Introduction

In the manufacturing industry, engine mounting brackets are crucial components for various applications, such as outboard motor mount plates and outboard mounting brackets. Choosing the right supplier for these parts is essential for ensuring quality, performance, and cost-effectiveness. That's where Buttler Precision Machinery Co., Ltd. comes in as a leader in providing top-notch engine mounting brackets.

The Importance of Engine Mounting Bracket Suppliers

Engine mounting brackets play a vital role in supporting and securing engines in place, whether it's for automotive use or gas appliances. The quality and reliability of these brackets directly impact the overall performance and safety of the end product. Therefore, having a dependable supplier is crucial for businesses in need of these components.

Choosing the Right Supplier for Your Business

Selecting a supplier that can meet your specific requirements is essential. From quality materials to customization options and cost-effective production, finding the right partner can make all the difference in your business's success.

Buttler Precision Machinery Co., Ltd.: A Leader in Engine Mounting Brackets

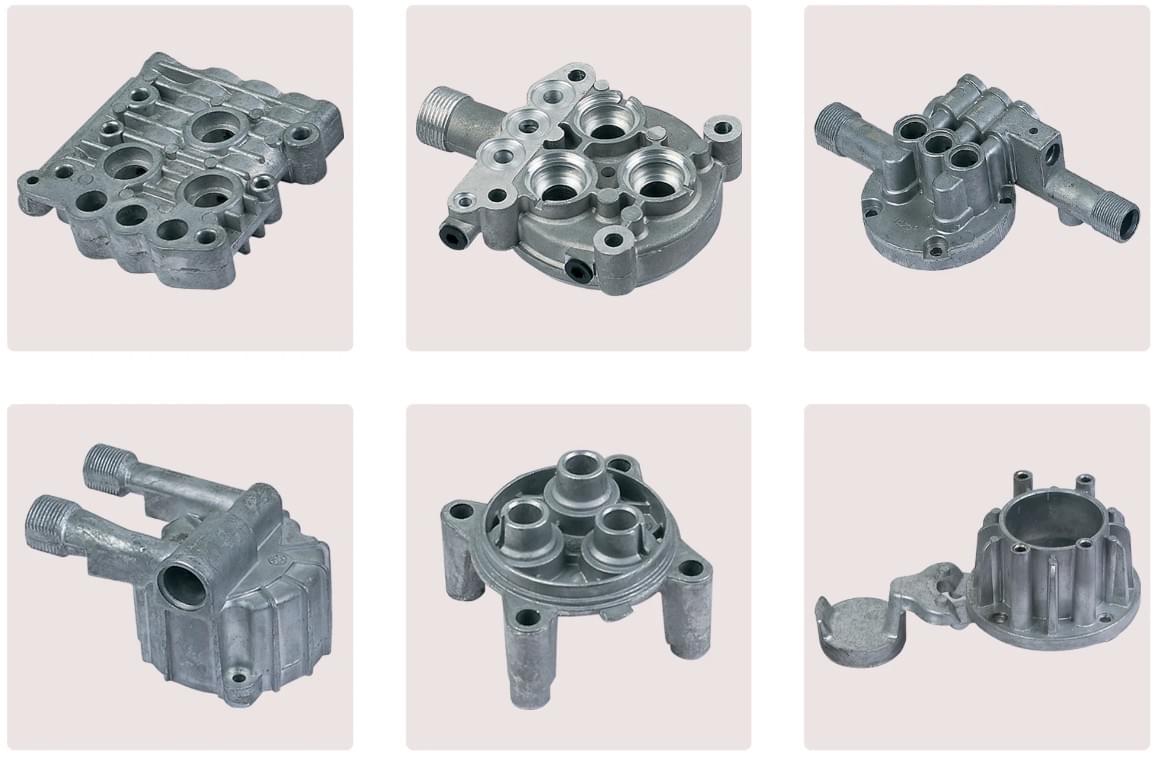

Buttler Precision Machinery Co., Ltd. stands out as an industry leader with its expertise in die-casting molds, aluminum and zinc castings, processing, surface treatment, assembly, and packaging. Their smart part engineering approach ensures better part designs while maximizing performance and casting quality.

What to Look for in an Engine Mounting Bracket Supplier

When searching for an engine mounting bracket supplier, it's crucial to prioritize quality materials and manufacturing processes. Buttler Precision Machinery Co., Ltd. is known for its expertise in die-casting molds and aluminum castings, ensuring top-notch quality for engine mounting brackets. With a focus on precision and durability, Buttler's manufacturing processes guarantee reliable and long-lasting products.

Quality Materials and Manufacturing Processes

Buttler Precision Machinery Co., Ltd. utilizes advanced die-casting molds and high-quality aluminum materials to produce engine mounting brackets that meet the most stringent industry standards. Their commitment to excellence in manufacturing processes ensures that each bracket is durable, reliable, and able to withstand the rigors of heavy-duty applications.

Furthermore, Buttler Precision Machinery Co., Ltd. offers customization options for engine mounting brackets, allowing clients to tailor the design to their specific needs and requirements. Their team of design experts is well-versed in creating innovative solutions that optimize performance and efficiency. Whether it's a unique shape, size, or additional features, Buttler Precision Machinery Co., Ltd. can accommodate a wide range of customization requests.

Customization Options and Design Expertise

In addition to quality materials, customization options are essential when choosing an engine mounting bracket supplier. Buttler offers design expertise that allows for tailored solutions to meet specific requirements. Whether it's a unique outboard motor mount plate or a specialized outboard mounting bracket, Buttler's team of experts can provide customized designs to fit any application.

Buttler's design expertise also extends to cost-effective and efficient production processes. By utilizing advanced manufacturing techniques and streamlined production methods, Buttler is able to offer competitive pricing without sacrificing quality. This means customers can benefit from customized engine mounting brackets that are not only tailored to their specific needs but also affordable and produced in a timely manner.

Cost-Effective and Efficient Production

Cost-effectiveness and efficiency are key considerations when selecting a supplier for engine mounting brackets. Buttler Precision Machinery Co., Ltd.'s streamlined production process ensures that customers receive high-quality products at competitive prices without sacrificing efficiency or lead times.

Remember, when choosing an engine mounting bracket supplier, prioritize quality materials, customization options, design expertise, cost-effectiveness, and efficient production processes – all of which are areas where Buttler Precision Machinery Co., Ltd. excels!

Benefits of Working with Buttler Precision Machinery Co., Ltd.

Innovative Tooling Designs for Better Part Designs

At Buttler Precision Machinery Co., Ltd., we offer innovative tooling designs specifically engineered for better engine mounting bracket designs. Our smart part engineering ensures that your parts are optimized for maximum performance and casting quality, while minimizing the need for secondary operations. With our Engineering Design Review Process, we can help you enhance your new and existing parts at no cost to you.

Wide Range of Casting and Processing Services

When you work with Buttler Precision Machinery Co., Ltd., you gain access to a wide range of casting and processing services for your engine mounting bracket needs. From die-casting molds to aluminum and zinc castings, our expertise covers all aspects of manufacturing to meet your specific requirements. We are committed to delivering high-quality products through our comprehensive services.

In addition to our casting and processing services, we also offer reliable assembly and packaging solutions to ensure that your engine mounting brackets are ready for use upon delivery. Our team is experienced in handling the assembly of various components, and we take pride in our meticulous attention to detail. Whether you require custom packaging or bulk shipments, we can tailor our services to meet your specific needs.

Reliable Assembly and Packaging Solutions

Buttler Precision Machinery Co., Ltd. also provides reliable assembly and packaging solutions for outboard motor mount plates, outboard mounting brackets, and other related products. Our attention to detail ensures that every part is assembled with precision and care, while our packaging solutions guarantee safe delivery to your doorstep.

Industries Served by Buttler Precision Machinery Co., Ltd.

Buttler Precision Machinery Co., Ltd. serves a wide range of industries with their high-quality engine mounting bracket solutions.

Automotive Industry

The automotive industry relies on durable and reliable engine mounting brackets to ensure the smooth and efficient operation of vehicles. Buttler provides top-notch outboard motor mount plates and outboard mounting brackets that meet the stringent requirements of automotive manufacturers.

Gas Appliance Manufacturers

Gas appliance manufacturers require sturdy and precision-engineered outboard motor brackets to support the weight and movement of their products. Buttler offers customized solutions for gas appliance manufacturers, ensuring that their outboard mounting brackets meet the highest standards of quality and performance.

Power Tool Manufacturers

Power tool manufacturers demand robust and resilient engine mounting brackets to enhance the functionality and durability of their products. Buttler's expertise in die-casting molds and processing allows them to deliver tailor-made outboard motor mount plates that meet the specific needs of power tool manufacturers.

Smart Part Engineering for Maximum Performance

When it comes to maximizing performance and quality, Buttler Precision Machinery Co., Ltd. excels in providing innovative tooling designs for engine mounting brackets. By utilizing state-of-the-art engineering techniques, they ensure that their products are engineered for cost-effective manufacturing while delivering top-notch performance and durability. With a focus on precision and quality, Buttler is the go-to supplier for smart part engineering solutions.

How Buttler Precision Machinery Co., Ltd. Maximizes Performance and Quality

Buttler Precision Machinery Co., Ltd. goes above and beyond to maximize the performance and quality of their engine mounting brackets. They utilize advanced engineering techniques to optimize part designs, ensuring that each bracket meets the highest standards of durability and reliability. By prioritizing performance in their smart part engineering processes, Buttler sets themselves apart as a leader in the industry.

Minimizing the Need for Secondary Operations

One of the key advantages of working with Buttler Precision Machinery Co., Ltd. is their ability to minimize the need for secondary operations when it comes to engine mounting brackets. Their innovative tooling designs and precision manufacturing processes result in parts that require minimal additional work, saving time and costs for their clients. This emphasis on efficiency makes Buttler a top choice for businesses looking to streamline their production processes.

Delivering Cost-Effective Manufacturing Solutions

In addition to maximizing performance and minimizing the need for secondary operations, Buttler Precision Machinery Co., Ltd. is committed to delivering cost-effective manufacturing solutions for engine mounting brackets. Their expertise in die-casting molds, aluminum and zinc castings, processing, surface treatment, assembly, and packaging ensures that they can offer comprehensive solutions that meet their clients' budgetary requirements without compromising on quality or performance.

Furthermore, Buttler Precision Machinery Co., Ltd. stays ahead of the curve by investing in advanced technologies and innovative manufacturing processes to drive down production costs without sacrificing quality. By leveraging automation and digitalization, they are able to streamline their operations and reduce labor costs, ultimately passing these savings onto their clients. This forward-thinking approach ensures that Buttler Precision Machinery Co., Ltd. remains a competitive and cost-effective solution for engine mounting bracket manufacturing in the ever-evolving market.

The Future of Engine Mounting Bracket Suppliers

Trends and Innovations in the Industry

As the demand for high-quality engine mounting brackets continues to rise, the industry is seeing a shift towards more advanced materials and manufacturing processes. With the growing emphasis on lightweight yet durable components, suppliers are investing in innovative technologies to meet these evolving needs. Buttler Precision Machinery Co., Ltd. is at the forefront of this trend, offering cutting-edge solutions for engine mounting brackets that deliver superior performance and longevity.

Buttler Precision Machinery Co., Ltd. is committed to staying ahead of the curve when it comes to industry trends and innovations. By leveraging state-of-the-art materials and manufacturing processes, the company is able to produce engine mounting brackets that are not only lightweight but also incredibly durable. This allows automotive manufacturers to enhance the performance and longevity of their vehicles, meeting the evolving needs of consumers in today's market.

The Role of Buttler Precision Machinery Co., Ltd.

Buttler Precision Machinery Co., Ltd. plays a crucial role in shaping the future of engine mounting bracket suppliers with its commitment to smart part engineering and innovative tooling designs. By providing cost-effective manufacturing solutions that prioritize quality and performance, Buttler is setting new standards for the industry. Their expertise in die-casting molds, aluminum and zinc castings, as well as assembly and packaging, positions them as a leader in delivering top-notch engine mounting brackets for various applications.

Buttler Precision Machinery Co., Ltd. is dedicated to providing personalized solutions for their clients, ensuring that every engine mounting bracket meets the specific requirements of each application. This commitment to customization sets them apart from other suppliers in the industry and allows them to cater to a wide range of customer needs. With a focus on flexibility and adaptability, Buttler is able to stay ahead of market trends and deliver innovative solutions that drive long-term success for their clients.

Choosing the Best Supplier for Long-Term Success

In an increasingly competitive market, choosing the right supplier for engine mounting brackets is essential for long-term success. Buttler Precision Machinery Co., Ltd.'s comprehensive range of services, including customization options and reliable production capabilities, makes them an ideal partner for businesses looking to secure high-quality components that meet their specific requirements. With a proven track record of serving industries such as automotive, gas appliance manufacturing, and power tools, Buttler is well-equipped to support diverse needs with their expertise in outboard motor mount plates and outboard motor brackets.

In addition to their extensive industry experience, Buttler Precision Machinery Co., Ltd. also takes pride in their commitment to innovation and continuous improvement. By staying ahead of the curve with the latest technologies and manufacturing processes, Buttler is able to offer cutting-edge solutions that meet the evolving needs of their clients. This forward-thinking approach ensures that businesses partnering with Buttler can benefit from state-of-the-art engine mounting brackets that are designed for optimal performance and durability.

Conclusion

When it comes to making informed decisions for your business, choosing the right engine mounting bracket supplier is crucial. The impact of quality engine mounting brackets cannot be overstated, as they directly contribute to the performance and reliability of your products. Partnering with Buttler Precision Machinery Co., Ltd. ensures that you have access to innovative tooling designs, a wide range of casting and processing services, and reliable assembly and packaging solutions.

Making Informed Decisions for Your Business

Selecting a reliable engine mounting bracket supplier is a strategic decision that can greatly impact the success of your business. By carefully considering factors such as quality, customization options, and cost-effectiveness, you can ensure that your products meet the highest standards in performance and durability.

The Impact of Quality Engine Mounting Brackets

Quality engine mounting brackets are essential for maintaining the structural integrity and functionality of various applications like outboard motor mount plates and outboard motor brackets. Choosing a supplier like Buttler Precision Machinery Co., Ltd. guarantees that you receive top-notch products that meet industry standards and exceed customer expectations.

Partnering with Buttler Precision Machinery Co., Ltd.

By partnering with Buttler Precision Machinery Co., Ltd., you also benefit from their state-of-the-art manufacturing facilities and advanced technology, which allows for precise and efficient production processes. This means that you can expect high-quality, cost-effective solutions that are delivered on time, every time. Additionally, their dedication to continuous improvement ensures that you will always have access to the latest advancements in die-casting and casting technology.