Introduction

When it comes to manufacturing high-quality, durable aluminum parts, high pressure die casting aluminum is the go-to process. This method involves injecting molten aluminum into a steel mold at high pressure, resulting in precise and complex shapes with excellent surface finishes. The versatility and efficiency of high pressure aluminum die casting make it the preferred choice for a wide range of industries.

The Process of High Pressure Die Casting Aluminum

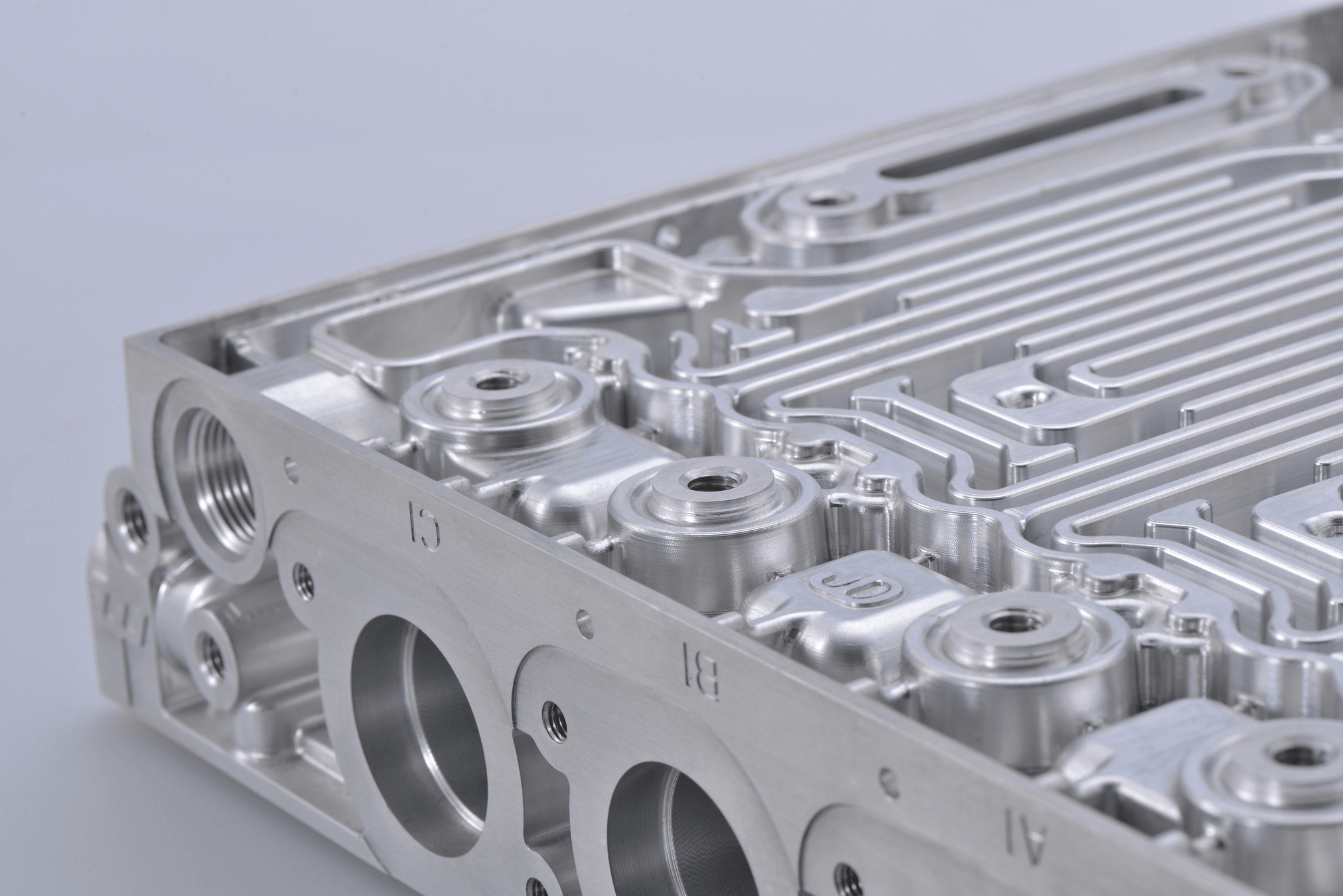

The process of high pressure die casting aluminum involves melting the metal and injecting it into a steel mold under extreme pressure. This results in the production of intricate and detailed parts with exceptional accuracy and consistency. With the ability to produce complex shapes at a rapid pace, high pressure aluminum die casting is ideal for large-scale production.

Advantages of High Pressure Die Casting Aluminum

One of the key advantages of high pressure die casting aluminum is its ability to produce parts with excellent dimensional accuracy and smooth surface finishes. Additionally, this method allows for the production of lightweight yet durable components, making it highly desirable for various applications across industries.

Why Choose High Pressure Die Casting Aluminum

Choosing high pressure die casting aluminum offers numerous benefits, including cost-effectiveness, reduced waste, and shorter production cycles. The versatility of this process also allows for the creation of intricate designs that would be difficult or impossible to achieve through other manufacturing methods.

High Pressure Die Casting Process

High pressure die casting aluminum is a manufacturing process where molten aluminum is injected into a steel mold under high pressure. This process allows for the production of complex shapes with high precision and repeatability, making it ideal for a wide range of industries.

Overview of High Pressure Die Casting

The high pressure die casting process begins with the preparation of the mold, which is then sprayed with a lubricant to facilitate the release of the casting. The molten aluminum is then injected into the mold cavity at high speed and pressure, filling the cavity and solidifying quickly to form the desired part.

Importance of High Pressure Die Casting

High pressure aluminum die casting is crucial for industries that require lightweight yet strong components with complex geometries, such as automotive, aerospace, and consumer electronics. This process allows for mass production of parts with excellent dimensional accuracy and surface finish.

Key Features of High Pressure Die Casting

Key features of high pressure die casting include fast cycle times, high productivity, minimal material waste, and the ability to produce thin-walled parts without sacrificing strength. These features make it a cost-effective solution for manufacturing intricate aluminum components.

Remember that Ningbo Buttler Precision Machinery Co., Ltd. specializes in providing innovative tooling designs engineered for cost-effective manufacturing to maximize performance and casting quality while minimizing secondary operations in high pressure die casting aluminum processes.

Properties of High Pressure Die Casting Aluminum

Strength and Durability

High pressure die casting aluminum alloys are known for their exceptional strength and durability, making them ideal for demanding applications in various industries. The unique properties of high pressure aluminum die casting ensure that the final products can withstand high levels of stress and wear, providing long-lasting performance and reliability.

High pressure die casting aluminum alloys are also prized for their lightweight nature, making them an excellent choice for applications where weight is a concern. The low density of aluminum makes it an attractive option for industries such as automotive and aerospace, where reducing vehicle weight can lead to improved fuel efficiency and performance. Additionally, the lightweight nature of high pressure die casting aluminum alloys allows for easier handling and installation in various applications, providing added convenience and cost savings.

Lightweight

One of the key advantages of high pressure die casting aluminum is its lightweight nature. This makes it an excellent choice for applications where weight reduction is crucial, such as in the automotive industry. The lightweight properties of aluminum high pressure die casting also contribute to improved fuel efficiency and overall performance.

Heat Conduction

Aluminum is an excellent conductor of heat, and this property is further enhanced in high pressure die casting aluminum components. This makes them suitable for applications that require efficient heat dissipation, such as in electronic devices or heat exchangers. The superior heat conduction capabilities of high pressure aluminum die casting ensure optimal performance in demanding thermal environments.

High pressure die casting aluminum components are also commonly used in automotive applications, where efficient heat dissipation is crucial for maintaining optimal performance and longevity of the vehicle. The ability of high pressure aluminum die casting to quickly and effectively transfer heat away from critical components helps to prevent overheating and ensures reliable operation, even in extreme driving conditions. This makes high pressure die casting aluminum an ideal choice for a wide range of automotive parts, from engine components to transmission housings.

Applications of High Pressure Die Casting Aluminum

High pressure die casting aluminum is widely utilized in various industries due to its exceptional properties and versatility. Let's explore some of the key applications where high pressure aluminum die casting plays a crucial role.

Automotive Industry

The automotive industry extensively relies on high pressure die casting aluminum for manufacturing lightweight and durable components such as engine blocks, transmission cases, and structural parts. The ability of aluminum high pressure die casting to produce complex shapes with tight tolerances makes it an ideal choice for enhancing vehicle performance and fuel efficiency.

Moreover, the use of aluminum high pressure die casting in the automotive industry also contributes to reducing emissions and improving overall sustainability. By replacing heavier materials with lightweight aluminum components, vehicles become more fuel-efficient and produce fewer greenhouse gas emissions. This aligns with the industry's push towards environmental responsibility and cleaner transportation solutions.

Outdoor Lamp Series

High pressure aluminum die casting is also prominent in the production of outdoor lamp series, where the lightweight nature and corrosion resistance of aluminum alloys play a vital role. These components are designed to withstand harsh weather conditions while providing efficient lighting solutions for outdoor spaces.

Additionally, high pressure aluminum die casting allows for intricate and detailed designs to be achieved, making outdoor lamp series not only functional but also aesthetically pleasing. The versatility of aluminum alloys also enables the production of various shapes and sizes, catering to different design preferences and lighting needs. With the ability to withstand extreme temperatures and environmental factors, outdoor lamp series made through high pressure aluminum die casting are a reliable and long-lasting choice for outdoor lighting solutions.

Gas Appliance Parts

Gas appliance parts benefit from the use of high quality aluminum pressure die casting due to the material's excellent heat conduction properties and resistance to corrosion. From burner heads to valve bodies, high pressure die casting aluminum alloys factory ensures the production of reliable and efficient components for various gas appliances.

Quality Assurance in High Pressure Die Casting Aluminum

When it comes to ensuring the quality of high pressure die casting aluminum, Ningbo Buttler Precision Machinery Co., Ltd. stands out with their Smart Part Engineering. By providing innovative tooling designs and cost-effective manufacturing, they maximize performance and casting quality while minimizing the need for secondary operations. With their expertise in die-casting molds and aluminum processing, they offer a comprehensive solution for high pressure aluminum die casting.

Smart Part Engineering by Ningbo Buttler Precision Machinery Co., Ltd.

Ningbo Buttler Precision Machinery Co., Ltd. specializes in smart part engineering for high pressure aluminum die casting, offering better part designs that are engineered for cost-effective manufacturing. Their innovative tooling designs optimize performance and minimize the need for secondary operations, ensuring top-notch quality in high pressure die casting aluminum products.

Maximizing Performance and Casting Quality

With a focus on maximizing performance and casting quality, Ningbo Buttler Precision Machinery Co., Ltd. utilizes their expertise in die-casting molds and aluminum processing to deliver superior results in high pressure aluminum die casting. Their commitment to excellence ensures that every product meets the highest standards of quality.

Minimizing the Need for Secondary Operations

By minimizing the need for secondary operations, Ningbo Buttler Precision Machinery Co., Ltd. streamlines the production process for high pressure die casting aluminum, saving time and resources while maintaining exceptional quality throughout every stage of manufacturing.

Advantages in Production Efficiency

Innovative Tooling Designs

Ningbo Buttler Precision Machinery Co., Ltd. specializes in high pressure die casting aluminum molds, offering innovative tooling designs that are engineered for cost-effective manufacturing. By utilizing their Smart Part Engineering process, they are able to maximize performance and casting quality while minimizing the need for secondary operations.

By implementing innovative tooling designs and the Smart Part Engineering process, Ningbo Buttler Precision Machinery Co., Ltd. is able to streamline the production process and reduce the need for secondary operations. This not only saves time and resources but also ensures a higher level of consistency and quality in the final products. As a result, their cost-effective manufacturing approach allows for faster turnaround times and increased overall efficiency.

Cost-effective Manufacturing

With their expertise in high pressure aluminum die casting, Buttler Precision Machinery Co., Ltd. ensures cost-effective manufacturing processes that result in high-quality products. Their focus on efficiency and precision allows for the production of complex parts with minimal waste, ultimately saving time and resources.

Buttler Precision Machinery Co., Ltd. also prioritizes sustainability in their manufacturing processes, utilizing recycled aluminum materials to reduce environmental impact while maintaining the highest quality standards. By incorporating advanced technologies and innovative techniques, they are able to optimize production efficiency without compromising on product excellence. This commitment to eco-friendly practices not only benefits the planet but also enhances the company's reputation as a responsible and forward-thinking industry leader.

High Quality Aluminum Pressure Die Casting Alloys Factory

Buttler Precision Machinery Co., Ltd. operates a state-of-the-art high quality aluminum pressure die casting alloys factory, ensuring that only the best materials are used in the production of aluminum components. Their commitment to excellence in material selection and manufacturing processes sets them apart as leaders in the industry.

Furthermore, Buttler Precision Machinery Co., Ltd. utilizes advanced technology and automation in their production processes, leading to increased efficiency and precision. This allows them to meet tight deadlines and deliver high-quality aluminum components to their clients in a timely manner. By streamlining their manufacturing operations, they are able to reduce lead times and ensure a smooth production flow.

Conclusion

High pressure die casting aluminum has proven to be a game-changer in the manufacturing industry, offering unmatched performance and versatility. With the expertise of Ningbo Buttler Precision Machinery Co., Ltd., companies can benefit from innovative tooling designs and cost-effective manufacturing processes that maximize performance and casting quality while minimizing the need for secondary operations.

Maximizing Performance with High Pressure Die Casting Aluminum

The use of high pressure die casting aluminum alloys factory ensures superior performance, durability, and strength in a wide range of applications. By leveraging high quality aluminum pressure die casting molds, companies can achieve exceptional results in automotive, lighting, and gas appliance parts production.

The Versatility of High Pressure Aluminum Die Casting

High pressure aluminum die casting offers unparalleled versatility, making it suitable for a diverse array of industries and applications. Whether it's automotive components or outdoor lamp series, high pressure die casting aluminum delivers exceptional results that meet the highest standards of quality and precision.

The Future of Aluminum High Pressure Die Casting

As technology continues to advance, the future of aluminum high pressure die casting looks promising. With ongoing innovations in material science and manufacturing processes, we can expect even greater advancements in the performance, efficiency, and sustainability of high pressure die casting aluminum.