Introduction

High pressure die casting aluminum is a widely used manufacturing process that involves forcing molten aluminum into a steel mold under high pressure. This results in complex, high-quality parts with excellent dimensional accuracy and smooth surfaces. The process offers numerous benefits, including cost-effectiveness, high productivity, and the ability to produce intricate shapes with thin walls.

Understanding High Pressure Die Casting Aluminum

Understanding high pressure die casting aluminum involves grasping the intricacies of the process and its applications in various industries. It's crucial to comprehend how the molten aluminum is injected into the mold at high speed and pressure to create detailed components with minimal porosity.

The Process of High Pressure Die Casting Aluminum

The process of high pressure die casting aluminum involves several stages, including mold preparation, melting and injecting the metal, solidification, ejection of the part from the mold, and trimming excess material. Each step requires precision and expertise to ensure the production of flawless aluminum components.

Benefits of High Pressure Die Casting Aluminum

The benefits of high pressure die casting aluminum are numerous, such as excellent dimensional accuracy, smooth surface finish, fast production cycles, cost-effectiveness for large-scale production runs, and the ability to produce complex shapes with thin walls that are difficult or impossible to achieve using other processes.

What is High Pressure Die Casting Aluminum?

Definition and Explanation

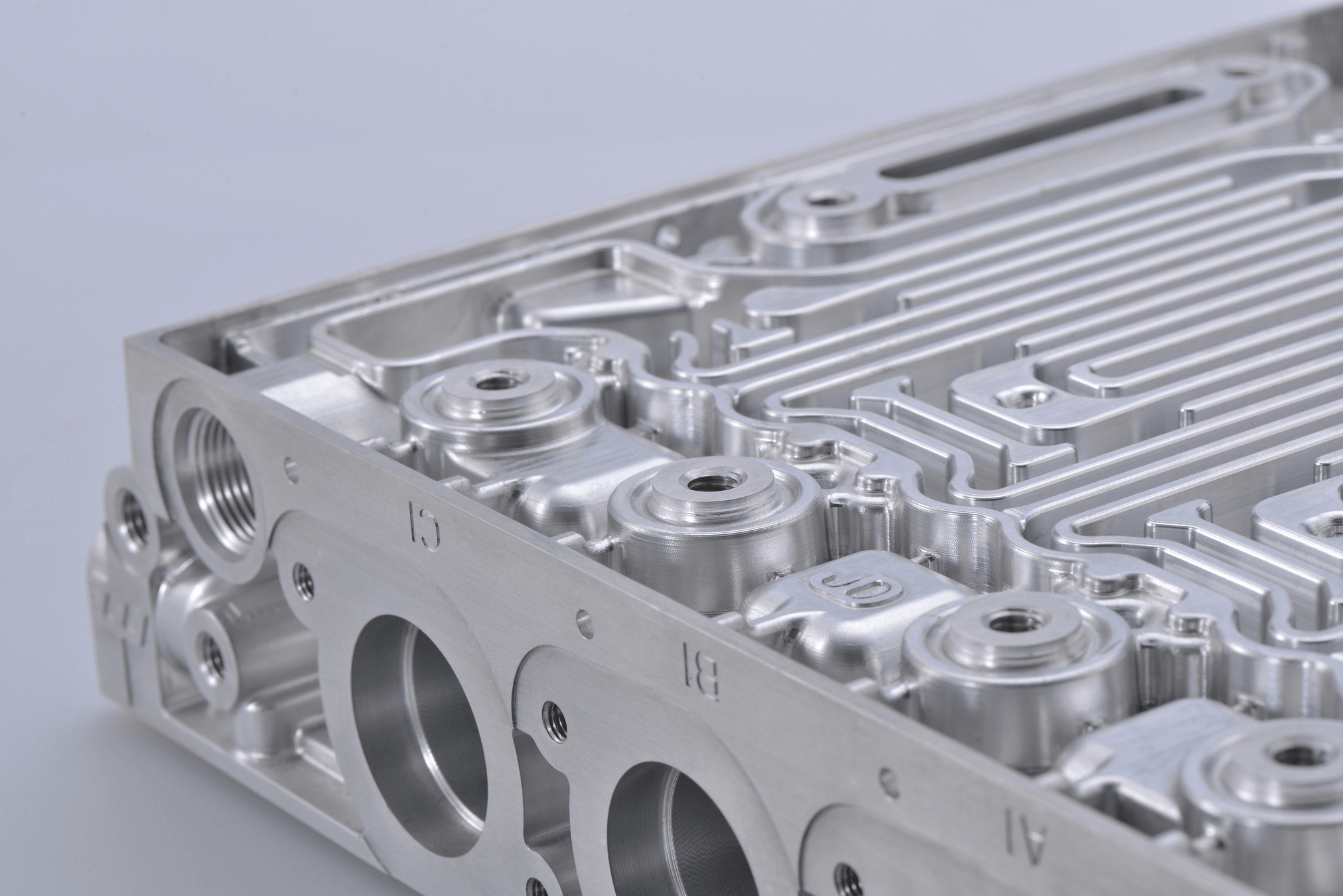

High pressure die casting aluminum is a manufacturing process that involves injecting molten aluminum alloy into a steel mold at high pressures. This results in complex, high-precision parts with thin walls and excellent surface finishes. The aluminum pressure die casting process ensures fast production rates and the ability to produce intricate shapes with tight tolerances. Additionally, this method allows for the production of parts with minimal porosity, making them suitable for applications requiring high strength and durability.

Key Characteristics of High Pressure Die Casting Aluminum

One of the key characteristics of high pressure die casting aluminum is its ability to produce parts with thin walls, complex shapes, and intricate details. The process also allows for the use of a wide range of aluminum alloys, providing flexibility in material selection for different applications. Additionally, high pressure die casting aluminum offers excellent dimensional accuracy and repeatability, making it ideal for mass production.

In addition to its ability to produce intricate details and thin walls, high pressure die casting aluminum also offers high strength-to-weight ratio, making it an ideal choice for applications where lightweight yet durable parts are required. This characteristic makes it particularly suitable for industries such as automotive, aerospace, and electronics, where the demand for high-performance components is paramount. Furthermore, the process of high pressure die casting aluminum allows for tight tolerances and minimal post-processing, resulting in cost-effective production and shorter lead times.

Applications of High Pressure Die Casting Aluminum

High pressure die casting aluminum is commonly used in automotive components, such as engine blocks, transmission cases, and structural parts due to its lightweight yet durable nature. It is also utilized in the production of consumer electronics, aerospace components, and various industrial machinery parts. The versatility of high pressure die casting aluminum makes it suitable for a wide range of industries and applications.

High pressure die casting aluminum's lightweight yet durable nature also makes it an ideal material for the production of consumer electronics. From smartphone and tablet casings to laptop components, high pressure die casting aluminum provides the strength and reliability necessary for these everyday devices. Its ability to be molded into intricate shapes and designs further enhances its appeal in the consumer electronics industry, where aesthetics are just as important as functionality.

Aluminum Pressure Die Casting Suppliers

Finding the Right Supplier

When looking for aluminum pressure die casting suppliers, it's crucial to consider their experience and expertise in high pressure die casting aluminum. Look for suppliers who have a proven track record of delivering high-quality products and have a deep understanding of high pressure die casting aluminum alloys.

It's also important to consider the supplier's production capacity and ability to meet your specific needs. Look for a supplier who can handle large volume orders and has the flexibility to accommodate any changes or customizations you may require. Additionally, consider their lead times and overall reliability to ensure they can consistently deliver on time without compromising quality.

Qualities to Look for in a Supplier

The key qualities to look for in an aluminum pressure die casting supplier include advanced technology and equipment, a strong commitment to quality control, and the ability to provide customized solutions. It's important to partner with a supplier who can offer flexibility in production volumes and has a proactive approach to problem-solving.

In addition to these key qualities, it is essential to find a supplier who is reliable and has a proven track record of on-time delivery. A supplier's ability to meet deadlines is crucial for maintaining a smooth production process and ensuring that your own delivery schedules are met. Furthermore, a reliable supplier can help you avoid costly delays and keep your operations running efficiently.

Benefits of Partnering with a Reliable Supplier

Partnering with a reliable aluminum pressure die casting supplier brings numerous benefits, including consistent product quality, on-time delivery, cost-effectiveness, and access to technical expertise. A trusted supplier will also offer support throughout the entire production process, from design optimization to final product assembly.

Remember that Ningbo Buttler Precision Machinery Co., Ltd. specializes in providing innovative tooling designs engineered for cost-effective manufacturing and maximizing performance while minimizing the need for secondary operations in high pressure die casting aluminum production.

High Quality Aluminum Pressure Die Casting

When it comes to aluminum pressure die casting, quality is of utmost importance. High-quality die casting ensures the durability and reliability of the final product, making it essential for various industries such as automotive, aerospace, and electronics. By using high-quality aluminum alloys and maintaining strict quality control measures throughout the casting process, manufacturers can ensure that their products meet industry standards and customer expectations.

Importance of Quality in Die Casting

The importance of quality in die casting cannot be overstated. Products that are manufactured using high pressure die casting aluminum must meet stringent quality standards to ensure their performance and longevity. Whether it's for structural components in automotive engines or intricate parts in electronic devices, high-quality die casting is crucial for the overall functionality and safety of the end product.

High-quality die casting also plays a significant role in reducing manufacturing costs and minimizing waste. By producing parts with tight tolerances and minimal porosity, manufacturers can decrease the need for additional machining and finishing processes, ultimately saving time and resources. Additionally, high-quality die casting results in fewer defects and scrap, leading to higher overall production efficiency and cost-effectiveness.

Factors That Contribute to High Quality

Several factors contribute to achieving high quality in aluminum pressure die casting. These include the use of premium aluminum alloys with superior mechanical properties, advanced mold design and manufacturing techniques, precise process control parameters, and rigorous inspection processes at every stage of production. By paying attention to these factors, manufacturers can consistently produce high-quality aluminum castings that meet or exceed industry standards.

In addition to the factors mentioned above, another key contributor to high-quality aluminum pressure die casting is the implementation of advanced automation and robotics in the production process. By utilizing cutting-edge technology, manufacturers can ensure precise and consistent casting results, minimizing human error and enhancing overall efficiency. This modern approach also allows for greater flexibility in design complexity, leading to more intricate and sophisticated castings that maintain exceptional quality standards.

Ensuring Consistency in Aluminum Pressure Die Casting

Consistency is key when it comes to aluminum pressure die casting. Manufacturers must ensure that each casting produced meets the same high standards of quality and dimensional accuracy. This requires tight process controls, regular maintenance of equipment, and continuous training for operators to maintain consistency in production. By implementing robust quality management systems, manufacturers can guarantee that every aluminum pressure die cast part meets the exact specifications required by their customers.

To further ensure consistency in aluminum pressure die casting, manufacturers can also invest in advanced technology and automation. By incorporating state-of-the-art equipment and software, they can minimize human error and improve repeatability in the casting process. This not only helps maintain consistency but also enhances overall efficiency and productivity, leading to cost savings and competitive advantages in the market.

China High Pressure Aluminum Die Casting Parts Factory

Exploring the Chinese Market

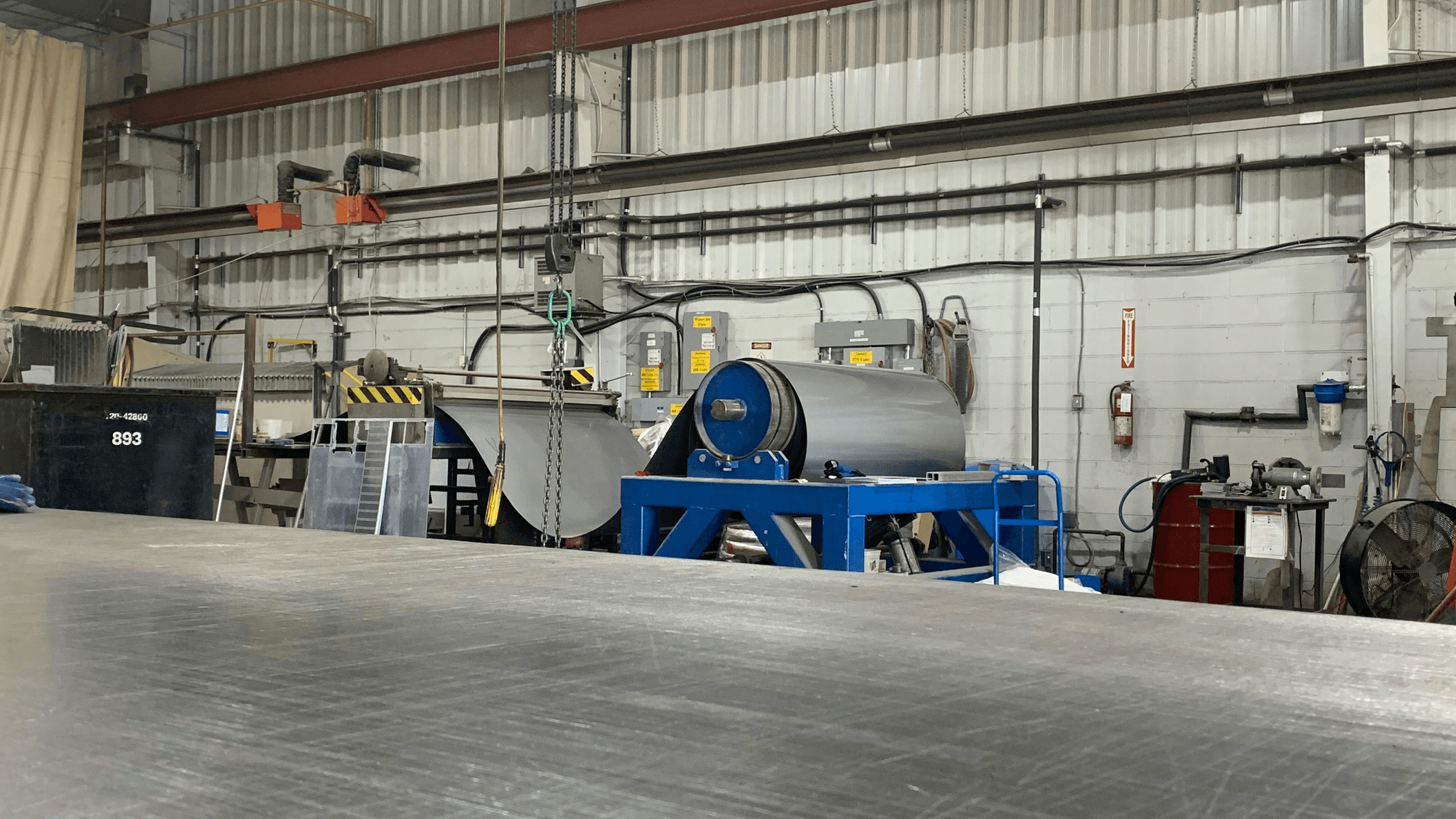

When considering high pressure die casting aluminum, exploring the Chinese market can open up a world of opportunities. With a strong manufacturing infrastructure and skilled workforce, China offers access to advanced technology and cost-effective production solutions for aluminum pressure die casting.

In addition, Chinese factories are known for their flexibility and ability to scale production according to demand. This means that businesses can easily adjust their production levels without facing significant delays or cost overruns. With the ability to quickly adapt to changing market conditions, working with a Chinese factory provides a level of agility that is essential in today's fast-paced business environment.

Advantages of Working with a Chinese Factory

Working with a Chinese factory for high pressure die casting aluminum provides several advantages, including competitive pricing, efficient production processes, and access to a wide range of high pressure die casting aluminum alloys. Additionally, China's manufacturing expertise ensures high-quality products and timely delivery.

Moreover, Chinese factories are known for their flexibility and ability to accommodate custom requirements. This means that businesses can work closely with the factory to develop unique high pressure die casting aluminum products that meet their specific needs. The ability to customize products allows companies to differentiate themselves in the market and cater to niche customer demands, giving them a competitive edge.

Finding the Right Partner for Die Casting Production

Finding the right partner for die casting production in China is crucial for success. Look for a supplier like Ningbo Buttler Precision Machinery Co., Ltd., which specializes in high quality aluminum pressure die casting molds and castings. Their smart part engineering approach ensures better part designs and cost-effective manufacturing. Additionally, Buttler Precision Machinery Co., Ltd. prides itself on its commitment to meeting deadlines and providing exceptional customer service, making them a reliable partner for your production needs.

Buttler Precision Machinery Co., Ltd.

Ningbo Buttler Precision Machinery Co., Ltd. is a leading company specializing in high pressure die casting aluminum and zinc castings, as well as die-casting molds. With a focus on smart part engineering, they offer innovative tooling designs to maximize performance and casting quality while minimizing the need for secondary operations.

Die Casting Molds and Aluminum & Zinc Castings

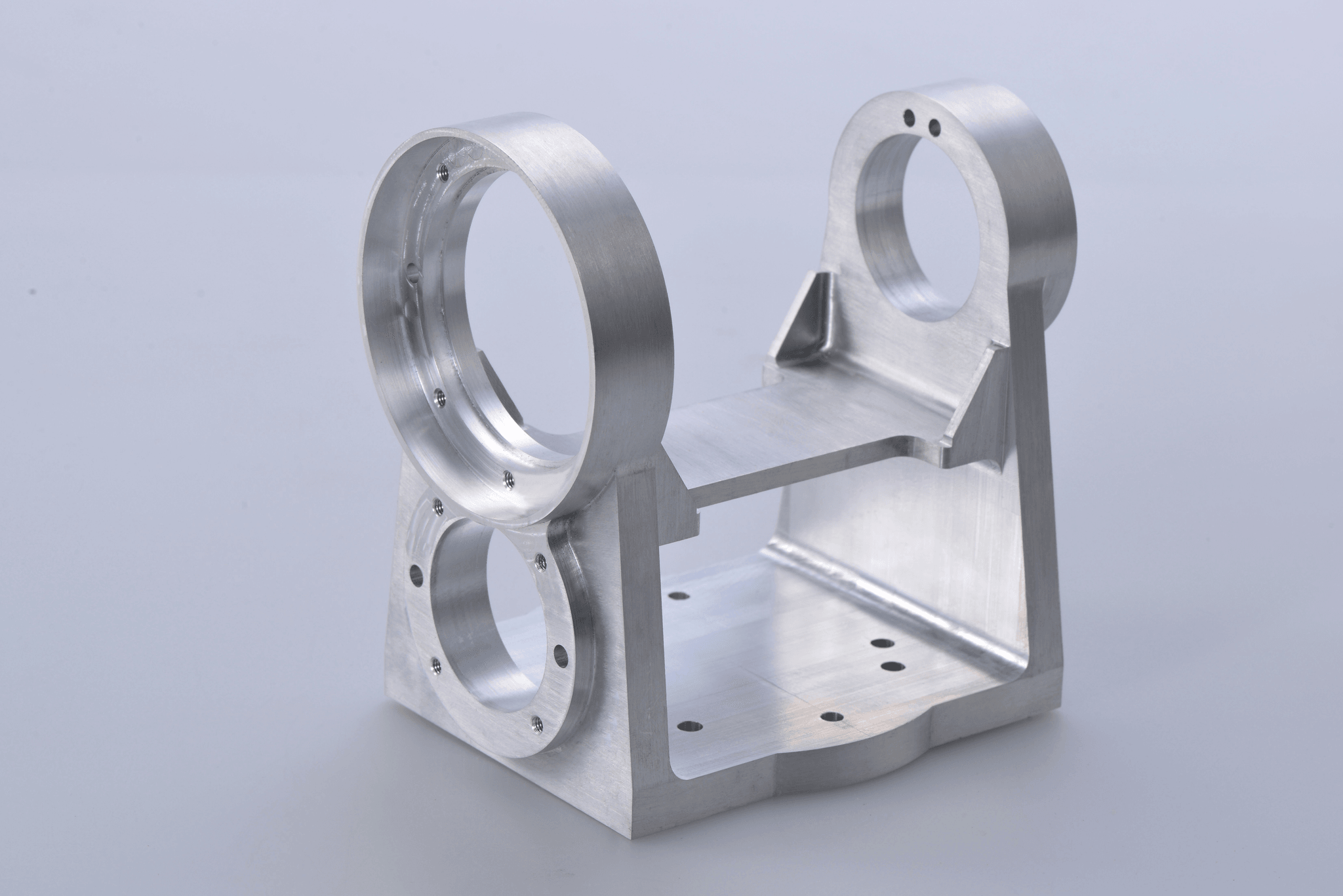

Buttler Precision Machinery Co., Ltd. excels in producing high-quality aluminum pressure die casting molds that are essential for creating complex and precise parts. Their expertise in aluminum pressure die casting ensures the production of durable and reliable components for various industries.

Smart Part Engineering for Better Part Designs

The company's smart part engineering approach involves utilizing innovative tooling designs to enhance part performance and quality while reducing the need for additional operations. This results in cost-effective manufacturing processes that benefit their clients by delivering superior products.

Range of Products and Services Offered by Buttler

Buttler Precision Machinery Co., Ltd. offers a comprehensive range of products and services, including processing, surface treatment, assembly, packaging, and engineering design review processes at no cost to the client. Their commitment to excellence makes them a valuable partner for businesses seeking high-quality aluminum pressure die casting solutions.

Conclusion

Advancing in High Pressure Die Casting Aluminum

As the demand for high pressure die casting aluminum continues to grow, it is essential to stay updated with the latest advancements in the industry. With technological innovations and new alloys being developed, high pressure die casting aluminum is constantly evolving to meet diverse industrial needs.

Making Informed Decisions in Die Casting

When it comes to aluminum pressure die casting, making informed decisions is crucial. From selecting the right materials and processes to choosing the best suppliers and manufacturers, a thorough understanding of high pressure die casting aluminum is essential for achieving optimal results.

Choosing the Right Partner for Die Casting Production

Partnering with reliable aluminum pressure die casting suppliers and manufacturers is key to successful production outcomes. Finding a supplier that offers high quality aluminum pressure die casting molds, advanced technology, and excellent customer service can make a significant difference in the overall success of your projects.