Introduction

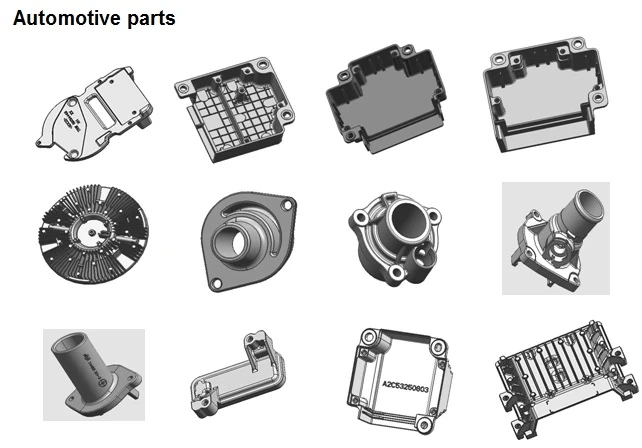

Choosing the right casting parts in the automotive industry is crucial for ensuring optimal vehicle performance and longevity. From die-casting components to aluminum structural components for electric vehicles, the quality of these parts directly impacts automobiles' overall functionality and safety. As an essential aspect of manufacturing, selecting high-quality casting parts can significantly enhance the efficiency and reliability of automotive applications.

Importance of Choosing the Right Casting Parts

The importance of selecting the right casting parts in automobile manufacturing cannot be overstated. These components are the building blocks for various vehicle systems, including engines, transmissions, and chassis. By opting for superior-quality casting parts, manufacturers can ensure that their vehicles meet stringent industry standards and deliver exceptional performance on the road.

Benefits of High-Quality Casting Parts

High-quality casting parts offer significant advantages for automotive applications. These components are essential for enhancing vehicle performance and durability.

Specifically, casting parts provide:

- Enhanced durability and resistance to wear and tear

- Precise fitment for optimal vehicle function

- Improved overall vehicle performance and efficiency

By incorporating superior casting parts, automotive manufacturers can reduce maintenance costs and increase customer satisfaction through reliable, long-lasting components.

Expert Tips for Selecting the Best Casting Parts

Selecting the best casting parts requires careful consideration of material composition, design complexity, production processes, and supplier capabilities. Collaborating with experienced suppliers who deeply understand die casting in the automotive industry and can provide valuable insights into optimizing part designs for maximum efficiency is essential.

Understanding Die Casting Components

Die-casting components play a crucial role in the automotive industry, providing the necessary strength and durability for various automobile parts. The die-casting process allows for highly accurate production of complex shapes, making it ideal for automotive applications.

Importance of Die-Casting in

the Automotive Industry

Die-casting is a manufacturing process that has become indispensable in the automotive industry. It's prized for producing parts with exceptional precision and a smooth finish. From the engine to the car's structure, die-cast components contribute significantly to a vehicle's reliability and performance.

Beyond quality, die casting offers several advantages for automotive manufacturers:

- Cost-effective production: Ideal for high-volume parts.

- Complex part creation: Enables the production of intricate shapes and thin-walled components.

- Lightweighting: Contributes to improved fuel efficiency.

- Durability: Produces parts capable of withstanding harsh operating conditions.

Die-casting is a technology that underpins the modern automobile, delivering performance and efficiency.

Key Considerations for Die Casting Components

When selecting die-casting components for automotive applications, it's essential to consider factors such as material strength, heat resistance, and dimensional stability. These components must meet stringent quality standards to ensure vehicle safety and performance. In addition to these considerations, it's important to factor in the components' overall weight. Lightweight materials can contribute to improved fuel efficiency and reduced emissions, making them an attractive option for environmentally conscious consumers. Furthermore, the ease of manufacturing and assembly should also be considered, as this can impact production costs and timelines.

Advantages of Aluminum Structural Components for Electric Vehicles

The electric vehicle market is rapidly expanding, increasing demand for lightweight and high-performance components. Aluminum die-castings offer an ideal solution due to their cost-effectiveness and sustainability.

Ningbo Buttler Precision Machinery Co., Ltd. excels in delivering innovative tooling designs for aluminum die-casting. Their expertise lies in optimizing manufacturing processes to enhance performance, casting quality, and cost-efficiency while minimizing the need for secondary operations. By focusing on smart part engineering and stringent quality control, they provide comprehensive solutions for the automotive industry.

Die casting is a crucial technology in automotive manufacturing. When selecting die-cast components, manufacturers should carefully consider the following factors:

- Material selection: Choose the appropriate aluminum alloy based on component requirements.

- Design optimization: Ensure the part design is suitable for die casting to prevent defects and maximize efficiency.

- Tooling quality: Invest in high-quality tooling to achieve precise and consistent castings.

- Process control: Implement robust process monitoring and control to maintain product quality.

By partnering with experienced die-casters like Ningbo Buttler, automotive manufacturers can effectively leverage this technology's benefits and produce high-quality, sustainable vehicles.

Factors for Choosing Casting Parts

The quality standards for die-casting components in the automotive industry are crucial. As the demand for high-performance and durable casting parts in automobile applications continues to rise, it's essential to ensure that the parts meet rigorous industry standards for safety and reliability. Choosing a supplier that adheres to these quality standards is paramount in guaranteeing the longevity and performance of your automotive components.

Smart part engineering plays a significant role in enhancing die-casting part designs in the automotive industry. With innovative tooling designs engineered for cost-effective manufacturing, manufacturers can optimize performance and casting quality while minimizing the need for secondary operations. This approach improves overall efficiency and ensures that the final products meet or exceed industry standards.

When selecting die-casting components for automotive applications, key features to look out for include factors such as material composition, structural integrity, and surface finish. Aluminum structural components have gained traction in electric vehicles due to their lightweight properties and exceptional strength-to-weight ratio. It's crucial to prioritize these key features when choosing casting parts to ensure optimal performance and durability in automotive applications.

Ningbo Buttler Precision Machinery Co., Ltd. specializes in providing top-notch die-casting molds, aluminum and zinc castings, processing, surface treatment, assembly, and packaging services for automotive applications. Their expertise in smart part engineering ensures better part designs with innovative tooling designs engineered for cost-effective manufacturing. By prioritizing quality standards and key product features, Buttler Precision Machinery guarantees high-performance casting parts suitable for various automotive needs.

Manufacturers can ensure that their components meet stringent industry requirements while maximizing performance and durability by focusing on quality standards, smart part engineering, and key features when choosing casting parts for automobile applications. With the right approach to selecting die-casting components, automotive companies can make informed decisions that lead to superior products with exceptional reliability and longevity.

Selecting the Right Supplier

Choosing the right supplier is crucial when sourcing high-quality casting parts in automobile manufacturing. Ningbo Buttler Precision Machinery Co., Ltd. plays a significant role in this process, specializing in die-casting molds, aluminum and zinc castings, processing, surface treatment, assembly, and packaging. With their expertise in smart part engineering for better part designs, they offer innovative tooling designs engineered for cost-effective manufacturing to maximize performance and casting quality while minimizing the need for secondary operations.

The Role of Ningbo Buttler Precision Machinery Co., Ltd.

Ningbo Buttler Precision Machinery Co., Ltd. is a key player in the die-casting industry, offering a comprehensive range of services, including die-casting molds, aluminum and zinc castings, processing, surface treatment, assembly, and packaging. Their expertise in smart part engineering allows them to provide innovative tooling designs engineered for cost-effective manufacturing to maximize performance and casting quality while minimizing the need for secondary operations.

In addition to their technical expertise, Ningbo Buttler Precision Machinery Co., Ltd. is also known for its commitment to quality and customer satisfaction. They have a proven track record of delivering high-quality products on time and within budget, making them a reliable partner for die-casting projects of any scale. Their dedication to continuous improvement and investment in state-of-the-art technology ensures that they stay at the forefront of industry trends and can meet the evolving needs of their clients.

How to Evaluate Die-Casting Suppliers

When evaluating die-casting suppliers for automotive parts production, factors such as their experience in the industry, capabilities in producing high-quality components, adherence to quality standards and certifications, and ability to provide value-added services such as engineering design reviews and cost optimization must be considered.

Furthermore, assessing the supplier's track record in meeting delivery deadlines and their ability to scale production as needed is important. A reliable die-casting supplier should have a proven history of on-time delivery and the flexibility to accommodate changes in production volume without compromising quality. This ensures that your automotive parts production stays on schedule and can adapt to market demands.

Qualities to Seek in a

Die-Casting Supplier

In selecting a die-casting supplier for automotive applications, seeking expertise in smart part engineering for better part designs, a comprehensive range of services, including processing and surface treatment capabilities, and a commitment to quality assurance and cost-effectiveness is important. Choosing a supplier like Ningbo Buttler Precision Machinery Co., Ltd. can ensure these qualities are precisely met.

Ensuring Casting Quality

Surface treatment plays a crucial role in ensuring the quality of casting parts in automobiles. Proper surface treatment enhances the parts' appearance, durability, and resistance to corrosion. With the right surface treatment, die-casting components can maintain their integrity and performance over an extended period, making them ideal for automotive applications.

Surface Treatment and Its Impact on Casting Quality

Surface treatment processes such as painting, powder coating, anodizing, and plating are essential for enhancing the overall quality of die-casting components in the automotive industry. These treatments protect environmental factors, ensuring that the parts remain in optimal condition throughout their lifespan. Manufacturers can guarantee superior quality and performance in automotive applications by carefully selecting the appropriate surface treatment for each component.

Importance of Assembly and Packaging in Die Casting

In die casting for automotive applications, assembly and packaging are critical stages that directly impact the quality of the final product. Proper assembly ensures that all components fit together seamlessly, contributing to the overall functionality and reliability of the automobile. Additionally, effective packaging protects the finished parts during transportation and storage, preventing any damage that could compromise their quality.

Proper assembly in die casting is crucial for ensuring that the final product meets the required specifications and standards. This includes aligning and fitting components together accurately, which directly impacts the automobile's functionality and performance. A well-assembled product not only enhances overall quality but also reduces the need for costly and time-consuming secondary operations, ultimately saving time and resources in the manufacturing process.

Minimizing the Need for Secondary Operations

Minimizing secondary operations is key to ensuring casting quality in automotive applications. By implementing smart part engineering and innovative tooling designs from a reputable supplier like Ningbo Buttler Precision Machinery Co., Ltd., manufacturers can minimize or eliminate secondary operations such as machining or welding. This saves time and resources and reduces potential sources of error, leading to higher overall casting quality.

Maximizing Performance and Cost-Effectiveness

Innovative Tooling Designs for Cost-Effective Manufacturing

When it comes to die casting in the automotive industry, innovative tooling designs play a crucial role in achieving cost-effective manufacturing. At Ningbo Buttler Precision Machinery Co., Ltd., we provide cutting-edge tooling designs to maximize performance and casting quality while minimizing the need for secondary operations. Our focus on smart part engineering ensures you get better part designs optimized for efficiency and cost-effectiveness.

Quality Assurance in Die Casting

Quality assurance is paramount for die-casting components for the automotive industry. At Ningbo Buttler, we have stringent quality control measures to ensure that every casting part meets the highest quality and performance standards. From material selection to production processes, we prioritize quality at every step to deliver die-casting components that exceed industry standards and customer expectations.

Achieving Maximum Performance with High-Quality Casting Parts

In the competitive landscape of the automotive parts die-casting market, achieving maximum performance is essential for staying ahead of the curve. By choosing high-quality casting parts from a reputable supplier like Ningbo Buttler, you can ensure that your automotive applications benefit from superior performance, durability, and reliability. With our expertise in aluminum structural components for electric vehicles, we are committed to delivering top-notch casting parts that elevate your automobile's performance.

Ensure Quality and Performance in Automotive Applications

When choosing casting parts for automobile applications, it's crucial to prioritize quality and performance. By understanding the significance of die-casting components and their role in the automotive industry, you can make informed decisions that benefit your manufacturing processes. With the right supplier, such as Ningbo Buttler Precision Machinery Co., Ltd., you can ensure top-notch casting quality and cost-effectiveness while maximizing performance.

Key Takeaways for Choosing Casting Parts

Focusing on factors such as quality standards, smart part engineering, and key features of die-casting components can ensure that you select the best casting parts for your automotive applications. Prioritizing high-quality materials and innovative tooling designs will yield superior performance and cost-effectiveness in your manufacturing processes.

Understanding the importance of die casting in the automotive industry allows you to prioritize surface treatment, assembly, and packaging for optimal casting quality. By minimizing the need for secondary operations and ensuring stringent quality assurance measures, you can guarantee that your automotive applications meet high-performance standards.

Making Informed Decisions for Die Casting in

the Automotive Industry

With a knowledgeable approach to selecting the right supplier for die-casting components, you can make informed decisions that benefit your manufacturing processes. Choosing a reputable supplier like Ningbo Buttler Precision Machinery Co., Ltd. ensures you have access to top-notch expertise in die-casting molds, aluminum and zinc castings, processing, surface treatment, assembly, and packaging.