Introduction

When it comes to the world of electric motor housings, understanding the importance of die casting is crucial. Aluminum die casting has revolutionized the production of motor housings, offering durability and precision like never before. Exploring the benefits of aluminum die casting for motor housings opens up a world of possibilities for efficient and high-quality electric drive motor housing designs.

Understanding Electric Motor Housings

Electric motor housings play a critical role in protecting the inner components of motors, ensuring their longevity and performance. These housings must be durable, heat-resistant, and lightweight to meet the demands of various applications.

Importance of Die Casting in Electric Motor Parts

Die casting has become an integral part of manufacturing electric motor parts due to its ability to produce complex shapes with high precision and repeatability. This process allows for cost-effective production without compromising on quality, making it ideal for mass production of aluminum electric drive motor housing.

Exploring Aluminum Die Casting for Motor Housings

Aluminum die casting has emerged as a game-changer in the production of motor housings, offering excellent thermal conductivity, corrosion resistance, and high strength-to-weight ratio. The versatility and efficiency of aluminum die casting make it a top choice for manufacturing aluminum motor housing and aluminium alloy electric motor housing.

The Role of Die Casting in Electric Motor Housings

Advantages of Die Casting for Motor Housings

When it comes to electric motor housings, die casting offers numerous advantages such as high dimensional accuracy, smooth surface finish, and the ability to produce complex shapes with thin walls. This makes it an ideal manufacturing process for producing electric motor housings that require precision and durability.

Furthermore, die casting allows for the incorporation of features such as mounting brackets and cooling fins directly into the housing design, eliminating the need for additional assembly processes. This not only streamlines production but also reduces the overall cost of manufacturing electric motor housings. Additionally, die-cast motor housings offer excellent thermal conductivity, making them ideal for applications where heat dissipation is a concern, such as in automotive and industrial settings.

Aluminum Die Casting for Electric Motor Housings

Aluminum die casting is particularly well-suited for electric motor housings due to its lightweight yet strong properties. The use of aluminum in electric drive motor housing ensures that the final product is not only durable but also lightweight, making it an ideal choice for various applications where weight is a concern.

Furthermore, aluminum die casting allows for intricate and complex designs to be easily achieved, providing engineers with the flexibility to create innovative motor housing designs that optimize performance and efficiency. This means that electric drive motor housings can be tailored to specific applications, ensuring that they meet the exact requirements of the intended use. Additionally, the excellent thermal conductivity of aluminum makes it an ideal choice for electric motor housings, as it helps dissipate heat efficiently, contributing to the overall performance and longevity of the motor.

Smart Part Engineering for Better Motor Housing Designs

Smart part engineering plays a crucial role in designing better motor housings. By utilizing innovative tooling designs engineered for cost-effective manufacturing, companies can maximize performance and casting quality while minimizing the need for secondary operations. This approach allows for the optimization of new and existing parts without incurring additional costs.

By implementing smart part engineering and innovative tooling designs, companies can also reduce lead times for motor housing production. This means that manufacturers can bring their products to market faster, giving them a competitive edge in the industry. Additionally, the use of cost-effective manufacturing processes allows for more flexibility in design iterations, enabling companies to quickly adapt to changing customer demands and technological advancements. Ultimately, this results in more agile and responsive businesses that can stay ahead of the curve.

Ningbo Buttler Precision Machinery Co., Ltd., specializes in providing smart part engineering solutions and innovative tooling designs engineered for cost-effective manufacturing to maximize performance and casting quality while minimizing the need for secondary operations!

Key Components of Electric Motor Housings

OEM Customized Machined Motor Parts

When it comes to electric motor housings, OEM customized machined motor parts play a crucial role in ensuring optimal performance and durability. These parts are specifically designed and tailored to meet the unique requirements of each electric motor, providing a perfect fit and seamless integration within the housing. With precision engineering and high-quality materials such as aluminum die casting, these customized parts contribute to the overall efficiency and reliability of the electric motor.

Aluminum Alloy Motor Shell

The aluminum alloy motor shell is a key component of electric motor housings, offering exceptional strength, lightweight construction, and superior heat dissipation properties. This durable and corrosion-resistant material is perfectly suited for the demanding conditions of electric motors, ensuring long-term performance and reliability. Through advanced manufacturing processes such as aluminum die casting, the motor shell can be precisely formed with intricate details and complex geometries to optimize functionality.

Die Casting Molds for Motor Housings

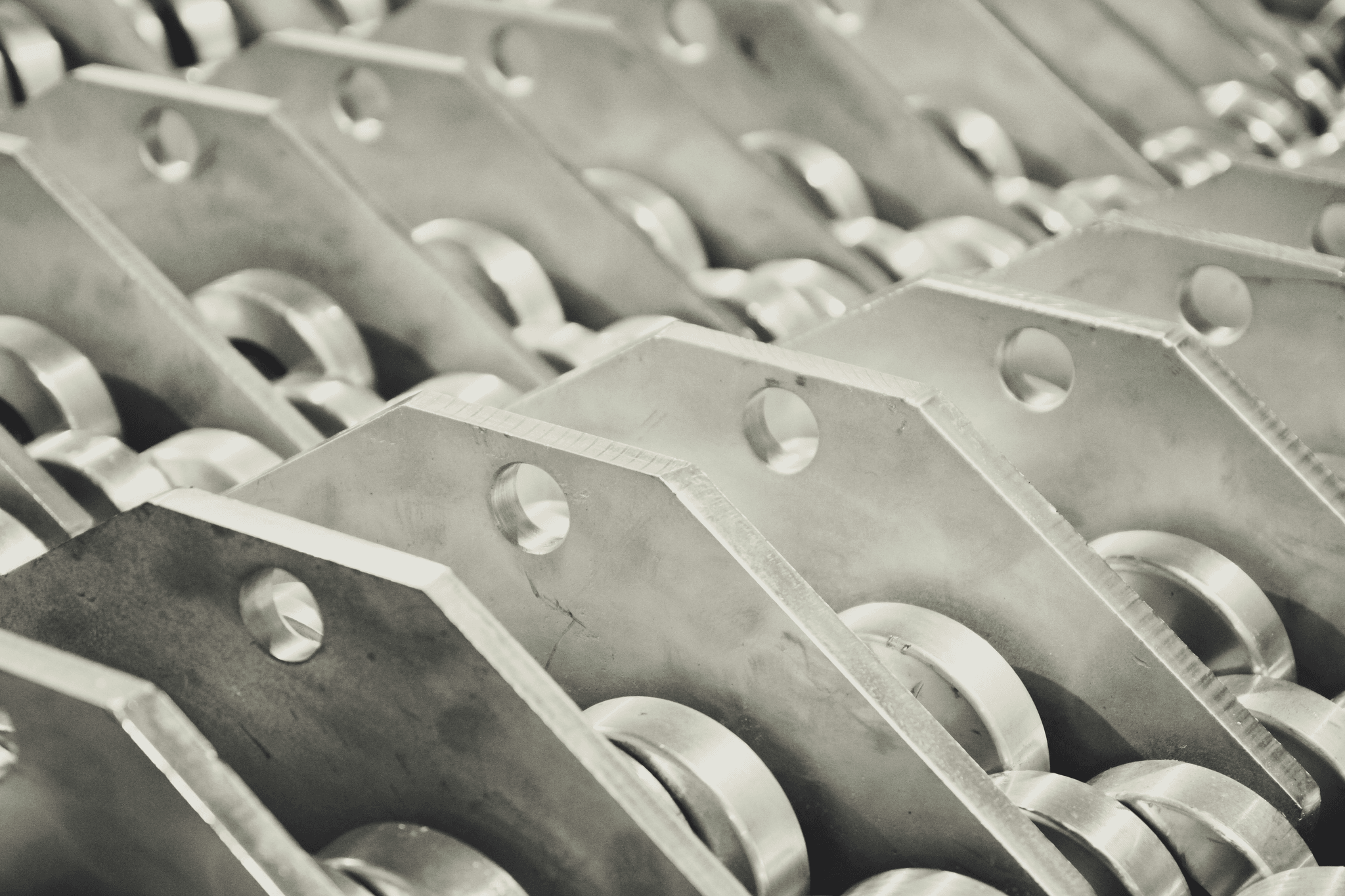

Die casting molds for motor housings are essential for producing high-quality components with consistent precision and accuracy. These molds are meticulously engineered to create intricate shapes and intricate designs that are integral to the performance of electric motors. By leveraging advanced technology and expertise in die-casting processes, companies like Buttler Precision Machinery Co., Ltd. specialize in delivering top-notch die casting molds that ensure the production of flawless motor housings.

By incorporating OEM customized machined motor parts, aluminum alloy motor shells, and precision die casting molds into electric motor housings, manufacturers can achieve unparalleled performance, durability, and efficiency in their products.

Quality Standards and Surface Treatment for Motor Housings

Maximizing Performance and Casting Quality

When it comes to electric motor housings, maximizing performance and casting quality is crucial. Aluminum die casting offers the advantage of producing complex shapes with high precision, ensuring optimal performance for electric motor housings. With OEM customized machined motor parts in aluminum die casting, you can achieve superior quality and durability for your motor housing designs.

Furthermore, aluminum die casting allows for the integration of features such as cooling channels and mounting points directly into the motor housing design. This level of customization ensures that the motor housing is optimized for heat dissipation and structural support, ultimately enhancing overall performance. Additionally, the high precision of aluminum die casting results in minimal material waste, making it a cost-effective solution for producing motor housings with superior performance and casting quality.

Surface Treatment and Assembly of Motor Housings

Surface treatment plays a significant role in enhancing the functionality and appearance of aluminum electric drive motor housings. From powder coating to anodizing, the surface treatment ensures corrosion resistance and aesthetic appeal. Additionally, precise assembly of aluminum motor housings is essential to maintain structural integrity and functionality.

Furthermore, the surface treatment process also provides an opportunity to incorporate branding and labeling onto the motor housings, allowing for easy identification and recognition of the product. This not only adds a professional touch to the overall appearance but also serves as a marketing tool for the company. By carefully considering the design and placement of these elements during surface treatment, manufacturers can effectively communicate their brand identity to customers.

Buttler Precision Machinery Co., Ltd.: Specializing in Die Casting Molds and Aluminum Castings

Ningbo Buttler Precision Machinery Co., Ltd. also offers customization services for electric motor housings, catering to a wide range of applications such as automotive, industrial machinery, and household appliances. Their team of experienced engineers and technicians work closely with clients to understand their specific requirements and deliver tailored solutions that meet their unique needs. This flexibility and attention to detail set Buttler Precision Machinery Co., Ltd. apart in the industry, making them a trusted partner for companies seeking high-quality electric motor housing components.

Diverse Applications of Electric Motor Housings

As the demand for electric motor housings continues to grow, they are being utilized in a wide range of applications. Automotive parts and gas appliance parts often require durable and high-quality aluminum electric drive motor housings to ensure optimal performance and longevity. The use of aluminum motor housings in power tool parts and appliance parts is also increasing due to their lightweight yet strong properties, making them ideal for these applications. Additionally, outdoor lamp series and other uses for motor housings benefit from the corrosion-resistant properties of aluminum alloy electric motor housing, ensuring reliability in various environmental conditions.

Automotive Parts and Gas Appliance Parts

In the automotive industry, the use of aluminum alloy electric motor housing has become increasingly popular due to its ability to withstand high temperatures and harsh conditions while maintaining structural integrity. Similarly, gas appliance parts such as water heaters and furnaces benefit from the corrosion-resistant properties of aluminum motor housing, ensuring long-term reliability and safety.

In addition to their durability and resistance to harsh conditions, aluminum alloy electric motor housings also offer the advantage of being lightweight. This makes them an ideal choice for power tool parts, as the reduced weight can improve the overall performance and handling of the tools. Whether it's a cordless drill or a circular saw, the use of aluminum motor housing contributes to making power tools more user-friendly and efficient.

Power Tool Parts and Appliance Parts

The lightweight yet durable nature of aluminum electric drive motor housing makes it an ideal choice for power tool parts such as drills, saws, and sanders. Additionally, various types of appliances such as washing machines, dryers, and refrigerators utilize OEM customized machined motor parts made from aluminum die casting for their superior performance and longevity.

The versatility of aluminum electric drive motor housing extends beyond just power tool and appliance parts. Outdoor lamp series also benefit from the lightweight and durable nature of aluminum die casting, providing a sturdy and long-lasting housing for the motors that power these outdoor lighting fixtures. With the ability to withstand various weather conditions, aluminum motor housings are an ideal choice for outdoor applications, ensuring the longevity and reliability of outdoor lamps in residential and commercial settings.

Outdoor Lamp Series and Other Uses for Motor Housings

The outdoor lamp series requires sturdy motor housings that can withstand exposure to changing weather conditions without compromising performance or aesthetics. Aluminum alloy electric motor housing provides the necessary durability and corrosion resistance required for outdoor applications while maintaining a sleek design that complements outdoor spaces beautifully.

The aluminum alloy electric motor housing not only provides the necessary durability and corrosion resistance for outdoor lamp series, but it also offers versatility for other uses. With its sleek design and robust construction, these motor housings can also be utilized for outdoor ceiling fans, security cameras, and other outdoor electrical fixtures. This multi-functional aspect adds value to the product and makes it a practical choice for various outdoor applications.

Conclusion

When it comes to choosing the right die casting for electric motor housings, aluminum die casting stands out as a top choice for its lightweight and durable properties. With OEM customized machined motor parts in aluminum die casting, the quality and performance of electric motor housings can be maximized to meet industry standards. The future of aluminum die casting for electric motor housings looks promising, with advancements in smart part engineering and innovative tooling designs from companies like Buttler Precision Machinery Co., Ltd.

Choosing the Right Die Casting for Motor Housings

Selecting the appropriate material for electric motor housing is crucial, and aluminum die casting offers the ideal combination of strength and lightweight properties. By opting for aluminum electric drive motor housing or aluminum alloy motor shell, manufacturers can ensure high-quality and cost-effective solutions for their products.

Maximizing Quality and Performance in Motor Housing Designs

With OEM customized machined motor parts in aluminum die casting, manufacturers can achieve precision engineering that maximizes the quality and performance of electric motor housings. By leveraging advanced tooling designs and engineering review processes, companies can minimize the need for secondary operations while optimizing part designs.

The Future of Aluminum Die Casting for Electric Motor Housings

As technology continues to advance, the future of aluminum die casting for electric motor housings looks promising. Companies like Buttler Precision Machinery Co., Ltd. are at the forefront of innovation, offering specialized expertise in die-casting molds, surface treatment, assembly, and packaging to meet evolving industry demands.