Introduction

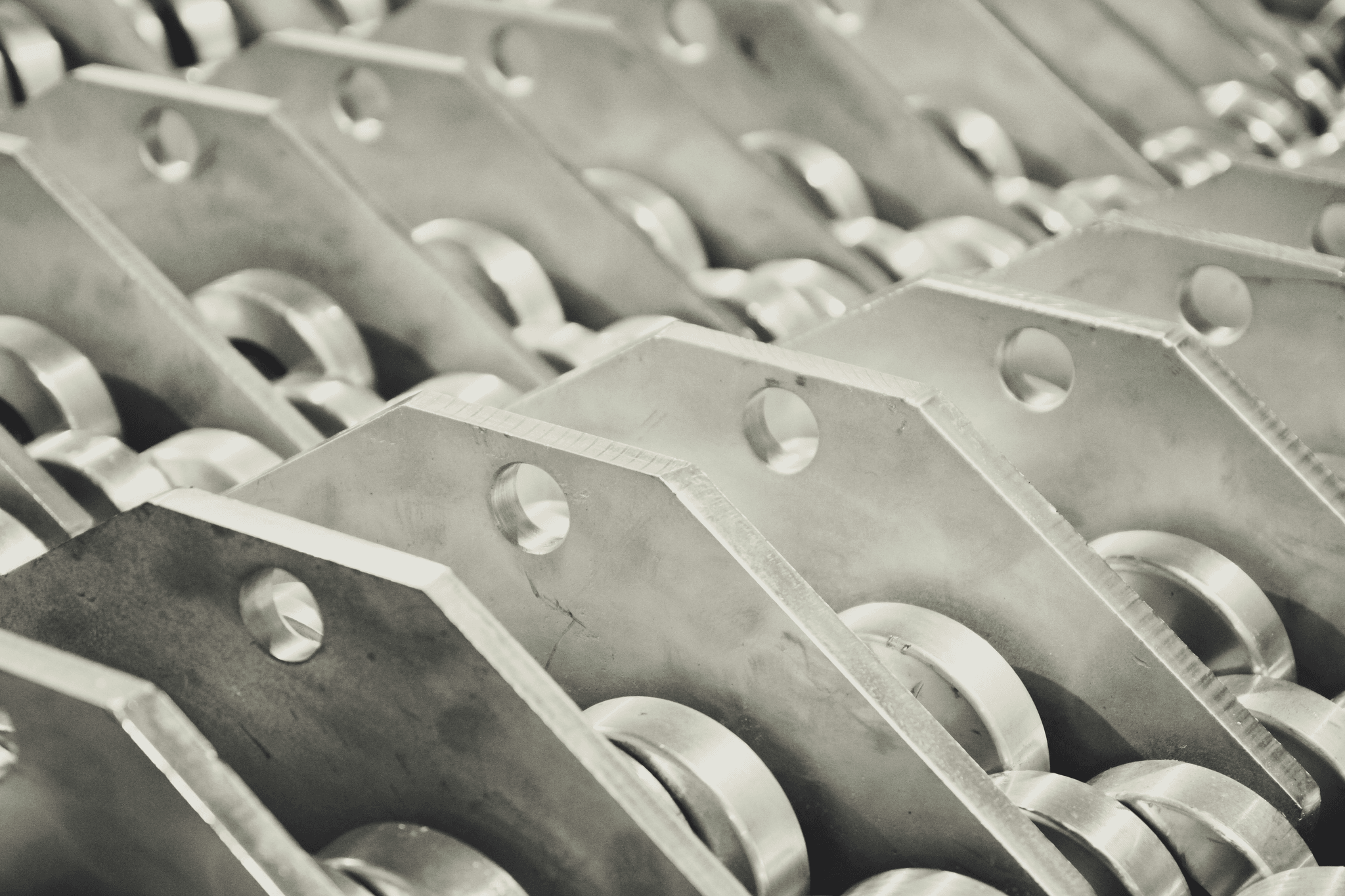

When it comes to die casting, the choice of aluminum alloy is crucial for achieving the desired results. Understanding the basics of aluminum alloys and knowing what aluminum alloys are suitable for die casting is essential for successful manufacturing. The importance of choosing the right alloy cannot be overstated, as it directly impacts the quality and performance of the final product.

Understanding the Basics of Aluminium Alloys

Aluminum alloys are widely used in die casting due to their lightweight, high strength, and excellent corrosion resistance. They offer a wide range of mechanical properties and can be easily cast into complex shapes, making them ideal for various applications in different industries.

What Aluminium Alloys for Die Casting?

When it comes to die casting, there are several cast aluminum alloys that are commonly used, including 7000 series aluminum, 6000 series aluminum, 5000 series aluminum, and 2000 series aluminum. Each type has its own unique properties that make them suitable for specific applications.

The Importance of Choosing the Right Alloy

Choosing the right aluminum alloy for die casting is crucial as it directly affects the performance and quality of the final product. Factors such as mechanical properties, corrosion resistance, and machinability should be carefully considered when selecting an alloy for a specific application.

Ningbo Buttler Precision Machinery Co., Ltd. specializes in providing innovative tooling designs engineered for cost-effective manufacturing to maximize performance and casting quality while minimizing the need for secondary operations!

The Advantages of Die Casting with Aluminium Alloys

When it comes to die casting, the choice of aluminium alloys plays a crucial role in determining the success of the process. Aluminium alloys are preferred for die casting due to their lightweight and strong properties, making them ideal for a wide range of applications. The 7000 series aluminum, 6000 series aluminum, 5000 series aluminum, and 2000 series aluminum are among the most commonly used cast aluminum alloys for die casting.

Lightweight and Strong

Aluminium alloys are known for their exceptional strength-to-weight ratio, making them perfect for applications where weight reduction is critical without compromising on durability. This characteristic makes them highly suitable for automotive parts, aerospace components, and various consumer goods.

High Corrosion Resistance

Another advantage of die casting with aluminium alloys is their high resistance to corrosion. This makes them a reliable choice for parts that are exposed to harsh environmental conditions or corrosive substances, such as marine components and outdoor equipment.

Excellent Thermal Conductivity

Aluminium alloys also exhibit excellent thermal conductivity, allowing for efficient heat dissipation in applications such as heat sinks and electronic enclosures. This property helps in maintaining optimal operating temperatures and prolonging the lifespan of the components.

With these advantages in mind, it's clear that choosing the right aluminium alloy is crucial for successful die casting processes. Buttler Precision Machinery Co., Ltd.'s expertise in smart part engineering ensures that your parts are designed and manufactured to maximize performance while minimizing secondary operations – all at no cost through their Engineering Design Review Process!

Common Types of Aluminium Alloys for Die Casting

When it comes to die casting, the choice of aluminium alloy is crucial. Different alloys offer varying properties and benefits, making it important to understand the options available. The most commonly used cast aluminum alloys include the 7000 series, 6000 series, 5000 series, and 2000 series. Each of these alloys has unique characteristics that make them suitable for different applications.

7000 Series Aluminum

The 7000 series aluminum alloys are known for their exceptional strength and heat resistance. They are often used in high-stress applications such as aerospace components and structural parts. With superior toughness and fatigue strength, these alloys are ideal for die casting parts that require durability and reliability in demanding environments.

6000 Series Aluminum

6000 series aluminum alloys are popular for their excellent combination of strength, corrosion resistance, and weldability. These alloys are widely used in automotive components, electrical fittings, and various consumer goods due to their good formability and machinability. Their versatility makes them a go-to choice for many die casting applications.

5000 Series Aluminum

The 5000 series aluminum alloys are known for their exceptional corrosion resistance and weldability. They are often used in marine environments, chemical processing equipment, and other applications where resistance to harsh conditions is essential. With good workability and high fatigue strength, these alloys offer reliable performance in die casting.

2000 Series Aluminum

2000 series aluminum alloys are valued for their high mechanical properties and excellent machinability. These alloys find application in aerospace components, structural parts, and other high-strength applications where precision machining is crucial. Their combination of strength and workability makes them a preferred choice for die casting projects with specific performance requirements.

Factors to Consider When Choosing the Right Alloy

When deciding on the best cast aluminum alloys for die casting, it's crucial to consider various factors. Mechanical properties play a significant role in determining the suitability of an alloy for a specific application. This includes aspects such as strength, ductility, and impact resistance, which can greatly impact the performance and durability of the final product.

Mechanical Properties

Aluminium alloys for die casting come in various forms with differing mechanical properties. The 7000 series aluminum, known for its high strength, is often used in aerospace applications due to its exceptional toughness and stress-corrosion cracking resistance. On the other hand, the 6000 series aluminum offers good formability and weldability, making it suitable for a wide range of die-cast components.

Corrosion Resistance

Corrosion resistance is another essential consideration when selecting cast aluminum alloys for die casting. The 5000 series aluminum is highly regarded for its excellent corrosion resistance and weldability, making it a popular choice for marine and chemical processing applications where exposure to harsh environments is common.

Machinability

Machinability is also a critical factor to take into account when choosing an alloy for die casting. The 2000 series aluminum stands out for its superior machinability and high mechanical properties, making it ideal for intricate components that require precision machining.

Partnering with Ningbo Buttler Precision Machinery Co., Ltd., renowned experts in die-casting molds and aluminium castings, ensures access to valuable insights on selecting the right alloy based on mechanical properties, corrosion resistance, and machinability. Their Smart Part Engineering approach optimizes part designs to maximize performance while minimizing secondary operations – all at no cost!

Applications of Different Aluminium Alloys in Die Casting

Automotive Parts

Aluminium alloys are widely used in the automotive industry for die casting due to their lightweight and high strength properties. 7000 series aluminum, such as A380, is commonly used for engine components and structural parts, while 6000 series aluminum, like A360, is preferred for wheels and suspension parts. The corrosion resistance of these alloys makes them ideal for exterior components like door handles and trim.

Gas Appliance Parts

When it comes to gas appliance parts, 5000 series aluminum alloys like A518 are the go-to choice for die casting due to their excellent corrosion resistance and weldability. These alloys are commonly used for burner heads, valves, and other components that come into contact with natural gas or propane.

Power Tool Parts

Die-cast power tool parts often utilize 2000 series aluminum alloys such as A201 or A206 due to their superior machinability and high strength properties. These alloys are commonly found in drill housings, gear casings, and motor components where durability and precision are crucial.

Appliance Parts

For household appliances like refrigerators and washing machines, cast aluminum alloys from the 6000 series such as A380 or A383 are popular choices due to their excellent thermal conductivity and ease of casting intricate shapes. These alloys are often used for motor housings, pump bodies, and other heat-sensitive components.

Quality Assurance in Die Casting with Aluminium Alloys

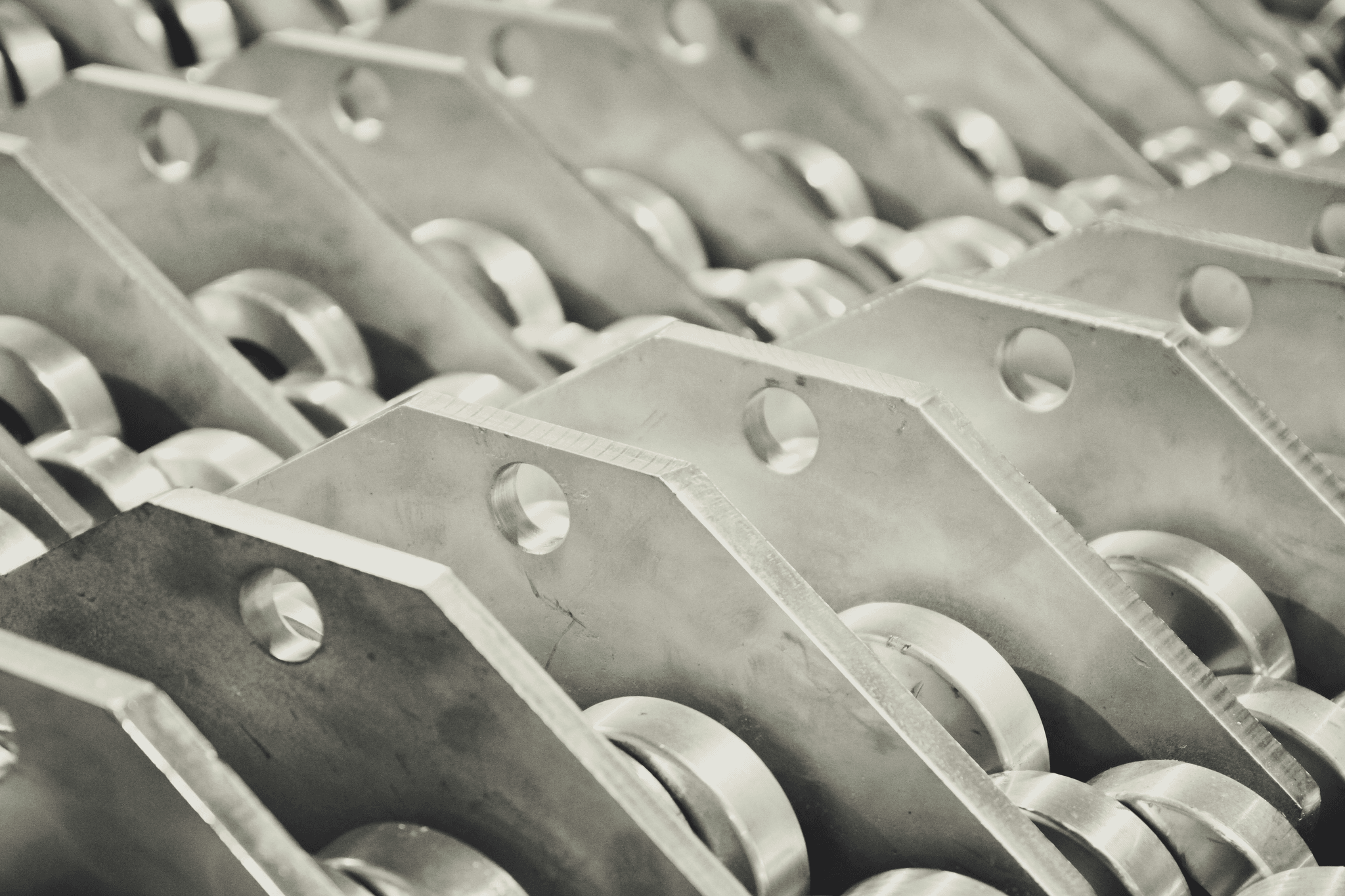

The Role of Smart Part Engineering

At Buttler Precision Machinery Co., Ltd., we understand the importance of smart part engineering in die casting with aluminium alloys. Our team specializes in creating innovative tooling designs that are engineered for cost-effective manufacturing, ensuring better part designs and optimized performance. By leveraging our Engineering Design Review Process, we can help you maximize the potential of your new and existing parts without any additional cost.

With our smart part engineering expertise, we prioritize the importance of maximizing performance and casting quality in die casting with aluminium alloys. Our innovative tooling designs are engineered to not only be cost-effective but also to enhance the overall performance of the parts produced. By focusing on optimizing performance, we can ensure that your parts meet the highest standards for quality and durability.

Maximizing Performance and Casting Quality

When it comes to die casting with aluminium alloys, maximizing performance and casting quality is essential for achieving superior results. With our expertise at Buttler Precision Machinery Co., Ltd., we are dedicated to delivering high-quality cast aluminum components that meet your specific requirements. Our focus on precision engineering and advanced manufacturing processes ensures that every part meets the highest standards of performance and quality.

Furthermore, our commitment to minimizing the need for secondary operations sets us apart from other die casting providers. By utilizing innovative techniques and state-of-the-art equipment, we are able to produce aluminum components with precise dimensions and flawless surface finishes, reducing the need for additional finishing processes. This not only saves time and resources but also ensures that our products are ready for immediate use upon delivery.

Minimizing the Need for Secondary Operations

One of the key advantages of die casting with aluminium alloys is the ability to minimize the need for secondary operations, saving time and costs in the production process. At Buttler Precision Machinery Co., Ltd., our smart part engineering approach allows us to design parts that require minimal post-casting machining or finishing, resulting in efficient production and reduced lead times for your projects.

Remember, choosing the right aluminium alloy for die casting is crucial, as it directly impacts the performance and quality of your components. By partnering with Buttler Precision Machinery Co., Ltd., you can benefit from our expertise in smart part engineering, maximizing performance and quality while minimizing secondary operations for cost-effective manufacturing solutions.

Conclusion

Making Informed Decisions for Die Casting

When it comes to die casting, it's crucial to make informed decisions about the type of aluminum alloy to use. Understanding the different cast aluminum alloys available and their specific properties is essential for achieving the desired results in your die casting projects. One important consideration is the strength and hardness of the alloy, as this will impact the durability and performance of the final product. Additionally, factors such as corrosion resistance, thermal conductivity, and machinability should also be taken into account when selecting the right aluminum alloy for your project.

Choosing the Right Aluminium Alloy for Your Project

With a variety of options available, from 7000 series aluminum to 6000 series aluminum, it's important to carefully consider the specific requirements of your project. Factors such as mechanical properties, corrosion resistance, and machinability should all be taken into account when selecting the right alloy for your die casting needs. It's also crucial to consider the cost-effectiveness and availability of the chosen alloy, as these factors can significantly impact the overall success of your project. Additionally, consulting with industry experts and leveraging their knowledge and experience can provide valuable insights into making the best decision for your die casting requirements. By partnering with Buttler Precision Machinery Co., Ltd., you can benefit from their expertise in die casting and ensure that you are using the most suitable alloy for your specific application. Their team can offer guidance on material selection, design optimization, and production processes to help you achieve optimal results for your project.

Partnering with Buttler Precision Machinery Co., Ltd. for Expertise in Die Casting

For expert guidance on choosing the most suitable cast aluminum alloy for your die casting project, consider partnering with Ningbo Buttler Precision Machinery Co., Ltd. Their specialization in die-casting molds and processing, along with their Smart Part Engineering approach, ensures that you receive top-notch expertise and support throughout your project.

Remember, making informed decisions about cast aluminum alloys is crucial for the success of your die casting projects. By choosing the right alloy and partnering with experts like Buttler Precision Machinery Co., Ltd., you can ensure that your projects are carried out with precision and efficiency.