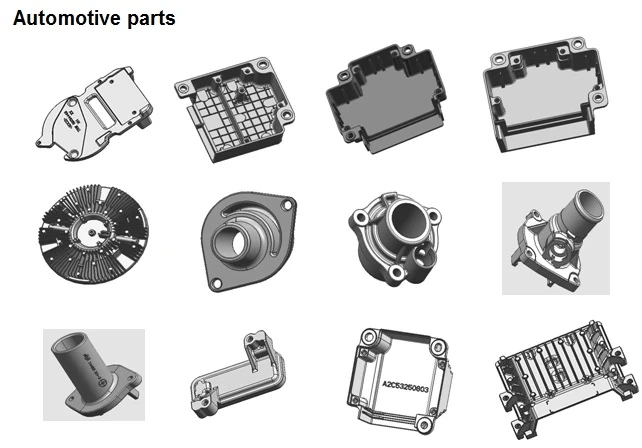

Introduction

When it comes to die casting, finding the right factory is crucial for ensuring quality and efficiency in production. Whether you need aluminum die casting or precision die casting, choosing the right manufacturer can make all the difference in the final product. There are several factors to consider when selecting a die casting factory, and it's essential to understand the process and industry standards to make an informed decision.

Understanding Die Casting Process

Die casting is a manufacturing process that involves injecting molten metal into a steel mold under high pressure. This results in a precise and accurate mold replication, making it suitable for producing complex shapes with high dimensional accuracy. Understanding this process is essential for choosing the right die casting manufacturer.

Importance of Choosing the Right Factory

The choice of a die casting factory can significantly impact your products' quality, cost, and lead time. An experienced and reliable manufacturer will have the expertise to deliver consistent results while meeting your specific requirements for aluminum die casting or precision die casting.

Factors to Consider When Selecting a Die Casting Factory

Die casting is a cornerstone process for many industries, allowing for the creation of complex and precise metal parts. But with so many die casting factories, how do you choose the right one for your project? Here are some key factors to consider to ensure a successful partnership:

1. Industry Experience and Expertise

Look for a factory with a proven track record in your specific industry. Their experience translates into a deeper understanding of the unique challenges and requirements of your product. This expertise allows them to provide valuable insights and optimize the casting process for your application.

2. Quality Assurance Measures

Quality is paramount. Choose a factory with a robust quality assurance program in place. This includes stringent inspection procedures throughout the production process, from raw materials to finished parts. Look for certifications that demonstrate their commitment to quality, such as ISO 9001.

3. Production Capacity and Efficiency

Consider your production volume and lead time requirements. Does the factory have the capacity to handle your specific needs? Look for a manufacturer with efficient production processes to ensure timely delivery and meet your project deadlines.

4. Technical Capabilities and Equipment

The complexity of your design will determine the necessary technology. Does the factory have the equipment and technical skills to handle your project? This includes things like die casting machines with the appropriate cargo, CNC machining capabilities for post-casting processes, and advanced quality control technology.

5. Customer Service and Communication

Open and transparent communication is crucial. Choose a factory that prioritizes customer service and fosters a collaborative partnership. Look for a team that is responsive to your inquiries, addresses your concerns promptly, and keeps you informed throughout the production process.

Additional Considerations:

- Cost: While cost is a factor, focusing solely on the cheapest option can backfire. Look for a factory that offers a good balance between competitive pricing and exceptional quality.

- Location: Depending on your needs, geographic location might influence your decision. Consider factors like potential import/export duties and ease of communication if working with an overseas factory.

Selecting the right die casting factory is an investment in your project's success. By prioritizing these key factors, you can find a reliable partner who possesses the experience, technology, and commitment to quality to deliver the parts you need on time and within budget. This strong partnership ensures you receive the best possible value and a competitive edge in your market.

1. Industry Experience

Ningbo Buttler Precision Machinery Co., Ltd. is a leading die casting manufacturer with extensive industry experience. With over 20 years in the die casting industry, Buttler has honed its expertise to deliver top-notch solutions for various industries.

Longevity in the Die Casting Industry

Buttler's longevity in the die casting industry speaks volumes about its commitment to quality and customer satisfaction. As a trusted die casting factory, their track record of success and customer loyalty is a testament to their unwavering dedication to excellence.

Specialization in Aluminum Die Casting

When it comes to aluminum die casting, Ningbo Buttler Precision Machinery Co., Ltd. is the go-to choice for exceptional quality and precision. Their specialization in aluminum die casting sets them apart as an industry leader, catering to diverse needs with unparalleled expertise.

Ningbo Buttler Precision Machinery Co., Ltd. doesn't just stop at meeting industry standards; they exceed them with their expertise in precision die casting. Their commitment to delivering top-notch quality and attention to detail is evident in every project they undertake. With a team of skilled professionals and state-of-the-art technology, they ensure that the final product meets the most stringent requirements.

Expertise in Precision Die Casting

Precision die casting demands meticulous attention to detail, and Buttler excels in this area with unmatched expertise. Their focus on precision ensures that every component meets exact specifications, guaranteeing superior performance and reliability.

Buttler's dedication to quality assurance is evident in their rigorous testing and inspection processes. Each component undergoes thorough examination to ensure it meets the highest standards for precision die casting. This commitment to quality results in superior performance and reliability and reflects Buttler's unwavering dedication to customer satisfaction.

2. Quality Assurance

Ningbo Buttler Precision Machinery Co., Ltd. is a trusted and reliable die casting factory, specializing in aluminum die casting. With a strong emphasis on quality assurance, they hold various certifications and accreditations to ensure compliance with industry standards and regulations. As a leading die casting manufacturer, they prioritize quality at every stage of the production process.

Certifications and Accreditations

Ningbo Buttler Precision Machinery Co., Ltd. is an ISO 9001-certified aluminum die casting factory, demonstrating its commitment to maintaining high-quality management systems. Additionally, it holds relevant industry-specific certifications and accreditations that validate its expertise in precision die casting and manufacturing processes.

Furthermore, Ningbo Buttler Precision Machinery Co., Ltd. has obtained industry-specific certifications and accreditations that testify to its dedication to excellence in precision die casting and manufacturing processes. These certifications validate its expertise and proficiency in meeting the industry's stringent quality standards. This commitment to continuous improvement and adherence to best practices ensures that customers receive products of the highest caliber.

Testing and Inspection Processes

The die casting manufacturer employs rigorous testing and inspection processes to guarantee the integrity of its products. Through advanced testing methods and state-of-the-art equipment, it ensures that each aluminum die casting meets the highest standards for dimensional accuracy, surface finish, and mechanical properties.

Commitment to Continuous Improvement

At Ningbo Buttler Precision Machinery Co., Ltd., continuous improvement is ingrained in the culture. They are dedicated to enhancing their manufacturing processes, implementing new technologies, and refining their quality control measures to consistently deliver superior products to their clients.

Furthermore, Ningbo Buttler Precision Machinery Co., Ltd. is committed to employee training and development to ensure its team is equipped with the latest skills and knowledge. By fostering a culture of learning and innovation, it can stay ahead of industry trends and adapt to changing market demands. This proactive approach allows it to consistently meet and exceed customer expectations.

3. Production Capacity

Ningbo Buttler Precision Machinery Co., Ltd. has established itself as a leading die casting manufacturer specializing in aluminum die casting. With a state-of-the-art facility and a team of skilled professionals, our die casting factory is equipped to handle large orders easily.

Scalability for Large Orders

At Ningbo Buttler, we understand the importance of scalability for large orders. Our advanced manufacturing processes and efficient production lines allow us to seamlessly scale up production to meet our clients' demands without compromising on quality or lead times.

Our commitment to scalability is reflected in our investment in state-of-the-art equipment and technology. This allows us to optimize our production processes, minimize downtime, and increase efficiency. As a result, we can easily accommodate large orders without sacrificing the quality of our products or extending lead times.

Efficient Manufacturing Processes

Our aluminum die casting factory is equipped with cutting-edge technology and streamlined manufacturing processes that ensure high efficiency and precision in every step of the production process. This allows us to deliver high-quality products and ensures cost-effectiveness for our clients.

In addition to high efficiency and precision, our streamlined manufacturing processes also allow for flexibility in production. This means we can easily adapt to changes in demand or specifications without sacrificing quality or lead times. Our agile approach ensures that our clients receive the products they need, when they need them, without compromising on performance or cost-effectiveness.

Reliable Lead Times

When you partner with Ningbo Buttler Precision Machinery Co., Ltd., you can rest assured that your orders will be delivered on time, every time. Our commitment to reliable lead times is backed by our dedication to efficient operations and meticulous planning, ensuring your deadlines are always met. Additionally, our advanced tracking and monitoring systems allow for real-time visibility into the status of your orders, giving you peace of mind and the ability to plan accordingly. Furthermore, our proactive approach to identifying and addressing potential delays means we can take corrective action before they impact your delivery schedule, keeping everything on track smoothly.

4. Technical Capabilities

Ningbo Buttler Precision Machinery Co., Ltd. stands out as a leading die casting factory focusing on technical capabilities that set us apart from other die casting manufacturers. Our innovative tooling designs are tailored to meet the specific needs of our clients, ensuring efficient and cost-effective manufacturing processes. By leveraging advanced technology and industry expertise, we deliver high-quality aluminum die casting products that exceed expectations.

Innovative Tooling Designs

Our aluminum die casting factory is equipped with state-of-the-art technology to develop innovative tooling designs that optimize production. From intricate part designs to complex geometries, we have the expertise to create custom tooling solutions that enhance efficiency and accuracy in manufacturing. Our commitment to precision die casting ensures that each component meets the highest quality and performance standards.

Furthermore, our advanced engineering design review process ensures that every tooling solution is evaluated for effectiveness and efficiency. Our experienced engineers meticulously analyze each design to identify potential improvements or optimizations. This rigorous review process allows us to consistently deliver innovative tooling designs that maximize productivity and minimize production costs.

Advanced Engineering Design Review Process

At Ningbo Buttler Precision Machinery Co., Ltd., we offer our clients an advanced engineering design review process at no cost. This service allows us to collaborate closely with our customers to optimize new and existing parts for die casting aluminum production. By leveraging our technical expertise and industry knowledge, we provide valuable insights and recommendations for enhancing part designs, ultimately leading to superior results in the manufacturing process.

Emphasis on Smart Part Engineering

At our aluminium die casting factory, we prioritize smart part engineering as a key aspect of our technical capabilities. By focusing on smart part engineering, we aim to improve overall part design, functionality, and manufacturability while reducing costs and lead times for our clients. Our team is dedicated to finding innovative solutions that result in better part designs, ultimately delivering superior products that meet or exceed customer expectations.

5. Customer Service

When choosing a die casting factory, it's crucial to consider their communication level and responsiveness. At Ningbo Buttler Precision Machinery Co., Ltd., we prioritize clear and timely communication to meet our clients' needs at every step. Our team is always ready to address concerns or inquiries, providing a seamless and transparent experience.

Tailored Solutions for Unique Requirements

At Ningbo Buttler Precision Machinery Co., Ltd., we understand that not all projects are identical, so we offer tailored solutions for unique requirements. Whether aluminum die casting or precision die casting, our team works closely with clients to develop customized solutions that align with their specific needs and goals. We take pride in adapting to diverse project demands and delivering exceptional results each time.

Post-Sales Support and Collaboration

Our commitment doesn't end once the product is delivered – we believe in fostering long-term partnerships with our clients. At Ningbo Buttler Precision Machinery Co., Ltd., we provide comprehensive post-sales support and collaboration, promptly addressing any issues or feedback. We value client input and actively seek opportunities for continuous improvement, solidifying our reputation as a trusted partner in the die casting industry.

Remember, when it comes to your die casting needs, partnering with Ningbo Buttler Precision Machinery Co., Ltd. means gaining access to unparalleled expertise in aluminum die casting and precision manufacturing. With a focus on smart part engineering for better part designs, you can trust us always to deliver exceptional results!

Partner with Ningbo Buttler Precision Machinery Co., Ltd.

Finding the right partner is crucial for making informed decisions about your die casting needs. Ningbo Buttler Precision Machinery Co., Ltd. is a leading die casting manufacturer with extensive experience in aluminum and precision die casting. Their expertise in smart part engineering ensures better part designs and cost-effective manufacturing solutions that maximize performance and quality while minimizing the need for secondary operations.

Making Informed Decisions for Die Casting Needs

Choosing the right die casting factory is essential for the success of your project. With Ningbo Buttler Precision Machinery Co., Ltd., you can trust in their industry experience, commitment to quality assurance, and technical capabilities to meet your specific requirements. By partnering with a reputable manufacturer like Buttler, you can make informed decisions that will benefit your business in the long run.

Ningbo Buttler Precision Machinery Co., Ltd. stands out as an aluminum die casting factory with a strong emphasis on precision and quality assurance. Their dedication to continuous improvement, efficient manufacturing processes, and reliable lead times make them an ideal partner for all your die casting needs. With their specialization in smart part engineering, you can expect better-engineered part designs for optimal performance and cost-effectiveness.

Smart Part Engineering for Better Part Designs

By leveraging Ningbo Buttler Precision Machinery Co., Ltd.'s smart part engineering expertise, you can achieve better part designs tailored to your unique requirements. Their innovative tooling designs and advanced engineering design review process ensure that your parts are optimized for maximum efficiency and quality. With Buttler's focus on smart part engineering, you can expect superior results that exceed industry standards.