Introduction

When it comes to metal casting, die cast aluminum stands out as a top choice for manufacturers and engineers alike. Its advantages are numerous, making it a popular material for a wide range of applications. Exploring the benefits of die cast aluminum reveals its lightweight nature, durability, and cost-effectiveness. So why choose die cast aluminum over other materials for your next project? Let's delve into the many reasons that make die cast aluminum the go-to option for metal casting.

Advantages of Die Cast Aluminum

Die-cast aluminum is a popular choice for many industries due to its unique combination of properties. Here are some of the key advantages:

- Strength and Lightweight: Die-cast aluminum offers a superior strength-to-weight ratio. This means it can be incredibly strong without adding excessive weight, making it ideal for applications where weight reduction is crucial, such as in aerospace and automotive parts.

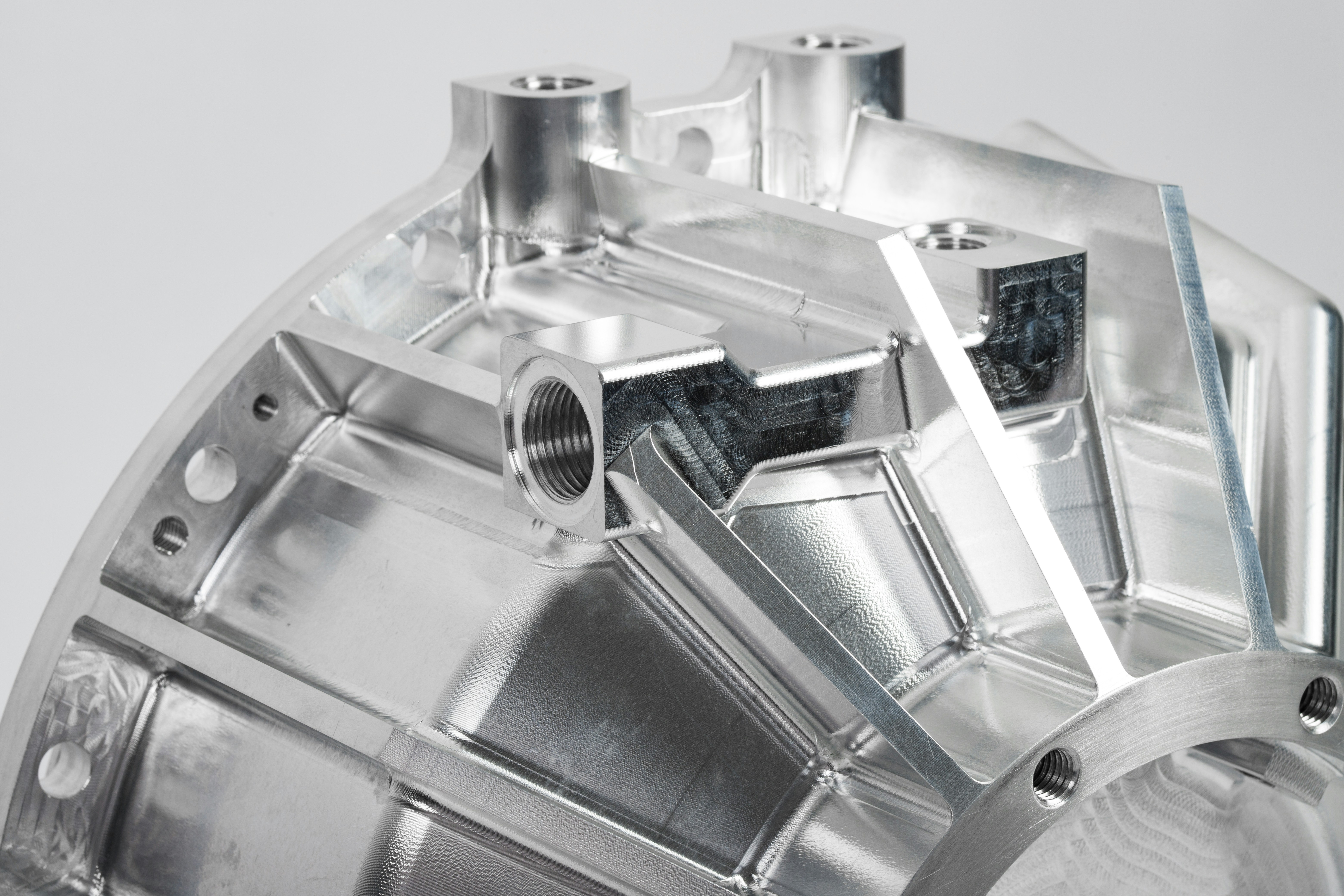

- Versatility and Precision: The die-casting process allows for creating complex shapes with high precision and dimensional accuracy. This versatility makes die-cast aluminum suitable for various components across various industries.

- Excellent Corrosion Resistance: Die-cast aluminum naturally forms a protective oxide layer that shields it from corrosion. This makes it perfect for parts exposed to harsh environments, such as outdoor or marine applications.

- Durability and Cost-Effectiveness: Due to its strength and corrosion resistance, die-cast aluminum components offer long-lasting performance with minimal maintenance requirements. This translates to a cost-effective solution for industries prioritizing reliability and low life-cycle costs.

Die-cast aluminum's unique blend of strength, weight, corrosion resistance, and versatility makes it a valuable material across numerous industries.

Exploring Die Cast Aluminum Benefits

Exploring the benefits of die cast aluminum reveals its ability to be molded into complex shapes with high precision, making it suitable for intricate designs and detailed components. The economic benefits of using die cast aluminum also make it an attractive choice for manufacturers looking to optimize production costs without compromising on quality.

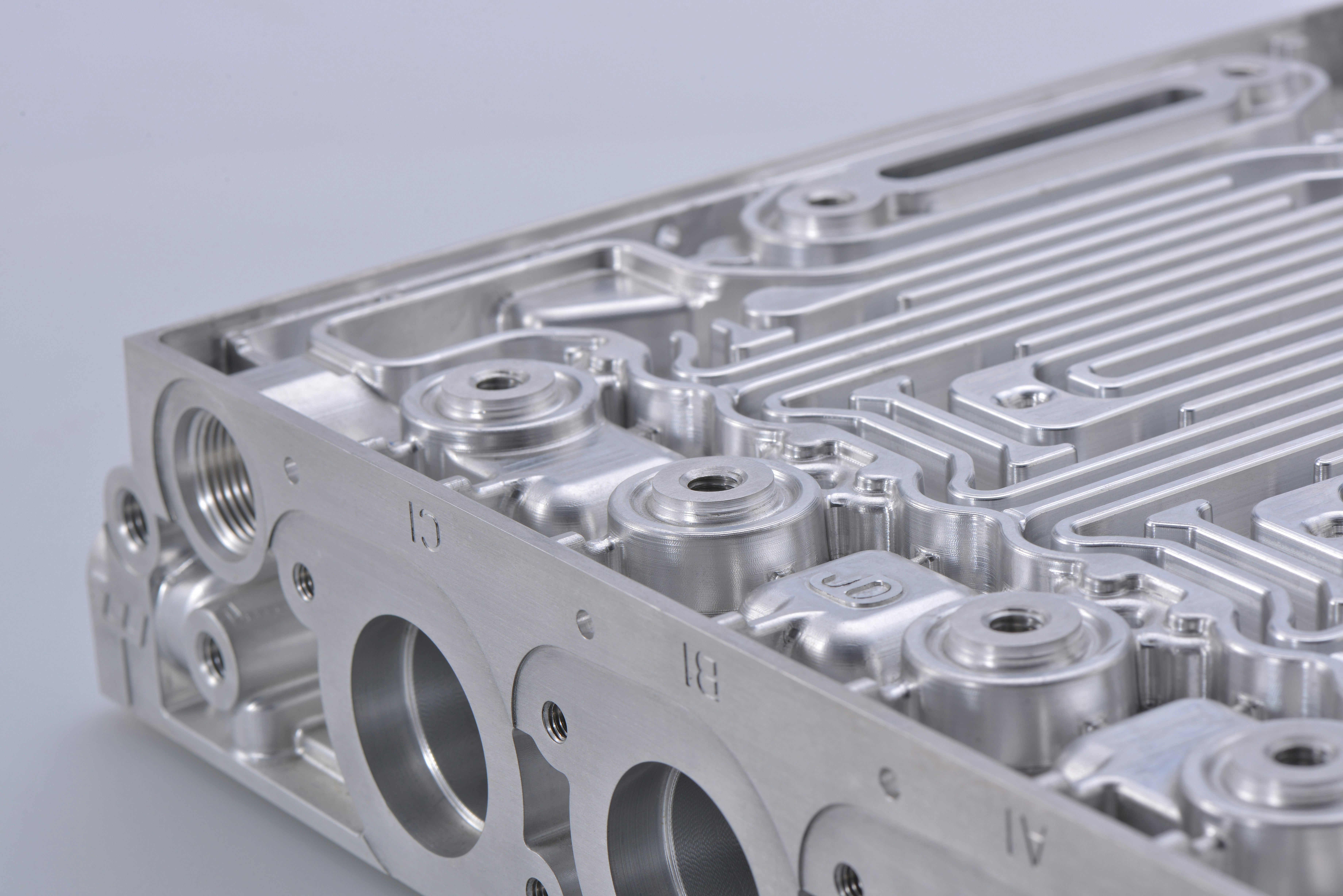

Furthermore, die cast aluminum offers excellent thermal conductivity, making it an ideal choice for components that require efficient heat dissipation. This property allows for producing high-performance parts for various industries, including automotive, aerospace, and electronics. Additionally, the lightweight nature of die cast aluminum makes it easier to handle during manufacturing and reduces shipping costs for finished products.

Why Choose Die Cast Aluminum

Die cast aluminum is a popular selection for metal components due to its numerous advantages. Here's why it stands out:

- Efficiency and Cost-Effectiveness: The die casting process allows for high-volume production with minimal waste, making it a cost-efficient choice for manufacturers.

- Lightweight Yet Strong: Die cast aluminum offers an exceptional strength-to-weight ratio. Components can be incredibly strong without adding unnecessary weight, a benefit for aerospace, automotive, and consumer electronics applications.

- Diverse Applications: Aluminum's versatility shines in its ability to be formed into complex shapes, making it suitable for various industries.

Die cast aluminum's efficiency, strength, weight savings, and diverse applications make it a compelling choice for manufacturers seeking high-performance and cost-effective components.

1. Lightweight and Strong

When it comes to metal casting, die cast aluminum stands out for its superior strength, making it a top choice for various applications. The aluminum metal casting process results in a product that offers exceptional durability and resilience, making it ideal for use in industries such as automotive, aerospace, and electronics.

Superior Strength of Die Cast Aluminum

The die casting process produces aluminum parts with impressive strength, capable of withstanding heavy loads and extreme conditions. This makes die cast aluminum an excellent choice for manufacturing components that require high structural integrity and reliability. Whether it's engine parts for automobiles or critical components for aircraft, die cast aluminum ensures top-notch performance.

Additionally, die cast aluminum's lightweight nature makes it an ideal choice for applications where weight reduction is crucial. Its low density allows for the production of strong and durable parts, yet significantly lighter than those made from other materials. This makes die cast aluminum perfect for industries such as aerospace, where every pound saved can significantly affect fuel efficiency and overall performance.

Lightweight Nature of Die Cast Aluminum

One of the key advantages of die cast aluminum is its lightweight nature, which makes it highly desirable for a wide range of applications. Despite being lightweight, die cast aluminum maintains its exceptional strength-to-weight ratio, providing an ideal combination for products that require both durability and reduced weight. This makes it a popular choice in industries where weight reduction is crucial.

Furthermore, die cast aluminum's lightweight nature also contributes to its ease of handling and transportation, making it a practical choice for manufacturers looking to streamline their production processes. Its reduced weight also means lower shipping costs and easier installation, improving its cost-effectiveness. This makes die cast aluminum a top choice for industries looking to optimize operations and minimize expenses.

Durability of Die Cast Aluminum

In addition to its strength and lightweight properties, die-cast aluminum boasts remarkable durability. Its resistance to corrosion and ability to withstand harsh environmental conditions make it a reliable material for long-term use. From outdoor equipment to electronic enclosures, die-cast aluminum ensures longevity and consistent performance.

2. Cost-Effective and Efficient

When it comes to metal casting, die cast aluminum stands out for its cost-effectiveness. By using metal casting sand molds, manufacturers can efficiently produce complex shapes and designs, reducing the need for additional machining. This not only saves time but also cuts down on material waste, making die cast aluminum a highly efficient choice for production.

Cost-Effectiveness of Die Cast Aluminum

Die casting with aluminum alloys offers a cost-effective solution for producing high-quality parts and components. Reusing the die for casting multiple parts reduces the overall production costs. Additionally, the lightweight nature of aluminum metal casting results in lower shipping expenses, making it a cost-effective option from start to finish.

Furthermore, die casting with aluminum alloys offers a cost-effective solution due to the high level of precision and accuracy that can be achieved. This results in minimal material waste and rework, reducing overall production costs. The ability to produce intricate and complex shapes with tight tolerances also adds to the cost-effectiveness of aluminum die casting, as it eliminates the need for additional machining processes.

Efficiency in Die Cast Aluminum Production

The die casting process allows for high-speed production of intricate and detailed parts with minimal post-processing required. Advanced technologies and automation in die cast aluminum manufacturing further enhance this efficiency. The combination of speed and precision makes die cast aluminum an efficient choice for meeting production demands.

Furthermore, die cast aluminum production offers economic benefits due to its recyclability and sustainability. Aluminum can be recycled repeatedly without losing its quality, making it a cost-effective and environmentally friendly option for manufacturers. This reduces material costs and minimizes the environmental impact of production processes, aligning with modern sustainability goals. Additionally, the lightweight nature of aluminum allows for reduced transportation costs, contributing to overall cost savings for manufacturers.

Economic Benefits of Die Cast Aluminum

Die-cast aluminum is a cost-effective material choice for many industries due to its unique properties and efficient manufacturing process. Here's how die-cast aluminum translates to economic benefits for manufacturers:

- Reduced Weight, Increased Efficiency: Die-cast aluminum's lightweight nature is a major advantage, particularly in the automotive industry. Lighter car parts contribute to better fuel efficiency, which translates to cost savings for manufacturers and consumers.

- Strength and Stability at Lower Costs: Die-cast aluminum offers excellent strength and dimensional stability despite being lightweight. This makes it ideal for electronic devices requiring strong yet compact components. Manufacturers benefit from achieving these qualities without using more expensive materials.

- Minimal Machining, Lower Production Costs: Die-cast aluminum's ability to be formed into complex shapes with high precision minimizes the need for additional machining. This translates to significant time and cost savings during production.

- High Precision, Reduced Waste: The high precision of die-cast aluminum parts ensures they meet strict quality standards, reducing the likelihood of defects and rework. This improves product quality and minimizes wasted materials and additional production costs.

Die-cast aluminum's combination of lightweight strength, design flexibility, and efficient production process makes it a compelling choice for manufacturers seeking to optimize their bottom line.

3. Versatility and Precision

Die cast aluminum is known for its versatile applications in various industries, making it a popular choice for manufacturers. From automotive parts to electronic components, die cast aluminum offers a wide range of possibilities due to its ability to be molded into complex shapes and designs.

Versatile Applications of Die Cast Aluminum

Die cast aluminum is widely used in the automotive industry for producing engine parts, transmission housings, and structural components due to its lightweight nature and superior strength. It is also commonly utilized in manufacturing electronic enclosures, aerospace components, and even household appliances, showcasing its versatility across different sectors.

Furthermore, die cast aluminum's excellent thermal conductivity makes it an ideal choice for heat sinks in electronic devices, ensuring efficient heat dissipation and optimal performance. Its corrosion resistance also makes it suitable for outdoor applications such as street lighting fixtures and signage, providing durability and longevity in harsh environmental conditions. The ability to be easily machined and finished further adds to its appeal in various industries.

Precision in Die Cast Aluminum Manufacturing

The die casting process allows for precise and intricate designs to be created easily, ensuring that each component meets strict dimensional tolerances. This precision in manufacturing makes die cast aluminum an ideal choice for parts that require high accuracy and consistency in their production.

Furthermore, the high dimensional accuracy and consistency achieved through die casting make it an excellent choice for parts used in automotive, aerospace, and electronics industries. This precision allows for seamless die-cast aluminum components integration into complex machinery and equipment, ensuring optimal performance and reliability. Additionally, the ability to easily create intricate designs means that manufacturers can produce lightweight yet durable parts that meet the specific requirements of various applications.

Diverse Uses of Die Cast Aluminum

From aluminum alloys to specialized casting dies, die-cast aluminum can be tailored to meet specific requirements, making it suitable for a diverse range of uses. Whether producing intricate decorative pieces or functional mechanical parts, die-cast aluminum offers endless possibilities for manufacturers seeking high-quality metal casting solutions.

Due to its lightweight yet durable properties, die-cast aluminum is widely used across various industries, from automotive components to consumer electronics. Its ability to withstand high temperatures and corrosion makes it ideal for manufacturing engine parts, heat sinks, and outdoor furniture. With the option of intricate designs and customization, die cast aluminum offers manufacturers the flexibility to create aesthetically pleasing and highly functional products.

Remember that when choosing the right material for your next project, die cast aluminum is a versatile and precise option with diverse uses across various industries.

Conclusion

Die-cast aluminum offers many advantages in the world of metal casting. Its lightweight nature, superior strength, and durability make it a top choice for various applications. The cost-effectiveness and efficiency in production further solidify its position as a preferred material. Its versatility and precision in manufacturing allow for diverse uses across industries, making it stand out among other metal casting options.

The Many Advantages of Die Cast Aluminum

Die-cast aluminum is a popular choice for metal casting due to its numerous advantages. Here's why:

- Lightweight yet Strong: Die-cast aluminum offers an exceptional strength-to-weight ratio. This means parts can be lightweight without sacrificing durability, making it ideal for applications where weight reduction is crucial, such as in the aerospace and automotive industries.

- Cost-Effective: Die-cast aluminum is a cost-effective solution for high-volume production runs due to its high production speed and minimal post-processing requirements.

- Versatile and Complex Shapes: Die-cast aluminum is highly versatile and can be formed into intricate designs and complex shapes with tight tolerances. This eliminates the need for extensive machining, further reducing production costs.

- Durable and Corrosion-Resistant: Die-cast aluminum parts are naturally corrosion-resistant, ideal for outdoor applications or parts exposed to harsh environments. This translates to a longer lifespan and reduced maintenance needs.

- Excellent Heat Resistance: Die-cast aluminum can withstand high temperatures and pressures, allowing it to be used in components subjected to demanding thermal conditions.

Die-cast aluminum's lightweight strength, cost-effectiveness, design flexibility, durability, and heat resistance makes it a highly versatile and valuable material for various applications.

Why Die Cast Aluminum Stands Out

Die cast aluminum stands out due to its exceptional strength-to-weight ratio, making it perfect for applications where both durability and lightweight properties are essential. Its ability to be easily shaped into intricate designs also sets it apart from other materials used in metal casting processes.

In addition to its strength and lightweight properties, die cast aluminum offers excellent corrosion resistance, making it a reliable choice for outdoor applications and harsh environments. Products made from die cast aluminum can withstand exposure to moisture, salt, and other corrosive elements without deteriorating, ensuring longevity and low maintenance requirements. Whether used in automotive components or outdoor furniture, die cast aluminum's resistance to corrosion adds significant value to its already impressive list of benefits.

Key Benefits of Choosing Die Cast Aluminum

Due to its numerous advantages, die-cast aluminum is a popular choice for many industries. Here are some of the key benefits of opting for die-cast aluminum:

- Economic Advantages: Die-cast aluminum offers cost-effective production, especially for high-volume projects. The mold's reusability and minimal post-processing requirements contribute to significant savings.

- Versatile Applications: Due to its excellent formability, die-cast aluminum can be crafted into complex shapes with intricate details. This makes it suitable for a wide range of applications across various industries.

- Precise Manufacturing: The die-casting process creates parts with tight tolerances and consistent dimensions. This precision ensures a high-quality finished product that meets exact specifications.

- Enhanced Performance: Aluminum alloys used in die-casting offer superior strength-to-weight ratio, good thermal conductivity, and excellent corrosion resistance. These properties make die-cast aluminum parts ideal for demanding applications.

- Lightweight Design: Aluminum's inherent lightness simplifies handling and transportation during the manufacturing process, reducing costs throughout the supply chain.

Die-cast aluminum provides a compelling combination of affordability, versatility, precision, and performance. These advantages make it a preferred material for various applications, ensuring the creation of high-quality and long-lasting products.