Introduction

Welcome to the world of die casting, a versatile manufacturing process that has revolutionized the production of complex metal parts. Whether you're a seasoned industry professional or a curious newcomer, understanding the die casting process is essential for unlocking its full potential. From its key applications to the advantages it offers, die casting has become an indispensable tool in modern manufacturing.

Understanding the Die Casting Process

At its core, die casting is a metal casting process that involves forcing molten metal into a mold cavity under high pressure. This process allows for the production of precise and intricate parts with excellent dimensional accuracy and smooth surface finishes.

Die casting is also known for its high-speed production capability, making it an efficient and cost-effective process for large production runs. Additionally, die casting allows for the use of a wide range of metals, including aluminum, zinc, and magnesium, providing versatility in material selection for different applications. Furthermore, the tooling used in die casting is durable and can withstand high temperatures and pressures, ensuring consistent and high-quality part production over extended periods.

Advantages of Die Casting

One of the main advantages of die casting lies in its ability to produce parts with tight tolerances and complex geometries, making it ideal for applications where precision is crucial. Additionally, die casting offers cost-effective manufacturing solutions by minimizing material waste and reducing the need for secondary operations.

Furthermore, die casting allows for the production of parts with excellent surface finishes and dimensional stability, resulting in high-quality products that meet industry standards. This makes die casting an attractive option for industries such as automotive, aerospace, and electronics, where the appearance and performance of components are critical. The ability to achieve consistent results with minimal variation also contributes to the reliability of die-cast parts in demanding applications.

Key Applications of Die Casting

Die casting is commonly used in a wide range of industries, including automotive, aerospace, electronics, and more. Its ability to produce high-quality parts at scale makes it an attractive choice for manufacturers looking to meet demanding production requirements while maintaining superior quality standards.

Die casting is also widely used in the production of consumer goods, such as kitchen appliances, power tools, and even toys. The ability to create complex shapes and intricate designs with precision makes die casting a preferred method for manufacturing these types of products. This process allows for the production of durable and high-quality parts that can withstand everyday use, making it an ideal choice for consumer goods manufacturers

Die Casting Explained

Die casting is a versatile manufacturing process commonly used to create metal parts with high precision and accuracy. It is often used in industries such as automotive, aerospace, and consumer electronics due to its ability to produce complex shapes with tight tolerances. The purpose of die casting is to efficiently mass-produce parts with consistent quality and minimal post-processing requirements.

What is Die Casting Used For

Die casting is commonly used with materials such as aluminum, zinc, and magnesium to produce a wide range of components including engine parts, gearboxes, and electronic enclosures. Its ability to create intricate designs makes it ideal for manufacturing complex geometries that are difficult or impossible to achieve through other methods.

Die casting is a versatile manufacturing process that allows for the production of high-quality, complex components with tight tolerances. This makes it an ideal choice for industries such as automotive, aerospace, and electronics, where precision and reliability are crucial. The ability to produce large quantities of parts quickly and cost-effectively also makes die casting a popular option for mass production.

The Die Casting Process

The die casting process involves injecting molten metal into a steel mold cavity under high pressure. This results in the rapid solidification of the material, producing a precise replica of the mold's interior geometry. The use of reusable molds allows for high production volumes at a fast rate, making die casting an efficient manufacturing method.

The die casting process is known for its ability to produce parts with high dimensional accuracy and smooth surface finishes. This makes it an ideal manufacturing method for industries such as automotive, aerospace, and consumer electronics. The use of steel molds also ensures that the final products have excellent mechanical properties, making them suitable for a wide range of applications. Additionally, the high production volumes and fast cycle times make die casting a cost-effective solution for businesses looking to scale up their production.

Materials Used in Die Casting

Die casting materials such as aluminum offer excellent strength-to-weight ratios and good corrosion resistance, making them suitable for various applications across different industries. Zinc alloys are preferred for their dimensional stability and impact resistance, while magnesium alloys are chosen for their lightweight properties and exceptional strength.

By choosing the right materials and understanding the die casting process, manufacturers can harness the advantages of this method to produce high-quality components efficiently.

Advantages of Die Casting

Die casting is commonly used for the production of high precision and accurate parts, making it a popular choice in various industries such as automotive, aerospace, and electronics. The purpose of die casting is to create complex shapes with high dimensional accuracy and smooth surface finishes. This manufacturing method is better than sand casting due to its ability to produce parts with tighter tolerances and finer surface finishes. Die casting materials such as aluminum, zinc, and magnesium are used when lightweight and durable components are required.

Precision and Accuracy

The precision and accuracy achieved through die casting not only ensure high-quality components but also contribute to cost-effective manufacturing. By minimizing the need for additional machining or finishing processes, die casting reduces production time and labor costs. This makes it an efficient and economical choice for producing large quantities of intricate parts with consistent quality. As a result, manufacturers can enjoy significant savings without compromising on the precision and accuracy of their components.

Cost-Effective Manufacturing

Die casting offers cost-effective manufacturing by reducing material waste, minimizing secondary operations, and achieving high production rates. By utilizing efficient tooling designs engineered for cost-effective manufacturing, companies can maximize performance while minimizing costs associated with additional machining or finishing processes. This makes die casting a highly efficient and economical choice for mass production.

In addition to reducing material waste and minimizing secondary operations, die casting also offers the advantage of achieving high production rates. This means that companies can produce large quantities of parts in a relatively short amount of time, allowing for faster turnaround times and increased efficiency. The ability to quickly manufacture parts at a high volume makes die casting an attractive option for businesses looking to streamline their production processes and meet demanding market demands.

Reduced Need for Secondary Operations

One of the key advantages of die casting is its ability to produce near-net-shape parts with minimal need for secondary operations such as machining or finishing. This streamlines the production process, reduces lead times, and ultimately lowers manufacturing costs. Ningbo Buttler Precision Machinery Co., Ltd.'s Engineering Design Review Process further optimizes part designs to minimize the need for secondary operations, resulting in significant time and cost savings.

Furthermore, die casting allows for the production of complex shapes and thin-walled parts that would be difficult or impossible to achieve with other manufacturing processes. This versatility opens up new design possibilities and reduces the need for additional operations to achieve the desired part geometry. By eliminating the need for secondary operations, die casting also minimizes material waste, making it a more sustainable and environmentally friendly manufacturing option.

Key Applications of Die Casting

Die casting is a versatile manufacturing method commonly used in various industries due to its precision and cost-effectiveness. What is die casting used for? It is commonly used in the automotive industry, gas appliance parts, and power tool parts. The purpose of die casting is to create complex and high-quality metal parts with minimal post-processing required.

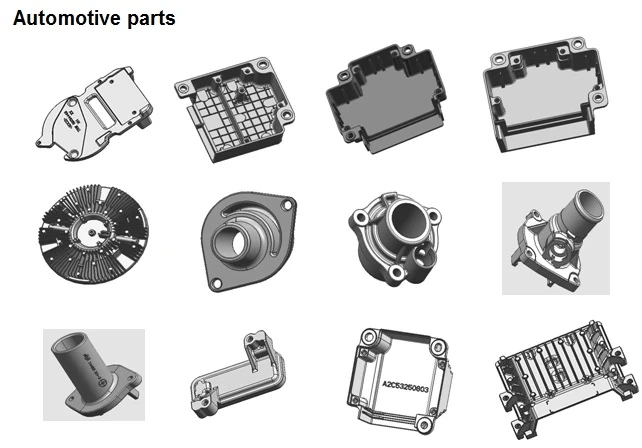

Automotive Industry

Die casting is commonly used with automotive parts such as engine components, transmission housings, and structural parts due to its ability to produce intricate shapes with high accuracy. The automotive industry relies on die casting for its lightweight yet durable components that enhance vehicle performance and fuel efficiency.

Moreover, die casting is also utilized in the production of gas appliance parts such as burner heads, valve bodies, and heat exchangers. This process allows for the creation of complex designs and intricate details that are essential for the efficient and safe operation of gas appliances. The use of die-cast components in gas appliances ensures reliability and longevity, meeting the high standards required for home and commercial use.

Gas Appliance Parts

Gas appliance manufacturers utilize die casting for producing burner heads, valves, and other intricate components that require precision and reliability. Die casting materials such as aluminum and zinc are often preferred for their corrosion resistance and thermal conductivity, making them ideal for gas appliance parts.

Gas appliance manufacturers also benefit from die casting due to the high level of intricacy that can be achieved in the production of burner heads, valves, and other components. The precision and reliability offered by die casting make it an essential process for ensuring the safe and efficient operation of gas appliances. Additionally, the use of materials such as aluminum and zinc provides durability and longevity to these parts, further enhancing their performance.

Power Tool Parts

Power tool manufacturers benefit from the use of die casting for creating durable and lightweight components such as gear housings, motor casings, and handles. Die-cast power tool parts offer superior strength-to-weight ratios compared to sand castings, resulting in more efficient tools with longer lifespans.

In addition to their strength and lightweight nature, die-cast power tool parts also offer excellent dimensional accuracy, ensuring precise fits and smooth operation. This level of precision is crucial for power tools to function at their best, providing users with reliable performance and consistent results. By utilizing die casting for these critical components, manufacturers can deliver power tools that meet the high standards of professionals and hobbyists alike.

Conclusion

Die casting is a versatile manufacturing method that is commonly used in a variety of industries for creating complex metal parts with high accuracy and precision. It is the preferred method for producing parts that require intricate shapes and thin walls, making it an ideal choice for automotive, gas appliance, and power tool parts. With its cost-effective manufacturing process and reduced need for secondary operations, die casting offers numerous advantages over sand casting.

Die Casting: A Versatile Manufacturing Method

Die casting is commonly used to create parts with intricate designs and thin walls, making it ideal for producing components for automobiles, gas appliances, and power tools. The purpose of die casting is to efficiently manufacture high-quality metal parts with minimal post-processing required. This versatile method harnesses the power of precision engineering to deliver cost-effective solutions for a wide range of industries.

Harnessing the Power of Die Casting

Ningbo Buttler Precision Machinery Co., Ltd. specializes in die-casting molds, aluminum and zinc castings, processing, surface treatment, assembly, and packaging. Their smart part engineering approach ensures better part designs that maximize performance while minimizing the need for secondary operations. By taking advantage of their Engineering Design Review Process at no cost, manufacturers can optimize their new and existing parts for maximum efficiency.

The Future of Die Casting Applications

As technology continues to advance, die casting materials play a crucial role in meeting the evolving demands of various industries. From lightweight aluminum alloys to durable zinc alloys, choosing the right materials is essential for achieving optimal results in die casting applications. Manufacturers need to stay abreast of material advancements to determine when to use specific alloys based on their unique properties and performance requirements.