Introduction

When it comes to manufacturing, the quality of die-casting components is crucial for ensuring the durability and performance of the final product. Choosing the right die-casting manufacturer is essential in achieving this goal. Buttler Precision Machinery Co., Ltd. stands out as a leader in the industry, offering top-notch expertise and services.

The Importance of Quality Die-Casting Components

Quality die-casting components are essential for producing durable and high-performing products across various industries. From automotive parts to appliances, the reliability and functionality of these components significantly impact the overall product quality.

When selecting a die-casting manufacturer, several key factors should be considered:

- Experience and Expertise: A proven record of producing high-quality components is crucial.

- Advanced Technology: Modern equipment and processes ensure consistent and precise results.

- Robust Quality Control: Rigorous testing and inspection guarantee product reliability.

Partnering with a skilled die-casting manufacturer is essential for achieving exceptional product performance and customer satisfaction.

Choosing the Right Die Casting Manufacturer

Selecting a reputable die-casting manufacturer is critical for ensuring your project receives the attention to detail and expertise it deserves. With so many options available, finding a partner like Buttler Precision Machinery Co., Ltd. can make all the difference in achieving superior results.

Buttler Precision Machinery Co., Ltd.: A Leader in Die Casting

Buttler Precision Machinery Co., Ltd. has established itself as a leader in die casting, specializing in aluminum and zinc castings, surface treatment, assembly, and packaging services. Their commitment to smart part engineering ensures better part designs that are cost-effective and high-performing.

Buttler Precision Machinery Co., Ltd. has also distinguished itself through its dedication to continuous improvement and innovation in die-casting technology. By investing in state-of-the-art equipment and cutting-edge techniques, the company stays ahead of industry trends and delivers superior-quality products to its customers. This forward-thinking approach not only enhances its manufacturing capabilities but also allows it to offer customized solutions for complex die-casting projects.

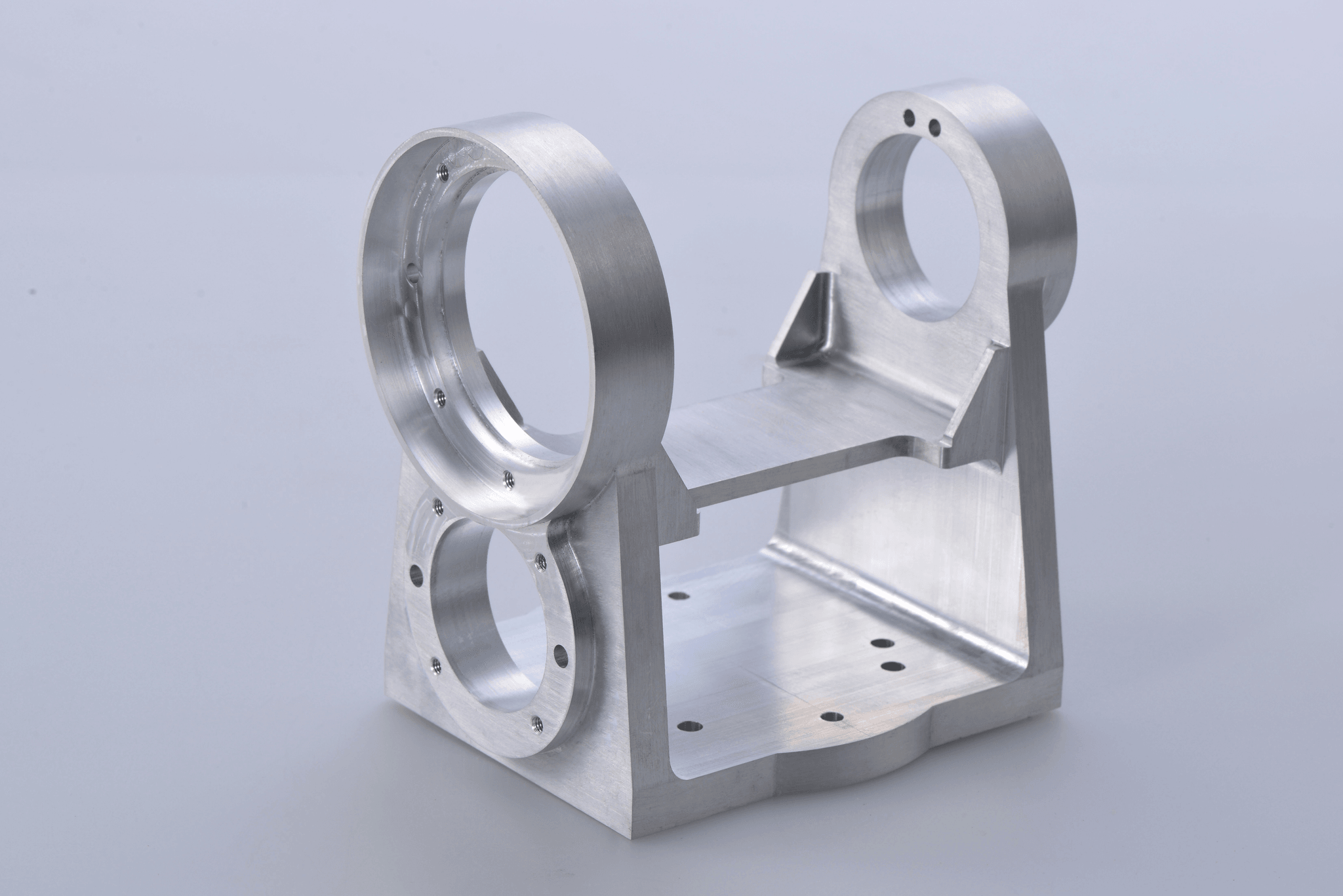

Understanding Die Casting Components

Die-casting components are metal parts manufactured using the process of injecting molten metal into a steel mold under high pressure. This method produces complex shapes with high accuracy and surface finish, making it ideal for various applications.

What Are Die Casting Components?

Die-casting components are typically made from non-ferrous metals such as aluminum, zinc, and magnesium. These parts are known for their high strength-to-weight ratio, excellent dimensional stability, and corrosion resistance, making them suitable for various industries, including automotive, aerospace, and consumer electronics.

Additionally, die-casting components offer high precision and intricate detailing, allowing for complex shapes and thin walls to be achieved with minimal machining. This results in cost savings and reduced material waste, making die casting a highly efficient manufacturing process. Furthermore, the ability to produce large quantities of parts rapidly makes die casting an ideal choice for mass production in industries where high-volume output is essential.

Key Benefits of Die Casting Components

Die casting components offer many advantages, making them a preferred option for many industries. Here's why:

- Exceptional Precision and Finish: High dimensional accuracy and smooth surface finishes are standard with die casting.

- Complex Designs Made Easy: Thin-walled sections with intricate details can be produced efficiently.

- Rapid Production and Cost-Efficiency: Die casting boasts faster production rates and cost-effective manufacturing than other metalworking methods.

- Unmatched Strength and Durability: Die-cast components excel in strength and durability, making them ideal for demanding applications.

Die-casting greatly benefits the automotive industry. Complex shapes and designs can produce innovative, lightweight parts that improve fuel efficiency and overall vehicle performance. Moreover, die casting ensures consistent and repeatable production, guaranteeing the highest quality standards.

Manufacturers can optimize their products for performance, efficiency, and longevity by selecting die-casting components.

Applications of Die Casting Components in

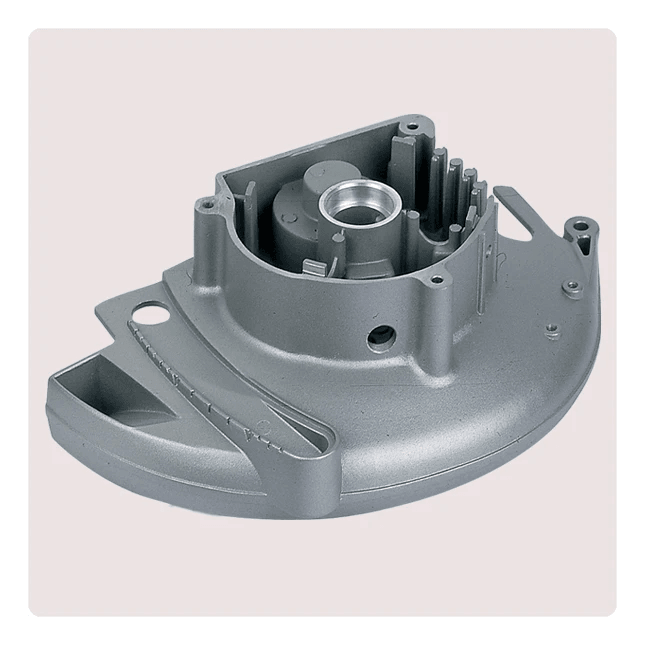

the Automotive Industry

In the automotive industry, die-casting components are widely used for producing engine parts, transmission housings, structural elements, and decorative trim pieces. The lightweight nature of aluminum die castings makes them desirable for improving fuel efficiency and reducing vehicle emissions.

Buttler Precision Machinery Co., Ltd. Die Casting Services

Ningbo Buttler Precision Machinery Co., Ltd. is a trusted leader in providing top-notch die-casting services for various industries. With their extensive expertise in die-casting molds, they offer superior solutions for producing high-quality aluminum and zinc casting components that meet the stringent demands of multiple applications.

Die Casting Mold Expertise at Buttler

Buttler Precision Machinery Co., Ltd. excels in die-casting mold design and manufacturing, ensuring that each component meets the highest standards of quality and precision. Their experienced team leverages advanced technology and innovative techniques to create molds that deliver exceptional performance and durability, making them the ideal partner for your die-casting needs.

Aluminum and Zinc Casting Capabilities

Buttler is committed to delivering exceptional aluminum and zinc casting solutions tailored to diverse industry needs. Our state-of-the-art facilities and skilled team produce intricate die-cast components characterized by precision, strength, and consistency.

Buttler specializes in providing top-tier casting solutions for the automotive and appliance sectors. Our in-depth industry knowledge ensures that our components meet stringent performance, durability, and aesthetics demands.

Our capabilities include:

- Precision die casting of aluminum and zinc components

- Specialized services for automotive and appliance industries

- Production of intricate and complex parts

- Commitment to quality and customer satisfaction

Buttler consistently exceeds customer expectations, from critical engine components to stylish appliance housings.

Specialized Services for Automotive and Appliance Parts

Buttler Precision Machinery Co., Ltd. specializes in providing tailored die casting solutions for automotive and appliance parts. They offer customized designs and manufacturing processes to meet specific performance criteria. Whether it's automotive engine components or appliance housing parts, they have the expertise to deliver top-quality casting parts that exceed expectations.

Now you can see how Buttler Precision Machinery Co., Ltd.'s die-casting services stand out in the industry. They offer unparalleled expertise in mold design, aluminum and zinc casting capabilities, and specialized solutions for automotive and appliance parts.

Quality Assurance in Die Casting

Buttler Precision Machinery Co., Ltd. stands out as a leader in the industry regarding ensuring casting quality in large molds. With its state-of-the-art facilities and expert team, it consistently produces high-quality die-casting components that meet the most stringent standards. Buttler guarantees precision and excellence in every casting by employing advanced quality control measures.

Ensuring Casting Quality in Large Molds

At Buttler, the focus on quality assurance starts with meticulously inspecting large molds to ensure they meet precise specifications. Their skilled engineers and technicians meticulously examine every detail of the mold to identify any potential issues or defects before production begins. This proactive approach allows for early intervention and correction, producing superior casting quality.

After the meticulous inspection process, Buttler's engineers and technicians leverage innovative tooling designs to ensure optimal performance of the large molds. By utilizing cutting-edge technology and advanced materials, they can create molds that meet precise specifications and deliver exceptional durability and longevity. This focus on innovative tooling designs not only enhances casting quality but also minimizes the need for frequent maintenance or replacements, ultimately saving time and resources for their clients.

Innovative Tooling Designs for Optimal Performance

Buttler's commitment to innovation is evident in its tooling designs, which are engineered for optimal performance and cost-effective manufacturing. By leveraging cutting-edge technology and smart part engineering, it maximizes casting quality while minimizing the need for secondary operations. This results in efficient production processes and superior end products.

Furthermore, Buttler's tooling designs prioritize durability and longevity, ensuring their components can withstand the rigors of high-volume production. This reduces downtime for maintenance and replacement and contributes to overall cost savings for manufacturers. Additionally, their designs are optimized for ease of use and maintenance, allowing seamless integration into existing production processes without significant disruption.

Importance of Surface Treatment in Die Casting Components

Surface treatment plays a crucial role in enhancing the performance and longevity of die-casting components. Buttler understands this importance and offers a wide range of surface treatment options, including painting, powder coating, anodizing, and more. These treatments not only improve aesthetics but also protect against corrosion, wear, and other environmental factors, ensuring the durability of the components.

Surface treatment improves the appearance and functionality of die-casting components. By applying surface treatments such as anodizing or powder coating, Buttler ensures that the components are better equipped to withstand harsh environmental conditions and resist corrosion. This improves the components' overall performance and extends their lifespan, providing long-term value to customers.

Automotive Parts Die Casting Market

The automotive industry demands high-quality, durable components to ensure vehicle safety and performance. Die-casting components are crucial in meeting these demands, providing the strength and precision required for automobile applications.

Meeting the Demands of the Automotive Industry

The automotive industry requires components that withstand rigorous conditions, including extreme temperatures and heavy loads. Die-casting components, such as aluminum parts manufactured by Buttler Precision Machinery Co., Ltd., are designed to meet these demands, ensuring optimal performance and longevity in automotive applications.

Buttler Precision Machinery Co., Ltd. utilizes advanced die-casting technology to produce high-quality aluminum parts with superior strength and durability. These components are engineered to withstand the harsh conditions of automotive applications, providing reliable performance and longevity for vehicle manufacturers and their customers. With Buttler's precision engineering and attention to detail, automotive companies can trust that their vehicles will be equipped with the best die-casting parts on the market.

High-Quality Casting Parts for Automobile Applications

Die-casting components are known for their exceptional quality and reliability, making them ideal for automobile applications. With their superior strength-to-weight ratio and dimensional accuracy, aluminum die-casting parts are widely used in the automotive industry to create lightweight yet durable components.

Furthermore, aluminum die-casting parts offer excellent corrosion resistance, making them ideal for use in automobile applications where exposure to harsh environmental conditions is common. This ensures the components remain durable and reliable, even in challenging operating environments. Additionally, die casting's versatility allows for complex and intricate designs, providing automotive manufacturers with greater flexibility in creating innovative and efficient vehicle components.

Buttler's Contribution to Automotive Parts Die Casting

Buttler Precision Machinery Co., Ltd. has been a key contributor to the automotive parts die-casting market, providing top-notch die-casting services for various automotive applications. With expertise in die-casting molds and aluminum casting capabilities, Buttler delivers high-quality components that meet the automotive industry's stringent requirements.

Choose the Best Die Casting Components for Your Project

When choosing the best die-casting components for your project, quality, and expertise are key. Buttler Precision Machinery Co., Ltd. offers superior die-casting solutions, focusing on innovative tooling designs and cost-effective manufacturing processes. Leveraging their expertise ensures top-notch results for your casting needs.

Selecting the right die-casting components is crucial for the success of your project. With Buttler's specialized services for automotive and appliance parts, you can trust that you're getting high-quality aluminum parts manufactured to meet your specific requirements. Their expertise in die-casting molds and aluminum casting capabilities makes them a top choice for reliable components.

Leveraging Buttler's Expertise for Superior Die Casting Solutions

Buttler Precision Machinery Co., Ltd.'s commitment to smart part engineering ensures better part designs that maximize performance and quality while minimizing the need for additional operations. Taking advantage of their Engineering Design Review Process allows you to optimize new and existing parts at no cost, setting your project up for success.

Advantages of Aluminum Parts Manufacturers in the Die Casting Industry

In the competitive die-casting industry, having a trusted aluminum parts manufacturer like Buttler on your side can make all the difference. Their expertise in surface treatment and assembly, combined with their focus on cost-effective manufacturing, sets them apart as leaders in producing high-quality aluminum die-casting parts for various applications.

Overall, when choosing die-casting components for automotive applications or other industries, Buttler Precision Machinery Co., Ltd.'s dedication to quality assurance and innovative solutions makes them a top choice in the market.