Introduction

Welcome to Buttler Precision Die Casting, where expertise meets innovation in custom die casting services. With a focus on aluminum and zinc die casting, we offer tailored solutions for your specific needs, ensuring unmatched quality and precision in every part.

The Expertise of Buttler in Custom Precision Die Casting

At Buttler, we specialize in die-casting molds, aluminum and zinc castings, processing, surface treatment, assembly, and packaging. Our smart part engineering approach provides innovative tooling designs engineered for cost-effective manufacturing to maximize performance and casting quality while minimizing the need for secondary operations.

The Benefits of Custom Die Casting Services

Our custom die casting services offer a range of benefits, including tailored solutions for your specific needs and cost-effective manufacturing with smart part engineering. With our expertise in aluminum and zinc die casting, we provide unmatched quality and precision in every part.

Why Aluminum and Zinc Die Casting is the Way to Go

When it comes to custom casting, aluminum and zinc die casting are the way to go for their precision and durability. With innovative tooling designs and a streamlined die casting process, Buttler ensures that your parts are manufactured with the highest level of quality.

The Advantage of Custom Die Casting

Custom die casting offers tailored solutions for your specific needs, ensuring that your parts are designed and manufactured to meet your exact requirements. At Ningbo Buttler Precision Machinery Co., Ltd., we specialize in custom die casting, providing personalized solutions for a wide range of industries and applications. Whether you need unique shapes, sizes, or finishes, our custom casting services can deliver the perfect solution for your project.

Tailored Solutions for Your Specific Needs

With custom die casting, you have the flexibility to create parts that are specifically tailored to your unique specifications. Whether you require complex geometries, intricate designs, or specific material properties, custom casting allows you to achieve the exact features and characteristics you need. At Buttler, we work closely with our clients to understand their specific requirements and deliver customized solutions that meet their expectations.

With our advanced technology and expertise in die casting, we are able to offer cost-effective manufacturing solutions through smart part engineering. By optimizing the design and production processes, we can minimize material waste and reduce production time, resulting in lower overall costs for our clients. Our team is dedicated to finding innovative ways to maximize efficiency without compromising on quality, ensuring that our tailored solutions are not only customized but also economical.

Cost-Effective Manufacturing with Smart Part Engineering

Our smart part engineering approach ensures cost-effective manufacturing processes that optimize efficiency and minimize waste. By leveraging innovative tooling designs and engineering expertise, we are able to produce high-quality parts at competitive prices. Our focus on smart part engineering enables us to streamline production processes and maximize the value of custom die casting for our clients.

Our smart part engineering approach also allows us to minimize the need for secondary operations, reducing production time and costs for our clients. By carefully designing parts and tooling, we are able to achieve the desired specifications without the need for additional finishing processes. This not only saves time and money but also results in a more efficient and sustainable manufacturing process.

Minimizing the Need for Secondary Operations

One of the key advantages of custom die casting is its ability to minimize the need for secondary operations such as machining or finishing. By utilizing precision aluminum molds and advanced die casting processes, we can achieve tight tolerances and excellent surface finishes without additional processing steps. This not only saves time and resources but also ensures consistent quality across all parts.

Additionally, the ability to minimize secondary operations also leads to cost savings for our clients. By reducing the need for additional machining or finishing processes, we can offer competitive pricing while still delivering high-quality custom die cast parts. This cost-effectiveness is a key benefit for businesses looking to streamline their manufacturing processes and improve their bottom line.

The Process of Die Casting

Ningbo Buttler Precision Machinery Co., Ltd. is at the forefront of custom die casting, offering expertise in aluminum and zinc casting, innovative tooling designs, and precision engineering for cost-effective manufacturing.

Understanding the Die Casting Process

The die casting process involves injecting molten metal into a steel mold under high pressure. This results in a precisely shaped part with a smooth surface finish. At Buttler, we excel in this process, ensuring that every part meets the highest quality standards.

The high pressure used in the die casting process ensures that the molten metal fills every intricate detail of the steel mold, resulting in parts with tight tolerances and minimal post-processing required. At Buttler, we have perfected our techniques to achieve precision in both aluminum and zinc casting, allowing us to meet the most demanding specifications for our customers. This level of accuracy and consistency is what sets us apart in the die casting industry.

Precision in Aluminum and Zinc Casting

With our advanced aluminum molds and state-of-the-art equipment, we achieve unparalleled precision in aluminum and zinc casting. Our expertise allows us to produce complex parts with tight tolerances, making us the go-to choice for custom die casting projects. Additionally, our innovative tooling designs allow for better part designs, ensuring that each component meets the highest standards of quality and performance. By constantly refining our processes and investing in cutting-edge technology, we stay at the forefront of the industry, delivering superior results for our clients.

Innovative Tooling Designs for Better Part Designs

At Buttler, we understand that innovative tooling designs are essential for creating better part designs. Our engineering team leverages smart part engineering to optimize part performance while minimizing material usage and production costs.

In addition to optimizing part performance and minimizing production costs, innovative tooling designs also play a crucial role in ensuring the durability and longevity of the parts. By incorporating advanced materials and precision engineering techniques, our team at Buttler is able to create tooling designs that enhance the overall quality and reliability of the parts, ultimately leading to greater customer satisfaction and reduced maintenance requirements.

The Applications of Die Cast Metal

Exploring Outdoor Lamp Series

When it comes to custom die casting for outdoor lamp series, Buttler's expertise in aluminum casting die and aluminum mold is unmatched. With precision die casting, they are able to create durable and high-quality lamp components that can withstand outdoor elements, making them the perfect choice for outdoor lighting solutions.

Buttler's dedication to precision die casting extends beyond just creating durable lamp components. Their expertise also allows them to design intricate and stylish outdoor lamp series that add a touch of elegance to any outdoor space. With their attention to detail and commitment to quality, Buttler's outdoor lamps not only provide reliable lighting solutions but also enhance the aesthetic appeal of any environment.

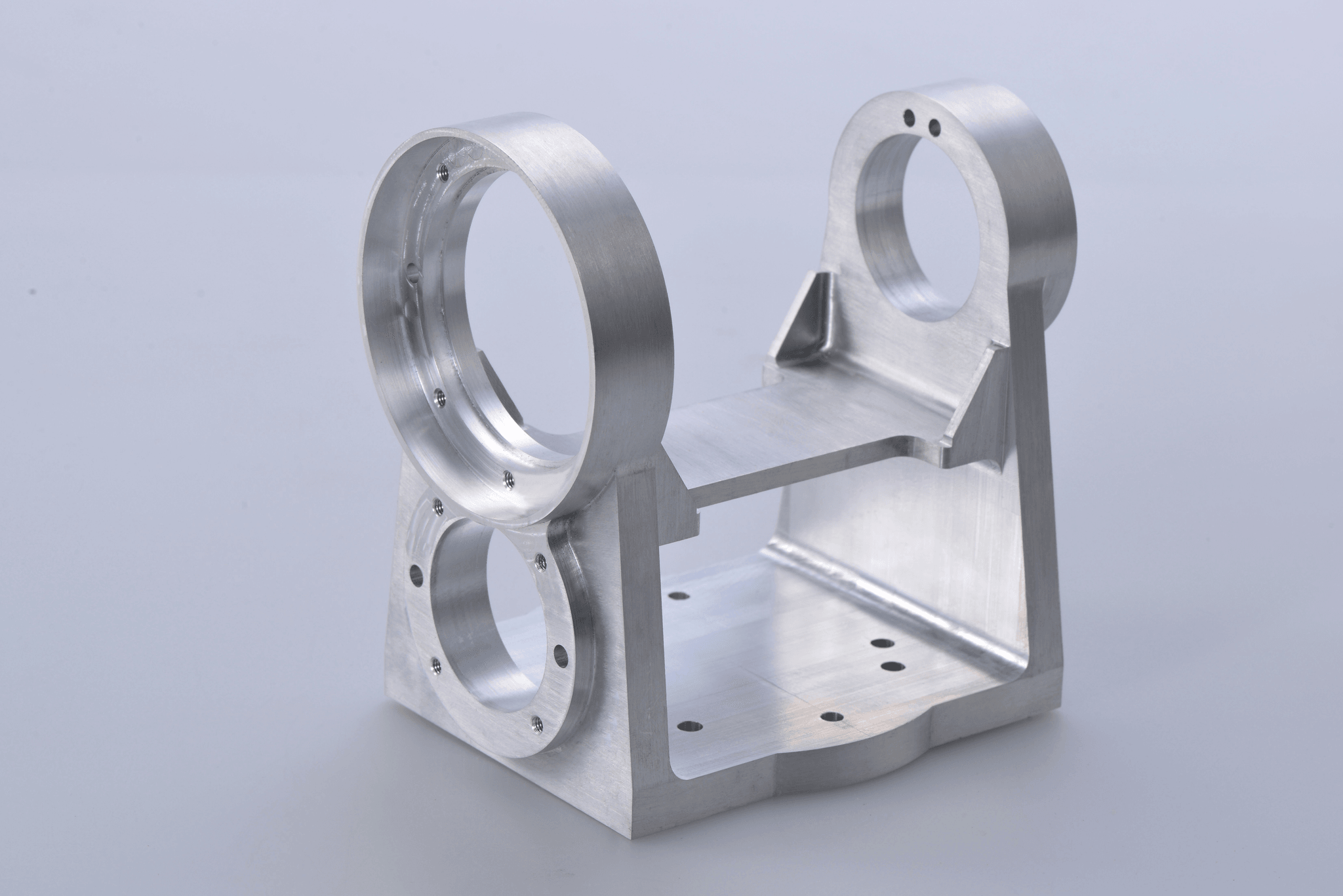

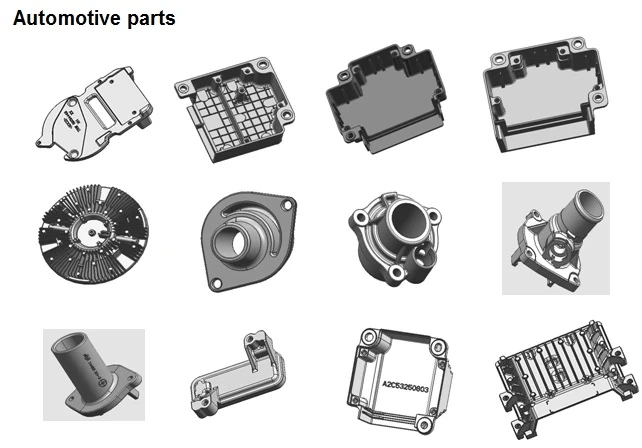

Automotive Parts Made with Precision

Custom die casting plays a crucial role in producing automotive parts with precision. Buttler's aluminum die casting process ensures that each part meets the strict quality standards required for automotive applications. From engine components to structural parts, their custom casting services deliver reliable and durable solutions for the automotive industry.

Additionally, Buttler's expertise in custom die casting extends to gas appliance parts and power tool components. With their advanced aluminum die casting process, they are able to produce precise and high-quality parts that meet the specific requirements of gas appliances and power tools. Whether it's burner components for gas stoves or housing for power drills, Buttler's custom casting services provide durable solutions for these industries.

Gas Appliance Parts and Power Tool Components

Gas appliance parts and power tool components require custom casting that can withstand high temperatures and heavy-duty use. Buttler's expertise in die cast metal allows them to produce complex parts with exceptional strength and heat resistance. Their attention to detail in the die casting process ensures that gas appliance parts and power tool components meet the highest performance standards.

Buttler's expertise in die cast metal not only allows them to produce complex parts with exceptional strength and heat resistance but also enables them to create custom designs that meet the specific needs of gas appliance manufacturers and power tool producers. By utilizing advanced die casting techniques, Buttler can offer tailored solutions for high-temperature applications, ensuring that their components can withstand the rigorous demands of gas appliances and power tools. This level of customization sets Buttler apart in the industry, providing clients with durable, reliable parts that enhance the performance and longevity of their products.

Conclusion

When it comes to finding the best choice for your parts, aluminum die casting stands out as the top option. With its unmatched quality and precision, Buttler's services ensure that your parts are manufactured to the highest standards. The advantages of choosing custom casting for your project cannot be overstated, as it allows for tailored solutions that meet your specific needs.

Why Aluminum Die Casting is the Best Choice for Your Parts

Aluminum die casting offers numerous benefits, including lightweight yet durable parts that can withstand high temperatures and corrosion. With Buttler's expertise in aluminum mold design and precision casting, you can trust that your parts will be manufactured with the highest level of quality and accuracy.

Aluminum die casting is not only known for its lightweight and durable parts, but also for its ability to produce complex shapes with high precision. This makes it an ideal choice for parts that require intricate designs and tight tolerances. With Buttler's expertise in aluminum mold design and precision casting, you can be confident that your parts will meet the highest quality standards and precise specifications, ensuring optimal performance in your applications.

Unmatched Quality and Precision with Buttler's Services

Buttler's commitment to smart part engineering ensures that each part is designed for cost-effective manufacturing without compromising on performance or quality. Their innovative tooling designs optimize the die casting process, resulting in superior part designs that meet even the most stringent requirements.

Buttler's commitment to smart part engineering not only ensures cost-effective manufacturing but also guarantees that performance and quality are never compromised. By utilizing innovative tooling designs, Buttler optimizes the die casting process, resulting in superior part designs that consistently meet even the most stringent requirements. This dedication to precision and excellence sets Buttler apart as a leader in the industry, providing unmatched quality that gives their clients a competitive edge.

Advantages of Choosing Custom Casting for Your Project

Custom die casting provides tailored solutions for your specific needs, allowing for unique part designs that are both efficient and cost-effective to produce. By minimizing the need for secondary operations, custom casting streamlines the manufacturing process and reduces overall production costs.

Custom casting also offers the advantage of improved part consistency and quality. With the ability to create intricate and complex designs, custom die casting ensures that each part is produced with precision and accuracy, reducing the likelihood of defects or inconsistencies. This level of quality control not only enhances the overall performance of the parts but also contributes to the longevity and reliability of the final product.