in Aluminium Die Casting

Ensuring Consistency and Precision in Die Casting

At Buttler Precision Machinery, we prioritize consistency and precision in the aluminium die casting process. Our state-of-the-art equipment and skilled technicians guarantee that each die cast aluminum part meets the highest quality standards, ensuring reliable application performance and durability. In addition to our focus on precision, we understand the importance of material selection for lightweight applications. By carefully choosing the right aluminum alloy for each specific part, we can optimize strength and weight to meet the unique needs of our customers' products. This attention to detail sets our die casting process apart and ensures superior performance in lightweight applications.

The Importance of Material Selection for Lightweight Applications

Choosing the right material is critical for the success of any lightweight application. Here are some key reasons why material selection plays such a vital role:

- Strength-to-weight ratio: Lightweight materials like aluminum offer a superior strength-to-weight ratio compared to heavier alternatives. This allows for the creation of components that are both strong and lightweight, optimizing performance.

- Corrosion resistance: Certain aluminum alloys boast excellent corrosion resistance, making them ideal for applications exposed to harsh environments, such as saltwater or extreme temperatures.

- Thermal conductivity: Aluminum's efficient thermal conductivity makes it suitable for applications requiring heat dissipation, such as radiators or engine components.

By leveraging our expertise in aluminum casting, we can meticulously select the most appropriate alloy for your specific needs. This ensures that the resulting aluminum die casting components are perfectly tailored for lightweight applications, delivering a balance of strength, weight, and performance.

How Buttler Ensures High-Quality Die Casting Components

Buttler’s commitment to delivering high-quality die casting parts is unwavering. We employ rigorous quality control measures throughout production, from material inspection to final product testing. This dedication to excellence guarantees that our cast aluminium components meet and exceed industry standards, providing unmatched reliability and performance.

By prioritizing consistency and precision in every step of the production process, carefully selecting materials for lightweight applications, and implementing rigorous quality control measures, Buttler Precision Machinery ensures that our aluminium die casting components are of the highest quality.

Cost-Effectiveness of Aluminium Die Casting

When it comes to cost-effectiveness, aluminium die casting components truly shine. The use of cast aluminum allows for high production rates, reducing labor costs and overall expenses. With Buttler’s competitive pricing and value proposition, you can expect top-notch quality without breaking the bank. This makes aluminium die casting the go-to choice for maximizing efficiency in lightweight applications.

The Economic Advantages of Aluminum Die Cast Components

Aluminum die casting offers a compelling set of economic advantages, making it a highly attractive manufacturing process. Here are some of the key benefits:

- Reduced Material and Energy Consumption: Aluminum die casting allows for creating intricate shapes with thin walls. This translates to lighter parts requiring less material and energy, ultimately lowering manufacturing costs.

- Affordable End Products: Aluminum die casting produces more cost-effective end products for consumers by minimizing material usage and streamlining the production process.

In conclusion, aluminum die casting presents a win-win scenario for manufacturers and consumers. By reducing material consumption and streamlining production, this versatile process leads to lower costs and more affordable end products.

Buttler’s Competitive Pricing and Value Proposition

At Buttler Precision Machinery, we understand the importance of delivering high-quality die casting parts competitively. Our value proposition lies in our commitment to providing cost-effective solutions without compromising excellence. With our expertise in aluminium die casting, you can expect superior components that won’t break the bank. Furthermore, our focus on maximizing efficiency in lightweight applications sets us apart from the competition. By utilizing advanced techniques and innovative designs, we can offer lightweight die casting parts that maintain strength and durability while reducing overall material costs.

Maximizing Efficiency in Lightweight Applications

In today’s world, lightweight applications are all the rage – and for good reason! They offer improved fuel efficiency, reduced emissions, and enhanced industry performance. By harnessing the power of aluminium die casting components, Buttler helps maximize efficiency in these applications without sacrificing strength or durability.

Remember to choose Buttler Precision Machinery for your die casting needs. We’re here to unlock the potential of aluminium die casting components and drive the future of lightweight applications with our expertise!

Applications of Aluminium Die Casting Components

Diverse Industries Benefiting from Aluminum Die Cast Parts

Aluminium die casting components are widely utilized in automotive manufacturing, aerospace, electronics, and consumer goods industries. The high strength-to-weight ratio of cast aluminum makes it an ideal choice for applications requiring durability and lightweight properties. From engine parts to electronic enclosures, aluminium die casting is crucial in various industrial sectors.

Buttler’s Role in Providing Custom Solutions for Various Applications

Buttler Precision Machinery is a leader in providing custom aluminum die casting solutions for various applications. Their expertise ensures high-quality, precise components tailored to each client's needs.

Here's what makes Buttler Precision Machinery the perfect partner for your custom aluminum die casting needs:

- Tailored Solutions: Buttler specializes in creating custom components for various industries, from intricate automotive parts to precise aerospace components.

- Complex Designs: Aluminum die casting allows for creating intricate shapes and designs, ideal for complex applications.

- Lightweight and Durable: Aluminum's strength and lightweight properties make it perfect for automotive and aerospace applications where weight reduction is crucial.

- Cost-Effective: By leveraging the efficiency of aluminum die casting, Buttler provides functional and cost-effective solutions for your projects.

With their expertise and commitment to quality, Buttler Precision Machinery can ensure your custom aluminum die casting needs are met with precision and efficiency.

Harnessing the Versatility of Aluminium Die Casting

The versatility of aluminium die casting also extends to its ability to be easily combined with other materials, such as plastics and metals, to create hybrid components that offer the best of both worlds in strength, durability, and cost-effectiveness. This adaptability makes aluminium die casting an attractive option for manufacturers looking to optimize their production processes and create innovative solutions for their customers. By harnessing the potential of hybrid components, industries can stay ahead of the curve and meet the evolving demands of the market.

Innovations and Trends in Aluminium Die Casting

As demand for lightweight applications continues to grow, advancements in die casting technology for aluminum components are crucial. New techniques and materials are being developed to enhance the strength and durability of cast aluminum parts, making them even more suitable for a wide range of industries. One of the key innovations in aluminum die casting is vacuum-assisted high-pressure die casting (HPDC), which allows for the production of complex, thin-walled parts with improved mechanical properties. This technology particularly benefits automotive and aerospace applications, where lightweight yet strong components are essential for fuel efficiency and performance.

Advancements in Die Casting Technology for Lightweight Parts

Innovations such as vacuum die casting and squeeze casting have revolutionized the production of aluminum die cast parts, allowing for greater precision and reduced porosity. These advancements result in components that are not only lighter but also stronger, making them ideal for applications where weight reduction is critical.

Buttler’s Commitment to Keeping Up with Industry Developments

At Buttler Precision Machinery, we understand the importance of staying at the forefront of industry trends. Our team continuously invests in research and development to integrate the latest die casting technologies into our manufacturing processes, ensuring our clients receive the most advanced solutions for their lightweight applications.

Meeting the Demands of Modern Lightweight Applications

With the rise of electric vehicles, aerospace innovations, and portable electronics, modern applications require aluminum die cast components that can withstand rigorous use while minimizing overall weight. Buttler is dedicated to meeting these demands by providing high-quality, innovative solutions that push the boundaries of what is possible with aluminum die casting.

As the demand for lightweight applications grows, Buttler remains at the forefront of innovation in aluminum die casting. Our team constantly researches and develops new techniques to create components that are not only durable but also incredibly lightweight. By staying ahead of industry trends and investing in cutting-edge technology, we can provide our clients with solutions that meet the evolving needs of modern applications.

Choose Buttler Precision Machinery for Your Die Casting Needs

When it comes to your die casting needs, Buttler Precision Machinery stands out as the top choice for high-quality aluminium die casting components. With our expertise in cast aluminum, we are dedicated to unlocking the potential of aluminium die casting components for various applications. Trust Buttler to lead the future of lightweight applications with our unparalleled knowledge and experience.

Buttler Precision Machinery is your go-to partner for all things aluminium die casting. With our commitment to excellence in aluminum die cast parts, we ensure that you receive top-notch quality and precision every time. With our extensive experience in aluminium casting, you can trust us to deliver outstanding results for your specific die casting requirements.

Unlocking the Potential of Aluminium Die Casting Components

Our expertise in die-cast aluminum allows us to unlock the potential of aluminium die-casting components fully. Whether it's custom die-casting parts or standard solutions, we have the knowledge and resources to bring your vision to life. Count on us to provide innovative and reliable cast aluminum solutions that meet and exceed your expectations.

The Future of Lightweight Applications with Buttler's Expertise

With Buttler Precision Machinery at the helm, the future of lightweight applications looks brighter than ever. Our dedication to staying ahead of industry trends and advancements in aluminium die casting technology ensures that we are well-equipped to meet the evolving demands of modern applications. Trust us to lead the way in delivering cutting-edge solutions for all your lightweight application needs.