Introduction

The demand for die-casting in the automotive industry is rising, with manufacturers recognizing the numerous advantages of die-casting components. Aluminum die casting has emerged as a game-changer, revolutionizing the production of automotive parts with its lightweight and durable properties.

The Growing Demand for Die Casting in

the Automotive Industry

As vehicles strive for greater fuel efficiency and performance, the demand for high-quality die-casting parts has surged. Manufacturers are increasingly turning to die-casting processes to meet these demands and stay ahead in the competitive automotive market.

Advantages of Die Casting Components

Die-casting components offer a multitude of benefits, making them an ideal choice for producing critical automotive parts. These advantages include:

- High strength-to-weight ratio

- Precision engineering

- Cost-effective manufacturing

- Enhanced durability

Due to these factors, die casting is preferred for creating robust and reliable automotive components.

Aluminium Die Casting: Revolutionizing Automotive Parts

Aluminum parts manufacturers are revolutionizing vehicle manufacturing with their innovative die-casting techniques. Using aluminum die-casting parts has transformed the industry by providing lightweight yet strong components that improve vehicle performance and fuel efficiency.

Lightweight and Strong

Aluminum die-casting parts are a game-changer in the automotive industry, especially regarding fuel efficiency. With their lightweight properties, these parts reduce the overall weight of vehicles, leading to improved fuel economy and lower emissions. Using aluminum die-casting components in automobile manufacturing is a strategic move towards meeting stringent environmental regulations and customer demand for more eco-friendly vehicles.

Aluminium Die Casting Parts for Fuel Efficiency

Aluminum die-casting parts play a crucial role in enhancing fuel efficiency in vehicles. Their lightweight nature helps reduce the vehicle's overall weight, leading to improved mileage and reduced carbon emissions. As an expert in producing high-quality aluminum parts for the automotive industry, Ningbo Buttler Precision Machinery Co., Ltd. is at the forefront of providing innovative solutions for fuel-efficient automobiles.

High Strength-to-Weight Ratio in Die Casting Parts

One key advantage of die-casting components is their high strength-to-weight ratio. Despite being lightweight, these parts offer exceptional strength and durability, making them ideal for use in critical automotive applications where performance and reliability are paramount. By leveraging advanced manufacturing techniques and materials expertise, aluminum parts manufacturers can produce components with superior strength while maintaining a lightweight profile.

Improving Vehicle Performance with Aluminium Parts

Incorporating aluminum die-casting parts into vehicle design contributes to fuel efficiency and enhances overall performance. Due to reduced vehicle weight, these components allow automakers to achieve better handling, acceleration, and braking performance. As an expert in producing precision-engineered aluminum parts for the automotive industry, Ningbo Buttler Precision Machinery Co., Ltd.'s innovative solutions are driving advancements in vehicle performance through lightweight yet durable components.

Precision and Complex Shapes

Aluminum die-casting parts are crucial in achieving precision and complex shapes in automotive components. With smart part engineering, manufacturers can design better geometries that enhance performance and functionality. Innovative tooling designs ensure cost-effective manufacturing by optimizing the die-casting process for complex shapes, producing high-quality parts with minimal waste. At Ningbo Buttler Precision Machinery Co., Ltd., we specialize in maximizing performance and quality with our state-of-the-art die-casting molds, ensuring superior precision and durability for all automotive applications.

Smart Part Engineering for Better Part Designs

Ningbo Buttler Precision Machinery Co., Ltd. excels in smart part engineering, creating better designs for die-casting components used in the automobile industry. Our team of experts utilizes advanced techniques to optimize part geometries, ensuring improved functionality and performance for automotive parts. By leveraging innovative engineering processes, we deliver superior die-casting components that meet the highest standards of quality and precision.

Innovative Tooling Designs for Cost-Effective Manufacturing

Our innovative tooling designs are engineered to streamline manufacturing, resulting in the cost-effective production of complex-shaped die-casting parts for automobiles. At Ningbo Buttler Precision Machinery Co., Ltd., we prioritize efficiency and sustainability by implementing cutting-edge tooling designs that minimize material wastage while maximizing production output. This approach allows us to offer high-quality automotive components at competitive prices without compromising performance or durability.

Maximizing Performance and Quality with

Die-Casting Molds

By utilizing advanced die-casting molds, we maximize the performance and quality of automotive components, setting new industry standards for precision and durability. Our commitment to excellence is reflected in our meticulous attention to detail during the mold design and manufacturing process, ensuring that each component meets the exact specifications required for optimal vehicle performance. Our expertise in die-casting molds empowers automotive manufacturers to deliver reliable and high-performing vehicles to consumers worldwide.

Cost-Effective Manufacturing

In the competitive world of automotive manufacturing, efficiency is key. Die-casting components are crucial in cost-effective production processes, and aluminum parts manufacturers like Ningbo Buttler Precision Machinery Co., Ltd. lead the way in this arena. By reducing the need for secondary operations, die-casting parts in automobiles can be produced with minimal waste and maximum efficiency.

Reducing the Need for Secondary Operations

Thanks to advancements in technology and smart part engineering, die casting in the automotive industry has evolved to minimize the need for secondary operations such as machining or welding. This not only streamlines the manufacturing process but also reduces overall production costs. Aluminum die-casting parts are manufactured with precision and durability, eliminating the need for additional finishing processes.

Efficient Processing and Surface Treatment

Efficient processing and surface treatment are essential aspects of cost-effective manufacturing in the automotive industry. Aluminum die-casting parts undergo advanced surface treatments to enhance their durability and corrosion resistance, ensuring a longer lifespan for vehicle components. Ningbo Buttler Precision Machinery Co., Ltd.'s expertise in this area ensures that each part is efficiently processed.

Smart Packaging Solutions for Die Casting Parts

Smart packaging solutions ensure die-casting parts reach their destination safely and securely, minimizing potential damage during transportation or storage. Ningbo Buttler Precision Machinery Co., Ltd.'s comprehensive packaging solutions guarantee that each aluminum die-casting part is carefully packaged to maintain its integrity throughout the supply chain.

Durability and Corrosion Resistance

Aluminium Die Casting Parts for Long-lasting Performance

Regarding durability in automotive parts, aluminum die casting is the go-to choice. With its high strength-to-weight ratio, aluminum parts provide long-lasting performance, making them ideal for automobile critical components. As a leading aluminum parts manufacturer, Ningbo Buttler Precision Machinery Co., Ltd. ensures that its die-casting components are engineered to withstand the rigors of everyday use in vehicles.

Enhanced Corrosion Resistance in Automotive Parts

Die-casting components' enhanced corrosion resistance is one key advantage in automobile manufacturing. Aluminum die-casting parts can withstand exposure to harsh environmental elements, ensuring they maintain their integrity and functionality over time. This makes them an excellent choice for critical automotive applications where durability and reliability are paramount.

Reliable Gas Appliance Parts Made of die-casting

In addition to automotive applications, die casting also plays a crucial role in manufacturing reliable gas appliance parts. With its precision engineering and high-quality materials, die casting ensures that gas appliance components can withstand the demands of daily use while maintaining their performance and safety standards. As an expert in die-casting technology, Ningbo Buttler Precision Machinery Co., Ltd. offers top-notch solutions for gas appliance manufacturers.

Environmental Benefits

As the demand for fuel-efficient vehicles continues to grow, die casting in the automotive industry plays a crucial role in achieving this goal. Lightweight aluminum parts manufactured by leading aluminum parts manufacturers, such as Ningbo Buttler Precision Machinery Co., Ltd., significantly improve automobile fuel efficiency.

Lightweight Aluminium Parts for Fuel Efficiency

Aluminum die-casting parts are known for their lightweight yet durable nature, making them ideal for enhancing vehicle fuel efficiency. By reducing the overall weight of automotive components, die-casting manufacturers contribute to lower fuel consumption and reduced emissions, aligning with global efforts to combat climate change.

Energy-Efficient Die-Casting Process

The energy-efficient die-casting process employed by aluminum parts manufacturers like Ningbo Buttler Precision Machinery Co., Ltd. ensures minimal environmental impact during production. By utilizing advanced technologies and sustainable practices, these manufacturers minimize energy consumption and waste generation, promoting eco-friendly manufacturing processes.

Eco-friendly Aluminium and Zinc Casting

Die-casting manufacturers are increasingly committed to eco-friendly practices, as evidenced by their expanded use of aluminum and zinc in automobile components. Zinc die casting, in particular, offers several advantages:

- Durability: Zinc castings are known for their exceptional strength and resistance to wear and tear.

- Corrosion Resistance: Zinc provides excellent protection against rust and other forms of corrosion, extending the lifespan of automotive parts.

- Sustainability: By utilizing zinc, manufacturers contribute to the overall sustainability of vehicles by reducing the need for replacements and minimizing environmental impact.

Incorporating zinc into die-casting processes highlights the industry's dedication to producing high-quality, long-lasting, and environmentally responsible automotive components.

Versatility in Applications

Ningbo Buttler Precision Machinery Co., Ltd. is at the forefront of providing die-casting components for a wide range of applications, including the production of outdoor lamp series. Our advanced aluminum die casting technology ensures the creation of durable, high-quality parts ideal for outdoor lighting fixtures, offering both aesthetic appeal and long-lasting performance.

Aluminium Die Casting for Outdoor Lamp Series

Our aluminum parts manufacturers specialize in producing die-casting parts for outdoor lamp series, offering lightweight yet robust solutions resistant to corrosion and environmental elements. With a focus on precision and durability, our aluminum die-casting parts are designed to withstand the rigors of outdoor use while maintaining their structural integrity and visual appeal over time.

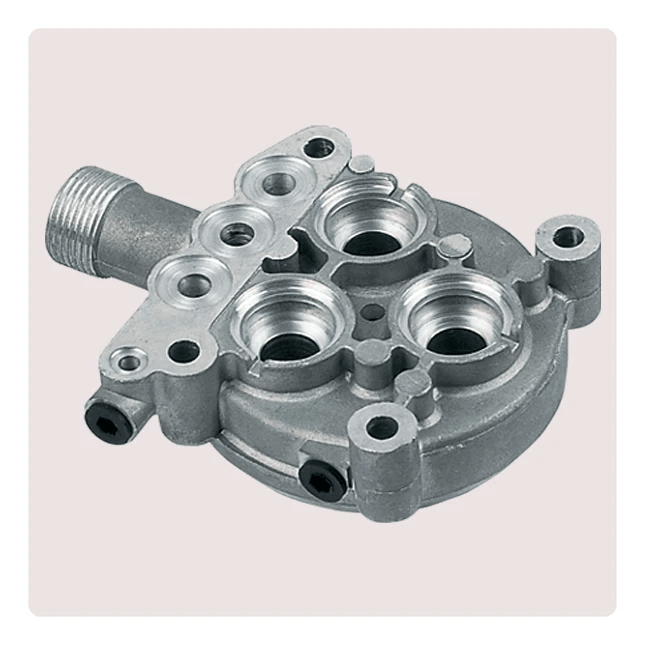

Diverse Automotive Parts Made with Die-Casting

Die casting is crucial in manufacturing diverse components such as engine blocks, transmission cases, and structural parts in the automotive industry. As a leading aluminum parts manufacturer, Ningbo Buttler Precision Machinery Co., Ltd. is dedicated to providing high-quality die-casting parts for automobile applications, contributing to the production of efficient and reliable vehicles with superior performance.

Power Tool Parts with Precision and Durability

In addition to outdoor lamps and automotive components, our expertise in die casting extends to producing power tool parts that require precision engineering and exceptional durability. With our innovative tooling designs and cost-effective manufacturing processes, we ensure that power tool manufacturers receive top-quality die-casting components that enhance the performance and longevity of their products.

Future of Die Casting in the Automotive Industry

As the automotive industry continues evolving, die-casting technology is advancing rapidly. With the development of innovative techniques and materials, die casting is poised to play an even more crucial role in producing automotive components. This will increase efficiency, improved performance, and cost-effective manufacturing processes.

Advancements in Die Casting Technology

The future of die casting in the automotive industry looks promising, thanks to continuous technological advancements. From improved die designs to enhanced process control systems, manufacturers are constantly pushing the boundaries of what is possible with die casting. These advancements are paving the way for more complex and precise parts that meet the automotive sector's ever-changing demands.

Potential Applications of Aluminium Die Casting

Aluminum die casting has revolutionized the automotive industry, offering numerous advantages. This process creates lightweight yet robust components, ideal for various applications.

Key benefits of aluminum die casting in automotive include:

- Improved fuel efficiency: Lighter vehicles consume less fuel.

- Enhanced vehicle performance: Aluminum components contribute to better handling and acceleration.

- Sustainability: Aligns with the growing demand for eco-friendly transportation.

By capitalizing on these strengths, aluminum parts manufacturers are well-positioned to drive innovation in the automotive sector. As the industry continues to evolve, aluminum die-casting will undoubtedly play a pivotal role in shaping the future of transportation.

Ningbo Buttler Precision Machinery Co., Ltd.: Leading the Way in Die Casting Innovation

Ningbo Buttler Precision Machinery Co., Ltd. stands at the forefront of die-casting innovation, offering comprehensive solutions for automotive manufacturers. Specializing in die-casting molds, aluminum and zinc castings, processing, surface treatment, assembly, and packaging, Buttler is committed to delivering high-quality products that meet the evolving needs of the automotive industry. Their expertise in smart part engineering and cost-effective manufacturing processes drives innovation and sets new standards for excellence.

With advancements in technology and materials coupled with the expertise of leading manufacturers like Ningbo Buttler Precision Machinery Co., Ltd., the future of die casting in the automotive industry looks bright. As demand for high-performance and sustainable vehicles continues to grow, aluminum die casting will play an integral role in shaping the next generation of automobiles.

The Role of Aluminium Die Casting in Revolutionizing Vehicle Manufacturing

The future of die casting in the automotive industry looks promising, with the increasing demand for lightweight and strong aluminum parts. As vehicle manufacturers strive for fuel efficiency and performance, die-casting components are crucial in revolutionizing vehicle manufacturing. Ningbo Buttler Precision Machinery Co., Ltd. is the premier aluminum parts manufacturer, leading the way in innovative die-casting technology.

The Promising Future of Die Casting in

the Automotive Industry

The growing emphasis on lightweight and strong materials in the automotive industry has paved the way for die casting to shine. With its numerous advantages, including precision, cost-effectiveness, durability, and environmental benefits, die casting is set to play a pivotal role in shaping the future of vehicle manufacturing.

Aluminum die-casting parts have proven instrumental in enhancing fuel efficiency and vehicle performance. As automobile manufacturers continue to prioritize lightweight yet durable components, aluminum die casting is at the forefront of this revolution.

Ningbo Buttler Precision Machinery Co., Ltd.: The Premier Aluminium Parts Manufacturer

Ningbo Buttler Precision Machinery Co., Ltd. has established itself as a leader in manufacturing die-casting molds and aluminum parts. Focusing on smart part engineering for better part designs, efficient processing and surface treatment techniques, and eco-friendly practices, Buttler is poised to shape the future of die casting in the automotive industry.