Introduction

When it comes to zinc die casting, finding the best zinc die casting manufacturer is crucial for ensuring high-quality products. Zinc die casting is an essential process in manufacturing, offering a wide range of benefits that make it a preferred choice for many industries. Choosing the right die casting manufacturer can make all the difference in the quality and efficiency of your production process.

The Best Zinc Die Casting Manufacturer

As a key player in the industry, Ningbo Buttler Precision Machinery Co., Ltd. stands out as a top-notch zinc die casting manufacturer. Their expertise in die-casting molds and specialization in aluminum and zinc castings make them a trusted partner for companies looking to achieve exceptional results.

Why Zinc Die Casting is Essential

Zinc alloy, commonly used in the die-casting process, offers numerous benefits such as high strength, durability, and dimensional stability. The impact of die casting in manufacturing cannot be overstated, as it allows for complex shapes with tight tolerances to be produced with ease.

Choosing the Right Die Casting Manufacturer

When choosing a die casting manufacturer, it's important to consider factors such as expertise, quality assurance measures, and service offerings. With Ningbo Buttler Precision Machinery Co., Ltd., you can rest assured that you are partnering with a company that prioritizes smart part engineering and exceptional quality control.

Understanding Zinc Die Casting

Zinc die casting is a crucial process in manufacturing, and finding the right zinc die casting manufacturer is essential for quality products. The use of zinc alloy in die casting offers numerous benefits, including high strength, durability, and excellent electrical conductivity. This makes it an ideal choice for a wide range of applications, from automotive parts to electronic components.

Benefits of Zinc Alloy

Zinc alloy is known for its exceptional strength and durability, making it a popular choice for die casting applications. Its high dimensional stability and excellent electrical conductivity make it ideal for producing complex shapes with thin walls, ensuring precision and reliability in the final product. Additionally, zinc's ability to withstand extreme temperatures makes it suitable for various industries, from automotive to telecommunications.

Furthermore, zinc alloy's corrosion resistance and ability to be easily plated with other metals such as nickel and chrome make it a versatile material for a wide range of applications. This makes it an excellent choice for products that require a decorative finish or protection from environmental elements. Whether used in the production of door handles, faucets, or automotive parts, zinc alloy's ability to maintain its appearance and structural integrity over time adds significant value to the end product.

The Impact of Die Casting in Manufacturing

Die casting plays a significant role in modern manufacturing processes, offering cost-effective solutions for producing high-quality metal parts with minimal waste. The efficiency and versatility of die casting have revolutionized the production of complex components across industries such as aerospace, medical devices, and consumer electronics.

Die casting has also contributed to the reduction of material waste in manufacturing, as the process allows for precise control over the amount of metal used in production. This not only helps to minimize environmental impact but also leads to cost savings for manufacturers. Furthermore, die casting enables the production of parts with intricate designs and complex geometries that would be difficult or impossible to achieve through other manufacturing methods.

Exploring the Process of Die Casting

The die casting process involves injecting molten metal into a steel mold under high pressure to create intricate shapes with tight tolerances. This method allows for the mass production of precise components with minimal post-processing requirements. From aluminum casting dies to zinc castings, the die cast process ensures consistent quality and uniformity in every part produced.

The die casting process is highly versatile, allowing for the production of a wide range of shapes and sizes to meet diverse industry needs. Whether it's intricate automotive components or complex electronic parts, die casting can accommodate various design specifications with precision and efficiency. This flexibility makes it a preferred method for manufacturers looking to create high-quality, customized parts for their products.

Ningbo Buttler Precision Machinery Co., Ltd.

Ningbo Buttler Precision Machinery Co., Ltd. is a leading zinc die casting manufacturer with extensive expertise in die-casting molds. Their specialization in aluminum and zinc castings ensures top-notch quality and precision in every project they undertake. What sets them apart is their innovative tooling designs, tailored to provide cost-effective manufacturing solutions that maximize efficiency and quality.

Expertise in Die-Casting Molds

Ningbo Buttler Precision Machinery Co., Ltd. boasts unparalleled expertise in die-casting molds, ensuring the highest level of precision and accuracy in every component they produce. Their skilled team of engineers and technicians are dedicated to delivering exceptional results, making them the go-to choice for all die casting needs.

Specialization in Aluminum and Zinc Castings

With a focus on aluminum casting die and zinc castings, Ningbo Buttler Precision Machinery Co., Ltd. has established itself as a leader in the industry. Their commitment to excellence shines through in the quality of their products, making them a trusted partner for companies seeking top-tier aluminum and zinc castings.

With a focus on aluminum casting die and zinc castings, Ningbo Buttler Precision Machinery Co., Ltd. has established itself as a leader in the industry. Their commitment to excellence shines through in the quality of their products, making them a trusted partner for companies seeking top-tier aluminum and zinc castings. In addition to their exceptional product quality, Ningbo Buttler Precision Machinery Co., Ltd. also prides itself on innovative tooling designs that enable cost-effective manufacturing processes. By continuously refining their tooling designs, they are able to offer competitive pricing without compromising on the precision and durability of their castings.

Innovative Tooling Designs for Cost-Effective Manufacturing

Ningbo Buttler Precision Machinery Co., Ltd.'s innovative tooling designs are engineered to optimize manufacturing processes, ultimately reducing costs without compromising on quality. By leveraging their smart part engineering solutions, clients can benefit from better part designs that enhance efficiency and performance while minimizing the need for secondary operations.

Furthermore, Ningbo Buttler Precision Machinery Co., Ltd.'s tooling designs are tailored to specific manufacturing requirements, ensuring a customized approach for each client. This level of personalization allows for greater precision and accuracy in the production process, leading to higher quality end products. Additionally, their innovative designs are constantly evolving to keep up with the latest advancements in manufacturing technology, staying ahead of the curve in delivering cost-effective solutions.

Smart Part Engineering

Ningbo Buttler Precision Machinery Co., Ltd. is at the forefront of smart part engineering, offering innovative tooling designs for cost-effective manufacturing. Our expertise lies in maximizing performance and casting quality, ensuring that our clients receive top-notch products that meet their exact specifications.

Maximizing Performance and Casting Quality

At Ningbo Buttler, we understand the importance of maximizing performance and casting quality in zinc die casting. Our team of experts works tirelessly to ensure that every part produced meets the highest standards, delivering exceptional results for our clients. By implementing advanced technology and innovative processes, we are able to achieve superior precision and consistency in our zinc die casting operations. This not only enhances the overall performance of the parts but also minimizes the need for secondary operations, saving time and resources for our clients.

Minimizing the Need for Secondary Operations

By focusing on smart part engineering, we aim to minimize the need for secondary operations in zinc die casting. Our innovative tooling designs are engineered to streamline the manufacturing process, reducing the time and resources required for additional operations.

Our approach to smart part engineering also includes a focus on better part designs for efficiency and quality. By optimizing the design of the parts themselves, we can eliminate the need for secondary operations by ensuring that the parts are manufactured to the highest standards from the outset. This not only saves time and resources but also results in a superior final product that meets or exceeds customer expectations.

Better Part Designs for Efficiency and Quality

With a commitment to better part designs, we prioritize efficiency and quality in every aspect of zinc die casting. Our engineering team leverages cutting-edge technology and industry best practices to create parts that not only meet but exceed our clients' expectations.

Our focus on better part designs extends to every stage of the manufacturing process, from initial concept to final production. By integrating design for manufacturability principles into our engineering approach, we ensure that the parts we create are not only efficient and high-quality but also cost-effective to produce. This commitment allows us to deliver exceptional value to our clients while maintaining the highest standards of performance and reliability.

Service Offerings

Ningbo Buttler Precision Machinery Co., Ltd. offers a comprehensive range of services to meet all your die casting needs. From designing and manufacturing die casting molds to providing expertise in aluminum and zinc castings, our team is dedicated to delivering high-quality products for your specific requirements.

Die Casting Mold Services

At Ningbo Buttler, we specialize in providing top-notch die casting mold services tailored to your exact specifications. Our expert team of engineers and designers will work closely with you to develop and produce custom die cast dies that meet the highest standards of quality and precision.

Aluminum and Zinc Casting Expertise

With our extensive experience in aluminum casting die and zinc alloy die casting, we have the expertise to deliver exceptional results for your casting projects. Whether you require intricate components or large-scale production runs, our skilled technicians are equipped to handle any challenge with precision and efficiency.

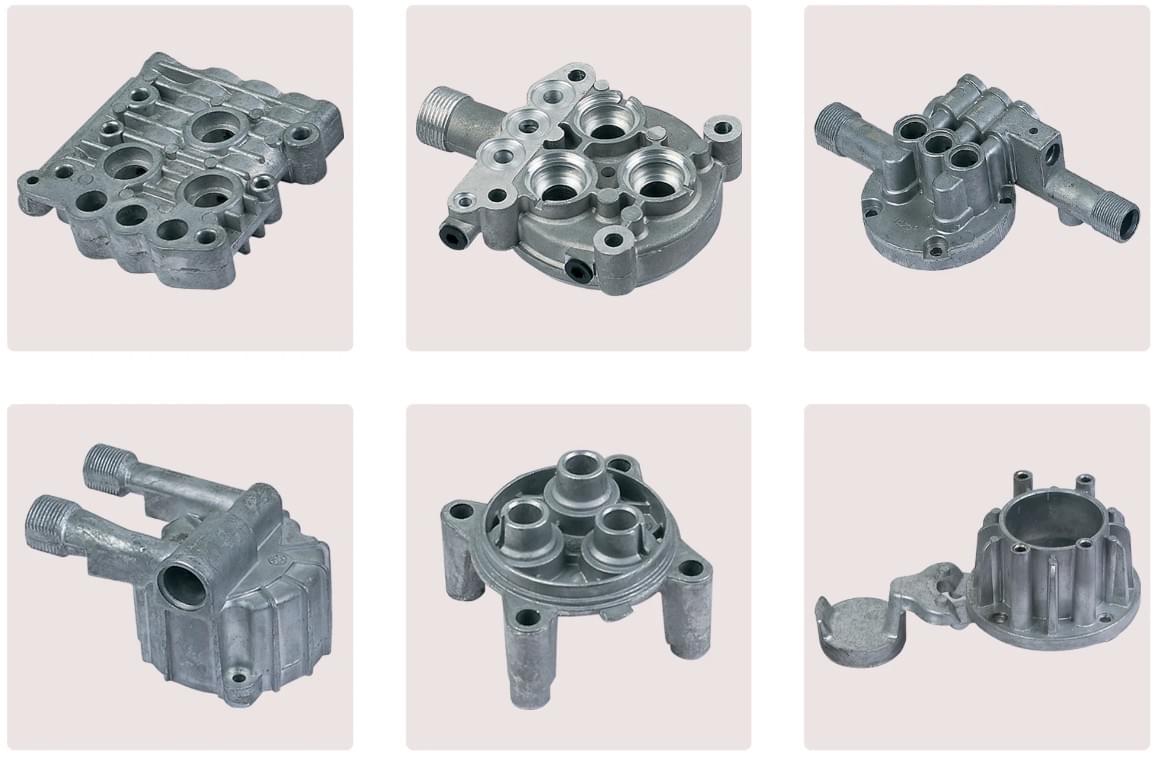

Diverse Range of Product Offerings

From automotive parts to electronic components, Ningbo Buttler offers a diverse range of product offerings to cater to various industries. Our commitment to innovation and excellence ensures that we can meet the unique demands of each client, delivering superior products that exceed expectations.

Quality Assurance

Ningbo Buttler Precision Machinery Co., Ltd. is committed to ensuring surface treatment quality, with a focus on providing impeccable finishes for all zinc die casting products. Our state-of-the-art facilities and expert technicians guarantee that every part meets the highest standards of surface treatment, enhancing both appearance and durability.

Ensuring Surface Treatment Quality

Our team meticulously inspects and tests each product to ensure that the surface treatment meets our stringent quality standards. From polishing to plating, we go above and beyond to deliver flawless finishes that exceed customer expectations. With our expertise in zinc die casting, you can trust that your parts will have a superior surface finish.

Attention to Assembly and Packaging

At Ningbo Buttler Precision Machinery Co., Ltd., we understand the importance of proper assembly and packaging in preserving the integrity of die-cast products. Our dedicated staff pays close attention to every detail, from component assembly to final packaging, ensuring that your parts arrive in perfect condition.

Commitment to Exceptional Quality Control

Quality control is at the heart of everything we do at Ningbo Buttler Precision Machinery Co., Ltd. Our rigorous quality assurance processes are designed to maintain consistency and reliability across all our zinc die casting products. From initial design to final inspection, we are dedicated to upholding the highest standards of quality in every aspect of our manufacturing process.

Conclusion

When it comes to finding the right zinc die casting manufacturer, Ningbo Buttler Precision Machinery Co., Ltd. stands out as a leader in the industry. Their expertise in die-casting molds and specialization in aluminum and zinc castings make them the top choice for manufacturers looking to maximize efficiency and quality. With their commitment to exceptional quality control and innovative tooling designs, Buttler ensures that your parts are engineered for cost-effective manufacturing.

Finding the Right Zinc Die Casting Manufacturer

Choosing the right zinc die casting manufacturer is crucial for the success of your manufacturing process. With Ningbo Buttler Precision Machinery Co., Ltd., you can trust that you are working with a team of experts who are dedicated to providing high-quality, cost-effective solutions for your die casting needs. Their specialization in aluminum and zinc castings, along with their innovative tooling designs, makes them the ideal partner for maximizing efficiency and quality in your manufacturing process.

Maximizing Efficiency with Smart Part Engineering

Smart Part Engineering is essential for maximizing performance and casting quality while minimizing the need for secondary operations. Ningbo Buttler Precision Machinery Co., Ltd.'s innovative tooling designs are engineered to optimize new and existing parts at no cost to you, ensuring that your manufacturing process is as efficient as possible. With their expertise in die-casting molds and commitment to cost-effective manufacturing, Buttler is dedicated to helping you achieve maximum efficiency in your production processes.

Quality Assurance with Ningbo Buttler Precision Machinery Co., Ltd.

Ningbo Buttler Precision Machinery Co., Ltd.'s commitment to exceptional quality control ensures that every part meets the highest standards of excellence. From surface treatment to assembly and packaging, they pay attention to every detail to guarantee superior quality in every product offering. When it comes to choosing a zinc die casting manufacturer that prioritizes quality assurance, Buttler is the clear choice for manufacturers looking for reliability and excellence.