Introduction

When it comes to choosing the right material for your project, understanding the strength and durability of alloy steel versus aluminum is crucial. Exploring the key differences between these metals can help you make an informed decision. At Buttler Precision Machinery Co., Ltd., we specialize in die-casting and aluminum castings, providing expertise in producing high-quality parts for various industries.

Understanding the Strength: Alloy Steel vs Aluminum

Many people wonder, Is alloy steel stronger than aluminum? The answer lies in the composition and properties of each material. While carbon steel offers excellent strength, aluminum sheet metal is known for its versatility and lightweight nature. At Buttler, we understand the importance of choosing the right material for specific applications, which is why we specialize in die casting molds to ensure precision and quality.

Exploring the Key Differences

The types of metal used in manufacturing play a significant role in determining the strength and durability of a product. Aluminum alloy offers a unique combination of strength and corrosion resistance, making it a popular choice for various applications. At Buttler, our specialization in aluminum castings allows us to provide high-quality parts that meet industry standards while offering exceptional performance under pressure.

Buttler's Expertise in Die-casting and Aluminum Castings

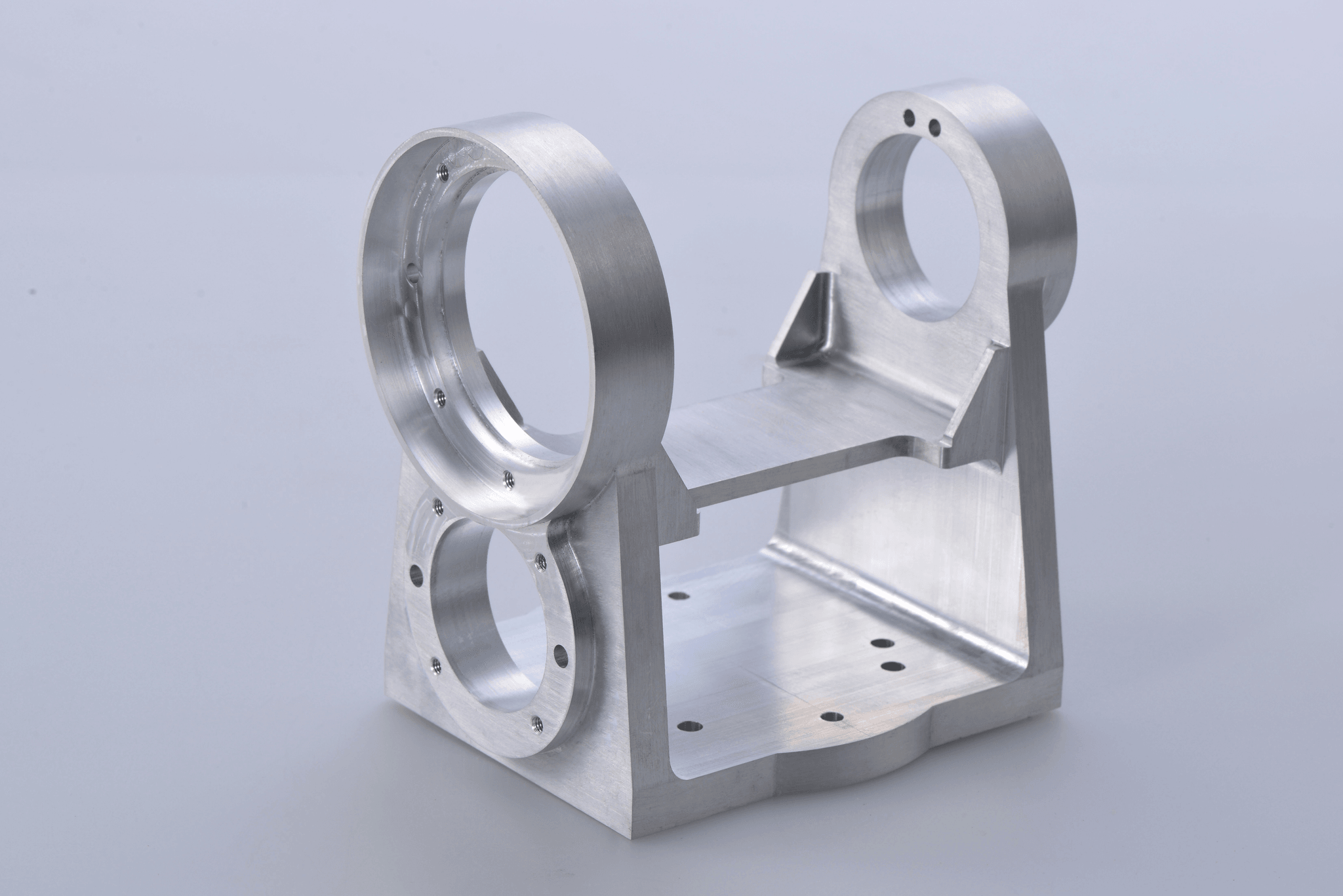

At Buttler Precision Machinery Co., Ltd., our expertise lies in die-casting molds and producing aluminum castings that meet our clients' specific requirements. Our commitment to smart part engineering results in better part designs that are cost-effective to manufacture without compromising on performance or quality. With our engineering design review process, we optimize parts at no cost to you, ensuring top-notch results for your projects.

Composition and Properties

Carbon Steel vs Aluminum Sheet

When comparing carbon steel and aluminum sheet, it's important to note that carbon steel is known for its strength and durability, making it a popular choice for structural applications. On the other hand, aluminum sheet offers a lightweight and corrosion-resistant option, making it ideal for industries such as aerospace and marine engineering. Buttler Precision Machinery Co., Ltd. specializes in die-casting molds for both carbon steel and aluminum sheet, providing customized solutions for various industry needs.

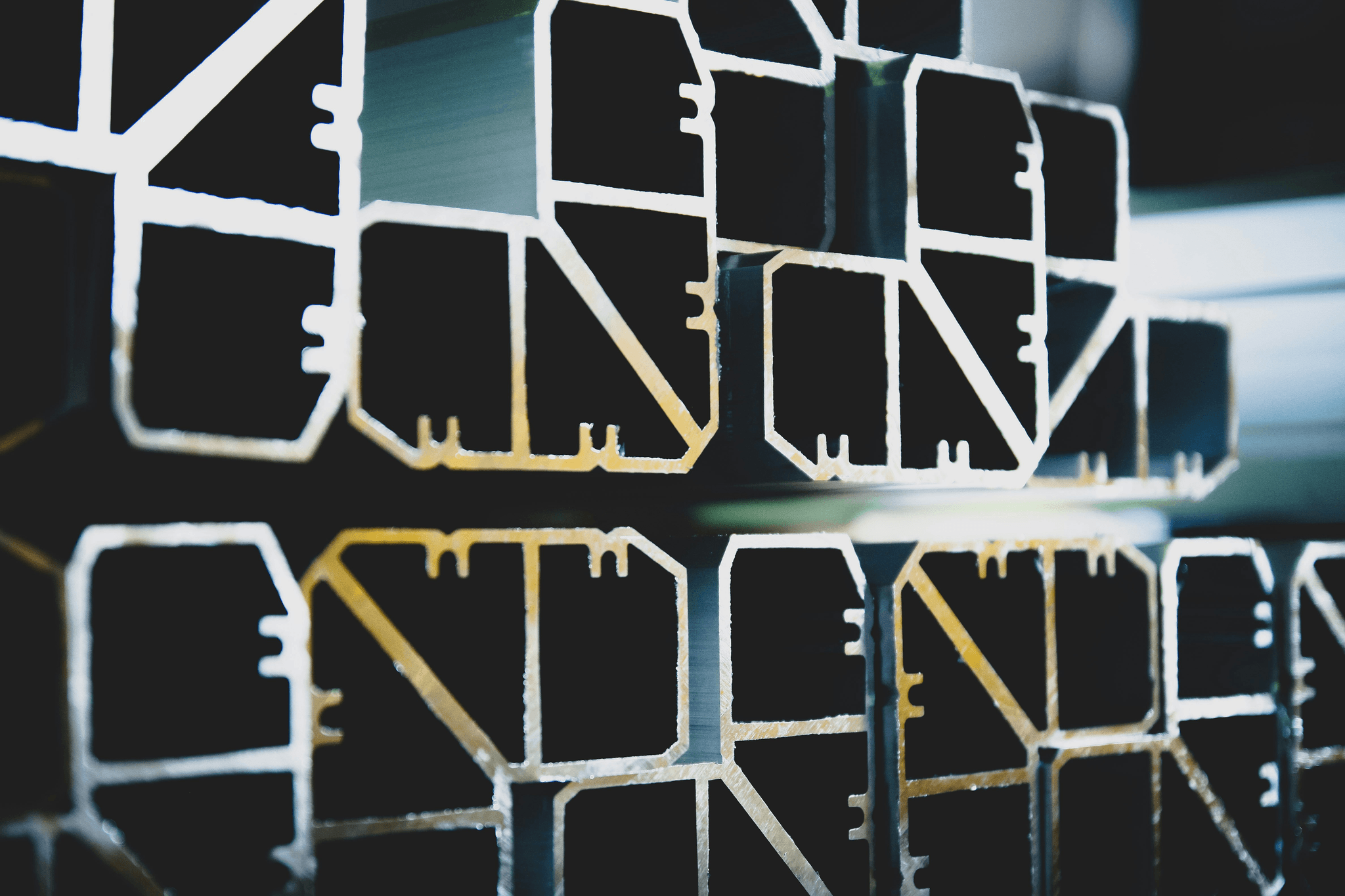

The Versatility of Aluminum Alloy

Aluminum alloy is known for its versatility, offering a wide range of mechanical properties that can be tailored to specific applications. With its high strength-to-weight ratio, corrosion resistance, and thermal conductivity, aluminum alloy is widely used in the automotive, aerospace, and construction industries. Buttler's expertise in die-casting molds ensures the precise manufacturing of aluminum alloy components with superior quality and performance.

Buttler's Specialization in Die Casting Molds

Buttler Precision Machinery Co., Ltd. specializes in the design and production of high-quality die-casting molds for various types of metal, including carbon steel and aluminum sheet. With a focus on smart part engineering and cost-effective manufacturing solutions, Buttler's team of experts provides innovative tooling designs engineered to maximize performance while minimizing the need for secondary operations. Take advantage of their Engineering Design Review Process to optimize your parts at no cost.

Strength and Durability

When comparing types of metal for strength and durability, alloy steel is often considered stronger than aluminum due to its higher tensile strength and hardness. However, aluminum sheet metal offers advantages in terms of corrosion resistance and lighter weight, making it a preferred choice for certain applications. At Buttler Precision Machinery Co., Ltd., our expertise lies in precision aluminum and zinc castings, ensuring the durability and reliability of the final products.

Comparing Types of Metal

Alloy steel is known for its exceptional strength and durability, making it a popular choice for heavy-duty industrial applications where high tensile strength is required. On the other hand, aluminum sheet metal offers a lightweight alternative with good corrosion resistance, making it suitable for aerospace and automotive industries. At Buttler, we understand the unique properties of each type of metal and specialize in producing precision castings to meet specific performance requirements.

Aluminum Sheet Metal vs Alloy Steel

Comparing aluminum sheet metal with alloy steel reveals the trade-offs between strength and weight. While alloy steel provides superior strength, aluminum sheet metal offers a lightweight solution without compromising on durability. Both materials have their own set of advantages, which is why Buttler Precision Machinery Co., Ltd. excels in producing high-quality castings using both aluminum and alloy steel to cater to diverse industry needs.

Buttler's Precision in Aluminum and Zinc Castings

At Buttler Precision Machinery Co., Ltd., we take pride in our precision engineering capabilities when it comes to producing aluminum and zinc castings with exceptional strength and durability. Our expertise in die-casting molds allows us to create intricate designs that meet stringent performance requirements while ensuring cost-effective manufacturing solutions for our clients.

Application and Usage

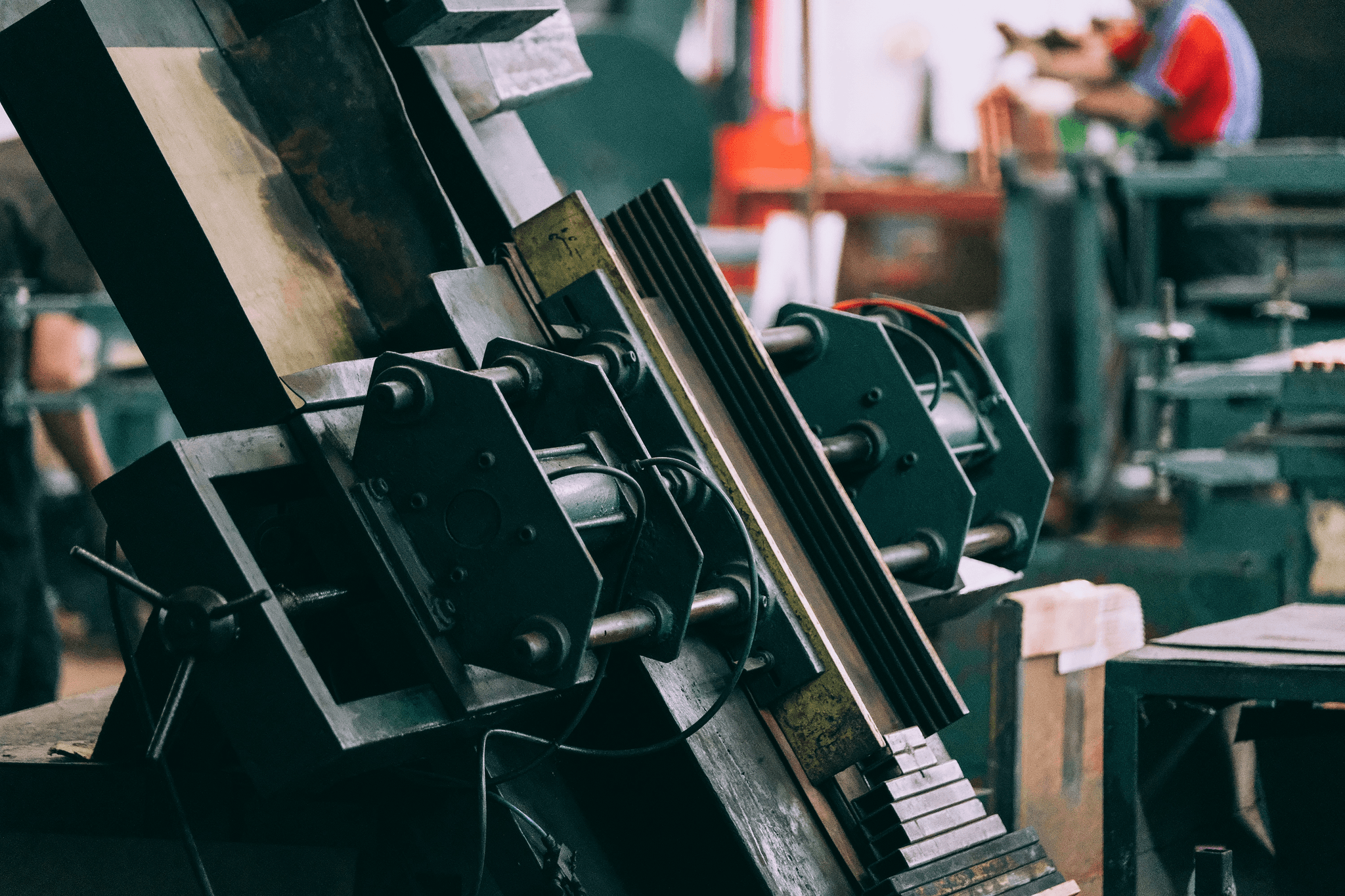

Alloy steel is widely used in industrial applications due to its strength and durability. It is commonly found in manufacturing equipment, machinery, and tools that require high tensile strength and resistance to wear and tear. The versatility of alloy steel makes it a popular choice for heavy-duty applications in construction, mining, and automotive industries.

Industrial Uses of Alloy Steel

Aluminum sheet is a preferred material in the manufacturing industry for its lightweight properties and corrosion resistance. It is commonly used in the production of automotive body panels, aircraft components, and household appliances. The ease of fabrication and formability of aluminum sheet makes it an ideal choice for various manufacturing processes such as stamping, bending, and welding.

Alu Sheet in Manufacturing

Buttler Precision Machinery Co., Ltd. offers a wide range of automotive parts and gas appliance components made from aluminum and zinc castings. With expertise in die-casting molds and surface treatment processes, Buttler provides high-quality parts that meet stringent industry standards for performance, durability, and aesthetics.

Buttler's Range of Automotive and Gas Appliance Parts

At Buttler Precision Machinery Co., Ltd., we take pride in our extensive range of automotive and gas appliance parts made from high-quality alloy steel and aluminum. Our expertise in die-casting and aluminum castings allows us to produce durable and reliable components that meet the rigorous demands of the automotive and gas appliance industries. Whether it's engine components, transmission parts, or gas appliance fittings, Buttler has the capability to deliver precision-crafted parts that ensure optimal performance and longevity.

In addition to our commitment to quality, Buttler's specialization in die casting molds enables us to offer customized solutions for automotive and gas appliance manufacturers. We understand the unique requirements of these industries and work closely with our clients to develop efficient and cost-effective manufacturing processes. With our focus on precision engineering, we strive to provide innovative solutions that enhance the performance and reliability of automotive and gas appliance parts, ultimately contributing to the success of our customers' products in the market.

With Buttler Precision Machinery Co., Ltd., you can trust that you are choosing a partner who is dedicated to delivering top-notch automotive and gas appliance parts. Our range of capabilities, combined with our commitment to excellence, makes us the ideal choice for manufacturers looking for reliable components that meet their specific needs.

Weight and Density

Understanding the Weight of Aluminum

When considering the weight of aluminum, it's important to note that it is a lightweight metal, making it ideal for applications where weight is a concern. Its low density allows for easy handling and transportation, making it a popular choice in industries such as aerospace and automotive manufacturing.

Comparing Aluminum Alloy with Cast Aluminum

Aluminum alloy offers a balance between strength and weight, making it a versatile choice for various applications. On the other hand, cast aluminum provides excellent corrosion resistance and is often used in outdoor settings due to its durability. Both options offer unique advantages based on specific project requirements.

Buttler's Outdoor Lamp Series

Buttler Precision Machinery Co., Ltd.'s outdoor lamp series showcases their expertise in utilizing aluminum and cast aluminum for durable outdoor lighting solutions. The use of these materials ensures longevity and resistance to environmental elements, making them an ideal choice for outdoor applications.

Remember that Buttler Precision Machinery Co., Ltd.'s commitment to cost-effective manufacturing solutions extends to their expertise in utilizing different types of metals to meet specific project needs. Whether it's die-casting molds or precision engineering designs, Buttler has the knowledge and experience to deliver high-quality results tailored to your requirements.

Performance Under Pressure

When it comes to strength, the debate of whether alloy steel is stronger than aluminum is a hot topic. While alloy steel is known for its high tensile strength and toughness, aluminum has its own advantages in terms of weight and corrosion resistance. In certain applications, aluminum can be just as strong as steel, making it a versatile choice for various industries.

Strength of Aluminum vs Steel

In the battle of strength, alloy steel often comes out on top due to its higher tensile strength and toughness compared to aluminum. However, when considering weight and corrosion resistance, aluminum holds its ground. This makes it suitable for applications where lightweight materials are preferred without compromising on durability.

Aluminum's Role in Power Tool Parts

Aluminum's lightweight yet sturdy nature makes it an ideal material for power tool parts. Its ability to withstand pressure and impact while remaining lightweight allows for efficient and durable power tools that are easy to handle.

Buttler's Focus on Better Part Designs

At Buttler Precision Machinery Co., Ltd., we understand the importance of creating parts that can perform under pressure. Our expertise in die-casting molds and precision engineering allows us to design aluminum parts that meet the demands of various industries while maximizing performance and durability.

Remember that at Buttler Precision Machinery Co., Ltd., we specialize in creating innovative tooling designs engineered for cost-effective manufacturing to maximize performance and casting quality while minimizing the need for secondary operations!

Surface Treatment and Processing

Aluminum's Surface Treatment

When it comes to aluminum, surface treatment is crucial for enhancing its corrosion resistance and improving its appearance. Anodizing is a common method used to create a protective oxide layer on the surface of aluminum sheet metal, making it more durable and resistant to wear and tear. Buttler Precision Machinery Co., Ltd. offers expertise in aluminum surface treatment, ensuring that your aluminum parts are of the highest quality and durability.

In addition to anodizing, another effective method for surface treatment of aluminum is powder coating. This process involves applying a dry powder to the surface of the metal, which is then heated to form a protective layer. Powder coating not only enhances the appearance of aluminum parts with a wide range of color options but also provides excellent protection against corrosion and abrasion. At Buttler Precision Machinery Co., Ltd., we have the capabilities to provide high-quality powder coating services, ensuring that your aluminum components are both visually appealing and long-lasting.

The Processing of Alloy Steel

Alloy steel undergoes various processing methods to achieve desired properties such as strength, hardness, and resistance to wear. Heat treatment, forging, and machining are common processes used to manipulate the microstructure of alloy steel for specific applications. Buttler's commitment to engineering cost-effective manufacturing solutions includes expertise in the processing of alloy steel, ensuring that your parts meet the required specifications with precision and efficiency.

Buttler's team of skilled engineers and technicians are well-versed in the latest advancements in alloy steel processing, allowing us to offer innovative solutions for even the most complex manufacturing challenges. By staying at the forefront of technological developments, we ensure that our clients receive the highest quality parts that are tailored to their specific needs. Our commitment to cost-effective manufacturing extends beyond simply meeting specifications; we strive to optimize production processes and reduce waste, ultimately saving our clients time and money.

Buttler's Commitment to Engineering Cost-effective Manufacturing Solutions

Buttler Precision Machinery Co., Ltd.'s commitment to engineering cost-effective manufacturing solutions encompasses a comprehensive approach to die-casting molds, aluminum and zinc castings, processing, surface treatment, assembly, and packaging. Their expertise in smart part engineering results in better part designs that maximize performance while minimizing the need for secondary operations. With a focus on innovative tooling designs engineered for cost-effective manufacturing, Buttler ensures that your project meets high-quality standards without compromising on efficiency or budget.

Furthermore, Buttler Precision Machinery Co., Ltd. is dedicated to staying ahead of industry trends and technological advancements. By continually investing in research and development, they are able to offer cutting-edge solutions that improve manufacturing processes and reduce production costs. Their commitment to staying at the forefront of innovation ensures that your project will benefit from the latest advancements in die-casting molds, aluminum and zinc castings, and other manufacturing techniques.

Conclusion

When it comes to making informed material choices for your projects, it's crucial to understand the strengths and weaknesses of different metals. Whether you're considering alloy steel or aluminum, it's important to weigh factors such as strength, weight, and durability. By exploring the properties of carbon steel, aluminum sheet metal, and cast aluminum, you can make a well-informed decision that aligns with your project's requirements.

Finding the Right Metal for Your Project

Choosing the right metal for your project is essential for its success. Alloy steel may be stronger than aluminum in some applications, but aluminum alloy offers versatility and lightweight properties that make it ideal for various uses. Understanding the types of metal available and their unique characteristics can help you find the perfect fit for your specific project needs.

When considering the right metal for your project, it's important to also take into account the environmental factors that may affect the material. For example, if your project will be exposed to harsh weather conditions or corrosive elements, stainless steel may be a better choice due to its resistance to rust and corrosion. On the other hand, if your project requires high conductivity and heat resistance, copper may be the ideal metal for the job. Understanding how different metals interact with their environment can help you make an informed decision that will ensure the success of your project.

Choosing Quality with Buttler Precision Machinery Co., Ltd.

As you navigate through the process of selecting the right metal for your project, consider partnering with Buttler Precision Machinery Co., Ltd. Their expertise in die-casting molds, aluminum and zinc castings, surface treatment, and assembly ensures that you receive high-quality parts engineered for cost-effective manufacturing. With a focus on smart part engineering and better part designs, Buttler is committed to delivering top-notch solutions tailored to your requirements.

In conclusion, by understanding the composition and properties of different metals such as carbon steel, alu sheet, aluminum sheet metal, and cast aluminum, you can make informed decisions about which material best suits your project needs. Whether it's industrial uses of alloy steel or precision in die casting molds provided by Buttler Precision Machinery Co., Ltd., choosing quality materials is vital for achieving optimal results in manufacturing processes.