Introduction

Are you ready to take your metal casting projects to the next level? With effortless metal casting molds, you can elevate your craft and unleash your creativity like never before. Whether you're a seasoned professional or just starting, mastering the art of metal casting is key to creating stunning pieces that stand out from the rest.

Elevate Your Craft with Effortless Metal Casting Molds

You can achieve precision and detail in every project with high-quality metal casting molds. From sand casting to die casting, the right molds are essential for bringing your designs to life. And with the expertise of Ningbo Buttler Precision Machinery Co., Ltd., you can trust that you're getting top-notch quality and innovation in every mold.

The Key to Mastering Metal Casting

Understanding the different metal casting methods is crucial for success in your projects. Whether sand casting, die casting, or aluminum casting, each technique requires a unique approach and skillset. By mastering these methods, you can create masterpieces that exceed expectations. Additionally, being well-versed in metal casting will allow you to experiment with new designs and push the boundaries of what is possible in metalwork. Embracing creativity and innovation in your approach to metal casting will set you apart from others in the field and open up new opportunities for artistic expression.

Unleash Your Creativity with High-Quality Metal Casting Molds

Mold casting offers limitless possibilities for bringing your creative visions to life. With the right tools, you can craft unique and high-performance pieces. Ningbo Buttler Precision Machinery Co., Ltd. specializes in smart part engineering to deliver superior mold designs for optimal results.

Our high-quality metal casting molds provide the following:

- Precision and detail: Capture even the most intricate designs.

- Versatility: Suitable for jewelry, decor, industrial components, and more.

- Creativity: Express your unique style and expertise.

Unlock your full potential with Ningbo Buttler's mold-casting solutions. Contact us today to discuss your project.

Understanding Metal Casting

Metal casting is a versatile process that involves pouring molten metal into a mold to create intricate shapes and designs. It is a cost-effective method for producing complex parts with high precision. Whether you are a hobbyist or a professional, metal-casting molds play a crucial role in achieving the desired results.

The Basics of Metal Casting

At its core, metal casting involves melting metal and pouring it into a mold to solidify and take the shape of the mold cavity. Sand casting is one of the most common methods used in metal casting, where sand is packed around a pattern to create the mold cavity. This method is ideal for producing large parts and is suitable for ferrous and non-ferrous metals.

Exploring Different Metal Casting Methods

In addition to sand casting, there are various other methods, such as die casting, which uses reusable molds called dies to produce complex shapes with high accuracy and surface finish. Die casting is particularly popular for mass production of small to medium-sized parts made from aluminum, zinc, and other non-ferrous alloys.

Another popular metal casting method is investment casting, also known as lost-wax casting. This process involves creating a wax pattern coated with a ceramic material to form the mold. Once the mold is heated, the wax melts and leaves a cavity filled with molten metal to create the final part. Investment casting is ideal for producing intricate and detailed parts with excellent surface finishes.

Choosing the Right Metal for Your Casting Project

When it comes to metal casting, selecting the right material is crucial for achieving the desired mechanical properties and surface finish. Aluminum casting offers lightweight solutions with excellent corrosion resistance, making it suitable for automotive and aerospace applications. On the other hand, iron casting provides high strength and wear resistance, making it ideal for heavy-duty industrial components.

With this understanding of metal casting methods and materials, you can make informed decisions when choosing the right approach for your next project. Whether sand casting or die casting, each method has unique advantages that can be leveraged to bring your creative ideas to life in metal form!

The Art of Die Casting

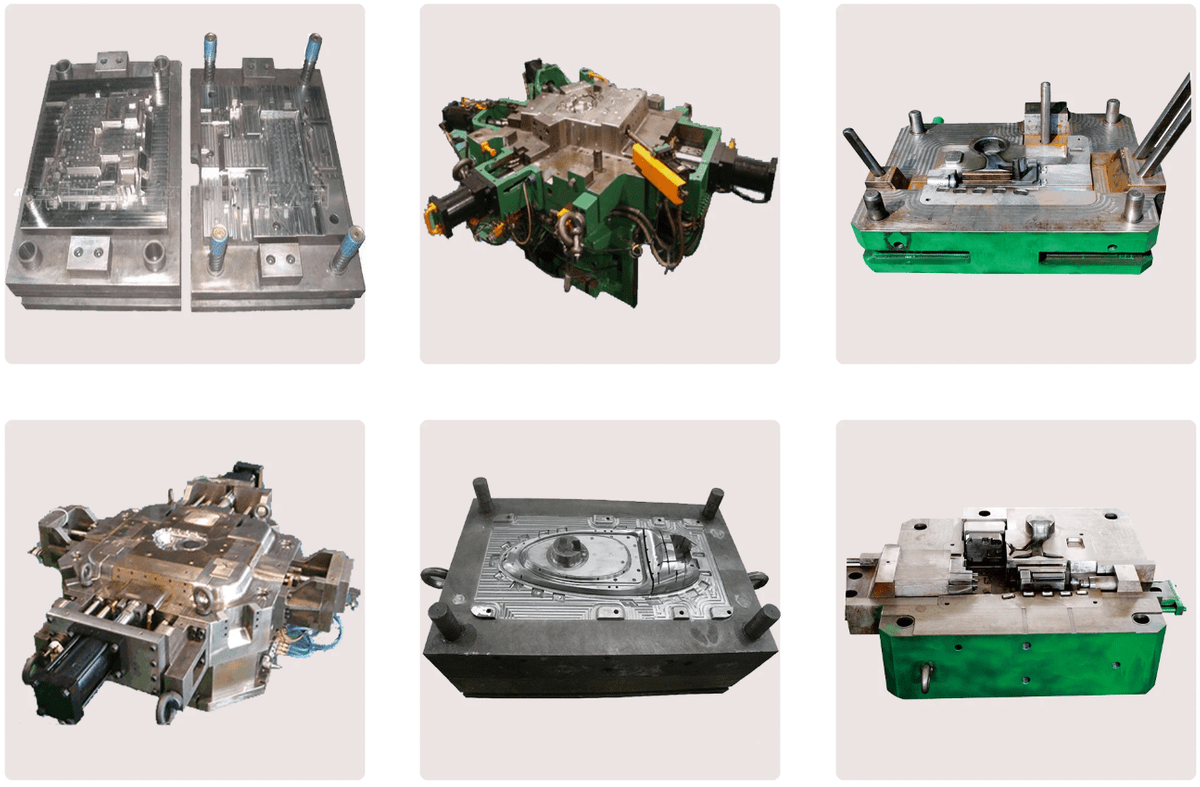

Ningbo Buttler Precision Machinery Co., Ltd. is the go-to expert for die casting. With their specialized expertise in die-casting molds, aluminum and zinc castings, and innovative tooling designs, they are the perfect partner for your metal casting projects. Leveraging their knowledge and experience will ensure your die-casting project is executed precisely and excellently.

Key Benefits of Die-Casting Molds

Die-casting molds offer a range of benefits that make them an ideal choice for metal casting projects. From high dimensional accuracy and smooth surface finishes to the ability to produce complex shapes with tight tolerances, die-casting molds provide unmatched versatility and efficiency. Choosing the right die-casting mold for your project can achieve superior results while minimizing production costs.

Innovations in Die Casting Technology

The world of die-casting is constantly evolving, with new technologies and innovations driving advancements in the industry. From improved materials and coatings to enhanced automation and process control, the latest innovations in die-casting technology are revolutionizing the way metal parts are produced. By staying at the forefront of these developments, Ningbo Buttler Precision Machinery Co., Ltd. ensures they can offer their clients cutting-edge solutions for their die-casting needs.

Exploring Aluminum and Zinc Casting

Smart Part Engineering for Better Part Designs

Regarding metal casting, smart part engineering is crucial for achieving better part designs. Ningbo Buttler Precision Machinery Co., Ltd. specializes in innovative tooling designs engineered for cost-effective manufacturing, maximizing performance and casting quality while minimizing the need for secondary operations. With their expertise, you can optimize your new and existing parts at no cost.

Furthermore, aluminum casting offers numerous advantages, making it a preferred choice for many industries. Its lightweight nature makes it ideal for applications where weight reduction is crucial, such as automotive and aerospace industries. Additionally, aluminum's high thermal conductivity and corrosion resistance make it suitable for parts that require heat dissipation and durability. With smart part engineering, Ningbo Buttler Precision Machinery Co., Ltd. can help you leverage these advantages to create better part designs that meet your specific requirements.

Advantages of Aluminum Casting

Aluminum casting offers a multitude of benefits for metal casting projects. This process utilizes the metal's unique properties to create lightweight, durable, and efficient products.

Ningbo Buttler Precision Machinery Co., Ltd. excels in aluminum casting, delivering high-quality, precise components for diverse applications. Key advantages of aluminum casting include:

- Lightweight and strong: Ideal for automotive parts and outdoor fixtures.

- Corrosion resistant: Ensures product longevity and durability.

- Excellent thermal conductivity: Facilitates efficient heat dissipation.

- Design flexibility: Enables complex shapes and thin walls.

- Cost-effective: Low tooling and machining costs optimize production.

Clients can benefit from innovative designs and streamlined manufacturing processes by leveraging Ningbo Buttler's expertise.

Maximizing Performance with Zinc Casting

Zinc casting is another valuable option for metal casting projects, offering exceptional performance benefits. With its ability to achieve intricate designs and tight tolerances, zinc casting is perfect for gas appliances or power tool parts. Leveraging the expertise of Ningbo Buttler Precision Machinery Co., Ltd., you can maximize performance with top-notch zinc casting molds.

Zinc casting is ideal for intricate designs and tight tolerances and offers excellent corrosion resistance, making it a durable option for outdoor applications. Whether you need parts for outdoor furniture or marine equipment, zinc casting can provide long-lasting performance in harsh environments. By partnering with Ningbo Buttler Precision Machinery Co., Ltd., you can ensure that your zinc casting molds are optimized for maximum durability and reliability.

Creating Masterpieces with Mold Casting

Metal casting molds are essential for creating masterpieces in metal casting. These high-quality molds are crucial in shaping and forming molten metal into intricate designs and functional parts. Whether it's sand casting, die casting, or mold casting, the quality of the mold directly impacts the outcome of the metal casting process.

Enhancing Your Craft with High-Quality Molds

Investing in high-quality metal casting molds is a game-changer when it comes to enhancing your craft. The precision and durability of these molds ensure that your castings turn out exactly as intended, without any defects or imperfections. With advanced technologies and expert craftsmanship, companies like Ningbo Buttler Precision Machinery Co., Ltd. offer a wide range of top-notch molds designed to elevate your metal casting projects to new heights.

Investing in high-quality metal casting molds ensures precise and flawless castings and saves you time and money in the long run. By using expertly crafted molds with advanced technologies, you can streamline your production process and reduce the need for rework or corrections. This means you can focus on creating unique designs and pushing the boundaries of your craft without being held back by subpar molds.

Crafting Unique Designs with Mold Casting

Mold casting allows for endless creativity and innovation when crafting unique designs. Whether it's intricate patterns, textures, or complex geometries, metal-casting molds enable artists and engineers to bring their visions to life with unparalleled precision and detail. By leveraging the versatility of mold casting techniques, you can push the boundaries of what's possible in metal design and fabrication.

The Versatility of Mold Casting

Mold casting is a versatile manufacturing process that produces intricate components across various industries. This method offers cost-effective and efficient production solutions, from complex automotive parts to precision gas appliance components.

Mold casting excels in:

- Producing intricate and detailed components: Its precision allows for creating complex shapes.

- Serving diverse industries: Its adaptability suits automotive, appliance, and other sectors.

- Streamlining production: It offers efficiency and cost-effectiveness in manufacturing processes.

By harnessing the power of mold casting, businesses can enhance their production capabilities and deliver high-quality products to meet market demands.

The Perfect Mold for Every Project

Metal-casting molds are crucial in creating durable and visually appealing designs in the outdoor lamp series. Whether looking for intricate details or sleek modern shapes, sand-casting molds can bring your vision to life with precision and reliability.

Outdoor Lamp Series

With sand-casting molds, the outdoor lamp series can be crafted with intricate details and durable materials to withstand the elements. Whether you're designing traditional lanterns or modern fixtures, metal casting molds provide the versatility and quality needed to elevate your outdoor lighting projects.

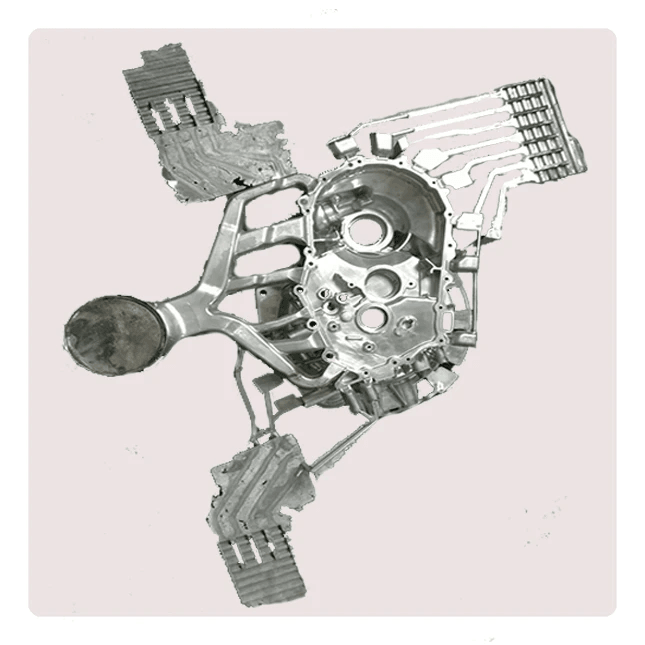

Automotive Parts

In the automotive industry, die-casting molds are essential for producing high-quality aluminum and zinc castings that meet strict performance and safety standards. From engine components to body parts, die-casting technology ensures precise and durable automotive parts that enhance functionality and aesthetics.

Gas Appliance Parts

Iron casting molds offer the strength and heat resistance needed to withstand demanding conditions for gas appliance parts. With precise mold designs, gas appliance parts can be manufactured with exceptional durability and performance, ensuring safety and reliability for home and commercial use.

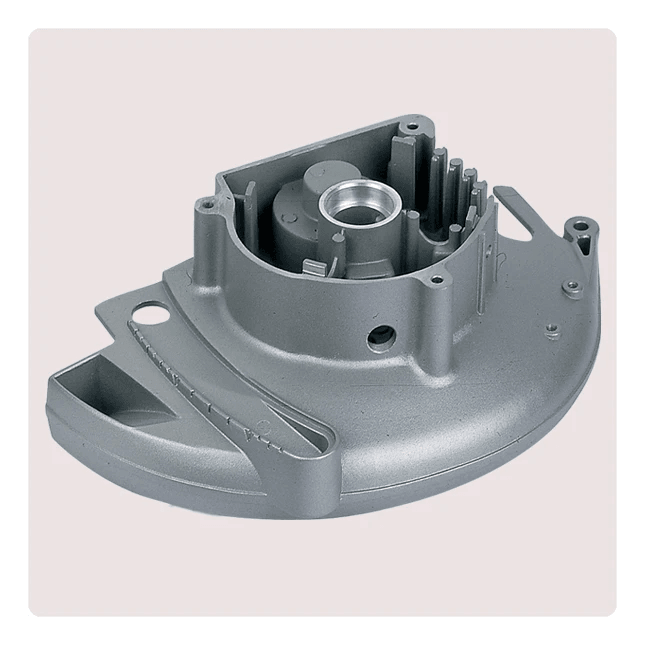

Power Tool Parts

Regarding power tool parts, aluminum casting molds provide lightweight yet robust solutions that enhance tool performance and longevity. Leveraging advanced mold casting techniques allows power tool parts to be engineered for optimal strength-to-weight ratios without compromising durability or precision.

Appliance Parts

In appliance parts, metal casting molds enable the production of complex shapes and intricate details essential for functionality and aesthetics. Whether it's components for kitchen appliances or HVAC systems, mold casting technology ensures high-quality parts that meet rigorous performance standards.

Elevate your craft with effortless metal casting molds from Ningbo Buttler Precision Machinery Co., Ltd., where expertise meets innovation to unleash creativity in every project!

Elevate Your Craft with Ningbo Buttler Precision Machinery Co., Ltd.

Ningbo Buttler Precision Machinery Co., Ltd. is your go-to partner for metal casting. With expertise in die-casting molds, aluminum and zinc castings, and smart part engineering, they are dedicated to elevating your craft and unleashing your creativity with high-quality metal casting molds.

Unleash Your Creativity with High-Quality Metal Casting Molds

With a wide range of metal casting molds available, you can explore the art of sand casting, die casting, and mold casting to create unique designs that showcase your craftsmanship. Whether it's iron casting or aluminum casting, the possibilities are endless when accessing top-notch metal casting molds.

Mastering the Art of Metal Casting

By leveraging the expertise of Ningbo Buttler Precision Machinery Co., Ltd., you can master the art of metal casting and take your projects to new heights. Their commitment to innovation in die-casting technology and smart part engineering ensures you have the tools to bring your creative vision to life.

In conclusion, when it comes to metal casting molds, Ningbo Buttler Precision Machinery Co., Ltd. is the ultimate partner for elevating your craft. With their expertise in die-casting molds and innovative tooling designs engineered for cost-effective manufacturing, you can trust them to help you achieve exceptional results in every project.