Introduction

When it comes to understanding automotive mounting brackets, it's essential to explore their role in vehicle stability and performance. Engine mounting brackets, in particular, play a crucial role in supporting the engine and ensuring optimal performance. The importance of quality car brackets cannot be overstated, as they directly impact the overall safety and functionality of a vehicle.

Understanding Automotive Mounting Brackets

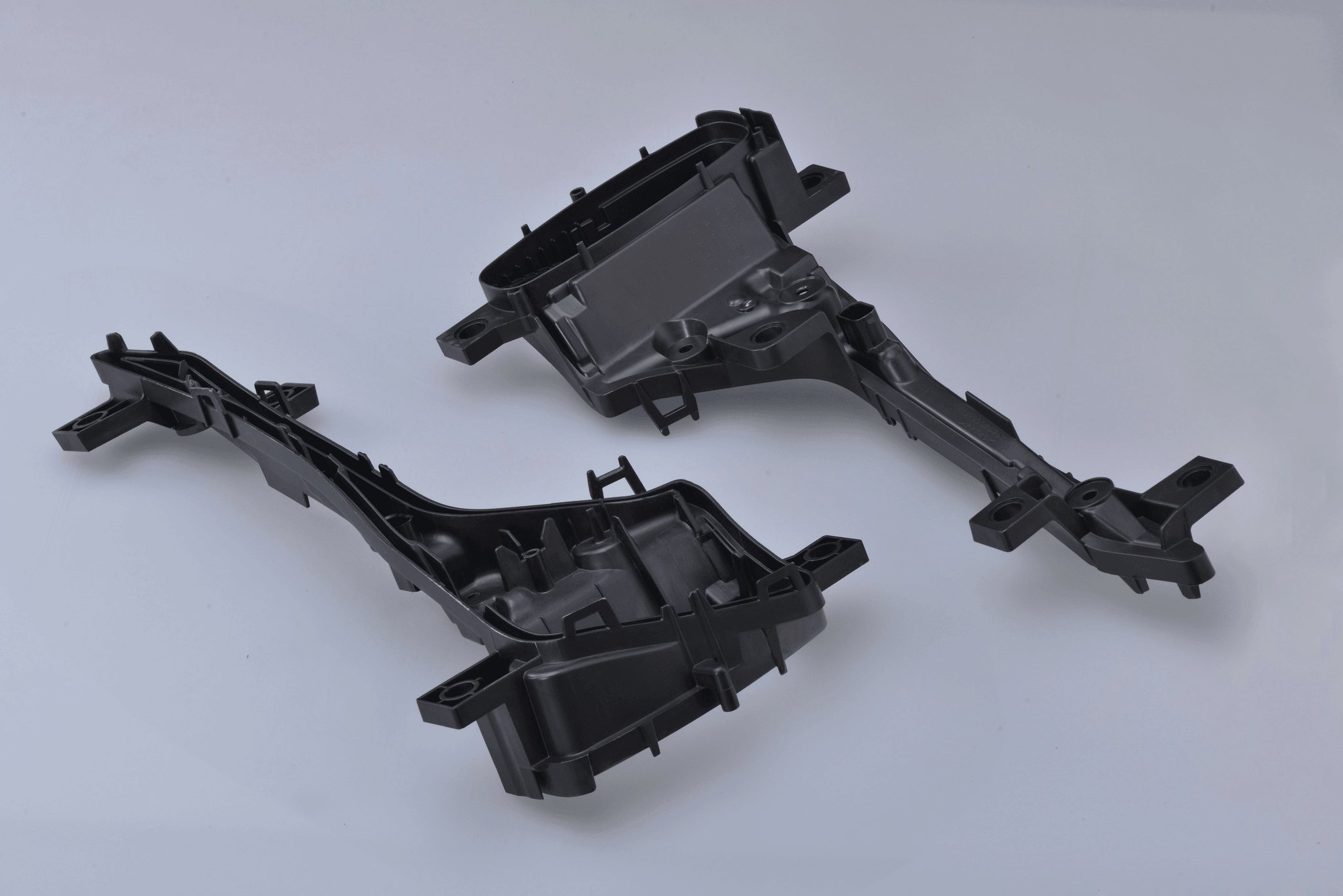

Automotive mounting brackets are essential components that provide support and stability to various parts of a vehicle. These brackets come in different types, such as engine mounting brackets and car bracket bumpers, each serving specific functions to ensure the proper functioning of the vehicle.

Exploring Engine Mounting Brackets

Engine mounting brackets are specifically designed to support the weight of the engine and absorb any vibrations or shocks generated during operation. They are crucial for maintaining the alignment and positioning of the engine within the vehicle's chassis, ultimately impacting its overall performance.

Importance of Quality Car Brackets

Quality car brackets are vital for ensuring the safety and reliability of a vehicle. From engine mounting brackets to other types of automotive brackets, using high-quality materials and innovative designs is essential for maximizing performance while minimizing the need for secondary operations.

What is an Automotive Mounting Bracket?

Automotive mounting brackets are essential components that provide support and stability to various parts of a vehicle. They are commonly used to secure components such as engines, bumpers, and exhaust systems in place, ensuring proper alignment and functionality. These brackets are crucial for maintaining the structural integrity of the vehicle and play a key role in overall safety and performance.

Functions and Applications

The primary function of automotive mounting brackets is to securely hold different vehicle components in place, preventing unnecessary movement or vibration. Engine mounting brackets, for example, help to support the engine within the vehicle's chassis, ensuring proper alignment and reducing excessive noise and vibration. Additionally, car bracket bumpers provide crucial support for the bumper assembly, contributing to impact resistance during collisions.

In addition to supporting the engine and bumper assembly, car mounting brackets also play a crucial role in holding other components such as the exhaust system, transmission, and suspension in place. The proper alignment and secure attachment of these parts are essential for the overall performance and safety of the vehicle. Without reliable mounting brackets, these components could shift or become loose, leading to potential malfunctions or hazards on the road. Therefore, investing in high-quality mounting brackets is essential for maintaining the integrity and functionality of a vehicle.

Types of Car Mounting Brackets

There are various types of car mounting brackets designed to accommodate different components within a vehicle. Some common examples include engine mounting brackets, transmission mounts, exhaust system hangers, and suspension mounts. Each type is specifically engineered to provide optimal support for its designated component while withstanding the rigors of daily use.

In addition to providing support for vehicle components, car mounting brackets also play a crucial role in maintaining overall vehicle stability. By securely holding various parts in place, these brackets help prevent excessive movement or vibration that could impact the handling and performance of the vehicle. Furthermore, the proper installation and maintenance of mounting brackets can contribute to a smoother and more comfortable driving experience, as they help minimize noise and vibration from engine and exhaust system components. Ultimately, these brackets are essential for ensuring that all vehicle parts work together harmoniously to deliver a safe and enjoyable driving experience.

Importance in Vehicle Stability

Automotive mounting brackets are integral to maintaining overall vehicle stability and performance. They help distribute weight evenly across various components, preventing excess stress on individual parts. This contributes to smoother handling, reduced vibrations, and improved overall driving experience for the driver and passengers.

By evenly distributing weight and preventing excess stress on individual parts, automotive mounting brackets play a crucial role in minimizing wear and tear on the vehicle's components. This not only enhances the longevity of the vehicle but also reduces the frequency of maintenance and repairs, ultimately saving the owner time and money. Additionally, by promoting smoother handling and reduced vibrations, these brackets contribute to a safer driving experience for both the driver and passengers.

The Role of Engine Mounting Brackets

Impact on Engine Performance

Engine mounting brackets play a crucial role in maintaining the stability and performance of the engine within a vehicle. They provide support and absorb the vibrations produced by the engine, ensuring smooth operation and reducing noise and harshness in the cabin.

Materials Used in Manufacturing

High-quality materials such as aluminum, steel, or composite materials are commonly used in manufacturing engine mounting brackets. These materials are chosen for their strength, durability, and ability to withstand the weight and stress of the engine during operation.

In addition to the choice of materials, innovative designs play a crucial role in the performance of engine mounting brackets. Engineers are constantly exploring new shapes, configurations, and attachment methods to optimize the bracket's ability to absorb vibrations and shocks from the engine. By incorporating advanced design principles, manufacturers can enhance the overall stability and longevity of the mounting system, ultimately leading to improved performance and reliability.

Innovative Designs for Better Performance

Innovative designs of engine mounting brackets are continuously being developed to improve performance and longevity. By utilizing advanced engineering techniques, manufacturers like Buttler Precision Machinery Co., Ltd. are able to create brackets that offer superior vibration damping, reduced weight, and increased overall vehicle performance.

Smart Part Engineering for Car Brackets

When it comes to automotive mounting brackets, Buttler Precision Machinery Co., Ltd. is a leading expert in smart part engineering. Their focus on innovative tooling designs and cost-effective manufacturing solutions sets them apart in the industry. With their expertise in die-casting molds, aluminum and zinc castings, processing, surface treatment, assembly, and packaging, Buttler ensures top-notch quality for car brackets.

Buttler Precision Machinery Co., Ltd.

Buttler Precision Machinery Co., Ltd. is a trusted name in the automotive industry for their specialization in die-casting molds and high-quality aluminum and zinc castings. Their commitment to excellence extends to their engineering design review process that optimizes new and existing parts at no cost to the customer.

Buttler Precision Machinery Co., Ltd. has earned a reputation for delivering high-quality products that exceed industry standards. Their die-casting molds and aluminum and zinc castings are known for their durability and precision, making them the top choice for automotive manufacturers. In addition to their exceptional products, Buttler Precision Machinery Co., Ltd. also provides unparalleled customer service, ensuring that every client's needs are met with professionalism and efficiency.

Maximizing Performance with Innovative Designs

At Buttler Precision Machinery Co., Ltd., they understand the importance of maximizing performance with innovative designs when it comes to car brackets. Their smart part engineering approach ensures that each bracket is engineered for optimal performance while minimizing the need for secondary operations, resulting in top-notch casting quality.

Cost-Effective Manufacturing Solutions

One of the key advantages of partnering with Buttler Precision Machinery Co., Ltd. is their cost-effective manufacturing solutions for automotive mounting brackets. By focusing on efficient processes and innovative designs, they are able to offer high-quality car brackets at competitive prices, making them a preferred choice in the industry.

Another advantage of Buttler Precision Machinery Co., Ltd.'s cost-effective manufacturing solutions is their ability to customize automotive mounting brackets to meet specific client requirements. Their team of skilled engineers and designers work closely with clients to understand their needs and create tailored solutions that are both functional and cost-efficient. This level of customization ensures that clients receive the exact product they need without overspending on unnecessary features.

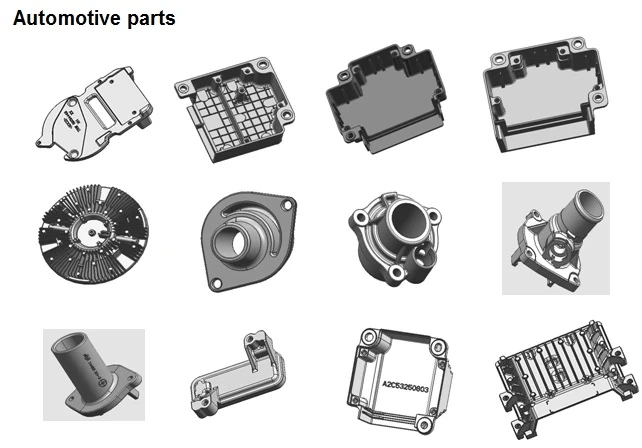

Aluminum Die Casting in Automotive Parts

Ningbo Buttler Precision Machinery Co., Ltd. specializes in aluminum die casting for automotive parts, offering superior quality and precision in their castings. With a focus on smart part engineering, they provide innovative tooling designs to maximize performance and casting quality while minimizing the need for secondary operations.

Ningbo Buttler Precision Machinery Co., Ltd.

Ningbo Buttler Precision Machinery Co., Ltd. is a leading manufacturer of automotive mounting brackets, known for their expertise in die-casting molds, aluminum and zinc castings, processing, surface treatment, assembly, and packaging. Their commitment to smart part engineering ensures that their products are designed for cost-effective manufacturing without compromising on quality.

Ningbo Buttler Precision Machinery Co., Ltd. has a strong focus on innovation and continuous improvement, ensuring that their automotive mounting brackets are at the forefront of industry standards. By investing in advanced technology and machinery, they are able to consistently deliver superior quality aluminum casting products that meet the specific requirements of their clients. This dedication to staying ahead of the curve sets them apart in the market, providing customers with reliable and high-performance solutions for their automotive needs.

Superior Quality Aluminum Casting

The company's specialization in aluminum die casting results in superior quality automotive mounting brackets that offer durability and reliability. By utilizing innovative tooling designs and advanced manufacturing processes, Ningbo Buttler Precision Machinery Co., Ltd. delivers high-quality castings that meet the stringent requirements of the automotive industry.

Furthermore, Ningbo Buttler Precision Machinery Co., Ltd. takes pride in its surface treatment and assembly process, ensuring that the automotive mounting brackets not only meet high-quality standards but also look aesthetically pleasing. The company utilizes state-of-the-art finishing techniques such as powder coating, anodizing, and polishing to enhance the appearance and corrosion resistance of the castings. Additionally, their meticulous assembly process guarantees that each bracket is flawlessly put together for seamless integration into the final automotive product.

Surface Treatment and Assembly Process

In addition to producing top-notch aluminum castings, Ningbo Buttler Precision Machinery Co., Ltd. also focuses on surface treatment and assembly processes to ensure that their automotive mounting brackets are ready for installation and use in vehicles. Their attention to detail in these final stages of production further underscores their commitment to delivering exceptional products.

Conclusion

Quality engine mounting brackets offer several advantages for your vehicle, including enhanced stability, improved performance, and increased safety. Choosing the right automotive mounting bracket is crucial to ensure the proper functioning and longevity of your car. When it comes to quality casting and innovative designs, Buttler Precision Machinery Co., Ltd. is your trusted partner in providing top-notch automotive mounting brackets that meet industry standards and exceed expectations.

Advantages of Quality Engine Mounting Brackets

Investing in high-quality engine mounting brackets can significantly enhance the overall stability and performance of your vehicle. These brackets help to absorb vibrations and shocks, reducing noise and ensuring a smoother driving experience. Additionally, quality brackets contribute to the structural integrity of the car, enhancing safety for both the driver and passengers. Moreover, high-quality engine mounting brackets are designed to withstand extreme conditions, providing durability and longevity to your vehicle's engine system. This means less frequent replacements and maintenance, saving you time and money in the long run.

Choosing the Right Automotive Mounting Bracket

When selecting an automotive mounting bracket for your car, it's essential to consider factors such as material durability, design innovation, and manufacturing precision. Opting for a reputable supplier like Buttler Precision Machinery Co., Ltd. ensures that you receive top-quality brackets that are engineered for optimal performance and longevity.

Buttler Precision Machinery Co., Ltd.: Your Partner in Quality Casting

Ningbo Buttler Precision Machinery Co., Ltd. stands out as a leading provider of die-casting molds, aluminum and zinc castings, surface treatment, assembly, and packaging services. Their commitment to smart part engineering results in better part designs that maximize performance while minimizing costs. With their expertise in producing superior automotive mounting brackets through innovative tooling designs, they are dedicated to delivering exceptional products that meet or exceed industry standards.

Moreover, Buttler Precision Machinery Co., Ltd. prides itself on its state-of-the-art facilities and advanced technology, which enable them to consistently produce high-quality automotive mounting brackets with precision and efficiency. Their team of skilled engineers and technicians are dedicated to staying ahead of industry trends and advancements, ensuring that their products are always at the forefront of innovation. This commitment to excellence sets them apart as a reliable partner for companies seeking top-tier casting and molding solutions.

By partnering with Buttler Precision Machinery Co., Ltd., you can be confident in receiving high-quality automotive mounting brackets that are engineered for excellence in performance and durability.